Scope

Upgrade walls that separate the garage from the house by providing a continuous air control layer on the garage side of the wall and adding rigid foam insulation, as follows:

- Remove the interior finish material (e.g., gypsum board; lath and plaster) along the garage return walls and ceiling where they interface with the shared wall to allow access for creating an air sealing control layer.

- Block (with additional gypsum board or other rigid material) and seal all gaps between the existing wall finish (e.g., gypsum board; lath and plaster) and the inside face of the exterior wall and roof sheathing. Seal any seams or openings in the rim joist if exposed.

- Install insulating sheathing.

- Provide attachment blocking as required to allow for the installation of new interior finishes/fire protection layer (e.g. gypsum board) as required by code.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

When exterior walls are being renovated to increase insulation levels, special care must be taken when air sealing and insulating shared walls at attached garages. The wall that provides a separation between the garage and the living space, while not exposed to the elements, is still considered an exterior wall and part of the building enclosure. As such, continuity of the building enclosure air, thermal, and moisture control layers should be maintained where the garage interfaces with the house.

It can be argued that, for garages, control of airflow from the garage to the living space is the most important function of the building enclosure, as this impacts indoor air quality, fire control, sound control, and thermal performance. While the interior finish (e.g., gypsum board; lath and plaster) can serve as an air control layer, it is rarely continuous where the garage structure interfaces with the exterior wall of the house. In order to provide continuity of the air control layer, steps must be taken to extend the air control layer at the structural interfaces or to integrate the structure into the air control layer.

Similarly, it is also important to maintain the continuity of the thermal control layer (insulation) at the structural interfaces. This is done by either removing some framing or encapsulating framing with rigid insulation to limit the thermal bridging at the garage interface to the house.

The details below are designed with the assumption that the original sheathing and structure of the existing garage-house wall is remaining in place. While other conditions may exist, these details are felt to be representative of common conditions and illustrate the intent of control layer continuity.

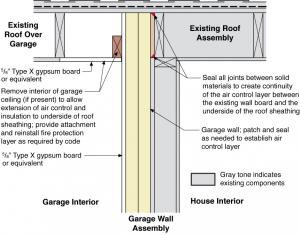

Interior Garage Wall to Exterior House Wall

Where the exterior wall of the house runs continuous past the garage interface, the interior wall finish of the perpendicular interfacing garage wall is cut back where it meets the house, exposing the stud cavity (Figure 1). This allows the garage interior finish (typically gypsum board or lath and plaster) to be sealed to the framing and inside surface of the exterior wall sheathing to create the air control layer continuity. The insulating sheathing is extended through the intersection to the exterior sheathing. Once the rigid foam has been installed, a new interior finish (typically gypsum board) is installed over the insulating sheathing, and the perpendicular return walls are patched and finished.

