Scope

Install an exhaust fan in the kitchen to exhaust steam and cooking odors to the outdoors.

- Install the fan to vent outdoors, not into an attic, crawlspace, or space between floors.

- Choose a smooth metal duct with the diameter specified by the fan manufacturer.

- Install the duct with the most direct route to the outside with as few bends as possible.

- Seal all seams and around ceiling and wall or roof penetrations with mastic or spray foam. Flash exterior surfaces as needed.

- Install a fan that meets Rater-measured airflow codes and standards for local exhaust; meet whole-house ventilation requirements if the kitchen fan is used for whole-house mechanical ventilation.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Regardless of what kind of ventilation system you have for the rest of the house, an exhaust fan should be installed in the kitchen to provide point or local exhaust to remove moisture and odors associated with cooking. The exhaust fan is typically located directly over the kitchen stove and is installed in a range hood or cabinet, integrated with a microwave oven, or mounted on the wall. The fan should be ducted to exhaust outside of the home, not into the attic, crawlspace, or another area inside the building. The duct serving the range hood should be made of rigid metal such as galvanized steel, stainless steel, or copper and have a smooth interior surface. It should meet the maximum length guidelines specified in the IRC (2015 IRC Table M1506.2) and the minimum diameter guidelines specified in the fan’s installation instructions; small-diameter ducts could trap grease, creating a fire hazard. It should be airtight, equipped with a back-draft damper, and independent of all other exhaust systems.

Recirculating fans that draw air through a filter and discharge it back into the room are not acceptable. Operable windows are a nice feature but they should not be relied on for consistent ventilation.

Kitchen fans can be run intermittently (occupant controlled) or continuously; some fan models have multiple speed settings and can be used for either.To fulfill the local exhaust airflow requirements of the International Residential Code (IRC 2015), kitchen fans operated intermittently should have a flow rate of 100 cfm or more and fans operated continuously should have a flow rate of 25 cfm or more. Select fans that are ENERGY STAR rated, and have low sound ratings and low power draw. ENERGY STAR recommends that local kitchen exhaust fans provide ≥ 5 air changes per hour of ventilation, depending on the kitchen volume. ENERGY STAR also recommends that exhaust fans have sound ratings of ≤ 1 sone if set to run continuously or ≤ 3 sones if operating intermittently.

Some home owners are installing commercial-scale cooking ranges with very powerful exhaust hood fans rated as high as 1200 cfm. Exhaust fan rates this high can easily backdraft a non-sealed-combustion furnace, water heater, or fireplace (Holladay 2010). Any installed exhaust fan operating in excess of 400 cfm must be provided with a makeup air system that will automatically start and operate simultaneously with the exhaust fan and will provide makeup air at a rate equivalent to the exhaust fan rate.

Although a single-point exhaust fan such as a kitchen fan could be used to provide code-required whole-house ventilation, this strategy is not recommended. For more on whole house ventilation strategies and requirements, see the Building America Solution Center Guide Whole-House Ventilation Strategies for New Homes and Whole-House Ventilation Strategies for Existing Homes.

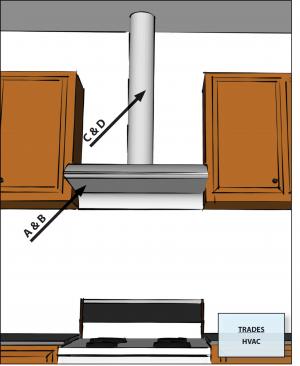

Kitchen exhaust fans may be installed by the HVAC vendor or installer or by the kitchen range vendor if it is part of that system. This task should be included in the contract for the appropriate trade depending on the workflow at specific job sites.

How to Install Exhaust Fans

Determine the appropriate fan size for your application. For a continuous rate of ≥ 5 ACH, ENERGY STAR recommends selecting a fan that provides more than 5 ACH in order to pull the required amount of air. For an intermittent rate of ≥ 100 cfm, ENERGY STAR recommends selecting a fan with a rating of 150 to 200 cfm. Choose ENERGY STAR-rated fans for energy efficiency and low noise level.

Proper sizing of kitchen exhaust fan. (Source: PNNL.) - Install the fan either in the range hood, the cabinet above the stove, or on the wall above the stove. Follow the manufacturer’s instructions. The fan may also be purchased as an integrated unit that comes with a microwave oven mounted into a cabinet above the stove. Cut openings in the ceiling for the fan or exhaust duct no wider than needed to fit the fan or duct and air seal the opening with caulk or spray foam. Connect the exhaust duct to the fan box with mechanical fasteners and seal with metal tape and/or mastic. Do not use cloth-backed duct tape.

