Scope

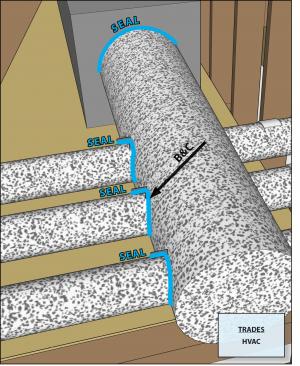

Air-seal and insulate fiber board ducts.

- Design a compact duct layout with short straight runs and minimal bends. Design the home to include ducts within conditioned space if possible. (The DOE Zero Energy Ready Home program requires that heating/cooling system supply ducts be installed within the conditioned space of the home.)

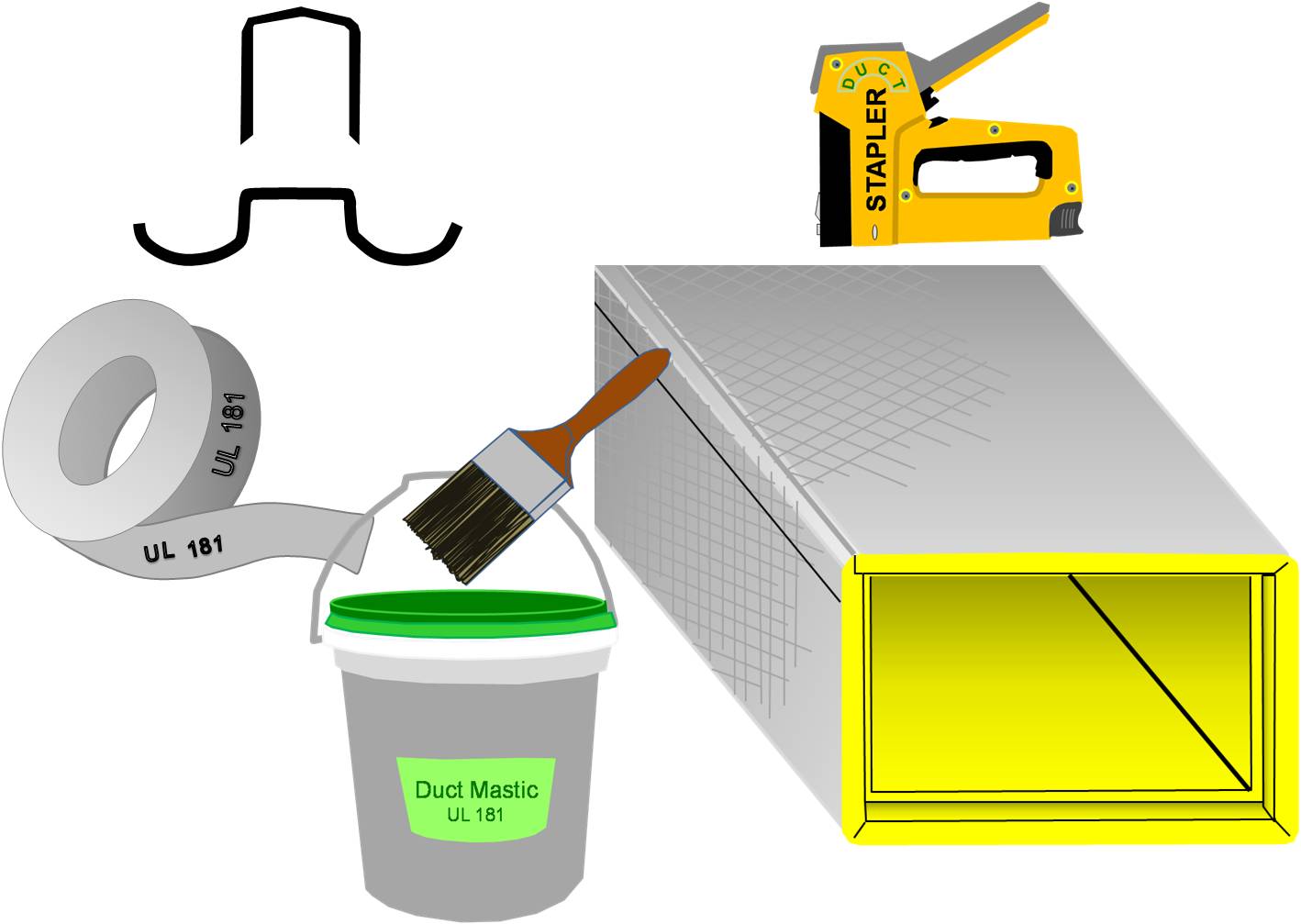

- Fabricate and install the fiber board ducts. To seal seams, use outward-clinched staples and UL-181A-approved metal tape that is heat activated or pressure sensitive or use mastic and fiber mesh tape. Use screws to secure connections to sheet metal collars, duct boots, or trunk lines. Wipe ducts to ensure they are clean and dry, then seal seams and joints with mastic or UL-181-approved metal tape.

- Ensure that all duct connections and seams are air sealed, regardless of whether components are located in conditioned or unconditioned space.

- Insulate all supply and return ducts located in unconditioned space. Meet code or program minimum R-value requirements. See the Compliance tab for R-value minimum requirements specified in the IRC, IECC, DOE Zero Energy Ready Home program, and ENERGY STAR criteria.

- Consider insulating all metal ductwork located in conditioned space, including supply and return ducts, duct boots, and exhaust ducts, to minimize condensation.

