Showing results 201 - 250 of 4973

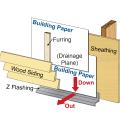

A drainage plane is created behind lap siding by installing furring strips on the exterior walls over house wrap which is overlapped and taped at all seams to serve as an air and water barrier.

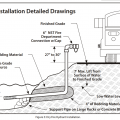

A dry hydrant is a pipe a homeowner can have installed in a natural water source on their rural property to provide easy access to the water by firefighting crews.

A drywell, shown here used for downspout catchment, can also be used to receive water from a French drain.

A duct leakage test is performed on a ducted heat pump system using a duct tester (blower fan) and a digital manometer.

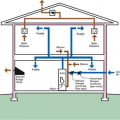

A ducted central return brings air from central return registers back to the air handler through insulated, air-sealed ducts

A ducted minisplit heat pump is hidden in the ceiling of this centrally located room with short duct runs to the registers located on each wall of the room.

A ductless heat pump is hidden behind a wall outcropping above the hallway ceiling.

A FIRM will identify specific SFHAs (colored and hatched areas) and localized BFEs (wavy black lines)

A flanged window unit is installed with straps that fasten to the interior surfaces of the plywood extension box; furring strips on each side of the window will be attached after the flanged window is installed and flashed

A flat plate solar hot water system heat potable water in a glass covered collector that sits on the roof.

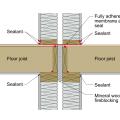

A flexible membrane was installed across the floor joists to prevent air movement between the floor joists in this multifamily 1-hr partition wall assembly

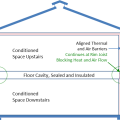

A floor cavity between the first and second floor can provide a conditioned space for HVAC ducts if the rim joists are insulated and air sealed, if sufficient space is available, and if open-web floor joists are used

A flow grid is inserted into the filter grille/slot to directly measure airflow.

A foam gasket is installed along the top plates before installing drywall as an air-sealing step to help achieve a quieter, draft-free home.

A foaming cleaner is used to clean the coils inside this ductless indoor unit; a mini-split bib surrounds the unit to contain overspray and drips

A foaming sprayer and mini-split bib are required to properly clean this ductless wall-mounted indoor unit

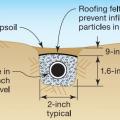

A French drain contains a perforated drain pipe wrapped in rock and landscape fabric.

A fresh air inlet is ducted to the return side of the home’s central air handler; a motorized damper and electronic controls help balance the flow of fresh incoming air with controlled exhaust to meet ventilation requirements

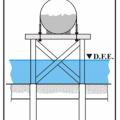

A fuel tank elevated above the design flood elevation on a platform in a high velocity flow area.

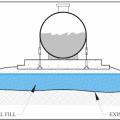

A fuel tank is strapped onto a concrete slab at the top of compacted fill above the DFE.

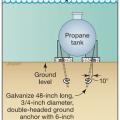

A fuel tank should be anchored with ground anchors designed for site conditions to maintain secure connection to its base in a flood or earthquake

A gable end failure due to improper bracing caused collapse of most of the trusses on this roof under hurricane force wind conditions.

A green strip is a type of fuel break planted with less flammable vegetation; e.g., crested wheatgrass.

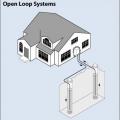

A ground source heat pump with an open-loop piping system using vertical injection and recharge

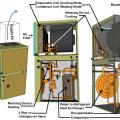

A ground-source heat pump has the same components as a standard air-to-air heat pump except that the liquid-to-refrigerant heat exchanger coil is located inside rather than outside

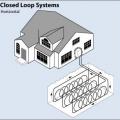

A ground-source heat pump used a fluid flowing through pipe loops to draw heat from or discharge heat the ground to heat or cool the indoor space.

A ground-source heat pump with a closed-loop horizontal “Slinky™ “piping arrangement

A gut rehab that includes drywall removal provides the opportunity to thoroughly insulate the walls.

A heat pump clothes dryer is a type of condensing clothes dryer that uses heat pump technology to efficiently dry clothes

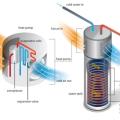

A heat pump water heater has a small heat pump located on top of the tank which extracts heat from the surrounding air to create hot water.

A high-efficiency gas boiler provides hot water to the faucets, to radiant heating loops in the basement floor, and to a hydro-coil for a central air heating system.

A high-efficiency heat pump is installed in a closet within this home’s conditioned space.

A home is tested at two points for enclosure air leakage

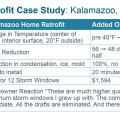

A Kalamazoo homeowner reduced wintertime chill, condensation, and snowblower noise by installing high-performance interior storm windows

A large bead of caulk is installed on the interior surface of the wall top and bottom plates to provide an air sealing gasket between the framing and the dry wall.

A layer of pea gravel or crushed stone, 4 inches thick and sloped 5%, provides a pest-resistant ground break around the perimeter of a slab foundation

A layer of pea gravel or crushed stone, 4 inches thick and sloped 5%, provides a pest-resistant ground break around the perimeter of a basement foundation

A layer of rigid foam is sandwiched between two layers of 2x8 lumber in this insulated header over a window.

A liquid-applied water barrier covers the walls, serving as a drainage plane, air and vapor barrier, and secondary window flashing beneath the rigid foam that will be installed next.

A low-sloped shed roof with the thermal boundary located at either a) the flat ceiling with a vented attic or b) the roof line for an unvented attic

A manometer is used to measure pressure differentials between indoors and outdoors when testing whole-house air leakage.

A masonry chimney is reconstructed to withstand seismic forces by adding an insert to the existing firebox

A masonry chimney is reconstructed to withstand seismic forces by completely retrofitting the firebox and chimney using light-frame construction on the top of the foundation

A masonry chimney is reconstructed to withstand seismic forces by maintaining the current firebox but replacing the chimney section with a metal flue and light-weight chimney enclosure.

A masonry chimney is shortened and capped at roof level to reduce its chances of detaching in high winds or earthquakes; the fireplace can no longer be used.

A mesh plastic rainscreen product separates the coated OSB from the siding, providing a drainage space and ventilation gap.