- Vent the kitchen fan exhaust directly to the outside, not into an attic, crawlspace, or space between floors. Use correctly sized, smooth metal duct. Seal seams and joints with mastic and/or metal tape. Install a back-draft damper that closes when the fan is not in operation. Install the duct with as few bends as possible and out of the way of other ducts or equipment in the attic. Take care not to dent or crush the duct during or after installation. The duct should be independent of other exhaust systems.

- Locate the exhaust duct outlet vent on the exterior of the home at least 10 feet from any air inlet. The outside termination should be covered with louvers, a screen, or a grille. The exhaust air should not be directed onto a walkway.

- If the fan is integrated with a microwave oven installed over the stove, install it according to the manufacturers’ instructions and 2015 IRC Section M1504.

- Exhaust hoods installed over domestic open-top broiler units should be made of metal and have a 1/4-inch clearance between the hood and the underside of combustible material or cabinets. The hood should extend the full width and depth of the cooktop, discharge to the outside, and have a backdraft damper, as specified in 2015 IRC Section M1505.

- The exhaust fan flow rate should be tested by a certified energy rater using test procedures listed in ANSI/RESNET/ICC 380-2016.

Success

Visually inspect and test the kitchen exhaust fan for proper installation as follows:

- Ensure that the fan exhausts outside, not into the attic; that it is set to exhaust, not recirculate; that any dampers on the outside termination are able to open freely; and that packing tape is removed.

- Confirm that any openings cut in the ceiling for the fan or exhaust duct are properly air sealed and that the exhaust duct is sealed to the fan box with both mechanical fasteners and mastic and/or metal tape and caulk or spray foam.

- Check the sone rating; ASHRAE 62.2-2007 requires 3 sones or less for intermittent (occupant-controlled) kitchen or bath exhaust fans or 1.0 sone or less for continuous fans.

- See the Compliance tab for code and ENERGY STAR guidelines regarding flow rates and efficacy for fans used for local exhaust. See the guide Whole Building Ventilation for codes and standards related to exhaust fans used for whole-house ventilation.

- A certified energy rater will test the fan’s operation to determine the flow rate using a flow hood, flow grid, anemometer, in accordance with test procedures listed in ANSI/RESNET/ICC 380-2016, or established by the Associated Air Barrier Council, National Environmental Balancing Bureau, or ASHRAE), or other equivalent method. Kitchen fans are typically rated by how many cubic feet per minute the fan will exhaust in a factory setting. Duct work, termination choices, and installation may decrease the measured cubic feet per minute below the factory-rated value.

Climate

No climate-specific information applies.

Training

Compliance

Retrofit

SCOPE

Install or replace the kitchen exhaust fan, if the kitchen currently lacks an exhaust fan or the existing fan is a recirculating model or has insufficient draw, as determined by occupant experience or through fan testing by a home energy rater.

If the current kitchen fan exhausts into the attic, crawlspace, or between floors, replace the duct with one that exhausts to the outside.

See the assessment guide, Pre-Retrofit Assessment of Attics, Ceilings, and Roofs.

For more on exhaust fan ventilation, see the U.S. Department of Energy’s Standard Work Specifications.

See the Scope tab for additional job specifications.

DESCRIPTION

Installation of a new kitchen exhaust fan is warranted if the kitchen currently has no exhaust fan or if the existing fan is a recirculating model that does not vent to the outside. Other reasons to replace the fan include noise or moisture complaints by the homeowner or fan testing as part of a home energy audit that reveals that the fan has insufficient draw. A less common reason to replace the fan is if it has too much draw. Commercial-grade cook tops that are installed in some home kitchen remodels often come with overly powerful exhaust hood fans that have exhaust flow rates far above what is required by code. If testing by a home energy rater reveals that the exhaust fan is, or could potentially, backdraft the fireplace or other combustion appliances in the home, and it is difficult to find wall space to install a vent large enough to supply a sufficient amount of makeup air to the kitchen, a less expensive option may be to replace the exhaust fan within the range hood with a fan that exhausts at a rate closer to what is required by code. Follow the installation instructions provided in the Description tab.

COMPLIANCE

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Kitchen Exhaust Fan = Kitchen Odor and Moisture Control Fan

Kitchen odor and moisture control fans use high-efficiency range hoods ducted to vent outdoors to remove odors and moisture from cooking. Recirculating type exhaust fans only filter the air and return it to the kitchen with much less effective and persistent health benefits. ENERGY STAR-rated exhaust fans meet performance criteria for energy efficiency and sound levels.