See the Compliance tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

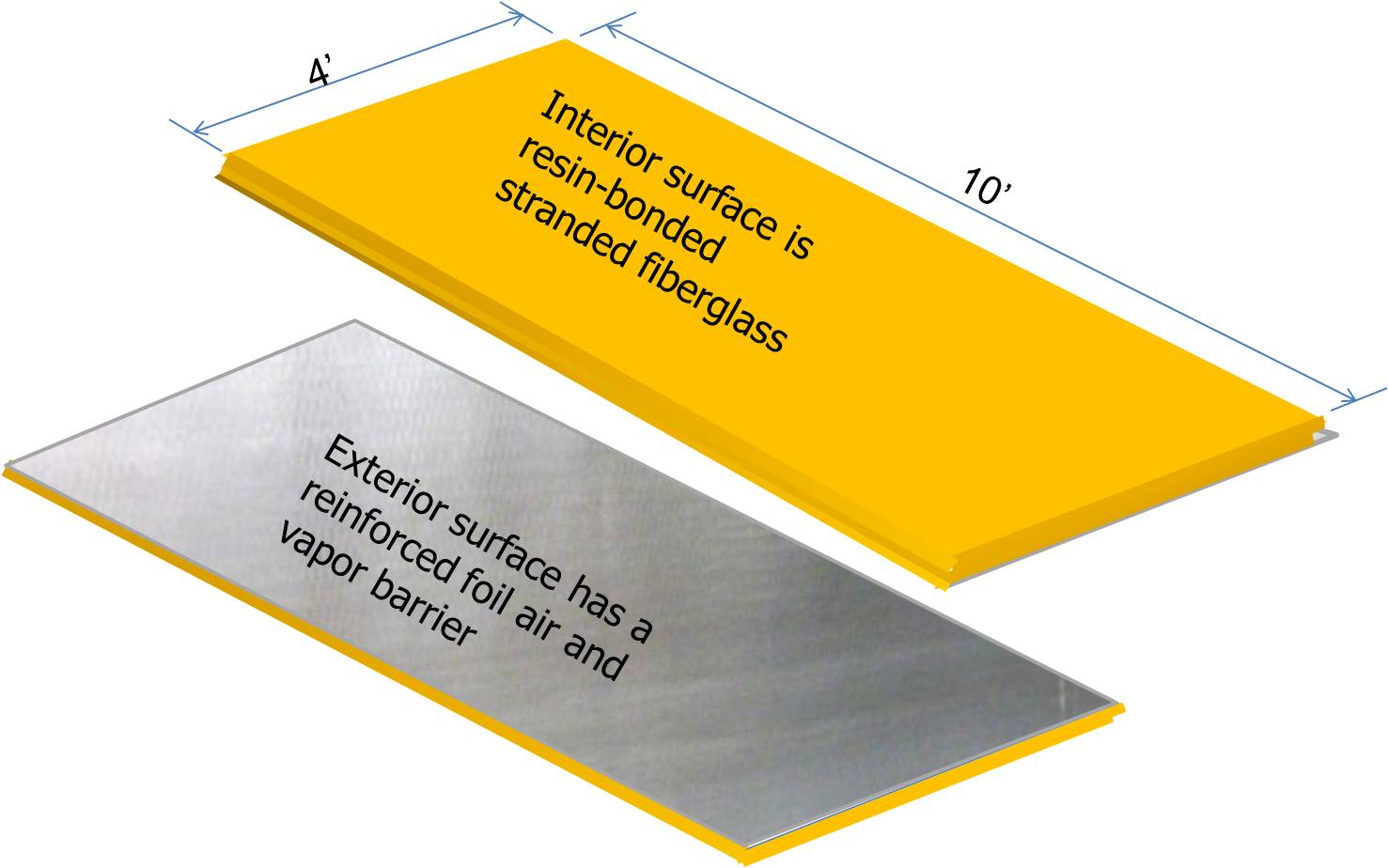

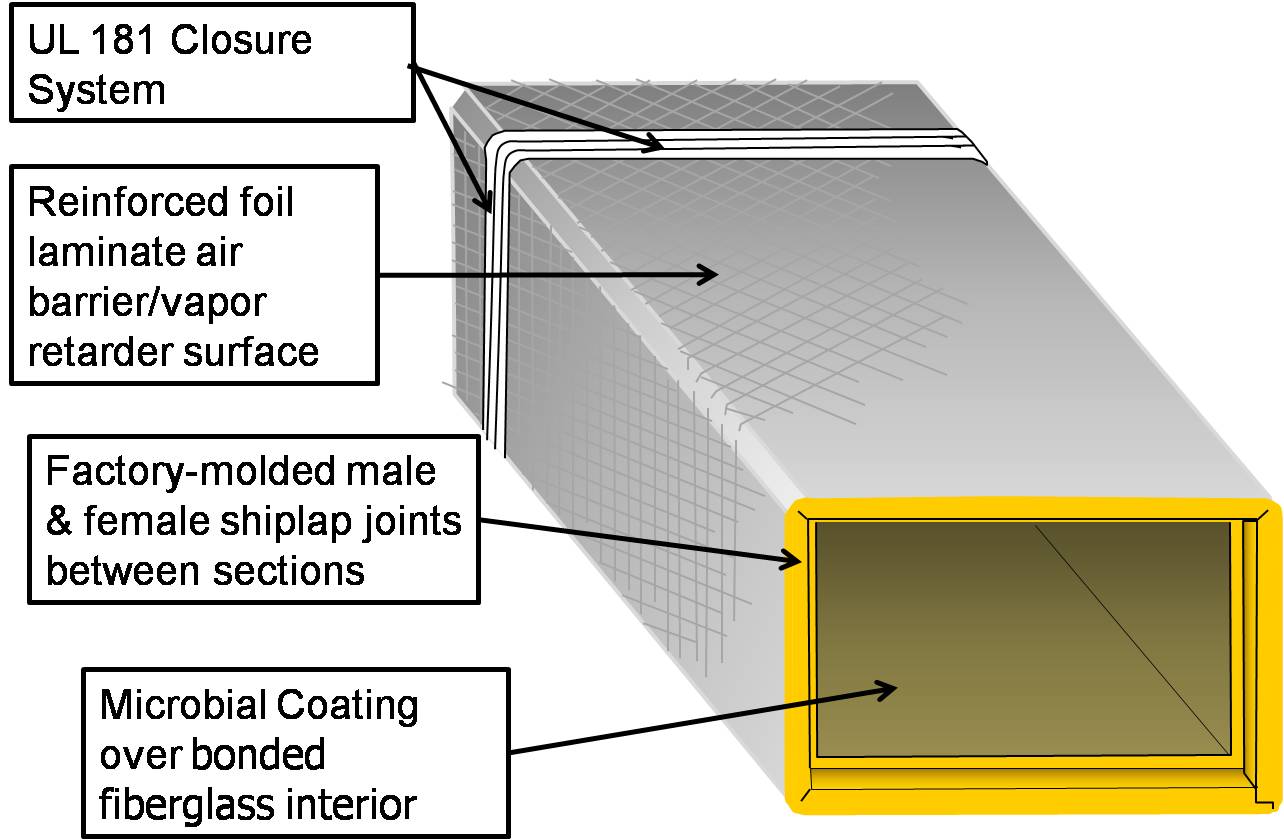

Fiber board used for the fabrication of supply and return air duct work for HVAC systems is constructed of resin-bonded strands of glass fibers (e.g., fiberglass) that are formed into flat sheets, typically 4 foot wide by 10 foot long or 4 foot wide by 8 foot long; it typically comes in thicknesses of 1, 1.5, and 2 inches. The exterior surface of the sheet is covered with a reinforced foil laminate air/vapor barrier. The interior surface that is in contact with air flow is not as smooth as metal because it consists of bare bonded fiberglass (Figure 1). Fibrous glass duct boards are available with a durable, hard interior surface treatment to prevent eroding of the bonded fiberglass; however, this type of fiber board is very expensive. Many brands of fiber board are also available with an antimicrobial coating on the interior surface. Fiber board ducting can be used for heating and cooling ducts; it is not recommended for ventilation ducts, especially in humid climates.

One advantage of fiber board is the fact that it is inherently insulating; the fibrous glass board carries an R-value of 4.3 per inch, so thicknesses of 1, 1.5, and 2 inches yield R-values of 4.3, 6.5, and 8.7. The product itself is air tight so the air tightness of the overall fiber board duct system is dependent on the care with which the sections are fabricated and the joints and seams are cut and sealed. The durability of the fiber board is also contingent on the care taken in constructing the ducts. The fabricator must be careful to not fracture the bonded fibers. A crack in the bonded fiberglass may not be noticed if it is concealed by the reinforced foil laminate but, over time, it can lead to the erosion of the glass fibers, creating a durability issue and compromising the insulation value of the duct.

Fiber board ducts have been tested for safe use at velocities up to 5,000 feet per minute and temperatures up to 250°F (121°C) (NAIMA 2010).

