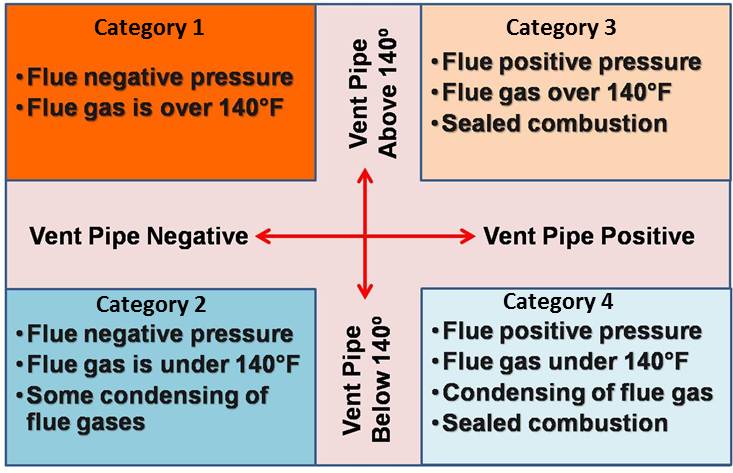

The 2012 National Fuel Gas Code (NFPA 54) puts combustion appliances in four categories based on flue vent pressures, flue gas temperatures (relates to condensing or non-condensing), and vent pipe materials, as shown in Figure 1.

Many older homes have Category 1 furnaces and water heaters and Category 1 appliances are still sold today. (See the Building America Solution Center guides Combustion Furnaces and Direct Vent Appliances and the report HVAC: A Guide for Contractors to Share with Homeowners, for more about the NFPA categories.) Category 1 appliances have an open combustion chamber and draw their combustion air from the room in which the appliance is located, known as the combustion appliance zone (CAZ). They also rely on high flue temperatures (relative to outside temperatures) to draw exhaust gases up and out of the flue. Because so much of the heat goes up the chimney, natural draft furnaces have very low Annual Fuel Utilization Efficiency (AFUE) ratings, usually 70% or less. A newer type of Category 1 furnace has an induced draft fan that pulls air through the combustion chamber, which assists in getting a draft started and encourages more complete combustion for higher efficiencies of 80% to 86%. However, because the furnace still relies on negative flue pressure to carry away combustion byproducts, the induced-draft furnace can, like the naturally drafted furnace, have the potential to backdraft. Backdrafting occurs when combustion gases spill into the CAZ rather than going up the flue because the CAZ has become depressurized with respect to the flue.

Category 2 applies to some commercial furnaces but no residential furnaces. Most Category 3 furnaces are high-efficiency oil furnaces with gun type burners and efficiencies ranging from 82% to 88%.

Most high-efficiency (90% to 98% AFUE) furnaces available today are Category 4 sealed-combustion, direct-vent condensing furnaces that have a sealed flue pipe, which vents directly outdoors while a second pipe brings combustion air directly to the sealed combustion chamber. A draft fan pulls air through the combustion chamber to a primary heat exchanger and then a second heat exchanger which condenses water vapor in the emissions, capturing most of the remaining heat, resulting in emissions that are so low temperature that the flue pipe, like the vent pipe, can be made out of PVC. The sealed-combustion design virtually eliminates the potential for backdrafting.

Carbon monoxide (CO) is a major health threat that can quickly lead to death. CO poisoning is preventable. If the house has combustion appliances of any kind, carbon monoxide alarms complying with UL 2034 must be installed in close proximity to the combustion appliances and outside each separate sleeping area in the immediate vicinity of the bedrooms.

