Showing results 1 - 50 of 4973

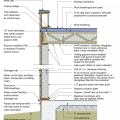

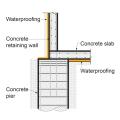

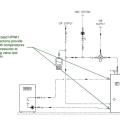

A method for preventing waterproofing issues at the intersection of a concrete pier, concrete retaining wall, and concrete slab.

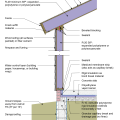

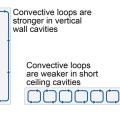

Airflow within drop-in ceiling assemblies is generally not a concern due to the limited vertical height. However, airflow within air gaps in walls is a concern due to the much larger vertical height.

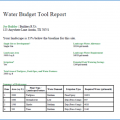

An example of the water budget tool report for determining a home's landscaping irrigation needs.

DOE's Building Energy Codes Program tracks the status of state energy code adoption and state equivalency to various versions of the International Energy Conservation Code.

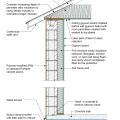

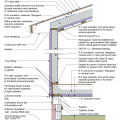

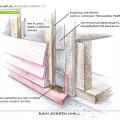

Example of the advanced framing technique, double-stud wall cavity, which will later be filled with blown insulation

Imery & Company built this custom for buyer home in the mixed-humid climate in Lilburn, GA, and certified it to DOE Zero Energy Ready Home specifications in 2018.

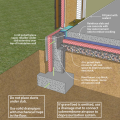

Impervious surfaces like patio slabs, sidewalks, and driveways that are within 10 feet of the home should slope away from the house.

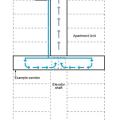

Individual ventilation systems for each dwelling unit in a multifamily building will require large numbers of penetrations in exterior facades

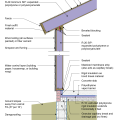

Install mesh insect barrier along the bottom of the rain screen behind the exterior cladding of above-grade walls

Place plants at least 18 inches from the building's walls and foundation and direct irrigation water to spray away from the structure.

Right - Drywall is installed as an air barrier above the central hallway duct chase prior to installing the trunk ducts.

Right: dedicated tank connections for HPWH inlet and outlet provide hydraulic separation

Taped plywood provides an air barrier beneath the cork insulation installed on the exterior of this home.

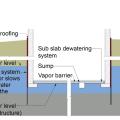

The “perimeter cutoff and dewatering” approach can be used to control groundwater in cases where the building foundation is below the groundwater table.

These folding louvered porch doors provide effective shade from low-angle east and west sunlight and can open for views; the photovoltaic panels overhead allow in filtered natural light

These schematics illustrate temporary deployment locations for probes during the commissioning process; these probes connect to smartphone commissioning applications.

This central ventilation system uses an energy recovery ventilator to supply air to the corridor and exhaust air from the elevator shaft of a multifamily building

[bundle] design studio built this attached home in the marine climate in Bellingham, WA, and certified it to DOE Zero Energy Ready Home specifications in 2021.

[bundle] Design Studio built this custom for buyer home in the marine climate in Bellingham, WA, and certified it to DOE Zero Energy Ready Home specifications in 2021.

[bundle] design studio built this custom spec home in the marine climate in Bellingham, WA, and certified it to Zero Energy Ready Home in 2016.

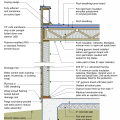

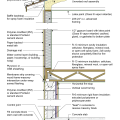

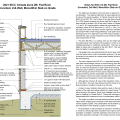

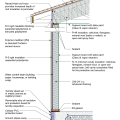

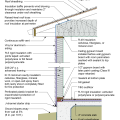

2021 IECC Climate Zone 1A: Flat Roof, Unvented, 2x6 Wall, Monolithic Slab on Grade

2021 IECC Climate Zone 1A: Flat Roof, Unvented, 2x6 Wall, Monolithic Slab on Grade (with notes)

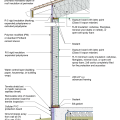

2021 IECC Climate Zone 2A: Flat Roof, Unvented, 2x6 Wall, Monolithic Slab on Grade

2021 IECC Climate Zone 2A: Flat Roof, Unvented, 2x6 Wall, Monolithic Slab on Grade (with notes)

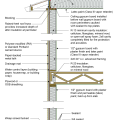

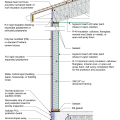

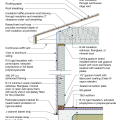

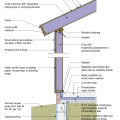

2021 IECC Climate Zone 2A: Unvented Attic with Spray Foam at Roof Deck, 2x6 Wall-CMU Wall, Elevated Slab

2021 IECC Climate Zone 2B: Flat Roof, Unvented, 2x6 Wall, Monolithic Slab on Grade

2021 IECC Climate Zone 2B: Flat Roof, Unvented, 2x6 Wall, Monolithic Slab on Grade (with notes)

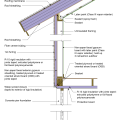

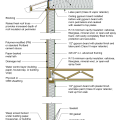

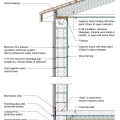

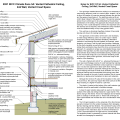

2021 IECC Climate Zone 3A: Vented Cathedral Ceiling, 2x6 Wall, Vented Crawl Space

2021 IECC Climate Zone 3A: Vented Cathedral Ceiling, 2x6 Wall, Vented Crawl Space (with notes)

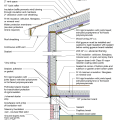

2021 IECC Climate Zone 3B: Vented Cathedral Ceiling, 2x6 Wall, Vented Crawl Space

![[bundle] design studio built this attached home in the marine climate in Bellingham, WA, and certified it to DOE Zero Energy Ready Home specifications in 2021.](/sites/default/files/styles/image_gallery/public/images/2021-Bundle-Flc-1-Aerial-Front-Elevation-Roof.jpg?h=9b6f7c84&itok=JcYZmkH8)

![[bundle] Design Studio built this custom for buyer home in the marine climate in Bellingham, WA, and certified it to DOE Zero Energy Ready Home specifications in 2021.](/sites/default/files/styles/image_gallery/public/images/2021-Bundle-Mid-1-Front-Elevation-Yard.jpg?h=251cce06&itok=AM9jb0yD)

![[bundle] design studio built this custom spec home in the marine climate in Bellingham, WA, and certified it to Zero Energy Ready Home in 2016.](/sites/default/files/styles/image_gallery/public/images/2016_Bundle_Birch-1-Front.jpg?h=654f81f0&itok=pd9jy-eb)