Scope

When HVAC ducts are installed in a vented attic in any climate, encapsulate the ducts in closed-cell spray polyurethane foam (ccSPF) to protect them from temperature extremes in the unconditioned attic space.

- Where possible, install ductwork so that it is in direct contact with (i.e., laying on) the ceiling and/or truss lower cords. Where all or some portion of the ducts cannot be laid on the attic floor (due to truss design or some other obstacle), then hang the ducts using straps or saddles to properly support the ducts.

- Use metal, flex, or fiber board ducts that are insulated to code. The duct insulation should include a vapor barrier cover.

- See the guide Support at Intervals for Flex Ducts for more on properly supporting ducts.

- Mechanically fasten and mastic-seal all duct connections.

- Test total duct leakage. Add additional sealant if necessary.

- Completely encase the ducts in closed-cell spray polyurethane foam (ccSPF) to the desired foam depth.

- This technique is appropriate for all climates including the humid or marine climates.

- This technique fulfills the DOE Zero Energy Ready Home program requirement that ducts be installed in conditioned space.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

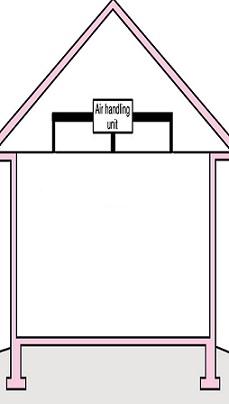

For homes with ducted heating and cooling systems, the best place to locate the duct system from an HVAC performance standpoint is within the conditioned space of the home, either in dropped ceilings, or between floors, or in a sealed and insulated basement, crawlspace, or attic. If the ducts must be located within a vented attic, one option for protecting the ducts and helping to minimize heat transfer between ducts and the unconditioned attic is to bury the ducts in the attic floor insulation. Where all or some portion of the ducts cannot be laid on the attic floor (due to truss design or some other obstacle), then the ducts can be hung or supported above the attic floor and encapsulated in closed-cell spray polyurethane foam insulation.

Metal, flex, or fiber board ducts can be used. The ducts should be covered with R-8 or higher duct insulation and the duct insulation should include a vapor barrier cover. All duct connections should be mechanically fastened and mastic-sealed. The ducts should be tested for total duct leakage and any leaks should be sealed. The ducts should be hung using straps or saddles to properly support the ducts. See the guide Support at Intervals for Flex Ducts for more on properly supporting ducts. Once these preparations are made, the ducts can be encapsulated in at least 1.5 inches of closed-cell polyurethane spray foam. Encapsulating the ducts in spray foam increases the R-value of the ductwork and reduces air leakage. The effective R-value of an encapsulated duct installation depends on the size of the ducts, the level of the duct insulation, and the thickness of the ccSPF insulation. For example, the effective R-value of an 8-inch round duct encapsulated with 1.5 inches of ccSPF is R-12.7.

How to Install Encapsulated Ducts

- Install ductwork with a minimum of R-8 duct insulation in accordance with low-profile duct design (Figure 1).

- Properly fasten and seal ducts at all connections. To attach flex duct, pull back outer liner, fasten inner liner over collar with tool-tightened tension tie, mastic seal the connection. Pull insulation and outer liner over the joint and seal to attached duct or boot with mastic or foil tape (Figure 2). The outer liner should not be attached with a tie as shown here but should be connected with mastic or foil tape to avoid compressing the insulation.

Test total duct leakage to ensure that the ducts have been adequately sealed (total duct leakage < 3 cfm25 per 100 ft2 of conditioned space, Figure 3). Testing should be performed before encapsulation because it may be difficult to correct sealing issues after the application of spray foam.

Figure 3. A duct blaster is used to test total duct leakage. (Source: Steven Winter Associates 2013.) - Apply at least 1.5 inches of ccSPF to all duct surfaces, including trunks, branches, and register boots. Ducts should be entirely encapsulated (see the Scope image).

Success

To minimize air leaks and maximize effective R-values, ccSPF must be applied to all surfaces to the ductwork. All duct connections should be mastic sealed and ducts should be tested for leakage with a duct blaster before the ccSPF is applied.

The 2009 IRC allows exposed installations of ccSPF in attics, but the spray foam must be specifically approved for installation without an ignition barrier.

Climate

Encapsulated ducts may be installed in all climate zones, including moist (A) and marine (C) climate zones.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

Compliance

Retrofit

SCOPE

In existing homes with vented attics and HVAC ducts that are hung in the attic, encase ducts in closed-cell spray polyurethane foam.

Before installing spray foam, inspect the ducts for missing or torn duct insulation; disconnected or leaking ducts; sagging or crushed ducts; or excess flex duct. Flex duct runs should be pulled taut to reduce internal airflow friction. See the following guides to remedy installation problems prior to sealing or adding insulation to an existing flex duct system:

Test ducts for air tightness using a duct blaster test.

Repair and air seal ducts as needed before installing spray foam insulation.

For more information, view the U.S. Department of Energy’s Standard Work Specifications regarding ducts.

Also see the Solution Center guide Pre-Retrofit Site Assessment of Attics, Ceilings and Roofs.

DESCRIPTION

Make any needed repairs as described above then follow installation guidance for new homes in the Description tab.

COMPLIANCE

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

Sales

HVAC Ducts in Unvented Attics =

Traditional vented attics can reach extreme temperatures compared to living spaces and are inhospitable to heating and cooling equipment and ducts. Comfort systems work much better when they are inside conditioned space. That’s why unvented attics that are fully insulated provide a more efficient location for comfort systems.