Scope

Install a continuous air barrier that is fully aligned with (touching) the insulation installed on top of the ceiling (on the attic floor) in a vented attic:

- The air barrier could consist of drywall that is taped and sealed at seams, or another durable, solid surface like plywood or OSB, or house wrap or a smart vapor retarder membrane that is sealed at the seams. Kraft-paper, paper products, or other materials that tear easily should not be used.

- If spray foam insulation is used, the spray foam can serve as the air barrier if it is at least 5.5 inch thick open-cell or at least 1.5 inch thick closed-cell spray foam insulation.

- Install an air barrier that is continuous and in full contact with the insulation.

- ENERGY STAR specifies that the air barrier can be installed at either the interior or exterior surface of the ceiling insulation in Climate Zones 1-3, but should be at the interior surface of the ceiling insulation in IECC Climate Zones 4-8 (ENERGY STAR).

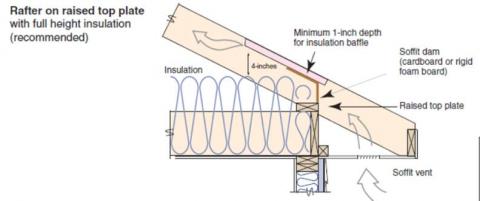

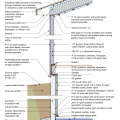

- Install an air barrier at the vertical edges of the insulation at the attic eaves in all climate zones using a wind baffle that extends to the full height of the insulation in every rafter bay or a tabbed baffle in each bay with a soffit vent that prevents wind washing in adjacent bays. Install wind baffles with the minimum code required clearance between the baffle and the roof deck.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

In simplest terms, a house is a six-sided assembly composed of four walls, a roof, and a floor. When these components are connected, they comprise the building enclosure or the physical shell of the home. Within these assemblies are components that comprise the home’s thermal envelope (insulation) and air barrier. For the best performance, the home’s thermal layer should be fully aligned with (in full continuous contact with) the air barrier. This guide primarily describes single-family construction. For guidance on air-sealing and insulating dwelling units in multi-story multifamily buildings where floors separate dwellings, see the Building America Solution Center guide Air Sealing and Compartmentalization in Multifamily Buildings.

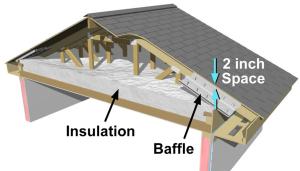

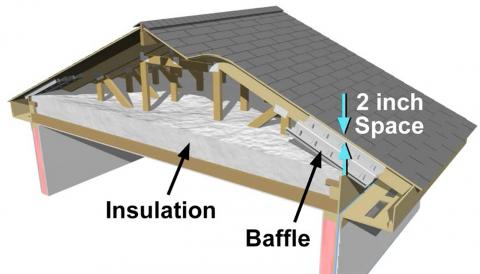

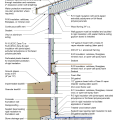

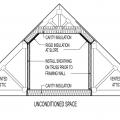

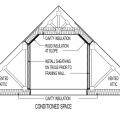

In a home with a vented attic, the ceiling provides the air barrier. The insulation in the vented attic should be in full contact with the ceiling below, which provides the air barrier for the top of the building enclosure (Figure 1).

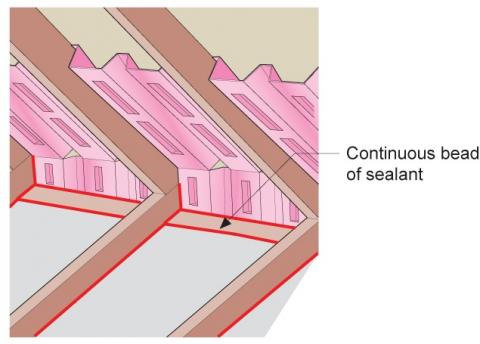

The ceiling air barrier usually consists of taped, mudded drywall, and should be continuous with all holes through it (such as for wiring, electrical boxes, light fixtures, flue and chimney pipes, duct chases, heating registers, soffits, etc.) thoroughly air-sealed before insulation is installed. For specific guides on air-sealing these and other items in the Building America Solution Center search for "air sealing" or by specific topics. For more on air-sealing the top plates to the ceiling drywall to provide a continuous ceiling air barrier, see the guide Air Sealing Drywall to Top Plates.

