Scope

Air-seal attic access panels and drop-down stairs to minimize air leakage.

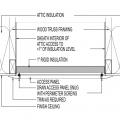

- Install a gasket around attic access openings to air seal between the opening and the panel covering. Insulate the cover with rigid foam that is glued in place or batt insulation that is mechanically fastened, e.g., with wires and screws.

- Install a durable, insulated cover for drop-down stairs that provide attic access and install an air-sealing gasket around the rim of the panel.

- Install blocking around the staircase or panel to serve as an insulation dam.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

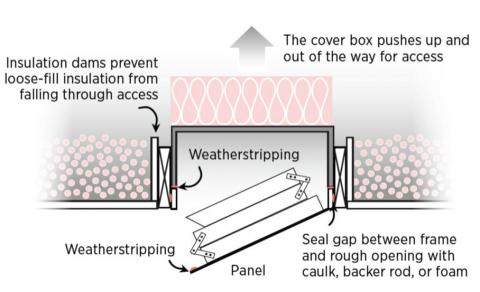

Good air-sealing and a continuous air barrier between the attic and the home’s conditioned (living) space are important, not only to save energy and reduce fuel bills, but also to prevent moisture problems in the attic. Sealing holes in the attic ceiling reduces the house’s “suction” (or stack effect) so less contaminants are drawn up into the house from the ground such as radon and other soil gases (Lstiburek 2010). Openings used for access to the attic such as access panels, doors into kneewalls, or dropdown stairs should be air sealed and insulated. To air seal, weather stripping should be added to either the frame or panel of the attic access panel or door and latch bolts or mechanical fastener should be installed that will pull the access door tight to the weatherstripping for an airtight seal. To reduce heat loss, these access panels, doors, or stairs should be insulated. Panels and doors can be insulated by gluing rigid foam to the panel or attaching batt insulation with bolts and wiring or metal strapping. Pull-down stair kits can be purchased with rigid insulation already attached to the panel Alternatively some pull-down stair kits come with rigid insulation already attached to the inside of the back door panel, between the panel and the stairs. Or a rigid foam box-shaped cover can be constructed or purchased that fits over the stairs and is lifted and placed out of the way when accessing the attic.

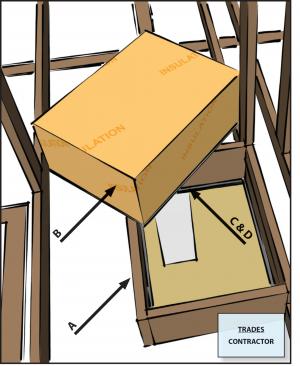

The insulated and gasketed attic cover might be installed by the framer or the insulation contractor. This task should be included in the contract for the appropriate trade depending on the workflow at the specific job site.

How to Air Seal Attic Access Panels

- Install wood trim pieces on the ceiling side of attic access hole framing. The trim should extend one-half inch to one inch around the inside edge of the access hole forming a ledge. The access panel will rest on this trim.

- Install weather stripping along the top of this ledge.

- Cut the access panel with even edges and one-quarter inch to one-half inch of clearance around the edges.

- Insulate the top of the access panel with rigid foam or fiberglass batt insulation that is glued or fastened with bolts and wires to the panel.

How to Air Seal Attic Pull-Down Stairs

- Install 1x2 or 1x3 wood trim pieces to surround the inside edge of the access hole framing. When closed, the back panel of the stairs will be rest up against this trim, so recess the trim enough to ensure the back panel will be flush with the ceiling.

- Install weather stripping along the bottom edge of this trim or along the inside top edge of the back panel to act as a continuous gasket.

- Install additional weather stripping along the top of this trim to provide air sealing for a box-shaped cover that will insulate the stairs.

a. Construct or purchase a box made of rigid foam insulation sized to fit the access hole. This box can be lifted and placed out of the way when accessing the attic. Additional batt insulation can be attached to the top of this box if desired.

b. Alternatively some pull-down stair kits come with rigid insulation already attached to the inside of the back door panel, between the panel and the stairs. - Add 1x8s or plywood strips cut to desired height to each side of the drop-down stairs framing to act as insulation dams to keep blown-in attic insulation from falling into the stairs.

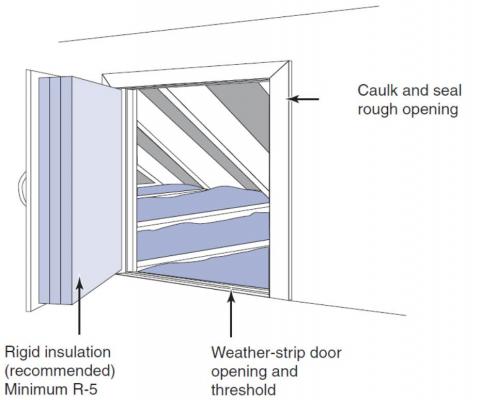

How to Air Seal an Attic Door

- Install weather stripping along the inside door frame and threshold.

