Scope

Insulate an attic or roof in an existing home by installing spray polyurethane foam (SPF) insulation - either open cell or closed cell - on the underside of the roof deck as follows:

- Inspect the existing roof shingles or roofing membrane for any deficiencies. If there is any history or evidence of leakage, correct the leaks and repair the damage before proceeding.

- If the roof is at or near the end of its service life, consider replacing the roof to ensure the roof will provide acceptable water control.

- Block the soffit vents.

- Install spray polyurethane foam insulation (and additional insulation other than spray polyurethane foam if desired) in the roof cavity to levels that meet or exceed the current adopted building and energy codes.

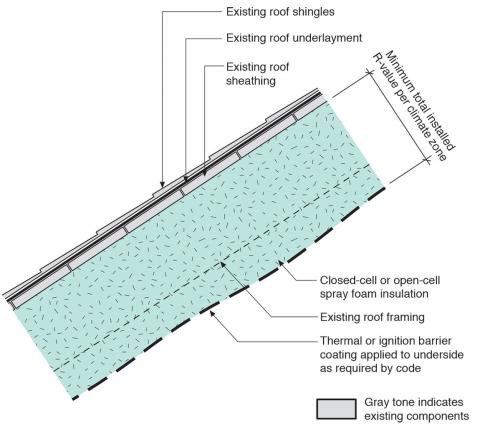

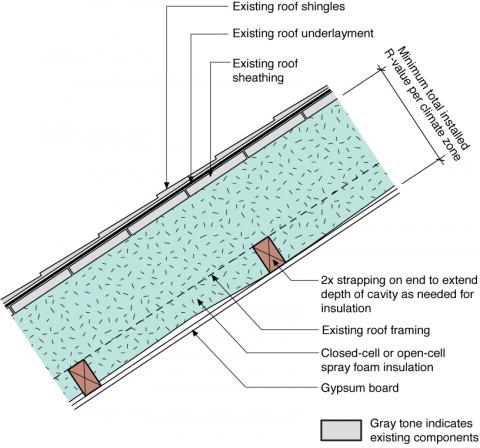

- Install a thermal barrier or ignition barrier (coating, gypsum board, or other material) over the spray polyurethane foam insulation if necessary based on the material properties of the spray polyurethane foam or as required by code. Note that not all spray polyurethane foams require thermal or ignition barriers.

- Seal any penetrations from the home into the attic through the attic floor.

- Provide conditioning, dehumidification, or controlled ventilation to the attic.

- Ensure the home has good ventilation.

- If seeking to qualify an existing home to the criteria of the IBHS Fortified Home Hurricane and High Wind standards, the criteria to seal the roof deck can be met by applying closed-cell spray urethane-based foam adhesives along the joints between the roof sheathing and roof framing members as well as along all seams between the roof sheathing panels.

See the following Building America Solution Center guides for more information:

- Pre-Retrofit Assessment of Attics, Ceilings, and Roofs

- Pre-Retrofit Assessment of Hazardous Materials

See the U.S. Department of Energy’s Standard Work Specifications (SWS) for more on installing spray polyurethane foam in unvented attics.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

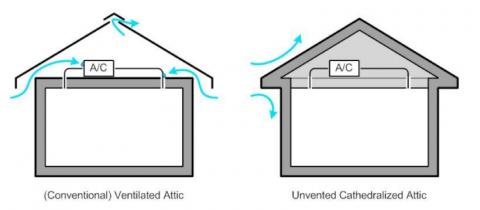

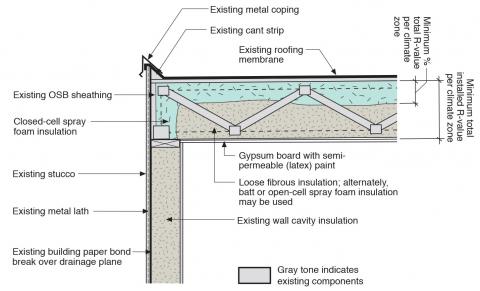

This guide describes the conversion of a vented attic to an unvented insulated attic by installing spray polyurethane foam (SPF) insulation - either open cell (ocSPF) or closed cell (ccSPF) - on the underside of the roof deck (Figure 1). Note that all spray foams contain polyurethane – ocSPF, ccSPF bio-based spray foams, sugar-based spray foams, and water-blown spray foams.

Many older homes have little or no attic insulation. Attic insulation can be installed on the attic floor if the attic will be a vented attic. Or insulation can be installed along the underside of the roof deck, which converts the attic to an unvented conditioned attic that can provide a protected environment for HVAC equipment, conditioned storage space, and living area (habitable space) that can be resilient, durable, and efficient in all climate zones.

