Scope

Thermally isolate heated garages in multifamily buildings from ambient space, and thermally isolate heated, partially heated, and unheated garages in multifamily buildings from interior occupied space.

- If the garage is heated, ensure that plaza decks and walls adjacent to ambient space are insulated.

- Regardless of if the garage is heated, partially heated, or unheated, ensure that any building components separating the garage from interior occupied space are insulated.

- Ensure that insulation placement on all garage structural slabs and walls are appropriate for your climate to prevent condensation and moisture issues.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Garages should be thermally isolated from the interior occupied space. ENERGY STAR Multifamily New Construction requires that walls and ceiling slabs in heated garages are insulated in some climate zones. However, even if the garage is unheated or partially heated, it is important to thermally isolate it from the rest of the building to ensure energy efficiency and occupant comfort. Recommended approaches for insulating garages will vary depending on climate zone and garage construction. The following sections will outline best practices and common approaches for thermally isolating garages in multifamily buildings.

Multistory Multifamily Buildings

Insulating Garage Podium Decks

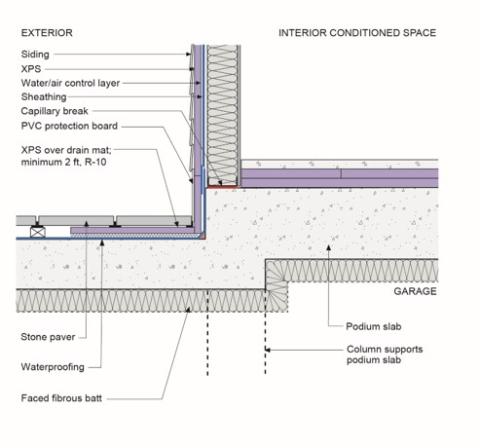

Podium decks, sometimes called plaza decks, are areas where the garage extends beyond the footprint of the building that sits on top of it. When podium and plaza decks are adjacent to interior conditioned spaces, they can be significant sources of energy loss if not properly insulated. Figure 1 illustrates a method for thermally isolating the plaza deck of a heated or partially heated garage from both the building and the exterior by adding insulation on the interior of the garage. Note that the heated or partially heated garage is insulated on all surfaces except the traffic surface and that insulation extends below grade.

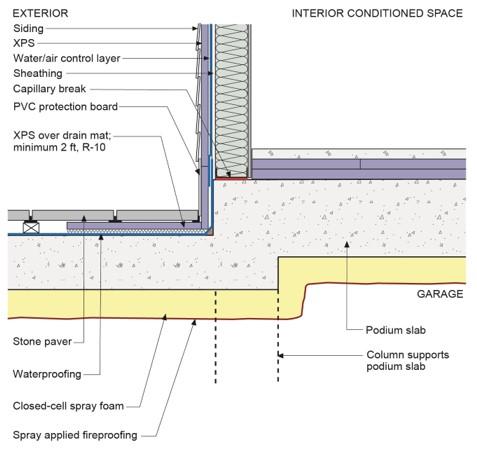

Figure 2 illustrates a method for mitigating thermal bridging where the plaza deck, ambient space, and interior occupied space meet by insulating both the exterior and garage-side faces of the plaza deck. Using the building example shown in Figure 1, where most of the plaza deck is beneath the building and some extends out from the building, insulation is installed both on the garage-side and the exterior-facing portion of the plaza deck that extends out from the building. The rigid insulation on the exterior side of the plaza deck usually extends no more than 4 feet from the exterior wall of the building. If the garage is heated or partially heated, the insulation on the garage side of the plaza deck should extend to the perimeter of the garage. The rigid insulation on the exterior side of the plaza deck is typically extruded polystyrene over a drainage mat to provide a capillary break between the waterproofing and extruded polystyrene. The insulation on the garage side of the plaza deck is often fiberglass or mineral wool batt insulation. However, it can be other insulation types, such as closed-cell spray polyurethane foam with a fireproofing layer (Figure 3) or a hybrid assembly of closed-cell spray polyurethane foam with fiberglass or mineral wool batt insulation (Figure 4).

Insulating Garages with Heated Plenum Spaces

In cold climates, the freezing of pipes that run through garage spaces is a common concern. Occupant comfort in dwelling units directly above the garage is also a concern because the slab between the garage and the conditioned space above can get cold even with adequate insulation. A common way of addressing both issues is to install an insulated dropped ceiling below the garage structural slab with a dedicated heater. For more information, please see the guide on Insulating Heated Garage Plenums in Multifamily Buildings.

