Scope

Install insulation along the underside of the roof deck of an unvented attic rather than on the ceiling deck of a vented attic for either of two reasons: to provide an unvented, conditioned space for locating HVAC equipment in the attic, and/or to provide a continuous thermal barrier for designs that have complex coffered ceiling planes and/or numerous penetrations for lights, speakers, vents, soffits, etc., which make it difficult to achieve an airtight ceiling plane.

Install insulation to levels that meet or exceed code or energy-efficiency program requirements.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Unvented roof assemblies, such as conditioned attics and unvented cathedral ceilings, are created by eliminating ventilation openings and moving the thermal (insulation), moisture, and air control boundaries to the plane of the roof deck. These unvented cathedralized attic assemblies (also known as a “compact” or “hot roof” assemblies) can be used to overcome two major problems associated with vented attics:

- Locating ducts/air handling units in the attic space can be a cause of major air leaks of conditioned air to unconditioned space (and thus forced infiltration/exfiltration), and heat/loss gain through the ductwork.

- Designs with complex coffered ceiling planes, and numerous penetrations by lights, speakers, vents, etc., make it practically difficult to achieve the airtightness required just below the insulation layer.

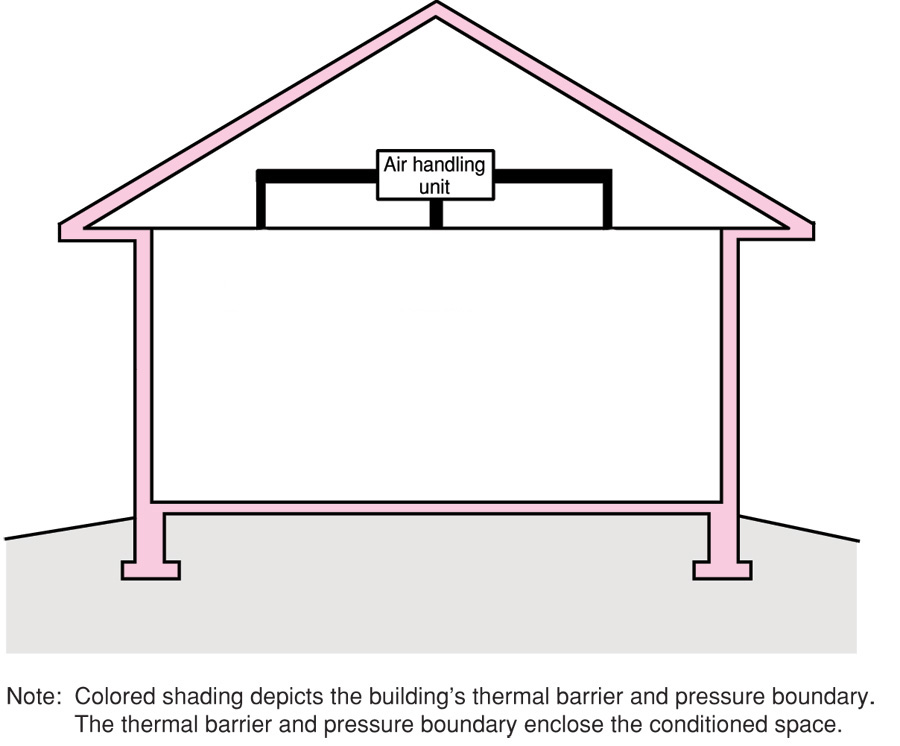

In cases where mechanical systems are located in attics, moving the air control layer and thermal control layer to the the roof deck has particularly large advantages compared to sealing and insulating attic ceilings and ductwork. In addition it might not be desirable (in hurricane or wildfire areas) or practical (in retrofit) to add roof vents at soffit locations. Accordingly, there may not be any practical alternative to moving the air control layer and thermal control layer to the roof deck (Figure 1). When this design choice is made, spray foams have advantages over alternative insulation methods because of the ability of spray foams to effectively air seal complex assemblies. Spray foam can provide the thermal and vapor control layers in both new and retrofit construction.

