Scope

Choose the highest performing heating and cooling equipment that project funding will allow, to meet the design load of the project.

Properly match the indoor and outdoor components of the heat pump system as demonstrated by a certificate from the Air Conditioning, Heating and Refrigeration Institute (AHRI). AHRI assigns a certification number and efficiency ratings to specific combinations of equipment (outdoor unit, indoor unit, indoor coil, fan type, etc.) that have been tested by the manufacturer according to AHRI test procedures using AHRI-specified test conditions. If an AHRI certificate is not available, a copy of the catalog data provided by the original equipment manufacturer (OEM) should be attached to the system indicating an acceptable combination and performance data.

Install the heat pump in accordance with the manufacturers’ instructions and relevant standards including ACCA Standard 5: HVAC Quality Installation Specification and ACCA’s Technician's Guide for Quality Installations and ACCA Standard 9: HVAC Quality Installation Verification Protocols.

Properly size the equipment for the design heating or cooling load of the home (whichever is larger), following the sizing guidelines in ACCA Manual S: Residential Equipment Selection. Calculate the heating and cooling load using the ACCA Manual J Residential Load Calculation. When determining equipment sizing per ACCA Manual S, use the original equipment manufacturer (OEM)’s expanded performance table to obtain performance data at design conditions, rather than using the performance data on the AHRI certificate, which lists heating and cooling capacity and SEER and EER cooling efficiencies at factory conditions of 90°F outdoor, 80°F indoor, and 67°F wet bulb.

The OEM-listed total cooling capacity at design conditions should be between 95% and 115% of the design total heat gain (or 95% to 125% for heat pumps in IECC climate zones 4-8) or the next nominal size. The next largest nominal piece of equipment available may be used to satisfy the latent and sensible cooling requirements. Single-speed systems generally have OEM nominal size increments of one-half ton. Multi-speed or multi-stage equipment may have OEM nominal size increments of one ton. Therefore, the use of these advanced system types can provide extra flexibility to meet the equipment sizing requirements.

If the whole-house ventilation system uses the heat pump air handler, then the fan motor should be a variable speed electronically commutated motor (ECM) or an integral control motor (ICM) that includes a controller (e.g., a smart cycler) that reduces the ventilation run time by accounting for hours when the HVAC system is already operating the fan for heating or cooling the home.

Design an efficient air distribution system with a compact layout in accordance with ACCA Manual D: Residential Duct Systems. Install ducts properly for maximum airflow and efficiency. Consider zoning for low-load homes (over 1,000 sq ft per ton of cooling) with thermostat-controlled dampers.

If you are participating in an energy-efficiency program, select cooling equipment that complies with the requirements for your climate zone. To determine your climate zone, see the International Energy Conservation Code (IECC) 2012 climate zone map on the Climate tab.

DOE Zero Energy Ready Home Notes

The U.S. Department of Energy’s Zero Energy Ready Home program allows builders to choose a prescriptive or performance path. The prescriptive path requires builders to meet or exceed the minimum HVAC efficiencies listed in Exhibit 2 of the DOE Zero Energy Ready Home National Program Requirements. The DOE Zero Energy Ready Home performance path allows builders to select a custom combination of measures for each home that is equivalent in performance to the minimum HERS index of a modeled target home that meets the requirements of Exhibit 2 as well as the mandatory requirements of Zero Energy Ready Home Exhibit 1. See the Compliance tab for specific program details.

ENERGY STAR Single-Family New Homes Notes

The ENERGY STAR Single-Family New Homes program allows builders to choose a prescriptive or performance path. The ENERGY STAR prescriptive path requires builders to meet the minimum HVAC efficiencies listed in Exhibit 1 of the National Program Requirements for ENERGY STAR Single-Family New Homes. The ENERGY STAR performance path allows builders to select a custom combination of measures for each home that is equivalent in performance to the minimum HERS index of a modeled reference home that meets the requirements of ENERGY STAR Exhibit 1 as well as the mandatory requirements of Exhibit 2. See the Compliance tab for specific program details.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Heat pumps use the same refrigeration cycle technology as your home’s refrigerator or air conditioner, pulling heat from one environment and dumping it into another. Unlike air conditioners made for cooling only, heat pumps are equipped with a reversing valve, which allows them to reverse the cycle to pull heat from the outdoor air and deliver it indoors in the wintertime. Most heat pumps installed in U.S. homes are central air-source heat pumps that draw heat from or shed heat to the outside air. A much smaller percentage of homes are equipped with ground source or water source heat pumps.