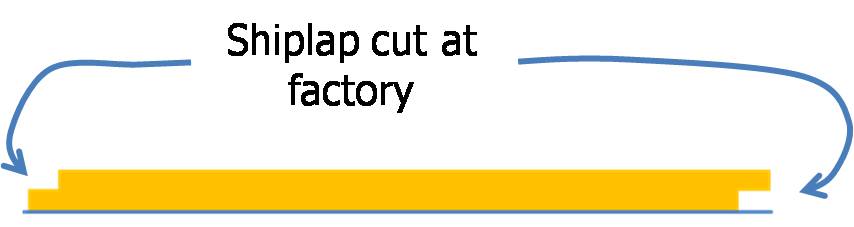

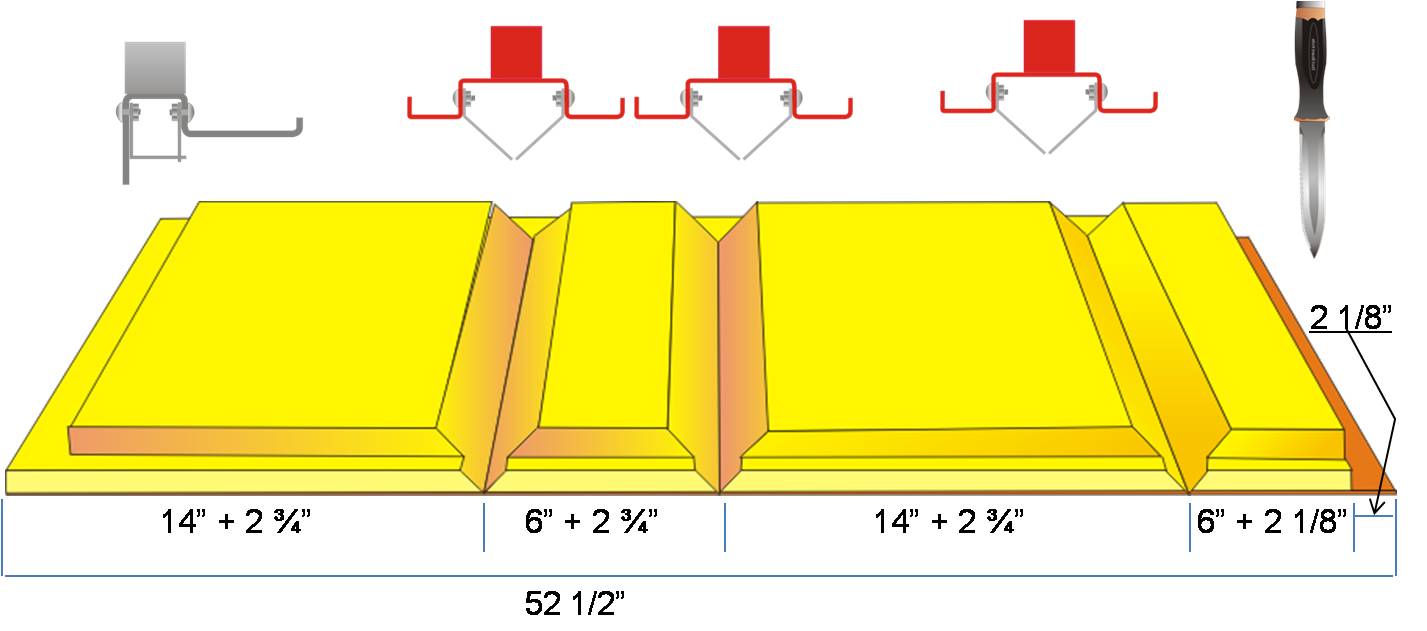

HVAC contractors who use fiber board ducts typically purchase duct board sheets by the carton (each carton contains 5 or 6 sheets) and fabricate the ducts themselves in the shop or on site. The sheets are available with straight edges or with factory-cut male-female shiplapped edges along each of the long sides (Figure 2). The sheets are cut and folded to the designed duct dimensions by the fabricator. Each 4-foot section is fitted together using the shiplapped ends (Figure 3).

Fiber board ducts are fabricated using either specially designed hand tools or grooving and closure machines. The duct sections are assembled by matching factory or field-cut shiplapped male and female ends. The shiplapping ensures close-fitting, smooth joints when duct sections are joined together. Duct fittings such as tees, offsets, elbows, and transitions are also fabricated from these sections or from flat duct board.

Typical tools used to fabricate fiber board duct systems in the field include a yardstick or tape measure, straight edge, duct board knife, marking pen, and edge-cutting tools. If hand cutting, the tools used should be fiber board cutting tools specifically designed for the intended cuts, to ensure a consistent connection. The cutting tools come in different sizes depending on the thickness of the fiber board being used: 1 inch, 1.5 inch, or 2 inch. The tool manufacturers color-code the tools red, orange, or grey to identify which type of edge or end cut the tool will make: the red tool cuts a V-shaped groove, the orange tool cuts a shiplap, and the grey tool makes a final or female shiplap (see Figure 4). When forming the inside corners of the duct, the fabricator can use either the V-groove or modified