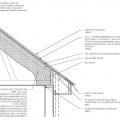

All unvented attic and cathedral ceiling designs must provide for either a very high degree of airtightness or avoidance of condensation due to warming of cold surfaces. To meet durability goals in most applications, the airtightness must be provided by a continuous membrane—preferably adhered to the top surface of the structural roof deck and under rigid insulation that provides condensation control. In designs where the air tightness is provided between framing elements, spray foam has been found to be a practical solution. However, all wood-to-wood joints in the framing must still be sealed.

The key to creating an unvented roof assembly is to keep the roof deck – the principle condensing surface in roof assemblies – sufficiently warm throughout the year such that condensation will not occur, or to prevent interior moisture laden air from accessing the roof deck (Lstiburek 2014). This is done by using what is referred to as “air-impermeable insulation,” such as rigid foam board or spray foam.

Two acceptable methods for insulating an unvented attic assembly in all climates are as follows:

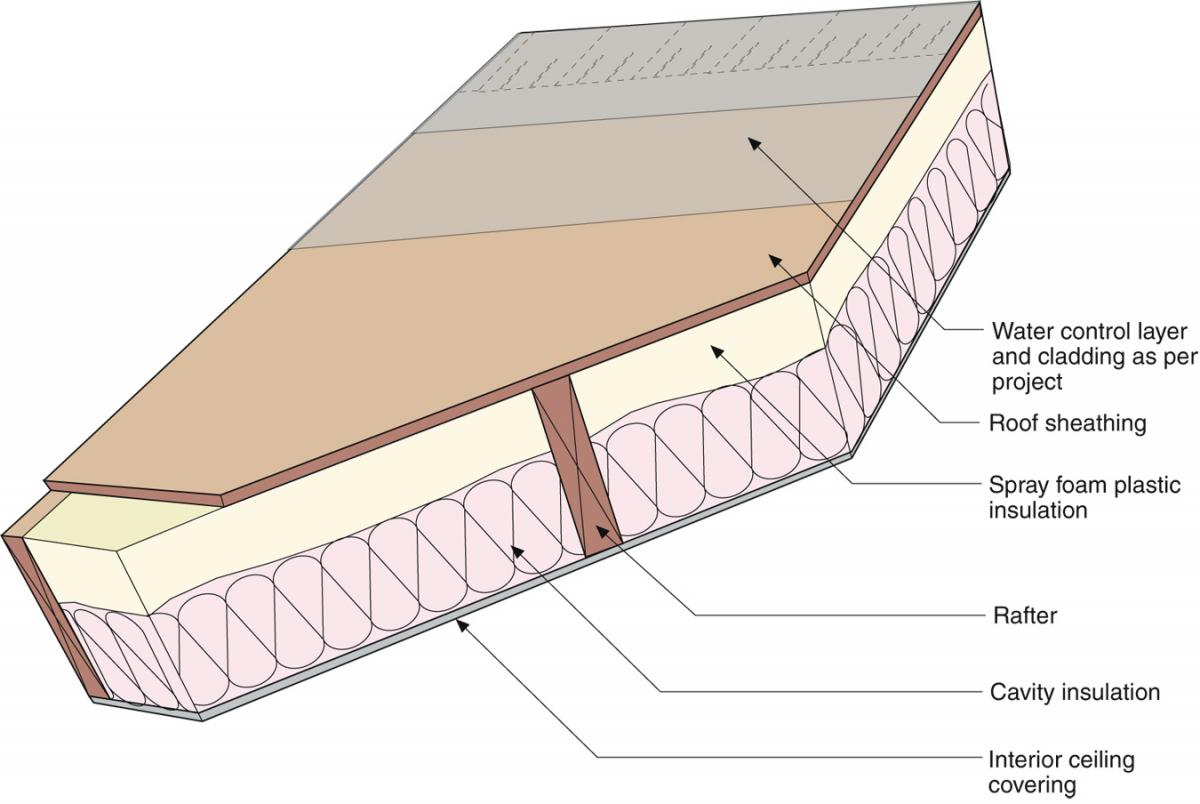

- Air-impermeable insulation (typically spray foam) installed to the underside of the roof sheathing. For more information on this technique see the guides Unvented Conditioned Attic with Spray Foam Insulation Below Roof Deck and Below Deck Spray Foam Insulation for Existing Roofs.

