Scope

Upgrade a garage ceiling when a portion of the interior of the house is located directly above the attached garage by adding insulation and air sealing as follows:

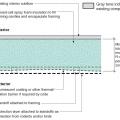

- Install insulating rigid foam sheathing to the underside of the existing garage ceiling, which typically has a finished surface of gypsum board or lath and plaster, or directly to the underside of the ceiling joists if the garage has an unfinished ceiling and the joist cavities are exposed. If the joist cavities are exposed, the layer of insulating sheathing will need to be foil-faced polyisocyanurate or XPS and the sheathing should be detailed to serve as the air control layer with seams taped and edges caulked or taped.

- Install blocking for reinstallation of existing services and attachments on the ceiling.

The U.S. Department of Energy’s Standard Work Specifications has additional information on insulating floors over garages.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

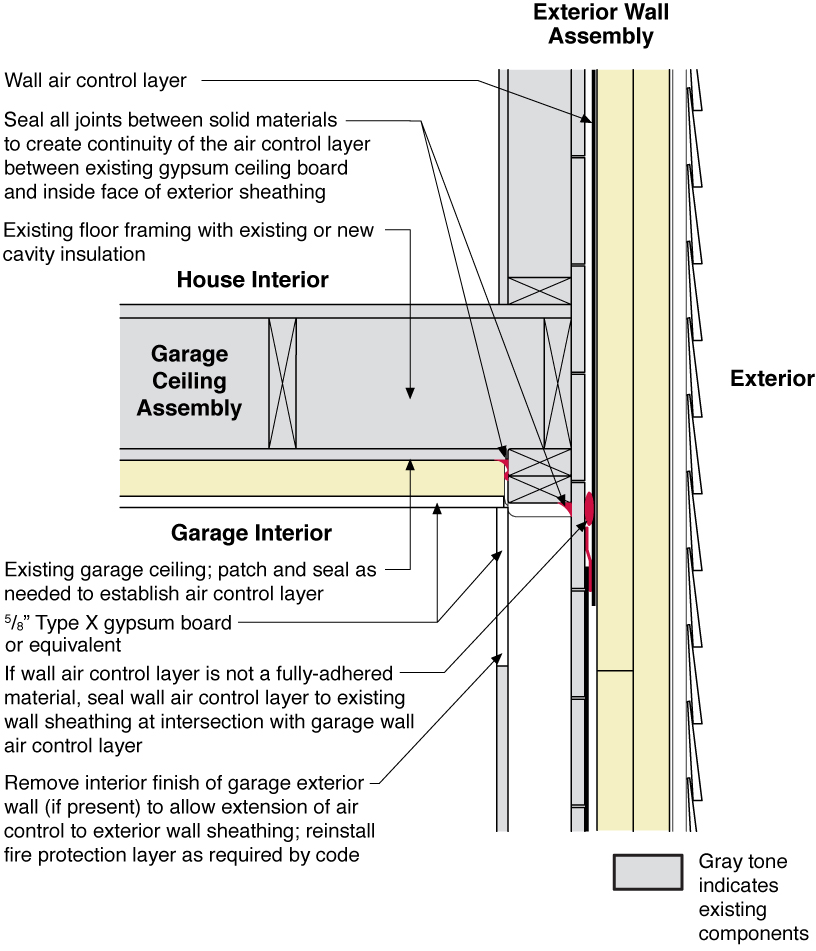

Adding insulating rigid foam sheathing to a garage ceiling can improve the comfort of floors above an attached garage and increase air sealing between the garage and the house. The insulating sheathing can be installed over an existing ceiling (Figures 1 to 3) or if there is no ceiling the foam can be attached directly to the ceiling joists.

Either way, a layer of gypsum board must be installed to cover the insulating sheathing for fire protection. If the ceiling cavity lacks insulation, additional blown or batt insulation can be installed prior to installing the insulating sheathing and gypsum board.

Other recommendations for insulating and air sealing a garage ceiling when there is living space above the garage can be found in the guides Floor Above Garage and Air Sealing Attached Garage.

How to Insulate a Garage Ceiling

- Inspect the existing garage ceiling. If ceiling drywall is in place, patch and air seal at seams and around existing penetrations as needed to establish a robust air control layer, as shown in Figures 1 to 3. Blow in loose-fill cavity insulation if desired.

- ALTERNATELY, if the ceiling joists are exposed, install either loose-fill with netting, batt, or spray foam cavity insulation.

- Install blocking for re-installation of existing services and attachments on the ceiling.

