Scope

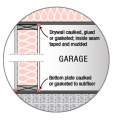

Ensure that the garage is separated from the conditioned space of the home by a continuous rigid air barrier.

- Seal all seams, gaps, holes, and openings in the air barrier with caulk, foam, or a rigid air barrier material before installing the insulation.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Isolating attached garages from the living space is critical for preventing the potential infiltration of carbon monoxide and other contaminants into the dwelling. Open joist bays above the garage that extend into living spaces are an unwanted air pathway. Cracks between and around the boards of the rim joist, the top plate, and the sill plate-foundation wall intersections are other areas where air can flow through if seams aren’t adequately sealed. In addition, certain conditions in the home can cause the home to become depressurized, making it even more likely for garage air to be drawn into the home through leaks in and around the rim joists. Depressurization can occur when the house is airtight and an exhaust fan, range hood, clothes dryer, or combustion appliance is operated, if adequate makeup air is not provided to the house through a fresh air intake (a duct that brings outside air to the return side of the air handler).

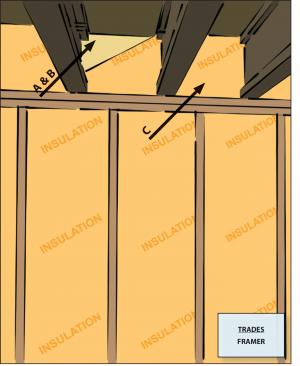

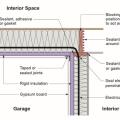

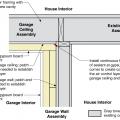

Walls and ceilings separating garages from conditioned spaces need to be sheetrocked (typically with 1/2-inch-thick Type X gypsum board) in accordance with local fire codes, but this is not the same as air sealing. All ceiling and wall penetrations (wiring, piping, ductwork, etc.) need to be sealed with appropriate sealants, such as caulk or canned spray foam. Or, a flash-and-batt approach can be used to insulate the garage ceiling and shared walls by spraying them with 2 inches of closed-cell spray foam, then filling the bays with fibrous batt insulation, as shown in Figure 1. All joist cavities that span between the garage and adjoining living spaces should be blocked with rigid material that is air-sealed in place or the framing should be designed so that rim joists or floor joists will serve as a naturally occurring air block at the shared wall.

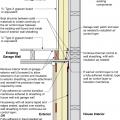

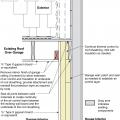

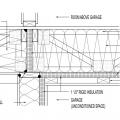

To provide an air barrier between the garage and the adjoining conditioned space, a solid air barrier material should be installed to-air seal joist bay openings spanning over the garage and conditioned space at the point above the wall separating the garage from the conditioned space. A rigid material like rigid foam board, drywall, OSB, or plywood can be cut to fit each joist bay opening (Figure 2). Each piece must be cut to fit then nailed and caulked or spray foamed into place, which is a labor-intensive process.

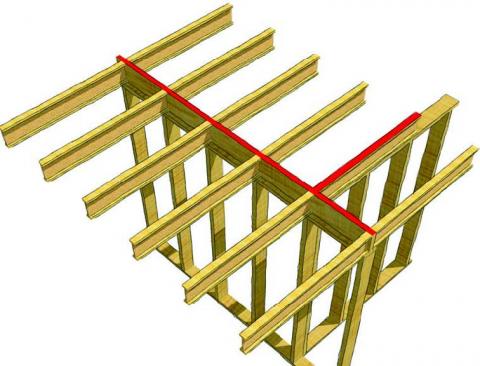

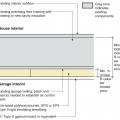

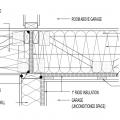

If the garage shares only one wall with the home, ideally the framing would be designed so that ceiling joists above the garage run parallel to the shared wall so that a ceiling joist can serve as a solid air barrier above the shared wall (Figure 3). Where open bays will span the shared walls, the floor joists can be cut so that they terminate on either side of a rim joist installed above and aligned with the shared wall (Figure 4). At the base of the wall, the joints between the mud sill and rim joist at the foundation line of the shared garage-to-house wall should be sealed. The drywall separating the garage from the house should be sealed to the framing members at the top plate, bottom plate, corners, and seams.