shiplap method. Some manufacturers recommend the modified shiplap method as providing a more stable corner (Knauf 2006). Many installers prefer the V-groove method for straight duct sections because it is much faster to assemble. They use the shiplap method for assembling and connecting fittings, branches, and other modifications.

Fiber board duct can also be machine fabricated in the shop using a grooving machine. A grooving machine can be set up to provide the same kinds of cuts as the hand tools, with the advantage that it can make multiple cuts at one time with consistency and precision.

In addition to the seam and edge cuts, the fiberglass is cut away 1.5 inches from the edge on one side leaving a foil flap that will serve to cover the finished seam. After the cuts are made, the fiber board is folded together to form a rectangle, and the flap is pulled taut over the opposite edge, then stapled in place using out-clinching staples. All seams and joints are sealed with UL-181A heat-sealing tape, pressure-sensitive tape, or mastic and fiber mesh tape.

When connecting fiber duct board sections to sheet metal components such as equipment flanges, fasteners such as sheet metal screws and washers are used to carry the mechanical load. Mastic and glass fiber fabric are typically used to air seal the connections at these points. However, approved pressure-sensitive aluminum foil tape or heat-activated aluminum foil/scrim tape may be used to seal the fiber board to the sheet metal when the operating pressure is less than 1 in. w.g. (250 Pa) and when sheet metal surfaces are cleaned in accordance with tape manufacturers’ instructions. Closure details may be found in Section IV of the North American Insulation Manufacturers Association Fibrous Glass Duct Construction Standard (NAIMA 2010).