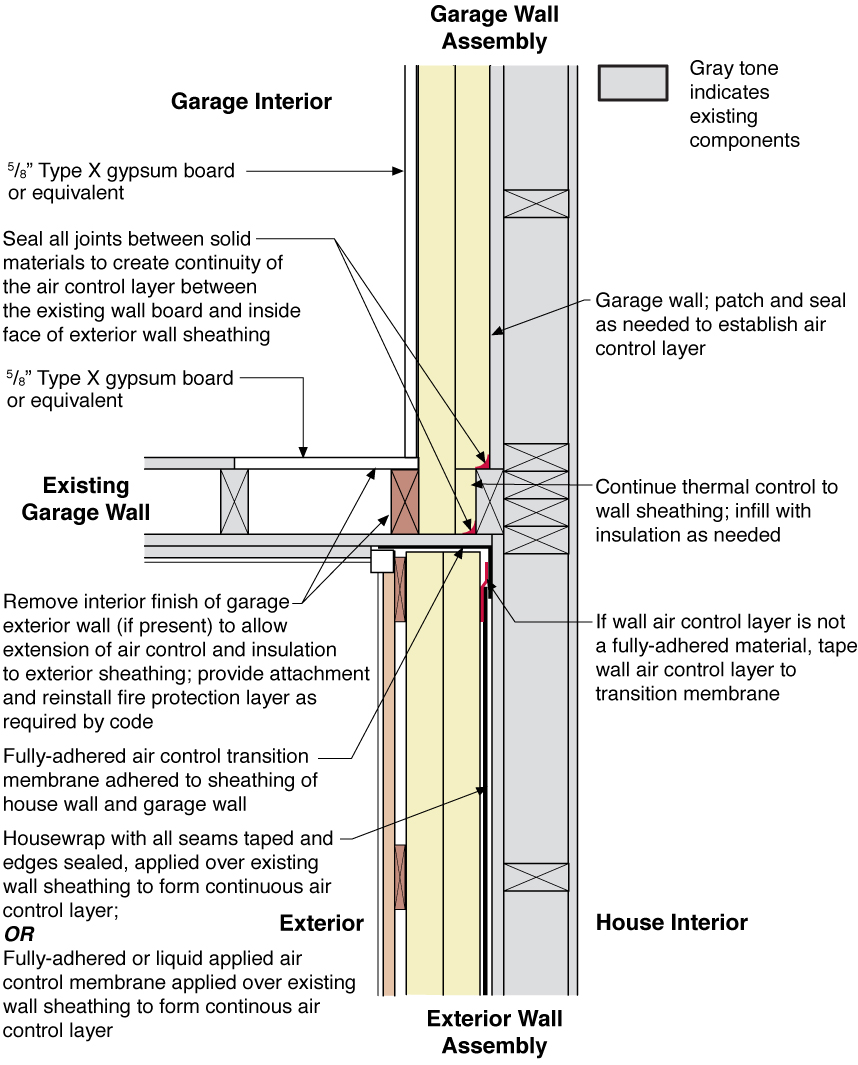

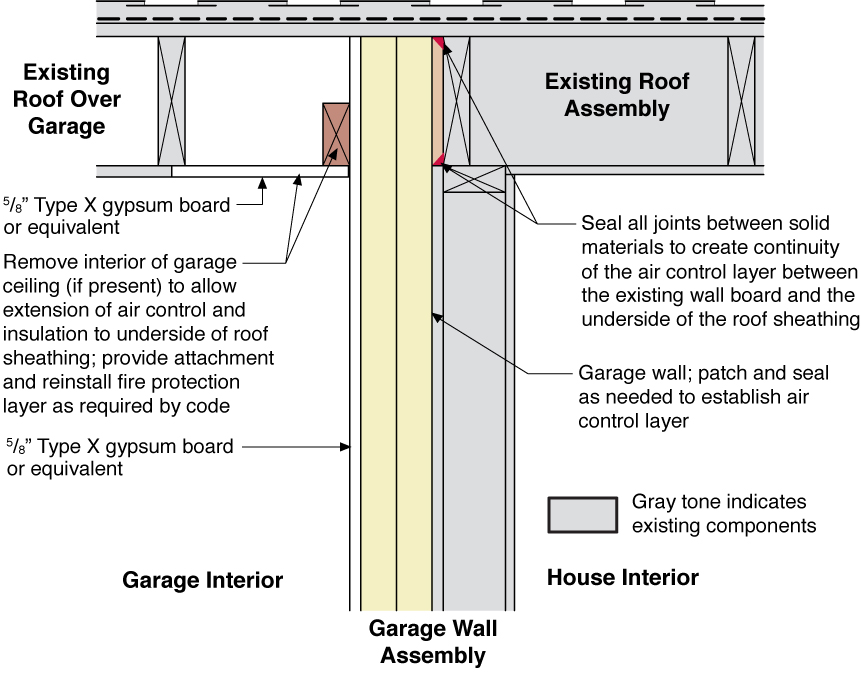

Garage Wall to Roof

Where the garage roof is shared with the roof of the house (Figure 2), or the exterior wall is run past the garage roof (Figure 3), the wall air control layer and insulation is extended up to the underside of the roof sheathing (Figure 2). In order to create continuity of the air control layer, a portion of the garage ceiling gypsum board is removed (if present) and any gaps between the top of the garage wall interior finish (typically gypsum board or lath and plaster) are blocked (with additional gypsum board or other rigid material) and sealed. The insulating sheathing is extended to the underside of the roof sheathing, and a new interior finish (typically gypsum board) is installed over the insulating sheathing. If needed, the ceiling is patched and finished.