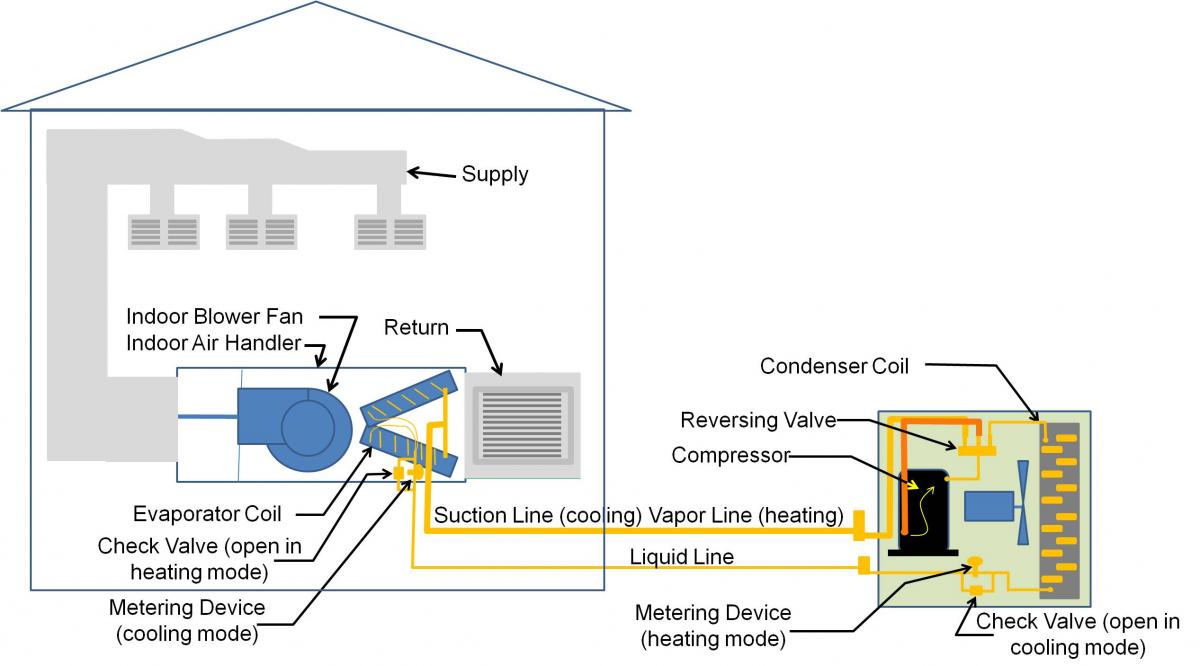

Most of these air-source heat pumps are split systems with an indoor unit and an outdoor unit that are connected by refrigerant lines (Figure 1). The indoor unit includes an evaporator coil and a metering device that are located in the air handler unit, which also contains a blower fan that blows the conditioned air into the supply ducts for distribution throughout the house and receives stale house air from the return ducts. The outside unit contains the condenser and the compressor. For more on the refrigerant cycle, see Mechanical Air-Conditioning.

Heat pumps (and air conditioners) are also available as packaged units, where the compressor, condenser, evaporator, and expansion device are all packed into one unit that is located outside, typically mounted on the wall or on the roof (Figure 2). The conditioned air is vented inside, either directly into a room or into a duct system for distribution throughout the home. A window air conditioner is a good example of a package unit. Many small commercial buildings are heated and cooled with roof-mounted packaged heat pump units.

Central heat pumps distribute the heated or cooled air through ducts, just like a central forced-air furnace. Another form of heat pump is the ductless mini-split heat pump. These split-systems feature a small ground- or wall-mounted outdoor unit connected via refrigerant lines to one or more indoor wall- or ceiling-mounted units that heat and cool the space they are in without the use of ducts.

Because the heating efficiency of standard, central air-source heat pumps drops when outside temperatures drop below about 35°F, a backup heat source is often needed. Air-source heat pumps can be all-electric or dual-fuel systems. All-electric air-source heat pumps come equipped with electric resistance strip heaters for supplementary heat if needed. Dual-fuel systems combine the air-source heat pump with another source of supplementary heat, such as a gas furnace.