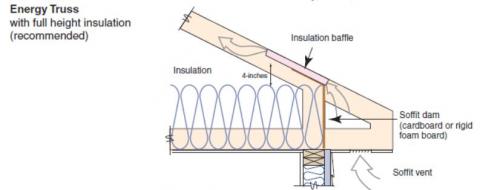

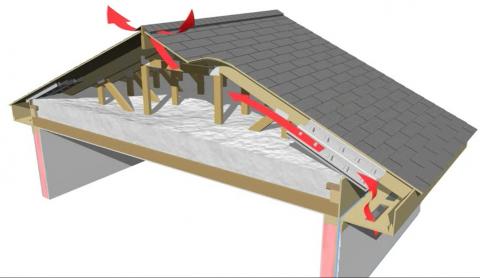

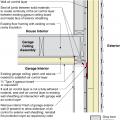

To help maintain consistent insulation over the ceiling air barrier, wind dams and baffles should be installed in the attic in every rafter bay that has a soffit vent (Figure 2). A wind dam (or a soffit dam as in Figures 3 and 4) consists of a piece of rigid material (like rigid foam, OSB, or plywood), that is installed vertically at the outside edge of the top plate. It is sealed to the top plate and extends up to the baffle. The wind dam and the baffle together direct air that flows in through the soffit vents to flow up along the underside of the roof deck to the ridge vents. It prevents wind that enters the soffit vent from pushing insulation away from the eaves and it also provides a "backstop" when insulation is installed to keep the insulation from covering the soffit vents. In some cases the exterior wall sheathing extends up to provide the wind dam (Figure 1).

Baffles are 2-inch-deep chutes made of plastic, cardboard, or metal, 2 to 4 feet in length, and 16 or 24 inches wide to fit in 16 inch on center (o.c.) or 24 inch o.c. rafter bays (Figure 4). They can be connected to the wind dam or they often come with a flat tab at the end that can be bent down to serve as the wind dam. The baffle maintains a 2 inch air gap between the underside of the roof deck and the insulation to guide air from the soffit vents up along the underside of the roof to ridge vents (Figure 5). The baffles also help to protect the insulation from wind washing.

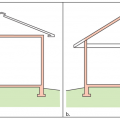

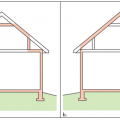

It is important to maintain a minimum amount of insulation, preferably equivalent to the insulation depth of the rest of the attic, over the top plates of the exterior walls. This will prevent cold spots along the exterior walls and ensure a consistent R-value across the ceiling. Building the roof with raised heel “energy” trusses or rafters (Figures 3 and 4) will allow the full height of insulation to be installed over the top plates. See Attic Eave Minimum Insulation for more information.

HOW TO AIR-SEAL AND INSULATE THE CEILING

- Design the home with raised heel energy trusses if you are using trusses (Figure 3) or roof rafters with a raised top plate if you are building the rafters on site (Figure 4).

- Thoroughly air-seal all holes through the ceiling.

- Install baffles in each rafter bay that has a vent. Choose and install the baffles correctly to provide the code-required minimum air space between the baffle and the roof deck.

- Cover the ceiling deck with blown, batt, or spray foam insulation to the full height required to meet or exceed the minimum value for the climate zone. ENERGY STAR requires that all insulated ceiling surfaces meet the requirements for ceilings, regardless of slope (e.g., cathedral ceilings, tray ceilings, conditioned attic roof decks, flat ceilings, sloped ceilings).

Success

Verify with a visual inspection that a continuous air barrier exists at the interior surface of the ceilings in Climate Zones 4-8 and at the interior or exterior surface of ceilings in Climate Zones 1-3. This air barrier should be fully aligned with the insulation across the entire surface of the ceiling including at the eaves. Verify that wind dams and baffles are installed in every bay with a soffit vent to prevent wind washing. Measure baffles to confirm that the baffles meet the minimum code-required clearance between the baffle and the roof deck.

Climate

Minimum insulation levels for attics are specified by climate zone in the International Energy Conservation Code (IECC). The insulation levels for the past several IECC and IRC code versions (2009, 12, 15, 18, and 21) are summarized in the Solution Center in the 2009-2021 IECC and IRC Minimum Insulation Requirements for New Homes.

To determine your climate zone see the maps below or go to the 2021 IECC Climate-Specific Building Assemblies tool in the Solution Center and click on the “Help me find by Climate Zone”: button. The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the 2009, 12, 15, and 18 IECC. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021.

Training

CAD

Compliance

Retrofit

SCOPE

Retrofit an existing ceiling to establish a complete thermal barrier by air-sealing and insulating.

- Air-seal the top plates and all penetrations through the ceiling, including the attic hatch and pull-down stair openings, chimneys, bathroom fans, recessed ceiling lights, electrical boxes, and plumbing stacks.

- Inspect attic eaves and soffit vents. Set aside existing insulation. Re-install any missing vent grating. Replace missing baffles and wind dams. Caulk top plate-to-drywall junctures, if accessible. Install insulation to full available height over top plates.

- See the Scope and Description tabs for additional guidance.

For more information on conditions that may be encountered when working in attics in existing homes, see the assessment guides on attics and hazardous materials.

See the U.S. Department of Energy’s Standard Work Specifications (SWS) for more on air sealing and working in attics. Follow safe work practices as described.