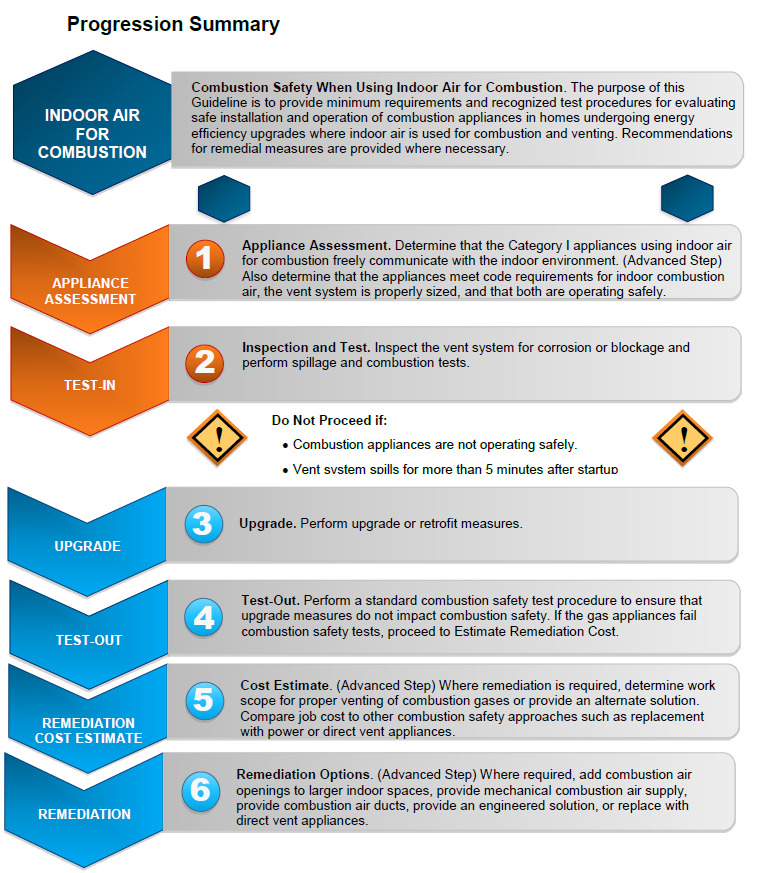

If Category 1 combustion appliances will be used in the home then contractors should follow the steps outlined in Figure 3 below for evaluating the safe operation of atmospherically vented combustion appliances in homes, taken from the Building America report, Measure Guideline: Combustion Safety for Natural Draft Appliances Using Indoor Air. The report provides guidance on general building code requirements and inspection procedures for natural draft appliances. Figure 1 identifies some steps as “advanced.” These steps are intended to be completed by certified auditors with special training or trained heating and cooling technicians. The inspection guidelines in the report are intended for trained residential energy retrofit inspectors to confirm that combustion appliances found in the home can operate as expected, or the inspector will refer problems to a qualified technician. As indicated in the report, the National Fuel Gas Code provides sizing tables for vent connectors, vertical vents, and masonry chimneys for safe venting of gas appliances. However, inspections will often reveal that the vent connector is not properly sized or an adjustment has been made to the vent system, the number and type of appliances, the addition of exhaust fans, or the appliance location.

These steps for combustion safety with Category 1 appliances installed inside the home can be summarized as follows, also from the report Measure Guideline: Combustion Safety for Natural Draft Appliances Using Indoor Air:

- Start with a visual inspection of the appliances and vent systems.

- Identify vent system design or installation flaws and have them addressed.

- Calculate the required air volume for indoor combustion air using one of several methods provided in the code. Guidance can found in the Solution Center guide, Combustion Appliance Zone (CAZ) Testing.

- Test for adequate draft and high carbon monoxide levels in the flue or in the space.

- Have a trained technician repair broken or damaged appliance components.

- Perform remediation or replace unsafe appliances before or during the energy efficiency upgrade.

- Conduct the upgrade and test the appliances again to ensure safe performance.

- Perform additional remediation as needed.

The Building Performance Institute has developed guidance on this titled Combustion Appliance Safety Inspection for Vented Appliances.