Unvented conditioned attics and roofs are significantly more “fire safe” in wildfire areas and where neighboring buildings are close. Ash and embers enter vented attics through attic vents. No vents means no ash or embers entering attics and much less risk of fire.

In high wind regions – particularly in coastal areas – wind-driven rain is a problem with vented attic and vented roof assemblies. Additionally, during high wind events, vented soffits have been known to collapse leading to building pressurization and window blowout and roof loss due to increased uplift. Unvented conditioned attics and roofs are safer during hurricanes; they outperform vented attics and roofs principally due to the robustness of their soffit construction.

If seeking to qualify an existing home to the criteria of the Insurance Institute for Building and Home Safety (IBHS) Fortified Home Hurricane and High Wind standards, the criteria to seal the roof deck can be met by applying closed-cell spray urethane-based foam adhesives along the joints between the roof sheathing and roof framing members as well as along all seams between the roof sheathing panels.

In coastal areas, salt spray and corrosion are a major concern with steel frames, metal roof trusses, and truss plate connectors in vented attics and vented roofs. This is not an issue with unvented conditioned attics that have no vents where salt spray can enter.

In flood areas, provision should be provided to allow access to roof tops if refuge, rescue, and evacuation becomes necessary. This can be provided by installing operable skylights or dormers or other alternatives that allow egress.

An unvented conditioned attic assembly should be considered if the attic will be used for habitable space, if the attic contains mechanical equipment or ductwork, if the roof structure is complex (i.e., difficult to vent due to obstructions), or if the ceiling plane is difficult to air seal (complex geometry or difficult access). It is possible to create a vented assembly with insulation at the roof deck and spray polyurethane foam where the primary benefit of the spray polyurethane foam is its air sealing properties.

If the roof has a low slope, there may not be sufficient space for the required insulation and ventilation space needed for a vented attic assembly, especially at the eaves, where insufficient insulation can contribute to ice damming. Therefore, low roofs are good candidates for conversion to an unvented conditioned attic with insulation along the underside of the roof deck.

This unvented conditioned attic or roof retrofit assembly approach applies all of the insulation to the interior side of the roof deck. Most roof cladding and water control materials (asphalt shingles, asphalt papers, self-adhered roof membranes, etc.) are vapor impermeable. In cold and mixed climates, this is effectively a vapor barrier on the “wrong side” of the assembly. Therefore, to address interstitial (within-the-cavity) condensation risks, special attention should be paid to the type and the levels of insulation in the roof assembly.

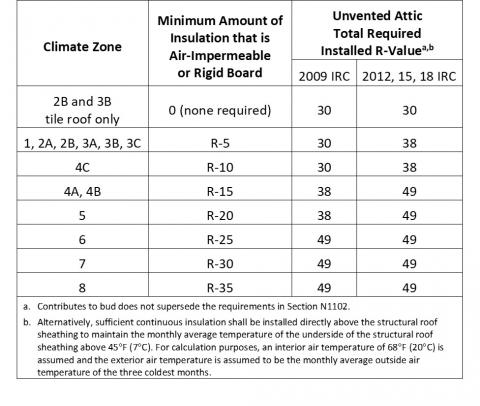

The building codes (e.g., §R806.5 in 2018 IRC) specify a minimum R-value requirement for “air impermeable” insulation in a roof assembly, such as rigid insulation or spray foam, to control wintertime condensation. In colder climate zones, the amount of air- and vapor-impermeable insulation required to control condensation increases. If using a hybrid approach, it is important to meet or exceed the required ratio of air- and vapor- impermeable insulation to air- and vapor-permeable insulation within the roof assembly.

For this assembly, replacement of the roofing is not required (unless it is at the end of its service life), but it is vital that the existing roof system provides robust protection from rainwater (“precipitation”), and that effective flashing and water control is in place. The low permeance of the roof exterior (cladding and water control layer) combined with the reduced drying due to the application of spray polyurethane foam means that the sheathing is more vulnerable to damage from rainwater penetration.

Figure 2 shows how converting a conventional ventilated attic to an unvented cathedralized attic brings the HVAC equipment into “conditioned” space.

Wherever vented unconditioned attics are converted to unvented conditioned attics, a means of moisture removal from the attic is necessary. The “conditioned” part of unvented conditioned attics or roofs is important.