When compared to an electric furnace or baseboard heaters, a heat pump can trim the amount of electricity used for heating by 30% or more. The efficiency of today's air-source heat pumps is one to two times greater than those available 30 years ago due to technical advances such as thermostatic expansion valves, variable-speed blowers, improved coil design, two-speed compressors (instead of single-speed compressors), and improved motor designs (DOE 2013). Recently available central heat pump models with variable-speed compressor designs that better match refrigerant flow to load can save even more and are more effective at lower outside temperatures. Ductless mini-split heat pump models have been available for several years that use variable-refrigerant-flow technology and can heat at 100% capacity at outdoor temperatures as low as -5°F. For more on ductless heat pumps, see the guide Mini-Split Heat Pumps.

Current federal law requires that air-source heat pumps have a minimum heating efficiency or Heating Season Performance Factor (HSPF) of 8.2 and a minimum cooling efficiency or Seasonal Energy Efficiency Ratio (SEER) of 14 (Code of Federal Regulations). Higher efficiency central air-source heat pump models are available with HSPF ratings above 13 and SEER ratings above 30 (See ENERGY STAR’s Most Efficient 2022 – Central Air Conditioners and Air Source Heat Pumps). For more on efficiency measurements, see Mechanical Air-Conditioning.

Ducts may need to be larger for a heat pump than for a gas or oil furnace because furnaces generally deliver air to the living space at between 130°F and 140°F. Heat pumps provide air at about 80°F to 115°F so more air needs to be delivered to provide the same amount of warmth. Your HVAC contractor should confirm that the supply air registers achieve a “throw” appropriate for a heat pump. Choosing the right register design can be important for minimizing comfort complaints because heat pumps blow more air at cooler temperatures than gas- or oil-fired furnaces. Some researchers suggest central-air-source heat pumps may need to be slightly oversized, to enable the system to provide enough warmth without turning on the backup heat.

Care should be taken when installing the heat pump system to seal the copper tubing refrigerant lines to keep moisture out of them during construction and the lines should be cleared with a vacuum pump to remove pockets of air before charging the lines with refrigerant. Any water or water vapor in the lines will mix with the oil used for lubricant in the refrigeration system creating an acidic sludge that eats away at compressor windings and clogs valve openings. Care should also be taken to follow the manufacturer’s specifications regarding the correct method for charging the refrigerant with the model to be installed. Too much or too little refrigerant can affect performance and efficiency.

How to Select and Install Central Air Source Heat Pumps

- Choose the highest performing heat pump project costs will allow, to meet the design heating or cooling load of the project. If you are participating in an energy-efficiency program, select equipment that complies with the requirements for your climate zone, as described in the Compliance tab.

- Confirm that the indoor and outdoor components of the heat pump system match, as demonstrated by a certificate from the Air Conditioning, Heating and Refrigeration Institute (AHRI) or a copy of the catalog data provided by the original equipment manufacturer (OEM) indicating an acceptable combination.

- Properly size the heat pump for the design heating or cooling load of the home, whichever is greater. Use ACCA Manual J to calculate your load and use ACCA Manual S to correctly size your system. This is especially important if you have done significant air sealing and insulating, which will reduce your heating and cooling load. When determining equipment sizing per ACCA Manual S, use the original equipment manufacturer (OEM)’s expanded performance table to obtain performance data at design conditions, rather than using the performance data on the AHRI certificate.

- Design an efficient air distribution system with a compact layout in accordance with ACCA Manual D. Install ducts properly for maximum airflow and efficiency in accordance with ACCA Manual D, and ACCA Standards 5 and 9. See also the Building America Solution Center guides on duct installation, insulation, and air sealing.

- During construction keep the copper refrigerant tubing charged with dry nitrogen and sealed with solder to keep moisture out of the lines.

- After connecting the indoor unit and the outdoor unit, vacuum the lines to 500 microns to remove air pockets.

- Follow the manufacturer’s recommendations for refrigerant charging. Too much or too little refrigerant can reduce the efficiency of the equipment and lead to premature component failures. Use the charging method recommended by the manufacturer. There are three methods for charging: the subcooling method (typically for units with a thermal expansion valve), the superheat method (typically for units with a fixed orifice), or the weigh-in method (using the refrigerant weight amount listed on the data plate on the outdoor unit). Verify that you are using the correct method for the specific heat pump model to be installed. Refrigerant charging must be done by an EPA certified technician.

- Make sure the condensate line and drain pans are correctly installed.

