Scope

When HVAC ducts are installed in a vented attic in a dry climate, bury the ducts in attic insulation to protect them from temperature extremes in the unconditioned attic space.

- Install ductwork so that it is in direct contact with (i.e., laying on) the ceiling and/or truss lower cords.

- Use metal, flex, or fiber board ducts that are insulated to code. The duct insulation should include a vapor barrier cover.

- Mechanically fasten and mastic-seal all duct connections.

- Test total duct leakage. Add additional sealant if necessary.

- Install loose-fill insulation to cover the ducts and the attic floor to meet or exceed the code-required R value for attic insulation.

- If using this technique in a humid or marine climate, the ducts must be encapsulated with spray foam before installing the blown insulation. See Encapsulated Ducts and Ducts Buried in Attic Insulation & Encapsulated for more information.

- This technique fulfills the DOE Zero Energy Ready Home program requirement that ducts be installed in conditioned space.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

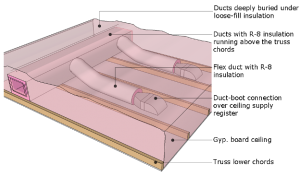

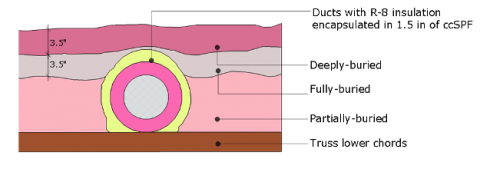

For homes with ducted heating and cooling systems, the best place to locate the duct system from an HVAC performance standpoint is within the conditioned space of the home, either in dropped ceilings, or between floors, or in a sealed and insulated basement, crawlspace, or attic. If the ducts must be located within a vented attic, one option for protecting the ducts and helping to minimize heat transfer between ducts and the unconditioned attic is to lay the ducts on the attic floor and cover them with the same blown insulation that is used to cover the attic floor. The ductwork should be installed so that it is in direct contact with the ceiling and/or truss lower cords. Metal, flex, or fiber board ducts can be used. The ducts should be covered with R-8 or higher duct insulation and the duct insulation should include a vapor barrier cover. All duct connections should be mechanically fastened and mastic-sealed. The ducts should be tested for total duct leakage and any leaks should be sealed. Once these preparations are made, the ducts can be buried in loose-fill insulation (typically blown fiberglass or cellulose) at the same time that the attic floor is being insulated. The insulation levels should meet or exceed the code-required R value for attic insulation. Figure 1 shows a duct that is partially, fully, or deeply buried in blown attic insulation.

If using this technique in the humid or marine climates, the ducts must be encapsulated with spray foam before installing the blown insulation. See Encapsulated Ducts and Ducts Buried in Attic Insulation & Encapsulated for more information.

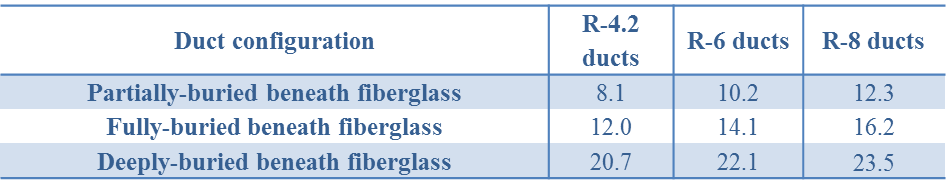

The effective R-value of a buried duct installation depends on the size of the ducts, the R-value of the duct insulation, and the depth of the loose-fill insulation. Table 1 shows effective R-values for 8-inch round ducts at three attic insulation levels and three duct insulation levels (R-4.2, R-6, and R-8).

Typically, the duct design will consist of one or more main supply trunk(s) and perpendicular duct branches serving each of the ceiling registers. If the trunk is perpendicular to the truss bottom chords, then the duct branches can be parallel and rest directly on ceiling. If the main truck is placed parallel to the ceiling supports, then the branches will need to run perpendicular to and rest on top of the truss chords. Either configuration will work, giving the designer the flexibility to select whichever method works best for a particular circumstance. In every case, a compact, low-profile layout should be a primary goal.

How to Install Buried Ducts After Ceiling is in Place

- Install ceiling gypsum board prior to installing buried ducts (Figure 2).

Install ductwork across lower truss cords or rafters or resting on the ceiling drywall. Install insulated ducts that have a minimum of R-8 duct insulation and in integral vapor barrier. Install the ductwork in accordance with a low-profile compact duct design (Figure 3).