- Install insulating sheathing (foil-faced polyisocyanurate, XPS or EPS Type II) as shown in Figures 1 to 3. Install over existing ceiling gypsum board or if there is not existing gypsum board, then attach directly to ceiling joists. If the ceiling joists are exposed or the existing garage ceiling is removed, the layer of insulating sheathing must be foil-faced polyisocyanurate or XPS and should be installed as the air control layer, so all seams should be taped and sealant should be applied around all wiring and other penetrations

- Install 5/8 inch Type X gypsum board or equivalent as the ceiling covering. Mud and tape seams.

Success

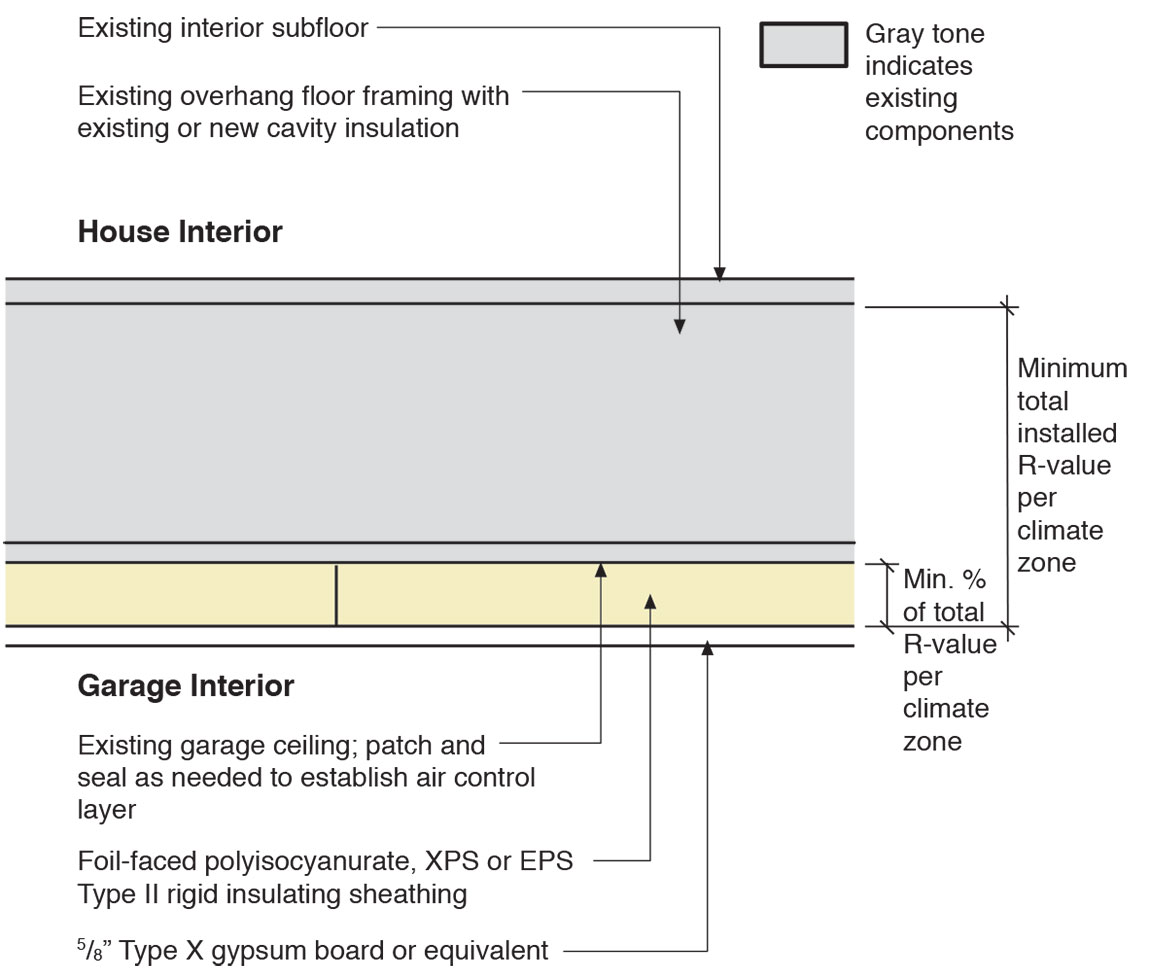

For a house with an attached garage, air leakage from the garage to the conditioned space of the home through the garage walls or ceiling can draw unwanted pollutants into the home. Steps should be taken to ensure that the health of the occupants will not be compromised by the retrofit. Airtightness of all walls, ceilings, and doors that are common between the attached garage and the interior of the house should be verified and improved, if needed. Fire protection must be provided as required by the current adopted building code.

Ensure the air control layer of the garage ceiling is continuous.

Maintain a proper ratio of vapor and air impermeable to vapor and air permeable insulation.

For information on interface of attached garages with a common wall, see Rigid Foam Insulation between Existing House and Garage Walls.