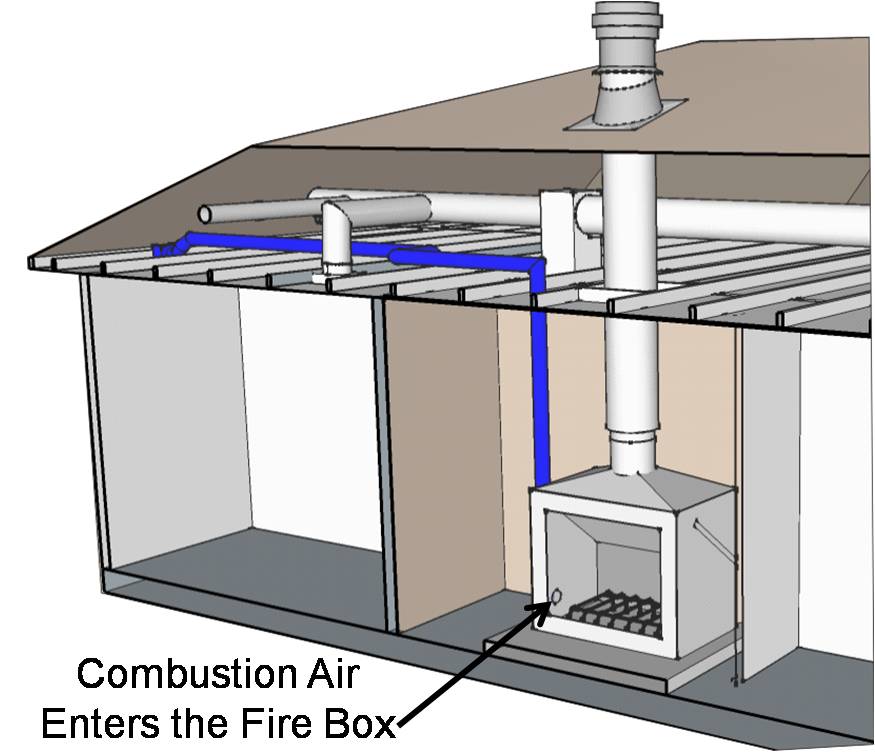

Most fireplaces in existing homes are natural drafted open-combustion appliances, meaning they draw combustion air from the room in which they are located and use the stack effect of a heated chimney to pull combustion byproducts up and out of the flue. When a natural-draft fireplace is operating at maximum burn, the natural draft can move as much as 400 CFM of air up the chimney; it actually has enough draw to backdraft other natural-draft-vented combustion appliances in the home. However, when the chimney is cool, such as when a fire is just getting started in a cold fireplace or when a fire has burned down or is on a low flame, the natural-draft fireplace is vulnerable to being backdrafted by forces as small as a 50 CFM kitchen or bath exhaust fan. To avoid the likelihood of backdrafting, the fireplace should have a dedicated combustion air duct that brings outside air directly into the firebox and tight-fitting glass doors across the face of the fireplace opening. Wood or pellet stoves should be equipped with a fail-safe draft inducer, or have a tight-fitting loading door and outdoor combustion air ducted to the firebox.

During an energy assessment if the rater finds a fireplace that is naturally drafted, the rater must verify that the total net rated exhaust flow of the two largest exhaust fans in the home is ≤ 15 CFM per 100 ft2 of occupiable space, or the rater must verify that the pressure differential is ≤ -5 Pa using BPI’s or RESNET’s worst-case depressurization test procedure. This test procedure is described in the Solution Center guide Fireplaces/Stoves with Proper Ventilation.

Building Science Corporation offers the following recommendations for solid fuel-burning hearth fireplaces to be acceptable in a high-performance retrofit home.

- flue liner in good condition (the flue liner may need to be repaired or a flue liner may need to be installed in older chimneys)

- airtight hearth doors

- outdoor combustion air ducted to firebox

- operable flue damper.

The U.S. Environmental Protection Agency’s Indoor airPLUS, a home labeling program focused on good indoor air quality, list several criteria related to fireplaces that constitute a good list of best practices for solid fuel-burning appliances located within the home’s conditioned space. These energy efficiency and emissions standards and restrictions are listed in the following bullets. Residents should be alerted when they have appliances that do not meet these criteria.

- Traditional masonry fireplaces designed for open fires are not permitted, with the exception of “masonry heaters” as defined by ASTM E1602 and Section 2112.1 of the 2012 International Building Code (i.e., fireplaces engineered to store and release substantial portions of heat generated from a rapid burn).

- Factory-built wood-burning fireplaces shall meet the certification requirements of UL 127 and emission limits found in the EPA Standard for New Residential Wood Heaters.

- Natural gas and propane fireplaces shall be mechanically drafted or direct vented, as defined by NFPA 54, Section 3.3.108, have a permanently affixed glass front or gasketed door, and comply with ANSI Z21.88/CSA 2.33.

- Wood stove and fireplace inserts as defined in Section 3.8 of UL 1482 shall meet the certification requirements of that standard, and they shall meet the emission requirements of the EPA Standards for New Residential Wood Heaters and WAC 173-433-100 (3).

- Pellet stoves shall meet the requirements of ASTM E1509.

- Decorative gas logs as defined in K.1.11 of NFPA 54 (the National Fuel Gas Code) are not permitted.

See the guides Fireplaces/Stoves with Proper Ventilation, Unvented Combustion Appliances, and Direct Vent Equipment for further information.

Do not install any unvented combustion space-heating appliances. These appliances include ventless gas-, propane-, and ethanol-burning fireplaces. Because they are not connected to a flue or chimney, they release combustion byproducts directly into the room where they are located. Efficiently burning ventless fireplaces will have a primarily blue flame. Defects such as plugged burner ports, a cracked burner, excessive gas input, impurities in the gas, or a gas leak somewhere in the unit will reduce the efficiency of the burn and increase the amount of byproducts released. If a ventless fireplace is discovered during an energy audit, the contractor should test the fireplace by operating the appliance for at least 10 minutes and testing ambient air near the appliance with a hand-held CO monitor, as described in the Building America Solution Center guide Unvented Combustion Appliances. If the CO level is above 35 ppm, the appliance must be removed or serviced and retested. Even when operating efficiently, ventless combustion appliances release significant amounts of water vapor into the space. These appliances produce 1 gallon of water vapor for every 100,000 Btus, so a 30,000-Btu appliance would release nearly 1 gallon of water vapor for every 3 hours of operation, adding greatly to indoor humidity levels.

Due to safety, health, and moisture concerns, Building America recommends that unvented appliances never be installed in homes (see HVAC: a Guide for Contractors to Share with Homeowners). Several states and municipalities have banned the use of non-vented combustion appliances.

Do not use building cavities, such as floor joist cavities, as the equivalent of a return air duct because these cavities are extremely difficult to seal and may contain contaminants. Leaky ducts can affect pressures inside the home which can impact the operation of combustion appliances. The Solution Center contains in-depth information on placing, sealing, and insulating ducts. See Step 4 and Step 5 of the Existing Homes tool.

Whenever combustion appliances are located in the home, follow safe work practices to minimize impacts to workers’ and occupants’ health. See the U.S. Department of Energy’s Standard Work Specifications for more information.