For more information, see the guides Floor Above Garage, Garage Rim/Band joist Adjoining Conditioned Space, Air Sealing Doors Adjacent to Unconditioned Space, and Air Leakage Testing Garage to House Air Barrier.

For multifamily buildings, see additional information about air-sealing garages in the guides Insulating Garages in Multifamily Buildings and Insulating Heated Garage Plenums in Multifamily Buildings. Similar principles apply when separating dwelling units at shared walls in multifamily buildings but additional measures are required, as described in the guide Air Sealing and Compartmentalization in Multifamily Buildings.

HOW TO AIR-SEAL BETWEEN THE GARAGE AND LIVING SPACE

- Air-seal the rim joist of the wall shared by the garage and the house. (See the guide Garage Rim Band Joist for more details.)

- If the floor joist above a shared garage-living space wall runs parallel to the shared wall, the joist will provide an air barrier above the sealed wall. Seal any holes and seams in the joist to complete the air barrier.

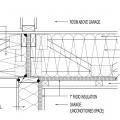

- Where ceiling joists run perpendicular to the adjoining wall, one option is to install a continuous rim joist to separate the two areas with separate but aligned ceiling joists on each side of the rim joist (see Figure 3 and Figure 4).

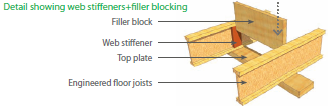

- Another option is to install solid blocking material in the joist bays over the common wall. Cut rectangles of rigid blocking material (plywood, polyisocyanurate, extruded polystyrene, etc.) to fit each floor joist bay cavity. Install a backstop for the blocking material by tacking furring strips to the joists in-line with the foundation or house wall. Insert rigid pieces into each joist bay and fasten with caulk or nails (Figure 5). When using I-joists, make sure to cut the air blocking material to fit the irregular shape of the opening. If using open web floor trusses, seal any holes in the open-web floor trusses at the shared wall, if needed (Figure 6). Use caulk or spray foam to air-seal all four edges in each bay (Figure 7). Make sure to completely air seal around the rigid air barrier to prevent moist air from reaching and condensing on the rim joist.

Insulate the rim joist with additional rigid foam that is caulked or foamed into place or with spray foam. Use urethane spray foam insulation to cover the rim joist, and seams with the top plate below and subfloor above (see Figure 8). Medium-density (closed-cell, 2 pounds/cubic foot) or low-density (open-cell, 0.5 pounds/cubic foot) foams provide acceptable results. Open-cell foams might require additional vapor and condensation control measures in IECC Climate Zone 6 and higher. Have the spray foam installed by a spray foam subcontractor or use two-part spray foam kits.

Spray foam in band joists is typically concealed between floors so no other thermal barrier is required; however, the International Residential Code (IRC) allows the spray foam at rim joists to be exposed in basement and crawlspace applications (i.e., without a 15-minute thermal barrier such as drywall) as long as the thickness is less than 3 1/4 (3.25) inches and has a density range of 0.5 to 2.0 pounds per cubic foot (see 2021 IRC R316.5.11). Closed-cell, 2-PCF spray foams were approved in the 2003 IRC and open-cell 0.5-PCF foams were approved in the 2009 IRC, alongside any intermediate densities (BSC 2009).

Climate Note: Although open-cell spray foam is acceptable in this application per code, closed-cell spray foam is preferred in hot-humid or extreme cold climates (IECC Climate Zones 1A, 2A, 7, and 8) (Zoeller 2009).

- Caulk or spray foam the garage slab-foundation wall junction. (See the guide Reduce Pest Intrusion for more on foundation sealing.)

Seal all penetrations through the shared walls and ceilings. See the Building America Solution Center guides on Air Sealing Electrical Wiring and Air Sealing Piping and Plumbing.

Use gaskets, airtight drywall technique, etc., to make the common wall and ceiling airtight. Consider a “flash” seal approach - spray foam the entire ceiling and/or inter-zonal walls of the garage to air-seal any cracks, holes, or seams. Then add batt or blown insulation to meet the insulation R-value requirement (Figures 1 and 9), at a cost savings compared to using spray foam alone to meet the insulation requirement. Cover the ceiling insulation with taped and mudded drywall.

