Showing results 2701 - 2750 of 4973

Right – EPA WaterSense-rated showerheads, faucets, and toilets contribute to both water and energy savings.

Right – Even house wrap is installed in the factory for these modular homes where each floor is factory assembled.

Right – Every seam and nail hole in these garage-to-house walls is sealed with tape.

Right – Examples of wall stud to sill plate and foundation and wall rod connectors and brackets.

Right – Examples of wall stud to top plate and stud to rim joist framing connectors and brackets.

Right – Fan with a cleanly cut and properly sized hole has been air sealed to drywall

Right – Fiberglass batt insulation fills the walls while the floor joists above are insulated with spray foam insulation to both insulate and air seal this transition space.

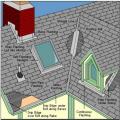

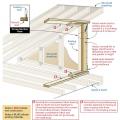

Right – Flashing is installed around chimney, skylight, vents, dormers, in valleys and at eaves

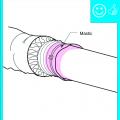

Right – Flex duct is properly connected to metal duct with a duct tie and connection is mastic sealed

Right – Flex ducts are properly supported with straps that don’t pinch the insulation; closed-cell spray foam will be applied to the underside of the roof deck of this hot-humid climate home to provide an insulated attic space for the HVAC ducts.

Right – Foam gasket is installed on the surface of the framing before plywood sheathing is installed on these factory-constructed wall panels.

Right – Foil-faced insulation was added after the crawlspace was dried and sealed by diverting water runoff, sealing off crawlspace windows and vents, and adding sump pumps and exhaust fan ventilation

Right – Foundation drainage mat was installed over the waterproof membrane that covers the sealed crawlspace window

Right – Full length 2x6 nailer has been installed to allow space for insulation at wall intersection

Right – Furring strips provide a drainage and ventilation gap between the siding and the cork insulation.

Right – Furring strips provide a drainage gap between the rigid foam and the siding.

Right – Furring strips were installed to provide a 3/8-inch drainage plane over the rigid foam and under the fiber cement lap siding.

Right – Graphite enhanced EPS fills these SIP panels, providing additional insulation value.

Right – Half-inch furring strips provide a rain screen and air gap between the weather-resistant membrane and the fiber cement siding on the exterior walls of this marine-climate home.

Right – Holes were drilled into the I joists between floors to run the small-diameter HRV ducts.

Right – Home owner guidance for safe operation of fireplaces

Right – Horizontal overhangs on this house block sunlight in the summer while allowing it in during winter

Right – Hot water from this heat pump water heater is distributed efficiently to each hot water use in the home through a central manifold via PEX piping.

Right – House without gutters has waterproof liner, drain tile, and gravel bed extending more than 5 feet from foundation

Right – Housewrap was properly shingled and taped on this wall assembly which places the housewrap beneath the rigid foam sheathing; wall cavities will be filled with spray foam.

Right – HVAC furnace filter is properly installed in cabinet with gasketed cover to prevent air leakage

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary

Right – ICFs are being installed to create a continuous air and thermal boundary