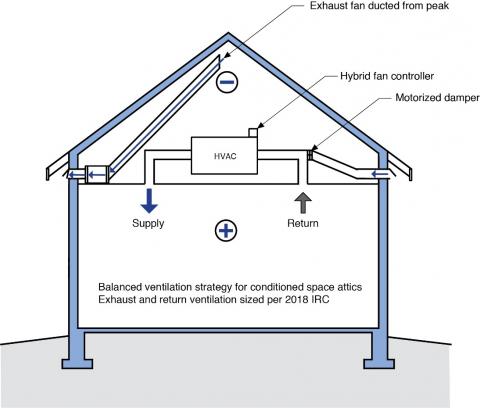

One of the best ways to remove moisture from the attic space is to provide air change. With the air change approach, air is exhausted from the peak of the attic using an exhaust fan ducted to the exterior. This creates a slight negative pressure in the attic and air is drawn from the house below. To create “balanced” ventilation in the house, supply air is provided from the outside to the return side of the air handler (Figure 3). The quantity of this air flow should be based on the International Residential Code – 2018. To prevent over-ventilation or under-ventilation, a motorized damper is installed at the outdoor air supply of the system. The operation of the motorized damper is coupled or linked to the operation of the attic exhaust fan – the attic exhaust fan operates only when the motorized damper is open and the HVAC system blower is operating.

Another approach is to provide balanced ventilation with heat recover or energy recovery. When heat recovery or energy recovery is used, exhaust air is pulled from the peak of the attic (as in Figure 2) and supply air is provided from the occupied portion of the house.

A third approach is to provide dehumidification (a “dehumidifier”) to the attic space.

A fourth approach is to provide ducted supply and ducted return air to the attic space using the HVAC system in the house. With this approach, the attic or roof space is directly coupled to the occupied portion of the house and the moisture control strategy for the house is used to provide moisture control for the attic space. Note that this fourth approach can only be used with spray foams that are not combustible or are covered or protected from fire.

Because this retrofit will seal the attic, any combustion appliances installed in the attic should be direct-vent sealed-combustion appliances that vent outdoors.

See the Climate tab for additional important information about vapor retarders in cold climates.

In Figures 4 through 6, the roof cladding is represented as shingles, but other roof claddings would be acceptable provided that the attachment of the roof cladding does not result in horizontal obstructions on the water control layer beneath the cladding.

How to Insulate a Roof from the Interior

- Inspect the integrity of the roof system (roofing membrane or shingles). Check for any deficiencies, water damage, active leaks, etc. Proceed only if needed repairs are performed.

- If there is an interior finish at the roofline (cathedral ceiling), remove the interior finish (plaster or gypsum board). Check the roof framing for any deficiencies, rot, water damage, active leaks, insect damage, etc. Proceed only if needed repairs are performed. Based on the findings, revise the roof assembly and review specific detailing as needed. Follow the minimum requirements of the current adopted building code regarding the wood roof framing construction.

- Block the soffit vents; a typical detail is to provide 2x blocking or extended wall sheathing at the exterior wall line, to provide a substrate for the spray foam.

- Apply spray foam at the underside of the roof sheathing and at the wall perimeter to create an air barrier connecting the wall to the roof, and to provide adequate thermal resistance to prevent condensation. All attic gable end walls now separate interior from exterior conditions and must be insulated and air sealed. A typical approach is to insulate the gable end walls with the same spray foam used at the roofline. Prior to installing spray foam, ensure the decking is dry and free of debris and dust to ensure adequate adhesion. Install additional non-spray-polyurethane foam insulation over the layer of spray polyurethane foam in wall and roof cavities if desired.

- Install a sprayed-on thermal or ignition barrier coating over the spray polyurethane foam insulation if necessary based on the material properties of the spray polyurethane foam or as required by code. Note that not all spray polyurethane foams require thermal or ignition barriers. (See AY-126 Thermal and Ignition Barriers For The SPF Industry).

- Inspect and air seal all penetrations through the attic floor.

- Provide controlled ventilation, balanced ventilation with heat recovery, install a dehumidifier, or supply conditioned house air to the attic as described above.

- Ensure the home has good ventilation and that any combustion appliances installed in the attic are direct-vent sealed combustion appliances that vent outside.

Success

Inspect the existing roof system, including the roofing membrane or shingles and framing, for any deficiencies and make any corrections if necessary. Consider roof replacement if roof is near end of service life.

Monitor the moisture content of the roof sheathing, when possible, during the construction process. Take measurements before the installation of the air-impermeable insulation to help ensure that the roof deck is dry enough to be covered with spray-foam insulation.

Spray polyurethane foam is a material that is essentially “manufactured” when applied at the building site. Given the importance of this material’s performance, quality control measures should be set in place. Some key issues include moisture content and temperature of the substrate, applied spray foam layer or “lift” thickness, ratios of the two spray foam components during application, and storage/handling of spray foam components. Further information is available at the Spray Polyurethane Foam Alliance.

Apply insulation to a debris- and dust-free surface to provide adequate thermal resistance to prevent condensation.

Apply insulation to the levels specified in the current adopted building and energy codes.