- Other Important Considerations:

- Install a self-closing, insulated, metal, fire-rated door with a good weather seal between the living space and the garage (see the BASC guide Air Sealing Doors Adjacent to Unconditioned Space).

- If the air handler for a central furnace must be located in the garage, it needs to be in an air-sealed closet (see the BASC guide No Ducts or Air Handlers Located in Garage and the report Air Sealing Mechanical Closets in Slab-On-Grade Homes). Do not have supply or return registers in the garage. If ductwork is located in the garage ceiling to service rooms above, verify that the ducts are air-sealed and insulated. Consider encapsulating the ducts with closed-cell spray polyurethane foam to ensure a complete air barrier (see the report Buried and/or Encapsulated Ducts).

- Install a passive vent from the garage to the outside. Consider installing a timer-operated exhaust fan that vents from the garage to the outside (see the guide Mechanical Ventilation for Attached Garage).

Success

If the home has an attached garage, visually inspect for cracks or improper sealing along the rim joist above walls separating the garage from the home. For joist bays that extend from over the garage ceiling to over or under living areas of the house, the joist bay cavities should be blocked off, air sealed, and insulated. Rim joists that run parallel to the shared wall should be air sealed and insulated at the rim joist.

Blower door testing conducted as part of the whole-house energy performance testing can indicate whether the rim joists have been successfully air sealed. Blower door testing can also help determine if the home is depressurized compared to the garage; if so, a means of supplying makeup air to the home may be called for to prevent garage fumes from being pulled into the home.

The following actions are also recommended to ensure that garage air is separated from house air:

- Visually inspect for cracks along the base of garage walls that adjoin living space and along sill plates on top of foundation walls on adjoining walls.

- Visually inspect that all penetrations through adjoining walls and garage ceilings below living spaces are sealed.

- Test the seal tightness of doors linking the garage with the rest of the home.

- Best practice is to not install HVAC equipment in the garage. If a furnace is installed in the garage, it should be sealed combustion and direct vent. Visually inspect that the furnace cabinets and ducts are air sealed with mastic or metal tape or, preferably, that the furnace is installed in an air-sealed closet. No return air registers should be installed in the garage. Any ducts installed in the garage should be sealed with mastic and tested for air tightness.

Climate

If the rim joists are to be sealed with spray foam both open-cell and closed-cell spray foam are acceptable, however, closed-cell spray foam is preferred in hot-humid or extreme cold climates (IECC Climate Zones 1A, 2A, 7, and 8) (Zoeller 2009).

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

CAD

Compliance

Retrofit

SCOPE

Air-seal the walls and ceilings of a garage that is attached to an existing home’s conditioned space and living areas.

- Determine which wall and ceiling assemblies in the garage are attached to the home’s living areas and inspect those assemblies for any cracks, holes, gaps, rot, water damage, or deterioration.

- Repair holes in ceilings or walls with sheet rock or plywood and seal to ensure a continuous air barrier.

- Remove and replace any sheet rock that is rotten or has extensive water damage.

- Use caulk or foam to seal any cracks or gaps. Sealants (e.g., caulk, fire-retardant caulk, fire-rated spray foam, etc.) should be compatible with all adjoining surfaces and meet the fire and air barrier specifications according to code.

- Alterations that expose the existing framing cavity may require the installation of additional insulation. See the Compliance tab for alterations and repairs to existing walls.

For more information on conditions that may be encountered when working with walls or ceilings in existing homes, see the pre-retrofit assessment guide on air sealing walls, windows, and doors.

For more guidance on sealing walls, see the U.S. Department of Energy’s Standard Work Specifications (SWS) and follow safe work practices as described.

DESCRIPTION

The walls and ceilings separating the home from the garage may not have gotten the same attention to air sealing and insulating as the other exterior walls when the home was originally built because builders sometimes overlook the fact that these walls and ceilings are part of the home’s “building thermal envelope” (the exterior walls, floors, ceilings, and other building components that provide a boundary between conditioned space and the outdoors or unconditioned spaces).

