Showing results 601 - 650 of 4973

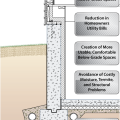

Because all of the structural load is carried by the SIP roof and wall panels, no trusses are needed, allowing the home to have vaulted ceilings and open interiors throughout.

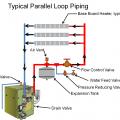

Because flue temperatures are cool, intake and exhaust ducts on a Category 4 direct-vent sealed-combustion condensing furnace can be made of PVC

Because heat pump clothes dryers recycle the hot air in the drum rather than venting it, they use 70% less energy than conventional electric clothes dryers while drying clothes in the same amount of time

Because the above-grade potions of the wall lack exterior insulation, condensation and even ice form during cold winter conditions

Because this ICF and spray foamed house is so well insulated, the HVAC system is smaller, the round metal ducts are smaller diameter, and the duct layout is more compact.

Bedrooms pressure-balanced and provide 1 sq. in. of free area opening per 1 CFM of supply air or achieve a Rater-measured pressure differential ≤ 3 Pa

Bedrooms pressure-balanced and provide 1 sq. in. of free area opening per 1 CFM of supply air or achieve a Rater-measured pressure differential ≤ 3 Pa

Bees made a nest in the drainage plane behind a brick veneer wall by entering via unscreened weep holes

Before conducting a blower door test, turn off any ambient gas water heater located in the conditioned space of the home; when the test is finished, turn the water heater back on and reset the pilot light if needed.

Before installing drywall, contractors install two beads of a sprayer-applied elastomeric sealant along framing and top plates to forma a flexible, air-tight seal between the framing and dry wall.

Before installing the windows, the window rough openings are sealed with a liquid-applied flashing that provides a seamless moisture and air barrier to protect the wall from water intrusion.

Before sealing and insulating the crawlspace, the windows were sealed, the window wells backfilled, and sumps pumps were installed that discharged to the gutter downspouts

Bellingham Bay Builders built this custom for buyer home in the cold climate in Friday Harbor, WA, and certified it to DOE Zero Energy Ready Home specifications in 2020.

Bellingham Bay Builders built this custom for buyer home in the marine climate in Bellingham, WA, and certified it to DOE Zero Energy Ready Home specifications in 2018.

Bellingham Bay Builders built this custom for buyer home in the marine climate in Seattle, WA, and certified it to DOE Zero Energy Ready Home specifications in 2019.

Berms are compacted earth or gravel ridges that slow the flow of water from rain, riverine flooding, or storm surges in coastal areas.

Berms, swales, bioswales, ridges, and vegetation all help to control rainwater runoff on residential sites.

Between the ICF foundation walls, the builder sprayed closed-cell spray foam directly onto the gravel base to provide a vapor barrier and continuous layer of insulation under the slab.

Bioswales or rain gardens filter storm water through vegetation and rock and sand substrate layers.

Bioswales receive rainfall and filter it through different substrate layers, preventing flooding and storm surges from occurring

Blocking installed on a flat roof for a PV system rack is sealed around the edges with sealant then will be covered with self-adhering roof membrane to prevent water leakage

Blower door tests can be an important part of a home energy assessment to check for comfort improvements

Blown cellulose insulation completely fills the netted wall and ceiling cavities.

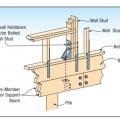

Bolted metal hurricane strapping ties the roofing to the framing and the framing to the foundation walls for resistance to high winds.

Borate-treated roof trusses and concrete masonry unit (CMU) walls are among the pest-resistant features of these Florida homes.

Bottom plate-subfloor joints, corners, and wiring holes are all sealed with foam to improve the airtightness of the homes.

BPC Green Builders built this custom for buyer home in the cold climate in Clinton, CN, and certified it to DOE Zero Energy Ready Home specifications in 2017.

BPC Green Builders built this custom for buyer home in the cold climate in Stamford, CT, and certified it to DOE Zero Energy Ready Home specifications in 2021.

BPC Green Builders built this custom for buyer home in the cold climate in Trumbull, CT, and certified it to DOE Zero Energy Ready Home specifications in 2020.

BPC Green Builders built this custom home in the cold climate in New Fairfield, CT, and certified it to DOE Zero Energy Ready Home specifications in 2013.

BPC Green Builders built this custom home in the cold climate in New Fairfield, CT, and certified it to DOE Zero Energy Ready Home specifications in 2014.

BPC Green Builders built this custom home in the cold climate in Watertown, CN, and certified it to DOE Zero Energy Ready Home specifications in 2015.

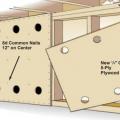

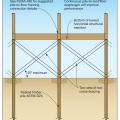

Braced cripple wall construction in crawlspace anchored to framing and foundation