Showing results 1 - 45 of 45

Air seal door and window rough openings with backer rod, caulk, or nonexpanding foam

All ceiling, wall, floor, and slab insulation shall achieve RESNET-defined Grade I installation

An NFRC glazing system energy performance label will report U-factor, solar heat gain coefficient, visible transmittance, and air leakage; if the window is ENERGY certified, the ENERGY STAR label will be located next to the NFRC label

Batt insulation should be cut to fit around wiring so that insulation can completely fill the wall cavity

Blown cellulose insulation completely fills the netted wall and ceiling cavities.

Ceiling, wall, floor, and slab insulation levels shall meet or exceed Builders Challenge levels

Faced fiberglass batt insulation can be stapled to the stud faces or slightly inset, but avoid compressing the batts

Home performance program labels are displayed on the electric panel showing the certifications this home has receivied, including ENERGY STAR Certified Home, the EPA Indoor airPLUS, and the Home Energy Rating System (HERS) score.

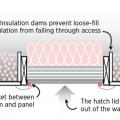

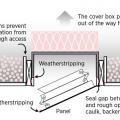

Install an ENERGY STAR labeled insulated door with an automatic closer. Weather strip the door frame

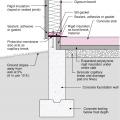

Right - Rigid foam slab edge insulation is installed along the exterior edge of a monolithic slab foundation.

Right – An ENERGY STAR washer and heat pump dryer save energy and money for home owners.

Right – This National Fenestration Rating Council (NFRC) label shows the insulation U-Factor, solar heat gain coefficient, visible transmittance, and condensation resistance for this triple-pane window.

Right – This regional production builder of DOE Zero Energy Ready certified homes provides monthly in-house training sessions to educate its staff on the energy-efficiency features of its high-performance homes.

Rigid foam forms an insulating bond break between the foundation wall and the slab

Southern Energy Homes constructed the first DOE Zero Energy Ready certified manufactured home and the DOE collected 15 months of performance data on it, a HUD code home, and an ENERGY STAR home.

Spray foam insulation is installed in open wall cavities to air seal and insulate

The EnergyGuide label for this refrigerator shows that it is estimated to use 630 kWh/yr (approximately 1.7 kWh per day) based on a standard test procedure

These apartments built by Haynes Construction in Meriden, Connecticut, achieved certification to both the U.S. Department of Energy’s Zero Energy Ready Home Program and the Passive House Institute U.S. and were funded as affordable housing.

These townhomes built by Haynes Construction in Meriden, Connecticut, achieved certification to both the U.S. Department of Energy’s Zero Energy Ready Home Program and the Passive House Institute U.S. and were funded as affordable housing.

This home bears a DOE Zero Energy Ready Home label on its front window next to the ENERGY STAR window label.

This Project Home Again home in New Orleans by Green Coast Enterprises, used simplified home plans and value engineering to provide affordable, hurricane- and flood-resistant homes in Louisianna.

Unfaced fiberglass batt insulation is installed to completely fill the wall cavities and is sliced to fit around wiring, piping, and other obstructions in the wall cavities

Wrong – Compression and misalignment because insulation is not split around plumbing

Wrong – Compression and misalignment because insulation is not split around wires