Climate

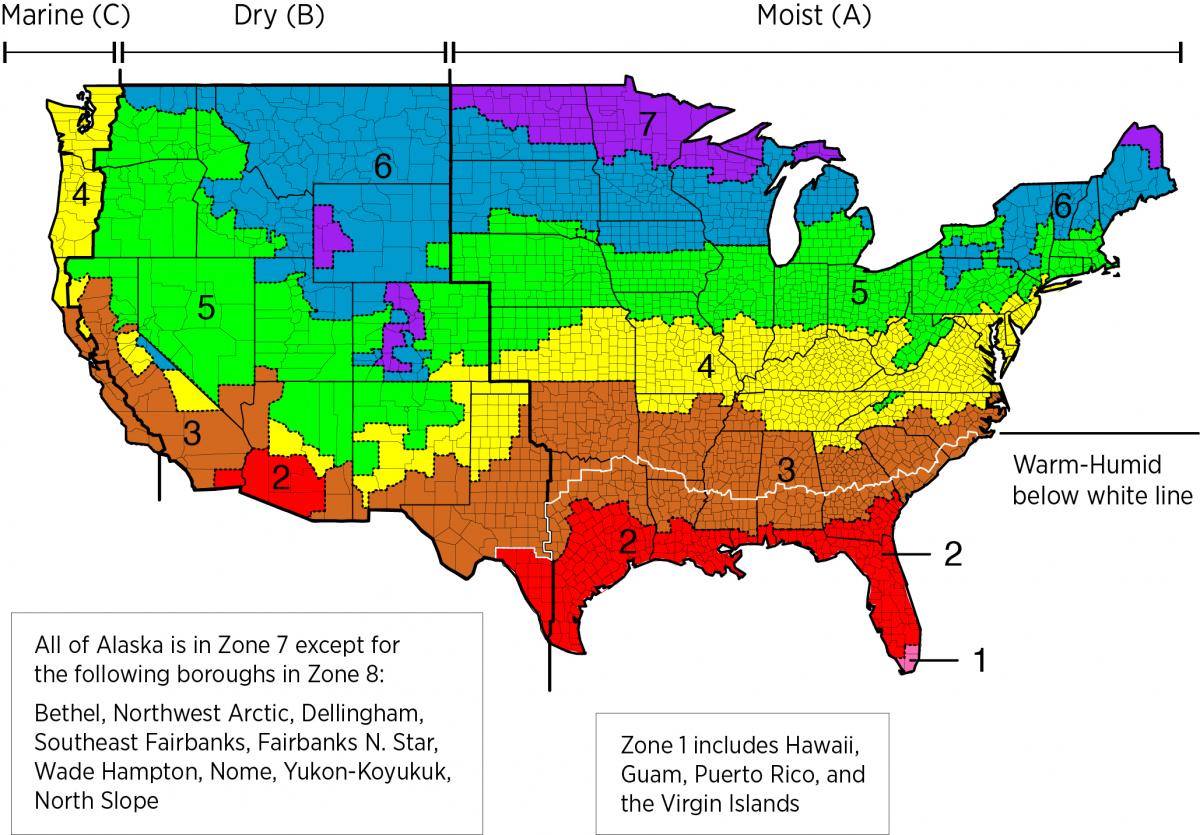

In house designs where there is living space above the garage, the garage ceiling should be treated as the floor assembly of the rooms above and should be designed for a specific hygrothermal region, rain exposure zone, and interior climate.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Figure 1. Climate Zone Map from IECC 2009, 12, 15, and 18. (Source: 2012 IECC)

Figure 2. Climate Zone Map from IECC 2021. (Source: 2021 IECC)

The insulation levels should be based on the minimum requirements for vapor control in the current adopted building code and the minimum requirements for thermal control in the current energy code. (See Table R601.3.1 Class III Vapor Retarders of the 2009 IRC (ICC 2009a) and Table R702.7.1 Class III Vapor Retarders of the 2012 IRC (ICC 2009b). Additional insulation can be added above these minimums to create high R-Value floor assemblies. The table below provides the minimum thermal resistance (R-value) requirements for framed floors specified in the 2009 IECC (ICC 2009b) and the 2012 IECC (ICC 2012b), based on climate zone.

Table 1. Framed Floor R-Value Requirements in the 2009 and 2012 IECC. (Source: 2009 IECC and 2012 IECC)

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

High-R Floor Insulation = High-Efficiency or Ultra-Efficient Floor Insulation

There are two levels of floor insulation: high-efficiency insulation, which meets the 2015 International Energy Conservation Code, and ultra-efficient insulation, which is 25% more efficient than this national code. Using high-efficiency and ultra-efficient insulation along with professional installation (e.g., no gaps, voids, compression, or misalignment with air barriers; complete air barriers; and minimal thermal bridging) creates conditioned spaces that require very little heating and cooling, along with even comfort and quiet throughout the house.