Example instructions for the field fabrication and assembly of one section of fiber board duct are provided below. Detailed instructions and dimensions for hand cutting and machine cutting fiber board ducts in several configurations are available on line from insulation manufacturers such as Knauf and Johns Manville and from the North American Insulation Manufacturers Association.

How to Field Fabricate a Fiber Board Duct with Inside Dimensions of 14x6 Inches

- Lay out a piece of 10x4 foot piece of fiber board, 1.5 inches thick, foil side down.

- Starting at the left edge, mark out center lines for each corner, plus the line for the start of the stapling flap (on the left). Because you will only need 52.5 inches of length to make a duct with inside dimensions of 14x6 inches, you could mark up and cut the 120-inch fiber board to get two 52.5-inch pieces with 15 inches left over.

- On the right edge of the board (opposite the end that has the stapling flap), cut the closure joint rabbet with a gray (female shiplap) tool. Use fiber board cutting tools specifically designed for the intended cut and for the thickness of fiber board you are using. Know your tools - cutting tools have a lip where the tool rests against the straight edge to cut a straight line. The distance from the lip to the cutting blade must be taken into account when centering the blade for the cut and this distance varies among tool brands.

- Use a red V-groove tool to cut the grooves on the first three centerlines for the corner folds.

Prepare the stapling flap by making a perpendicular knife cut through the insulation 1.5 inches in from the end, taking care not to cut the foil facing. Then, strip the fiberglass insulation from the facing.

Figure 5. The red cutting tool is used to cut the grooves on the first three centerlines for the corner folds for the fiberboard ducts. - Fold the fiber board to assemble the duct section, making sure that the corners meet and fold correctly for a snug fit. Be sure to properly seat the flush edge in the rabbet cut at the closure joint.

- To staple the seam, pull the flap taught over the opposite edge and, while holding the seam closed, slightly flatten the duct (about 30° beyond square). Staple the seam using out-clinching staples, starting at the center and working out toward each end of the seam, stapling one-half inch in from the edge at 2-inch intervals.

- Connect this section to other sections, making sure the male and female shiplapped ends of each section are firmly seated. Smooth the stapling flap over the adjoining section and staple at 2-inch intervals.

- Seal all longitudinal and circumferential joints using one of three approved methods:

- Seal the seams with UL-181A-H heat-activated aluminum foil/scrim tape. Center the tape strip over the edge of the stapling flap, press down, and heat seal following the tape manufacturers’ instructions.

- Seal the seams with UL-181A-P pressure-sensitive foil tape. Use tape that is at least 1 inch wider than the thickness of the fiber board. Center the tape over the edge of the stapling flap. Press down and rub in carefully using a squeegee or similar tool until the scrim pattern from the duct board facing shows through the tape. Heat seal if the temperature is below 40°F (4°C).

- Seal the seams with UL-181A mastic and fiber mesh tape. Brush on a 4-inch-wide coating of mastic over the stapled flap. Embed a strip of 3-inch-wide open-mesh glass fiber fabric tape in the mastic. Apply an additional coat of mastic over the tape to cover and fill in the mesh.

Where sheet metal connections are made with the fiber board duct, connect the fiberboard to the metal with flat head sheet metal screws that are one-half inch longer than the thickness of the fiber board and use 1-inch outer-diameter washers. Seal the metal-fiber board seams with mastic or approved tapes after cleaning the sheet metal surfaces of any oily residue per the tape manufacturers’ instructions.

Figure 6. To assemble and seal the fiber board ducts, use outward-clinched staples, and UL-181A approved heat-activated or pressure-sensitive tape or mastic and fiber mesh tape.

