Showing results 51 - 100 of 4972

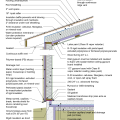

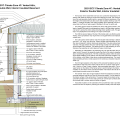

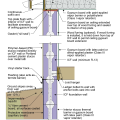

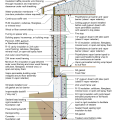

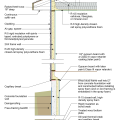

2021 IECC Climate Zone 3C: Vented Cathedral Ceiling, 2x6 Wall, Vented Crawl Space

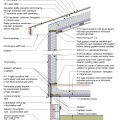

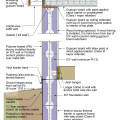

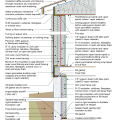

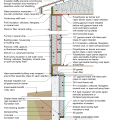

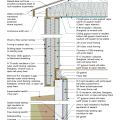

2021 IECC Climate Zone 4A: Vented Cathedral Ceiling, 2x6 Wall, Slab on Grade (with notes)

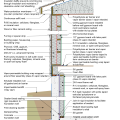

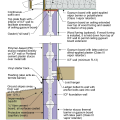

2021 IECC Climate Zone 4A: Vented Cathedral Ceiling, 2x6 Wall, Vented Crawl Space

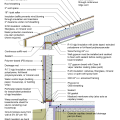

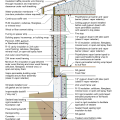

2021 IECC Climate Zone 4B: Vented Cathedral Ceiling, 2x6 Wall, Slab on Grade (with notes)

2021 IECC Climate Zone 4B: Vented Cathedral Ceiling, 2x6 Wall, Vented Crawl Space

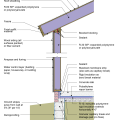

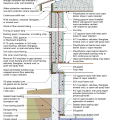

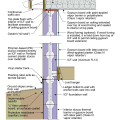

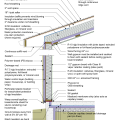

2021 IECC Climate Zone 4C: Vented Attic, 2x4 Wall, Interior Insulated Basement (with notes)

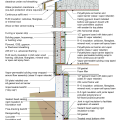

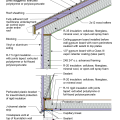

2021 IECC Climate Zone 4C: Vented Attic, Exterior Double Wall, Interior Insulated Basement

2021 IECC Climate Zone 4C: Vented Attic, Exterior Double Wall, Interior Insulated Basement (with notes)

2021 IECC Climate Zone 4C: Vented Attic, ICF Wall, ICF Basement Foundation (with notes)

2021 IECC Climate Zone 4C: Vented Attic, Interior Double Wall, Interior Insulated Basement

2021 IECC Climate Zone 4C: Vented Attic, Strapped 2x6, Interior Insulated Basement

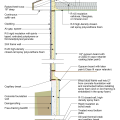

2021 IECC Climate Zone 4C: Vented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement

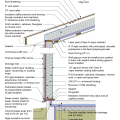

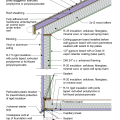

2021 IECC Climate Zone 4C: Vented Cathedral Ceiling, 2x6 Wall, Slab on grade (with notes)

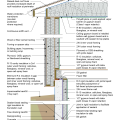

2021 IECC Climate Zone 4C: Vented Over-Roof, Unvented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement

2021 IECC Climate Zone 5: Vented Attic, 2x4 Wall, Interior Insulated Basement (with notes)

2021 IECC Climate Zone 5: Vented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement

2021 IECC Climate Zone 5A: Vented Attic, Exterior Double Wall, Interior Insulated Basement

2021 IECC Climate Zone 5A: Vented Attic, Interior Double Wall, Interior Insulated Basement

2021 IECC Climate Zone 5A: Vented Attic, Strapped 2x6, Interior Insulated Basement

2021 IECC Climate Zone 5A: Vented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement

2021 IECC Climate Zone 5A: Vented Over Roof, Unvented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement

2021 IECC Climate Zone 5B: Vented Attic, Exterior Double Wall, Interior Insulated Basement

2021 IECC Climate Zone 5B: Vented Attic, Interior Double Wall, Interior Insulated Basement

2021 IECC Climate Zone 5B: Vented Attic, Strapped 2x6, Interior Insulated Basement

2021 IECC Climate Zone 5B: Vented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement

2021 IECC Climate Zone 5B: Vented Over Roof, Unvented Cathedral Ceiling, 2x6 Wall, Interior Insulated Basement

2021 IECC Climate Zone 5C: Vented Attic, Exterior Double Wall, Interior Insulated Basement

2021 IECC Climate Zone 5C: Vented Attic, Interior Double Wall, Interior Insulated Basement