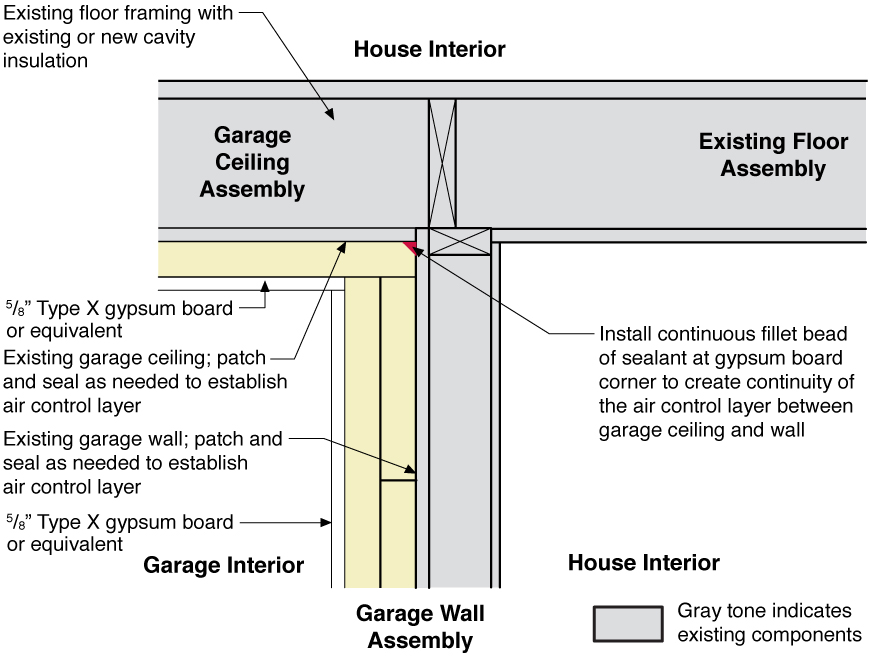

Garage Wall to Floor Above

Where there is a room located above the garage, the shared wall interfaces with the floor of the room above (Figure 4) and the air control layer and insulation of the wall is connected to the air control layer of the floor/ceiling assembly. (See Insulating Existing Floors over Garage for additional information on assembly options.) In the detail provided below, the interior finish of the wall is connected to the interior finish of the ceiling. The insulating wall and ceiling sheathing are installed over the existing wall and ceiling finishes and are continuous. A new interior finish (typically gypsum board) is installed over the insulating sheathing on both the wall and the ceiling.

How to Insulate the Wall between the House and the Garage

- Provide a continuous air control layer at the garage wall. Apply a continuous bead of sealant at the connection between the air control layer of the garage wall and the air control layer of the garage ceiling. If needed, install an infill strip of gypsum board or other rigid material and seal the joints between the solid materials to complete the air control layer of the garage wall.

- Remove the interior finish material (e.g., gypsum board; lath and plaster) at the inside corner(s) of the perpendicular garage walls where they interface with the shared wall to allow extension of the air control and insulation to the exterior sheathing.

- Seal the joints between solid materials to provide air sealing between the existing finish material (e.g., gypsum board; lath and plaster) and the inside face of the exterior wall sheathing.

- Install rigid insulating sheathing (foil-faced polyisocyanurate, XPS or EPS Type II) with joints offset horizontally and vertically and the joints of the outermost layer taped.

- Provide attachment/blocking and reinstall the fire protection layer (5/8” Type X gypsum board or equivalent) as required by the current adopted building code.

Success

Ensure the air control layer is continuous at the separation between the living space and the garage.

Seal all the connections and joints between the wall and ceiling air control layers.

Maintain a proper ratio of vapor-impermeable to vapor-permeable insulation (see the Climate tab).

Climate

The exterior wall assembly should be designed for a specific hygrothermal region, rain exposure zone, and interior climate.