Success

After ducts are installed and before drywall is installed, the duct system should be visually inspected by a HERS rater to ensure that all connections are properly fastened and sealed, preferably with mastic. Locations to inspect include the main supply trunk to branch connections, at the duct boots, duct splices, the return box to the return ducts, jump duct connections, and exhaust fan and ERV/HRV connections. HVAC ducts should be tested for air leakage and proper air flow with a duct blaster test. This test should be done before drywalling when any air leaks can still be accessed and sealed. Ducts should be insulated along the length including at connections, and the insulation should not be compressed by tight strapping, by framing members, or by excessive bending. The insulation should be a minimum of R-8 for all supply ducts and at least R-6 for all return ducts.

Climate

No climate specific information applies.

Training

Compliance

Retrofit

SCOPE

Additions

If new fiber board duct is added to an existing home either as part of an addition or an equipment upgrade, ensure that the duct is installed in runs that are as short, straight, and direct as possible and that they are well air-sealed and insulated as described in the Description tab.

Existing Buildings

In an existing building with fiber board duct and an under-performing HVAC system, inspect for lack of air sealing and adequate insulation. Symptoms may include poor comfort control and excessive energy use.

For more information, view the U.S. Department of Energy’s Standard Work Specifications regarding ducts.

If the ducts are located in the attic, review the guide Pre-Retrofit Site Assessment of Attics, Ceilings and Roofs.

If the ducts are located in the basement or crawlspace, review the guide Pre-Retrofit Assessment of Crawlspaces and Basements.

DESCRIPTION

Uninsulated (or under-insulated) ducts in unconditioned space results in a large portion of heating and cooling dollars being wasted. In humid climates, it also compromises building materials such as lumber, drywall, fasteners, and fixtures because warm, humid air that meets a cold surface (like an uninsulated or leaky duct delivering chilled air) results in the formation of liquid water that can damage materials, cause mold, and drip down through architectural features to cause unsightly staining. Repair and replacement of these items can easily cost more than the preventative duct insulation.

New ductwork should be installed in conditioned space whenever possible. Air sealing and insulating is even important for ducts in conditioned space as these measures can help ensure hot or cold air reaches its destination.

For the installation of fiber board ducts in retrofit and existing building situations follow all best practices and precautions described for new construction. Poor comfort control and wasted energy occur when conditioned air doesn’t make it all the way to the target space (due to leakage in the system) or when the target temperature of the conditioned air is compromised (heat gain or loss through uninsulated ductwork.) Additionally, duct leakage can drive infiltration increasing the entrance of uncontrolled outdoor air that requires conditioning.

See Duct Sealing for detailed sealing guidance.

Additions

Coordinate the duct layout for a new space with the design of the structure and other systems to ensure there is space for proper routing. As with new construction, use ACCA Manual D and provide a drawing of the layout to the homeowner for future reference.

Existing Buildings

See Pre-Retrofit Assessment of Existing HVAC Systems for a discussion of how to determine whether a flawed duct design may be contributing to poor HVAC system performance.

ENSURING SUCCESS

When re-routing ductwork, access the ducts directly from the basement, crawlspace, or attic if possible. If the ducts are behind finish materials such as drywall, it is tempting to make the smallest possible openings in existing ceilings and walls in an effort to reduce disruption. It will be impossible to fully examine the entire duct layout if openings are too small. Instead, cut openings in drywall large enough to fit head and shoulders so that the duct can be manipulated into the best possible orientation. Use ample hangers to support the duct in place and be sure to open the ceiling directly below any connections that must be adjusted so that collars and insulation can be examined from all directions to ensure a tight seal.

Although an existing duct system is generally not required to be brought up to code when making repairs (double check this with the local code official), you can take this opportunity to check the ducts for duct leakage and seal all accessible seams and joints; use outward-clinched staples and UL-181A-approved metal tape that is heat activated or pressure sensitive or use mastic and fiber mesh tape. You can also add duct insulation where it is deficient if you see evidence that condensation has been occurring, for instance in a humid crawlspace.

Starting with the 2009 International Energy Conservation Code (IECC) supply ducts located in unconditioned space must be insulated to at least R-8 and return ducts must be insulated to R-6.

COMPLIANCE

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

High-R Duct Insulation =

Without adequate duct insulation, there can be significant heat loss or heat gain as conditioned air travels through the comfort delivery system. This is especially true where ducts are located in an uninsulated attic or crawlspace. Insulation significantly reduces this energy loss and helps ensure conditioned air is effectively distributed from the comfort equipment to a home’s living spaces.