Given the increased airtightness associated with this retrofit, combustion safety and controlled mechanical ventilation upgrades are required to maintain acceptable indoor air quality.

Climate

In high wind regions – particularly in coastal areas – wind-driven rain is a problem with vented attic and vented roof assemblies. Additionally, during high wind events, vented soffits have been known to collapse leading to building pressurization and window blowout and roof loss due to increased uplift. Unvented conditioned attics and roofs are safer during hurricanes; they outperform vented attics and roofs principally due to the robustness of their soffit construction.

In coastal areas, salt spray and corrosion are a major concern with steel frames, metal roof trusses, and truss plate connectors in vented attics and vented roofs. This is not an issue with unvented, conditioned attics and roofs.

If seeking to qualify an existing home to the criteria of the IBHS Fortified Home Hurricane and High Wind standards, the criteria to seal the roof deck can be met by applying closed-cell spray urethane-based foam adhesives along the joints between the roof sheathing and roof framing members as well as along all seams between the roof sheathing panels.

In flood areas, provision should be provided to allow access to roof tops if refuge, rescue, and evacuation becomes necessary. This can be provided by installing operable skylights or dormers or other alternatives that allow egress.

The roof assembly should be designed for a specific hygrothermal region, rain exposure zone, and climate.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

In cold climates, interior relative humidity can directly affect the sheathing moisture content with open-cell or closed-cell spray-foamed roofs. Building Science Corporation recommends that winter-time relative humidity in homes located in Climate Zones 6, 7, or 8 should be maintained below 35% (Grin, Smegal, and Lstiburek 2013).

Open-cell spray foam should be a Class II vapor retarder or be coated with a Class II vapor retarder in cold climates 5, 6, 7, and 8 (2018 IRC R806.5). Class I vapor retarders should not be installed on the ceiling side of any spray foam installed on the underside of the roof decking in any climate zone as the vapor retarder will prevent drying to the inside in case of a roof leak.

The design should be based on the minimum requirements for the currently adopted building code and energy code. Additionally, it is important to maintain a sufficient ratio of air- and vapor-impermeable insulation to air- and vapor-permeable insulation within the roof assembly. In colder climate zones, the amount of air- and vapor-impermeable insulation needed to control condensation increases.

Table 1 below provides information on the code-recommended minimum levels of thermal resistance and the minimum levels of air-impermeable insulation for condensation control specified in Table R806.5 Insulation for Condensation Control of the 2018 IRC. For further explanation, see IRC FAQ: Conditioned Attics.

Table 1 shows an insulation ratio – the R-value on the top of the roof sheathing compared to the total R-value of the insulation. The ratio changes based on climate severity. The 2018 IRC specifies the ratios based on climate zone. Note how the ratio changes from approximately 10% to 70% as the assembly moves from hot climates to cold climates. Also note that in Climate Zones 5, 6, 7, and 8, the air-impermeable insulation (“SPF”) must either be a Class II vapor retarder or shall have a Class II vapor retarder coating or covering in direct contact with the underside of the air-impermeable insulation.

2018 International Residential Code (IRC)

The IRC Section R202 defines vapor retarder classes. A vapor retarder is defined as “a measure of the ability of a material or assembly to limit the amount of moisture that passes through that material or assembly.” Vapor retarder classes are defined by the IRC using the desiccant method with Procedure A of ASTM E96. These classes are:

- Class I: 0.1 perm or less

- Class II: 0.1 perm to 1.0 perm

- Class III: 1 perm to 10 perms.

The 2018 IRC Section R806.5 requires the following: In Climate Zones 5, 6, 7, and 8, any air-impermeable insulation shall be a Class II vapor retarder or shall have a Class II vapor retarder coating or covering in direct contact with the underside of the insulation.

The IRC for Climate Zones 1, 2, 3, or 4 requires that a Class I vapor control layer not be installed on the interior side of the assembly. This is to prevent inward-driven moisture from being trapped in the wall assembly. Installing a low-permeance vapor control layer on the interior in a cooling-dominated climate can quickly deteriorate the assembly.

Training

CAD

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

Application of Spray Foam Insulation Under Plywood and Oriented Strand Board Roof Sheathing, BA-1312

The following authors and organizations contributed to the content in this Guide.

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

High-R Attic Insulation = High-Efficiency or Ultra-Efficient Attic Insulation

There are two levels of attic insulation: high-efficiency insulation, which meets the 2015 International Energy Conservation Code, and ultra-efficient insulation, which is 25% more efficient than this national code. Using high-efficiency and ultra-efficient insulation along with professional installation (e.g., no gaps, voids, compression, or misalignment with air barriers; complete air barriers; and minimal thermal bridging) creates conditioned spaces that require very little heating and cooling, along with even comfort and quiet throughout the house.