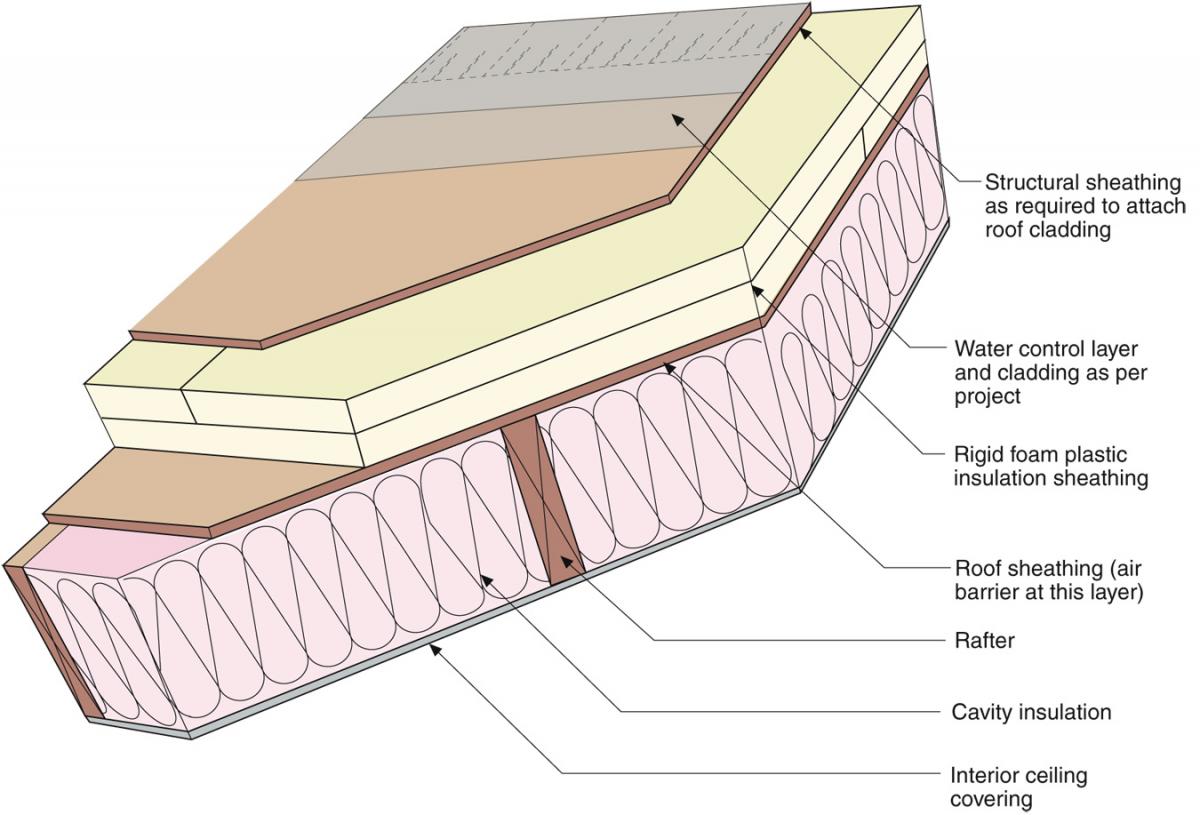

- Air-impermeable insulation (typically rigid foam insulating sheathing) installed over the roof sheathing. For more information on this technique see the guide Above Deck Rigid Foam Insulation for Existing Roofs.