Insulating Garage Walls

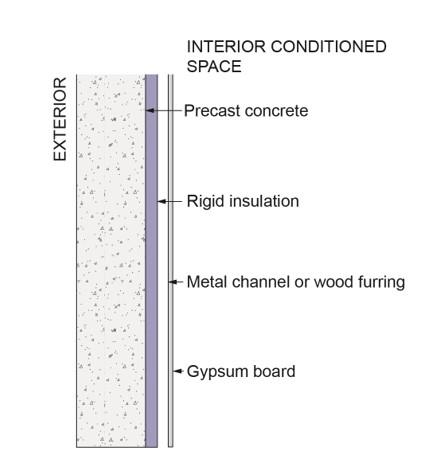

If the garage is heated or partially heated, or if the garage wall is adjacent to interior conditioned space, the garage walls should be insulated. Figure 5, Figure 6 and Figure 7 illustrate the use of cavity insulation or rigid insulation on the interior of above-grade garage walls. The insulation approaches are interchangeable regardless of whether the structural wall is concrete, precast concrete, or concrete block and whether the interior insulation layer(s) are within metal or wood framing/studs or furring. Note that it is not recommended to leave an air gap between the insulation layers and the structural wall assemblies. Further note that the assembly shown in Figure 5 should be limited to IECC Climate Zones 4 or lower due to the potential for condensation at the interior face of the structural concrete wall during the heating season. The assembly shown in Figure 5 is also not recommended for below-grade garage walls due to the potential for condensation at the interior face of the structural wall.

Figure 6 shows an assembly that can be used for above-grade or below-grade garage walls in any climate zone using continuous rigid insulation along the interior of the wall.

Figure 7 shows an assembly that can be used for above-grade or below-grade garage walls in any climate zone using a hybrid of continuous rigid insulation and cavity insulation.

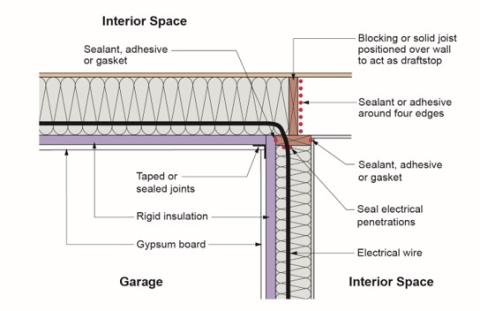

Insulating Garages Under Multifamily Row Houses/Townhouses

When garages exist below conditioned living space in multifamily row houses/townhouses, it is essential to thermally isolate the garage, whether the garage is heated, partially heated, or unheated. Figure 8 illustrates the use of rigid insulation and air sealing to provide thermal isolation at the junction between a garage and the interior occupied space above. Note that the rigid insulation assembly will need to meet applicable fire rating requirements.

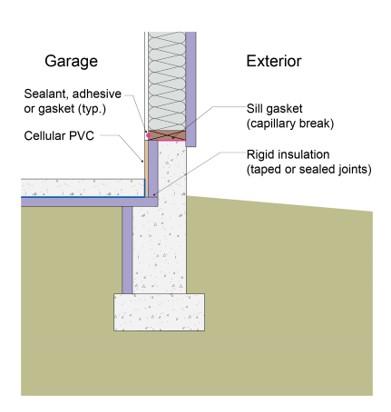

Figure 9 illustrates a strategy for effective thermal isolation for garages with basement foundations in IECC Climate Zones 3 and above.

Figure 10 illustrates a strategy for effective garage thermal isolation in IECC Climate Zone 3 or higher for multifamily row houses/townhouses with slab foundations. Note that where insulated walls intersect with garage slabs, fiber cement is often used to provide physical protection of the rigid insulation rather than gypsum board. Further note that if the garage is unheated, it is not necessary to insulate the wall between the garage and ambient space or the slab underneath the garage. However, for all garages, regardless of if they are heated, partially heated, or unheated, it is necessary to insulate the wall between the garage and interior occupied space.

Figure 11 illustrates a strategy for thermally isolating heated or partially heated garages with slab foundations in IECC Climate Zones 3 and above from the exterior using both cavity insulation and continuous rigid insulation.

Success

Where a garage is connected to the thermal envelope of a multifamily building, ensure that it is thermally isolated from the interior occupied space of the building, whether the garage is heated, partially heated, or unheated. Thermally isolate heated and partially heated garages from ambient space. Ensure that the insulation placement is appropriate to mitigate condensation issues in your climate. Be sure to air seal connections between the garage and the interior occupied space to increase the effectiveness of any insulation that is installed.

Climate

The best strategy for thermally isolating a garage is climate dependent. See the Compliance Tab for more information on required insulation levels in your climate zone. Furthermore, ensure proper placement of insulation to prevent moisture and condensation issues. For more information on condensation control in wall assemblies, see the guides on Condensation Control for Walls in Cold Weather, Class I Vapor Retarders Not Installed in Above-Grade Walls in Warm-Humid Climate, and No Vapor Retarders on Interior Side of Air-Permeable Foundation Insulation.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Building Science Corporation

Pacific Northwest National Laboratory