Maintaining the integrity of this thermal envelope, especially in regard to isolating the existing attached garage from living space is critical for preventing the potential infiltration of carbon monoxide and other contaminants into the dwelling. Over time, cracks or gaps may appear along the joints and seams in the sheet rock (gypsum board); at the mud sill, rim joists, subfloors, and bottom of the sheet rock; at ceiling-wall intersections; and at other areas where air can flow through if cracks or gaps are not adequately sealed. There could also be unsafe conditions that have existed since the house was built. For example, there could be open floor joist bays spanning from over the garage to over or beneath attached living space. These openings could allow garage fumes to enter adjoining rooms through cracks in subfloors or through leaks around sealing and wall penetrations. Any open joist bays must be closed off with solid blocking material and sealants as described in the Description tab.

Any HVAC equipment installed in the garage should be installed in an airtight closet and there should be no supply or exhaust registers in the garage.

In addition, certain changes to the home can cause the home to become depressurized, making it more likely for garage air to be drawn into the home if there are leaks in the air barrier between the home and the garage. Depressurization can occur when the house is airtight and an exhaust fan, range hood, clothes dryer, or combustion appliance is operated, if adequate makeup air is not provided to the house through a fresh air intake (a duct that brings outside air to the return side of the air handler). Changes to the house that could increase the likelihood of depressurization include adding a new higher powered range hood fan, adding or replacing exhaust fans, cleaning out the clothes dryer duct, air-sealing parts of the house, or adding a fireplace or other combustion appliance that does not have a sealed combustion chamber with a dedicated intake air duct.

To help ensure that an airtight barrier separates the house from the garage, inspect the common walls between the home and the garage. The garage can also be tested for pressure differences with respect to the house using a blower door test. These steps can be done by a home energy rater as part of a home energy assessment.

Also see the Solution Center guides Floor above Garage, Insulating Existing Floors over Garage, Garage Rim/Band Joist Adjoining Conditioned Space, Air Sealing Drywall to Top Plate, Air Sealing Doors Adjacent to Unconditioned Space, Air Sealing Attic Access Panels/Doors/Stairs, Rigid Foam Insulation Installed Between Existing House and Garage Walls, and No Ducts or Air Handlers Located in Garage.

How to Air-Seal Between the Existing Garage and Living Space

- Locate and inspect the air barrier separating the garage from the conditioned space of the house at the home’s thermal envelope. Test for separation between the two using a blower door test. Air-seal all seams, any leaks around penetrations, and any joist bay cavities as described in the Description tab.

- Replace any materials that show signs of rot or water damage. To minimize crumbling of plaster when cutting through existing plaster and wood lathe surfaces, use high-speed cutting tools such as powered multi-tools or an angle grinder with a diamond blade, to make clean cuts through the plaster and lathe. Protect surfaces, hang tarps to isolate the area, and operate a shop vac to capture the dust. Another trick is to apply a sealing compound to the back side of the lathe, if it is accessible, prior to cutting to minimize flexing. Apply masking tape to the lines to be cut to help hold the lathe together. Wetting may also help reduce dust generation.

- Assume that paint on surfaces painted prior to 1978 contains lead. Old plaster may contain asbestos. See the assessment guide on hazardous materials and the EPA Healthy Indoor Environment Protocols for Home Energy Upgrades (2011) for more information.

Check the door leading from the garage into the house. If the door is more than 15 years old, it may be a hollow door. A door between the garage and the home should be considered an exterior door. It should be either a solid core or insulated metal, fire-rated door. It should be weather-stripped, have a tight-fitting sweep, and have an automatic door-closing hinge. See the the guide Air Sealing Doors Adjacent to Unconditioned Space.

COMPLIANCE

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Air Sealed Attached Garage =

Air-sealed attached garages help block the leakage of carbon monoxide and other contaminants in the garage from getting into the home. This is achieved by blocking and air sealing floor framing cavities in ceilings above the garage that extend into living spaces; seams along the adjoining living space walls and foundation; and all seams and any holes between the ceiling and any living space above. In addition, any doors between the house and the garage should be self-closing and weather stripped, including a tight-fitting threshold sweep.