In both assemblies, air-permeable insulation (such as batt or loose fill) can be used to increase overall insulation value. This is by no means a requirement; however, it is typically the most economical way to achieve target (or code minimum) R-values. Alternately, “air-impermeable insulation” alone could be used for the entire insulation thickness, assuming that all climate-specific code requirements are met (see Climate section).

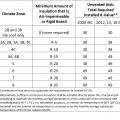

The minimum required thickness of the “air-impermeable insulation” is stated in Table R806.5 - Insulation for Condensation Control of the 2012 IRC, which provides prescriptive requirements for minimum rigid board or air-impermeable insulation R-values based on climate zone, in order to manage the condensation potential in the assembly. See the Climate tab for details.

When designing a highly insulated roof (high-R value roof), it is important, especially in cold climates, to note the ratio of vapor-impermeable to vapor-permeable R-values. For cold climates, the air-impermeable insulation is maintained at 50% or more of the total R-value of the roof system. This is for condensation control. When building high-R-value roof systems, Building Science Corporation (BSC) recommends that this ratio be maintained or exceeded. If an R-80 unvented cathedralized attic is to be constructed in a cold climate, it is recommended that a minimum of R-40 (50%) be air-impermeable insulation installed and layered according to Section R806.5 of the 2012 IRC. (see the case study “Application of Spray Foam Insulation Under Plywood and OSB Roof Sheathing” at the More Info tab.)

Below are general instructions for the two unvented attic designs.

Air-Impermeable Insulation Installed to the Underside of the Roof Sheathing in a Cathedral Ceiling

Figure 2 shows an unvented cathedralized attic design with air-impermeable expanding spray foam insulation installed at the underside of the roof deck.

How to Install Spray Foam under the Roof Deck in a Cathedral Ceiling

* It is recommended that the spray foam insulation is installed by a licensed professional applicator.

- Refer to the current state and local building codes for the minimum R-value of air-impermeable insulation required for the roof assemblies in your climate.

- Inspect the roof assembly to ensure it has proper drainage protection above the roof deck.

- Measure the moisture content of the wood prior to applying spray foam insulation to ensure it has dried to the levels recommended by the spray foam manufacturer.

- Ensure the weather conditions and temperatures for installing the insulation are as recommended by the spray foam manufacturer.

- Clean the surfaces of the roof sheathing and structural members so they are clear of any debris or dust to ensure proper adhesion of the spray foam.

- Cover any mechanical and electrical equipment and wiring prior to applying the insulation.

- Provide proper ventilation in the work area during application.

- It is recommended to hire a licensed professional applicator for the spray foam installation.

- Visually inspect the insulation installation.

- Refer to the current state and local building codes for definition and requirements for the ignition and thermal barrier as well as vapor diffusion retarder requirements.

- Install cavity insulation.

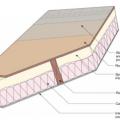

Air-Impermeable Insulation Installed Over the Roof Sheathing with a Cathedral Ceiling

Figure 3 shows an unvented cathedralized attic design with air-impermeable insulating sheathing installed over the roof deck. A structural nail base would typically be required over the rigid foam for a roof cladding such as asphalt shingles. To meet durability goals in most applications, the airtightness must be provided by a continuous membrane—preferably adhered to the top surface of the structural roof deck and under rigid insulation that provides condensation control.

How to Install Insulating Sheathing over the Roof Deck with a Cathedral Ceiling

- Refer to the current state and local building codes for the minimum R-value of air-impermeable insulation required for the roof assemblies in your climate.

- Install a weather-resistive, air-impermeable roofing underlayment (i.e., fully adhered membrane), properly lapped, and ensure it is integrated with the wall weather resistive barrier (e.g., house wrap).

- Inspect roof deck weather resistive barrier for any leaks or any inconsistencies.

- Install insulating sheathing in multiple layers with joints offset in both directions and taped.