- Test air flow and duct leakage.

Success

Choose the highest efficiency SEER and HSPF rated product possible.

Verify that the air handler is correctly matched to the outdoor unit. Matched systems can be verified at the AHRI website, listed under "Heat Pumps and Heat Pump Coils."

Install in accordance with the manufacturers’ instructions and relevant standards including ACCA Standard 5: HVAC Quality Installation Specification and the ACCA’s Technician's Guide for Quality Installations and ACCA Standard 9: HVAC Quality Installation Verification Protocols. These standards address quality installation and commissioning requirements for vapor compression cooling systems, heat pumps, combustion furnaces, and boilers.

Install the air handler and ducts within the home’s thermal envelope.

Follow the manufacturer’s recommendations for refrigerant charging.

Set the time-delay relay on the unit to 30 seconds or less in humid climates to prevent moisture on the evaporator coil from evaporating back into the air stream and contributing to indoor humidity. Set the fan on the central air conditioning systems to “Auto” rather than “On” for the most efficient operation. Set the compressor to start before the blower. Make sure the drain pans are correctly installed.

Climate

For ENERGY STAR and DOE Zero Energy Ready Home climate-specific guidance, see the Compliance tab.

In mild or cold climates, consider non-compression cooling options such as trees, awnings, pergolas, and porches to shade windows and walls; ceiling fans; and timer-controlled night-time ventilation cooling (Gilbride et al. 2011).

In humid and mild or cold climates, consider adding a dehumidifier for indoor humidity control in the shoulder seasons and in locations with short summers as an alternative to compression cooling.

In humid climates, set the time-delay relay on the unit to 30 seconds or less to prevent moisture on the evaporator coil from evaporating back into the air stream and contributing to indoor humidity.

Cold Climates

Heat pumps for space conditioning and water heating are an increasingly common technology in residential construction and are becoming more popular in cold climates. In climate zones 4 and up, a cold-climate-specific heat pump can be installed. Cold-climate heat pumps have greater capacity and efficiency at colder temperatures. They are equipped with a built-in defrost cycle to keep the outdoor coils from icing up. Even with heat pumps designed for cold climates, a severe winter weather event may cause the heat pump to ice over if the temperatures drop below the unit’s specifications for an extended period of time, so the occupant will need to melt the ice or carefully break it off the unit to keep it in good working condition.

Aftermarket heat trace can be installed on the outdoor unit if needed. While not potentially part of the factory default conditions, many heat pumps will come with manual directions on how to add heat trace for resiliency during winter. Depending on the distance of the equipment from the panel, this approach may lead to a long heat trace line and expensive energy bills. The heat trace can be wired to a glowing electric pilot switch in the mechanical room that will light up to indicate when the heat trace has been switched on. Turning on the heat trace only during time or conditions when needed is preferable to supplying the heat trace with hard-wired continuous power.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Compliance

Compliance

ENERGY STAR New Homes and Apartments

International Energy Conservation Code (IECC)

International Residential Code (IRC)

Air Conditioning Contractors of America (ACCA) Standards

ACCA Manual S - Residential Equipment Selection

ACCA Manual D - Residential Duct Systems

ACCA Manual J - Residential Load Calculation

ACCA Standard 5: HVAC Quality Installation Specification

ACCA Standard 9: HVAC Quality Installation Verification Protocols

Retrofit

SCOPE

Assess the need for replacing or upgrading the HVAC system. See Pre-Retrofit Assessment of Existing HVAC Systems.

Review the guide Pre-Retrofit Assessment of Combustion Appliances to ensure safe conditions exist and unsafe conditions won’t be introduced if combustion appliances are upgraded or replaced or if other energy-efficiency upgrades are made to a home with combustion appliances.

For more information, see the U.S. Department of Energy’s Standard Work Specifications regarding heat pump controls.

DESCRIPTION

Assessment

The typical lifespan of HVAC equipment is 15 to 20 years. New equipment has much higher efficiencies, safety, control flexibility, and performance capabilities. Existing equipment should be carefully assessed to determine whether investment in repairs, upgrades, or expansion is warranted. See the following BASC guides and resources for information to aid in making this determination. The guides also contain important safety and health information for dealing with older construction and equipment.

- Assessment of Existing HVAC Systems

- Existing HVAC System Upgrade or Expansion

- Building America Best Practices Series Volume 14 - HVAC: A Guide for Contractors to Share with Homeowners.

