Scope

Air-seal around recessed can light fixtures that are installed through ceilings to keep conditioned air from leaking into unconditioned space.

- Using a saw, cleanly cut a hole that is no more than 1 inch larger in diameter than the diameter of the can.

- Install ICAT-labeled recessed lighting fixtures.

- Seal around the can with caulk before installing trim or install a trim kit with a gasket.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Recessed “can” ceiling fixtures, or downlights, are the most popular home lighting fixture in the United States. However, recessed can fixtures can be energy intensive in the following ways:

- If they are not approved for insulation contact and are installed in an insulated ceiling, insulation has to be kept at least 3 inches from the fixture all the way around, leaving about 1 square foot of uninsulated ceiling space.

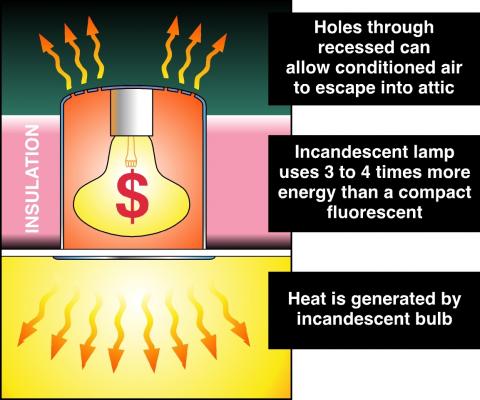

- Many homeowners and contractors install incandescent bulbs or R-lamps in the fixtures; these use four times the electricity of fluorescents and six times the electricity of LEDs, as well as generating heat that adds to air-conditioning loads.

- If the cans are not airtight, they allow conditioned air to escape from the living area into unconditioned spaces such as the attic.

Leaky recessed cans are an even greater issue than a hole in the ceiling. A non-airtight recessed can with an incandescent bulb can draw 3 to 5 times as much air as a hole the same size, thanks to the stack effect (Figure 1). When the light inside the can is turned on, the heat it generates turns the can fixture into a chimney, pulling air from the house up into the attic (McCullough and Gordon 2002).

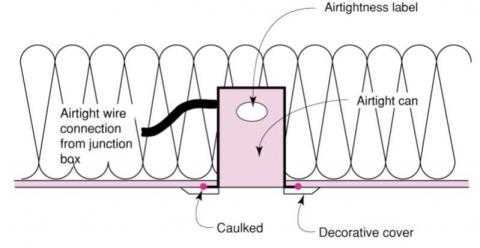

Recessed downlights that are installed in insulated ceilings are now required by code to be rated for insulation contact (IC) so that insulation can be placed over them. The housing of the fixture should also be rated airtight to prevent conditioned air from escaping into the ceiling cavity or attic, and unconditioned air from infiltrating the conditioned space. The fixture should bear a label showing it meets the ASTM E 283 requirement of ≤ 2.0 cfm of air movement from the conditioned space to the ceiling cavity when tested at 75 Pa, and the housing should be caulked or gasketed where it meets the ceiling (Lstiburek 2009). Some brands of can lights designated ICAT may still leak air. Check the fixtures you intend to use to see whether they appear to be well designed to be air tight. See the guide Insulating and Air Sealing Existing Non-ICAT Recessed Lights for more information.

If recessed lights are installed in insulated cathedral ceilings, there must be insulation with an R-value of R-10 or greater above the can in IECC climate zones 4 and higher to minimize condensation potential. Extra caution should be taken to ensure the recessed can is airtight in unventilated cathedral ceilings. Leaky light fixtures can allow moisture-laden indoor air to enter the roof assembly. If the moisture encounters cold roof sheathing, it can condense, leading to moisture accumulation and rot (Holladay 2011).

Some building scientists recommend against putting recessed can lights in cathedral ceilings (see for example Holladay 2011) and some recommend against putting recessed can lights in any insulated ceiling (for example, Bailes 2011). Other alternatives are to install the recessed cans in an air-sealed dropped soffit or to limit use of recessed cans to only ceilings of rooms that have conditioned space above them such as a second floor. Another option is to avoid recessed can fixtures all together and use surface-mounted or pendant fixtures instead. LED surface-mounted kits that look similar to recessed can lights are now available.

How to Air-Seal Recessed Can Lights in Insulated Ceilings

- Choose fixtures that are labeled ICAT, meaning they are approved for insulation contact and are airtight as determined by the ASTM E 283 air leakage test.

- Install according to the manufacturer’s instructions. Before installing the decorative trim, caulk the housing to the ceiling, or install the fixture using a manufacturer-supplied gasket (Figure 2).

Success

Inspect and verify that recessed can light fixtures installed in ceilings below unconditioned space are rated insulation-contact, airtight (ICAT). Blower door testing may help indicate whether the recessed can lights are sufficiently air-sealed. An infrared camera used in conjunction with the blower door testing may assist in detecting leakage. Experienced contractors can also detect air leakage with a smoke stick or by hand.

Climate

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

CAD

Compliance

Retrofit

For information on air sealing recessed can lights in existing homes, see the guide Insulating and Air Sealing Existing Non-ICAT Recessed Lights.

For more information, see the U.S. Department of Energy’s Standard Work Specifications regarding general penetrations.

See Compliance Tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Tight Air Sealed Home = Comprehensive Draft Protection

Poorly air-sealed homes are less comfortable and cost more to maintain because they provide a pathway for drafts, cold spots, moisture, and insects into the home. Comprehensive draft protection includes a continuous air barrier around the whole house along with caulking and sealing in all holes and cracks. This includes around wiring, plumbing, ducts, and flues; where wall framing meets flooring; around windows; where drywall meets top plates and sill plates; where rim joists meet foundation walls and subfloors; etc. Spray foam insulation can be used at rim joists, floors above unconditioned space, and in attics to insulate and air seal at the same time.