- Install OSB/plywood over the insulating sheathing to serve as a nailbase.

- Install proper roofing underlayment and roof cladding according to manufacturer’s instruction.

- Install cavity insulation.

How to Install Ducts in an Unvented Attic

When installing HVAC equipment in an insulated conditioned attic, good HVAC design principles still apply:

- Design a compact, duct layout with short, straight ducts runs. Seal and test ductwork for air leakage.

- Install a balanced ventilation system such as a heat recovery ventilator or central fan-integrated ventilation with a fresh air intake and timered exhaust. (For more information, see Whole-Building Delivered Ventilation.)

- Do not install low-efficiency heating systems that draw their combustion air from the attic. Instead install direct-vent sealed-combustion furnaces or heat pumps. (For more information, see Combustion Furnaces, Traditional Split Heat Pumps)

Success

Regular inspections should be conducted between major points in construction to check on the integrity of the water, air, thermal and vapor control layers of the roof. Monitor the moisture content of the roof sheathing, when possible, during the construction process. Take measurements before the installation of the air-impermeable insulation to ensure that the roof deck is dry enough to be covered. This is especially true for spray foam installed to the underside of the roof deck. Ensure correct ambient temperature for spray foam application and ensure that framing and underside of roof decking has been swept clean of dust and debris before installing spray foam.

When installing HVAC equipment in an insulated, conditioned attic, design a compact duct layout with short, straight ducts runs. Seal and test ductwork for air leakage. Install a balanced ventilation system. Install high-efficiency direct-vent sealed-combustion furnaces or heat pumps.

Climate

The International Energy Conservation Code (IECC) requires minimum levels of air-impermeable insulation for each climate zone.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Cold Climates

In high snow load climates it is preferable to keep heating equipment out of the attic, because heat transfer from the ducts or heating equipment to the roof deck of the attic can warm the deck, causing snow melt that could lead to ice dam formation. If HVAC equipment is installed in attics in cold climates, installers must be especially careful to thoroughly air seal and insulate the equipment.

See Lstiburek 2014 for additional discussion about insulating attics at the roof line in very cold climates with either closed-cell spray foam on the underside of the roof deck or rigid foam on top of the roof deck separated from the cladding by a ventilating air gap.

Training

CAD

Compliance

Retrofit

SCOPE

Convert a vented attic to an unvented attic and insulate using one of the methods described in the Description tab or similar.

- Close and seal all attic vents, including roof deck and soffit vents.

- If installing insulation above the decking, remove existing roof tiles or shingles and replace weather-resistant barrier if needed.

- Install above- or below-deck insulation.

See the U.S. Department of Energy Standard Work Specifications for additional guidance on preparing the roof deck for spray foam, insulating the underside of the roof deck with spray foam insulation, using polyurethane spray foam, and air sealing a cathedralized attic.

For guidance on working in attics, see the Pre-Retrofit Assessment of Attics, Ceilings, and Roofs.

DESCRIPTION

Convert a vented attic to an unvented attic and insulate using one of the methods described in the Description tab or similar. Prior to installing insulation, close off and seal all attic vents, including roof deck and soffit vents. If installing insulation above the decking, remove existing roof tiles or shingles and replace weather-resistant barrier if needed. Follow the installation guidance provided in the Description tab and as recommended by the manufacturer. Prior to installation, verify installation method with roofing contractor and local code officials.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

High-R Attic Insulation = High-Efficiency or Ultra-Efficient Attic Insulation

There are two levels of attic insulation: high-efficiency insulation, which meets the 2015 International Energy Conservation Code, and ultra-efficient insulation, which is 25% more efficient than this national code. Using high-efficiency and ultra-efficient insulation along with professional installation (e.g., no gaps, voids, compression, or misalignment with air barriers; complete air barriers; and minimal thermal bridging) creates conditioned spaces that require very little heating and cooling, along with even comfort and quiet throughout the house.