DESCRIPTION

Adding attic insulation is a popular retrofit in older homes. However, before adding insulation it’s important to make sure that the ceiling deck (attic floor) is well air-sealed. The porous blown or batt insulation typically used will do little to stop the movement of conditioned air out of the home and into the attic if there are gaps such as around light fixtures, flues, or dry wall-to-top plate junctures. In a home with a vented attic, the properly air-sealed ceiling with attic insulation on top serves as an important part of the home’s thermal envelope. See the Description tab for more on this concept. For the best performance, the home’s thermal layer should be fully aligned with (in full continuous contact with) the air barrier and the air barrier should be continuous with no air leaks.

Specific attic air-sealing measures are described in several Building America Solution Center guides, as well as in the Measure Guideline: Guide to Attic Air Sealing by Building Science Corporation. Note that locating penetrations underneath attic insulation is often challenging, and may require such steps as tracing wiring and measuring from base points visible from both the interior of the house and the interior of the attic. Note also that not all penetrations may be accessible for sealing (for example, those located at the perimeter of the attic where there is minimal head clearance). Sealing large and accessible holes will improve energy efficiency and comfort, even if the work cannot be performed perfectly at every single penetration.

Insulation should completely cover the attic floor and the insulation depth across the attic ceiling should be consistent. See the Description tab for a description of baffles and wind dams, which help to keep insulation from getting blown away from soffit vents while maintaining a ventilation gap from soffit vents to ridge vents.

Note that, although the purpose of air-sealing is to improve energy efficiency and comfort, it is important not to compromise health, safety, and durability in the process. Combustion safety, ventilation for indoor air quality, durability, and attic ventilation should be addressed first, before performing attic air-sealing. This work will be performed inside the attic so use safe work practices and be aware of hazardous conditions as described in the attic assessment guide.

How to Insulate and Air-Seal an Existing Attic to Establish a Consistent Thermal Boundary

- Inspect the house, checking for combustion appliances, controlled ventilation, and required attic ventilation.

Do not proceed if:- The house attic has active knob and tube wiring.

- The house attic has vermiculite insulation.

- The house attic has bathroom fans vented into the attic.

- The house has a leaking roof.

- The house has an unvented kerosene heater or gas fireplace.

- Ensure combustion safety. If there is a natural draft (Category 1) gas- or oil-fired furnace, water heater, or boiler located in the home, see the Pre-Retrofit Assessment of Combustion Appliances guide for more information including testing requirements. Consider replacing the natural draft appliances with a sealed combustion, induced draft, or power-vented appliance. Install carbon monoxide detectors.

- Ensure ventilation for indoor air quality. Air-sealing will reduce the amount of air that will enter the home through uncontrolled means. Controlled ventilation is required. See the guide Whole-Building Delivered Ventilation.

- Ensure Attic Ventilation. All roofs must be vented according to the applicable building code. Most residential roofs are vented with soffit vents, but ridge vents, mushroom cap vents, and gable vents are also common. The size and location of the vents should be determined by referencing the applicable building code. (See Lstiburek 2014.)

- Identify areas to be air sealed. This includes all penetrations through the ceiling, including the chimneys, flues, bathroom fans, electrical boxes, and plumbing stacks, recessed ceiling lights, attic hatch and pull-down stair openings, as well as top plates for all exterior and interior walls. The contractor may want to start with a walk-through of the home, noting potential sources of leaks on a sketch of the home.

- Move existing insulation away from penetrations and brush away dust and debris.

- Air-seal gaps, seams, and holes using caulk and spray foam sealants. Rigid board material such as plywood, OSB, drywall, or rigid foam board can be secured into place to seal larger gaps. See specific guides for more on sealing electrical, plumbing, and flues and penetrations with complicated interfaces such as recessed ceiling lights, dropped soffits, attic hatch and pull-down stair openings, and top plates for all exterior and interior walls.

- Replace insulation and add insulation to compensate for insulation compressed during air sealing activities.

- Inspect attic eaves and soffit vents. Set aside existing insulation. Re-install any missing vent grating. Replace missing baffles and wind dams. Caulk top plate-to-drywall junctures, if accessible.

- Replace insulation and add insulation to full available height over top plates.

- Add insulation to desired depth across the entire attic.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

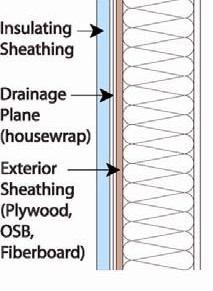

Fully Aligned Air Barriers = Whole-House Draft Barrier

A whole-house draft barrier is a continuous layer of air-tight materials that block air leaks. This barrier can be integrated with other materials to also function as a water barrier, thermal barrier, and vapor barrier. For example, rigid foam insulation can be used to block thermal flow as well as air flow when seams are sealed with tape, caulk, adhesives, or liquid-applied sealants. Some rigid foams have an integrated water control layer as well. Additionally, drywall can serve as an interior air barrier when the seams are taped and spackled, and caulk, spray foam, or gaskets are used to seal around wiring, plumbing, and other penetrations. It also serves as the vapor barrier when finished with paint. Insulation should be in full contact with the air barrier layer.