- Install a latch that will pull the door tight to the frame and the weather stripping. Do not undercut the door.

- Insulate the attic side of the door by gluing rigid foam to it or attaching batt insulation with screws and wire.

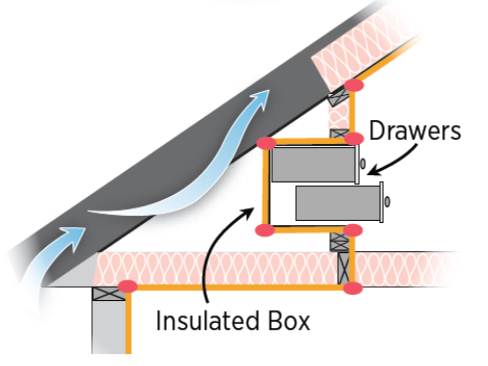

How to Air Seal an Attic Kneewall Drawer or Closet

- Build framing for the drawer or closet box.

- Insulate the framing rigid foam.

- Line the box with drywall, OSB, or plywood that is caulked at the seams.

Success

Consider installing attic access panels or drop-down stairs in unconditioned parts of the home, such as a garage or porch ceiling. If an attic access is installed in a conditioned room of the home, visually inspect that weather stripping has been installed around the opening and that the door or panel closes tightly along its entire perimeter. Air leakage can be detected during a blower door test with a smoke pencil, IR camera, or by feeling air flow with the hand.

Climate

Colder climates will increase the potential for heat loss and air leakage, and the impacts of that heat loss, if the attic access is not properly insulated and air sealed. Heat loss into the attic can warm the underside of the roof deck which can contribute to snow melt and ice dam formation. Significant air leakage from the house into the attic increases the potential for condensation and frost formation in the attic, if warmer vapor-laden conditioned air is allowed to escape into a wintertime attic with cold surfaces.

Training

CAD

Compliance

Retrofit

SCOPE

In existing homes, air seal attic access and drop-down stairs to minimize air leakage to and from unconditioned attic spaces.

- Inspect and repair or replace the existing attic door or hatch panel, as needed.

- See the Scope and Description tab for additional instructions.

For more information on conditions that may be encountered when working in existing attics, see the Pre-Retrofit Assessment of Attics, Ceilings, and Roofs. Also see the U.S. Department of Energy’s Standard Work Specifications (SWS) guidance on Pre-Retrofit Assessment of Attics, Ceilings, and Roofs

DESCRIPTION

- Inspect and replace or repair any missing, poorly fitting, loose, or damaged attic access doors, panels, or latching hardware.

- See the Description tab for additional air sealing installation information.

COMPLIANCE

Alterations

2009 IECC and 2009 IRC, 2012 IECC and 2012 IRC

2012 IECC, Section R101.4.3 / 2012 IRC N1101.3 and 2009 IECC 101.4.3 / 2009 IRC N1101.4.3 Alterations – General. Alterations to an existing building or portion of a building should comply with the provisions of the code as they relate to new construction without requiring unaltered portion(s) of the existing building to comply with this code.

2015 IECC and 2015 IRC, 2018 IECC and 2018 IRC

2015 IECC/2015 IRC, Section R501.1.1/N1107.1.1 Existing Buildings – General. Alterations to an existing building or portion of a building should comply with Sections R502/N1108, R503/N1109, or R504/N1110. Unaltered portions of the existing building are not required to comply.

R503.1/N1109.1 Alterations. General. Alterations to any building or structure should comply with the requirements of the code for new construction. Alterations should not negatively impact conformance of a building or structure to the provisions of this code; that is, code conformance should be the same as existed for the building or structure prior to the alteration. Alterations should not create an unsafe or hazardous condition or overload existing building systems. Alterations should be such that the altered building or structure uses no more energy than the existing building or structure prior to the alteration.

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Tight Air Sealed Home = Comprehensive Draft Protection

Poorly air-sealed homes are less comfortable and cost more to maintain because they provide a pathway for drafts, cold spots, moisture, and insects into the home. Comprehensive draft protection includes a continuous air barrier around the whole house along with caulking and sealing in all holes and cracks. This includes around wiring, plumbing, ducts, and flues; where wall framing meets flooring; around windows; where drywall meets top plates and sill plates; where rim joists meet foundation walls and subfloors; etc. Spray foam insulation can be used at rim joists, floors above unconditioned space, and in attics to insulate and air seal at the same time.