Showing results 151 - 200 of 4973

A blower door is used to test air leakage in this multifamily building during construction

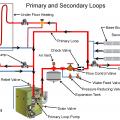

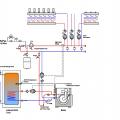

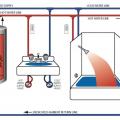

A boiler system can be set up with primary and secondary loops to supply hot water for multiple uses

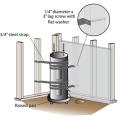

A braced water heater is attached to a raised platform that is anchored to the floor

A builder, energy efficiency consultant, and crew supervisor inspect a spray foam installation.

A Category I induced draft boiler uses an induced draft fan to pull air through the combustion chamber and to the flue

A caulk gun is a simple but power tool for sealing narrow cracks between framing and around penetrations.

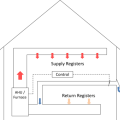

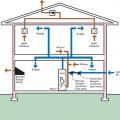

A central fan-integrated supply system uses a fresh air intake ducted to the home's central furnace or air handler unit to supply fresh air throughout the home

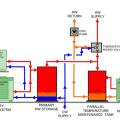

A central heat pump water heating system with a parallel loop tank temperature maintenance configuration uses a multi pass heat pump water heater to provide all the heat for hot water circulation temperature maintenance.

A central heat pump water heating system with a parallel loop tank temperature maintenance configuration uses a multi-pass heat pump water heater to provide all the heat for hot water circulation temperature maintenance

A central heat pump water heating system with a temperature maintenance swing tank configuration uses the water from the primary storage tank to provide most of the heat for hot water circulation temperature maintenance

A central rooftop fan supplies outdoor air to all floors of a multistory multifamily building, pressurizing the corridors and providing make-up air for the elevator shaft, which is depressurized by an exhaust fan.

A central rooftop fan supplies preconditioned outdoor air to every floor of a multistory multifamily building, pressurizing the corridors and providing make-up air for the elevator shaft, which is depressurized by an exhaust fan.

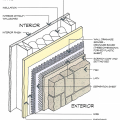

A coated OSB product with taped seams covers the walls to serve as both sheathing and weather-resistant barrier.

A combination of brackets and self-locking drawers. Drawer closures should be used to protect the home during seismic events.

A common method of addressing significant groundwater leakage in the foundation is to line the entire foundation assembly, including the slab, with a drainage layer.

A common method of addressing significant groundwater leakage in the foundation is to line the interior perimeter of the foundation with a drainage layer.

A comparison of a dirty furnace filter on left and clean filter on right. Dirty filters block airflow and make the furnace or air handler work harder.

A concrete slab floor can be elevated above local grade as a strategy to prevent flood damage.

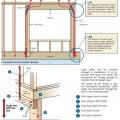

A concrete slab-on-grade foundation with exterior insulation, which can be elevated above the local grade as a flood-prevention strategy.

A cone or disc of plastic or sheet metal can be installed on pipes and downspouts to prevent rodents from climbing up the outside and gaining access to the roof

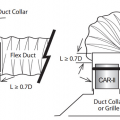

A constant airflow regulator is a modulating orifice that automatically regulates airflows in duct systems to constant levels

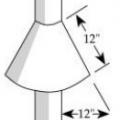

A constant airflow regulator is fitted into the neck of the supply duct to control air flow to deliver the design airflow regardless of pressure variations

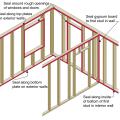

A continuous bead of sealant is installed to air seal along the top and bottom plates at all exterior walls and intersecting interior walls as well as around windows in exterior walls

A continuous drainage mat rainscreen made from vacuum-molded plastic provides uniform support for the siding and allows moisture to flow horizontally and diagonally in addition to vertically.

A continuous layer of polyethylene covers the crawlspace floor and is attached to the wall with wood nailing strips

A continuous load path uses structural connections to transfer horizontal and vertical loads from the roof to the foundation to help keep the building intact in high-wind and seismic events

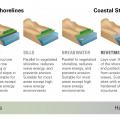

A continuum of green (soft) to grey (hard) shoreline stabilization techniques used to mitigate the effects of erosion

A cool roof utilizes materials with high solar reflectance and thermal emittance to reflect solar energy and reduce heat gain to the home

A cool room should have low enough heat gains to be easily cooled by a small single-zone cooling system such as a mini-split or a window air-conditioner as shown here

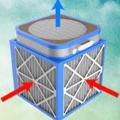

A Corsi-Rosenthal Box is a highly effective DIY air cleaner made of easy to obtain materials such as HVAC filters, a box fan, cardboard, and tape

A cross-section of a vinyl-framed window showing metal reinforcement which helps support the window and prevent collapse if exposed to heat from a fire.

A deck or other attached structure located at the top of a slope with vegetation underneath is at high risk of ignition during a wildfire

A demand plumbing layout uses a recirculation pump to speed delivery of hot water to plumbing fixtures.

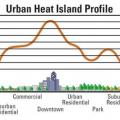

A dense concentration of buildings and pavement can create the Urban Heat Island Effect, where local temperatures can be several degrees higher than the surrounding areas

A detached garage offers more space to place solar panels with likely fewer roof penetrations and more options for roof pitch and orientation.

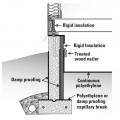

A dimpled plastic water barrier protects the insulated concrete form basement walls and carries any ground water down the walls to the footing drain to minimize the opportunity for water intrusion and frost heave.

A dimpled rain mat and perforated drain pipe provide drainage around the basement foundation.

A direct-vent sealed-combustion fireplace takes its combustion air directly from outside through a dedicated air inlet and vents combustion products directly outside

A direct-vent sealed-combustion furnace has dedicated pipes for combustion air and exhaust

A dormer with an openable window (not shown) can provide access to the roof if flood waters rise too high and too quickly; the dormer should be properly insulated, flashed, and air sealed