Figure 3. This duct is insulated with a minimum of R-8 insulation. (Source: Steven Winter Associates.) - Properly fasten and seal ducts at all connections. To attach flex duct, pull back outer liner, fasten inner liner over collar with tool-tightened tension tie, mastic seal the connection. Pull insulation and outer liner over the joint and seal to attached duct or boot with mastic or foil tape. The outer liner should not be attached with a tie as shown here but should be connected with mastic or foil tape to avoid compressing the insulation.

Test total duct leakage with a duct blaster to ensure that the ducts have been adequately sealed (total duct leakage < 3 cfm25 per 100 ft2 of conditioned space) (Figure 5).

Figure 5. A duct blaster is used to test total duct leakage. (Source: Steven Winter Associates.) - Air-seal the ceiling plane penetrations, including sealing the duct register boots to the gypsum board ceiling using canned spray foam (Figure 6).

Install loose-fill insulation to the specified depth, and verify that the ducts are covered to the level desired (Figure 7).

Figure 7. Loose-fill attic insulation is installed to the specified depth. (Source: Steven Winter Associates.) strong>How to Install Buried Ducts before the Ceiling Is in Place

-

Install ductwork across lower truss cords or rafters. Install insulated ducts that have a minimum of R-8 duct insulation and an integral vapor barrier. Install the ductwork in accordance with a low-profile compact duct design. Where ducts are running parallel to ceiling framing, provide temporary blocking to hang ducts approximately 2 inches above the ceiling plane to allow for the thickness of the spray foam. (Figure 8).

Figure 8. These ducts were installed before the ceiling drywall was installed. Ducts are supported by temporary strapping across the lower truss cords. (Source: Steven Winter Associates.) - Connect, seal, and test ducts as described above in Steps 3 and 4.

- Install ceiling gypsum board after installing ducts.

- Air seal ceiling plane and and install attic floor insulation as described in Steps 5 and 6 above.

-

Success

Buried ducts can be used in dry climates. For humid and marine climates, ducts should be encapsulated in at least 1.5 inches of closed-cell spray foam before burying in blown insulation. As with all advanced systems, the key to optimal implementation lies with the initial planning. To accommodate a buried ducts strategy, the designer must also consider how best to incorporate a low-profile design, where the system layout is specifically designed to place ducts as low as practical to allow ductwork to hug the drywall ceiling where possible. Other best-practice measures, which assist in achieving the desired low-profile layout, should be incorporated into the building, including compact HVAC distribution and right-sized HVAC sizing. Specifically, smaller ducts (lower duct height) and inboard registers (shorter duct runs) mean that there is less ductwork to bury.

Return trunks and branches could be treated in the same manner; however, to keep the HVAC distribution system at a minimum, while simultaneously providing good comfort and proper airflow, the use of central returns is recommended. Return air paths from bedrooms and other spaces can be accommodated by low-profile jump ducts.

Climate

Buried & encapsulated ducts may be installed in all climate zones, including moist (A) and marine (C) climate zones. The ccSPF insulation mitigates condensation concerns in these climates.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

Compliance

Retrofit

SCOPE

In existing homes with vented attics and HVAC ducts that are installed on the attic floor, bury ducts in blown attic insulation when adding or increasing attic insulation.

Before adding blown insulation,

- Inspect and test the ducts for missing or torn duct insulation; sagging, crushed. or excess flex duct; disconnected or leaking ducts.

- Repair and air seal ducts as needed before installing spray foam insulation.

- See the following for more information about insulating and air sealing metal, flex, or fiber board ducts.

- Flex duct runs should be pulled taut to reduce internal airflow friction. See the following guides to remedy installation problems prior to sealing or adding insulation to an existing flex duct system:

If ducts are hung in attic rather than laying on the attic floor, see the guide Encapsulated Ducts.

For more information, view the U.S. Department of Energy’s Standard Work Specifications regarding ducts.

Also see the Solution Center guide Pre-Retrofit Site Assessment of Attics, Ceilings and Roofs.

DESCRIPTION

Make any needed repairs as described above then follow installation guidance for new homes in the Description tab.

COMPLIANCE

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Steven Winter Associates, lead for the Consortium for Advanced Residential Buildings (CARB), a DOE Building America Research Team

Sales

Vented Attics with Buried HVAC Ducts =

Comfort systems installed in vented attics work much better when they are buried in insulation. Vented attics can reach extreme temperatures. Deeply burying the ducts in the attic's insulation provides significant protection from these harsh conditions. The ducts need to be tightly sealed to ensure optimum performance.