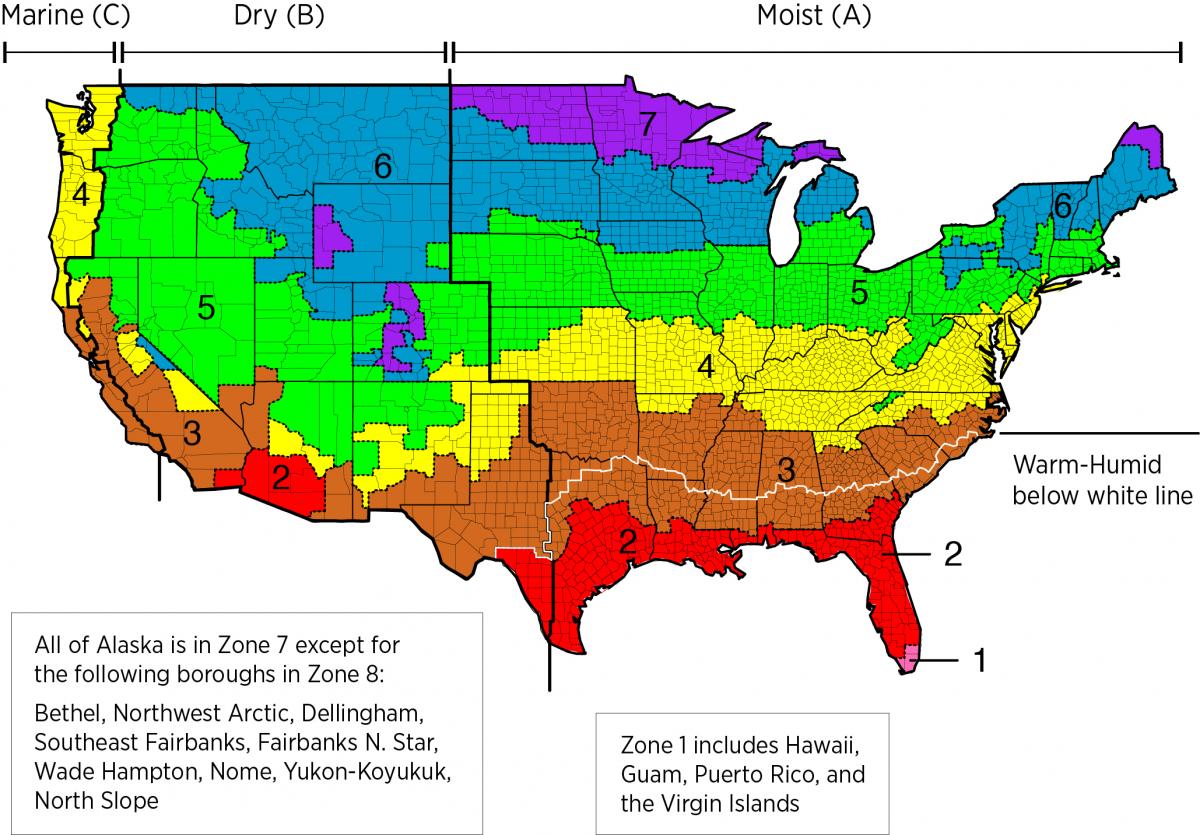

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

The insulation levels should be based on the minimum requirements for vapor control in the current adopted building code and the minimum requirements for thermal control in the current energy code. Additional insulation can be added above these minimums to create high R-Value exterior wall assemblies. The table below provides the minimum thermal resistance (R-value) requirements for exterior walls specified in the 2009 IECC (ICC 2009b) and the 2012 IECC (ICC 2012b), based on climate zone.

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

High-R Wall Insulation = High-Efficiency or Ultra-Efficient Wall Insulation

There are two levels of wall insulation: high-efficiency insulation, which meets the 2015 International Energy Conservation Code, and ultra-efficient insulation, which is 25% more efficient than this national code. Using high-efficiency and ultra-efficient insulation along with professional installation (e.g., no gaps, voids, compression, or misalignment with air barriers, complete air barriers, and minimal thermal bridging) creates conditioned spaces that require very little heating and cooling, along with even comfort and quiet throughout the house.