Replacement

If the existing HVAC system is a heat pump, current models likely offer much higher efficiencies and can perform at lower outdoor temperatures than those of 15 or 20 years ago. Although replacement of HVAC equipment can be costly and labor-intensive, it often reaps large rewards in energy cost savings and comfort.

If a decision is made to replace the equipment, it can be replaced in-kind, or with a different type of system. Modern, ducted heat pumps are available in a variety of capacities and efficiencies and can operate at wide temperature ranges, making them a viable alternative to fuel-fired furnaces in virtually all climates. They have the added advantage of a reversing valve, which allows them to provide either heating or cooling. When comparing heat pumps against furnaces with A/C, perform a full Manual J load calculation to compare annual operating costs, since there is no reliable way to equate AFUE with HSPF.

For decision-making guidance including a discussion of the available system types and their advantages, see Assessment of Existing HVAC Systems and Building America Best Practices Series Volume 14 - HVAC: A Guide for Contractors to Share with Homeowners.

See the following Building America Solution Center guides for more specific information on other HVAC systems:

Repair/Upgrade

Full system maintenance is often overlooked by homeowners who don’t understand the strong relationship between general maintenance and performance. Proper commissioning or recommissioning by a certified technician is especially important with heat pump equipment.

The Air Conditioning Contractors of America Association, Inc. (ACCA) is one of the best sources for guidance on the installation, commissioning, and maintenance of HVAC equipment. Their free Quality Standards can be found on the ACCA website.

Useful documents available for download from the ACCA website include the following:

- ACCA Standard 5 (2015): HVAC Quality Installation Specification - minimum design and installation requirements for HVAC applications by professional contractors following industry-recognized quality installation practices.

- ACCA Standard 12 (2014): Home Evaluation & Performance Improvement - minimum requirements to evaluate a residence with regard to energy efficiency, water conservation, occupant comfort, and indoor air quality.

- ACCA Standard 9 (2016): HVAC Quality Installation Verification Protocols - details the requirements, roles, and obligations of installers and others to ensure that HVAC installations comply with the ANSI/ACCA 5.

- ACCA Standard 4 (2013): Maintenance of Residential HVAC Systems - establishes the minimum level of acceptable compliance for HVAC equipment maintenance inspections for residential applications.

- ACCA Standard 6 (2015): Restoring the Cleanliness of HVAC Systems - procedures for cleaning HVAC systems.

Additions

If additional rooms will be added to the home, or if an attic, basement, or garage will be converted to living space and the home has an existing heat pump with central forced-air air handler, the existing system may have sufficient capacity to extend conditioning to the additional space. This should be confirmed by performing an accurate load calculation (ACCA Manual J) for the entire house including the addition. If the current system doesn’t meet the additional needed capacity (and/or for increased efficiency or for zone control) you may decide to add a new, dedicated HVAC system to serve the new space independently or you may choose to replace the existing system with a new more efficient system capable of serving the whole house.

When installing new ducts for the addition, consider the following:

- New ducts should be properly sized in accordance with ACCA Manual D.

- If using the existing heat pump, simply extending the nearest existing supply branch ducts into an addition is unlikely to deliver sufficient air flow to the addition because that takeoff was not designed for the new (combined) flow requirement. This will result in poor comfort for all spaces dependent on the modified branch, both existing and new.

- Ideally, install a separate, dedicated supply air trunk duct to serve the addition. This trunk should be run back as close to the furnace/air handling unit as practical. This will ensure that air flow to the addition is removed proportionally from the total system air flow and therefore will not affect the air flow balance in the existing house. Install manual balancing dampers in the supply trunks serving the addition and existing house to allow fine-tuning of the system.

- If there are interior doors separating the addition - or portions of the addition - from the main house, install transfer grilles, jump ducts, or ducted returns as required to ensure a return air path to the central air handling unit

COMPLIANCE

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Air Source Heat Pump/AC = High-Efficiency or Ultra-Efficient Heat Pump/AC

High efficiency air source heat pumps are built to save energy but are configured much like less efficient standard heat pumps. They include an outdoor unit and an indoor unit. The indoor unit typically ties into a home’s duct system to deliver warm or cool air throughout the house. Heat pumps take heat out of outdoor air to heat your home in winter. In summer the cycle is reversed; they pull heat out of your home and discharge it to the outdoors to cool your home.