Scope

Install structural sheathing (plywood/OSB) in exterior walls to ensure the building will resist design wind pressures. This guide provides an overview of wood structural sheathing in exterior walls with a focus on applications in hurricane-prone regions or other high-wind areas.

- Determine if the house is in a hurricane-prone region or other high-wind area (see Climate Tab).

- Select the appropriate thickness for wood structural sheathing panels.

- Minimum: 7/16” thickness. (Exception: 3/8” for gable end walls structural sheathing.)

- Determine the appropriate fastening schedule for the structural sheathing.

- Determine the amount and location of braced walls (shear walls) required at each story of the house. Ensure shear walls provide lateral stability.

See the Compliance tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

During a hurricane, tornado, or high winds, wall systems can succumb to structural failures and water damage due to exposed sheathing, Unsealed joints or penetrations in the wall structural sheathing or storm damage can allow rainwater to enter the building, causing severe damage, including saturation of insulation and drywall, potentially leading to extensive damage to sheathing, flooring, interior finishes, and household contents.

A fully sheathed wall of plywood or OSB, properly connected to the foundation below and roof above, is a strong barrier that resists the persistent forces of hurricanes, tornadoes, and high wind events. Wind loads are the most common loads that shear walls are designed to resist. Shear walls are walls composed of braced panels (also known as shear panels) to counter the effects of lateral load acting on a structure. Proper anchorage or connection prevents the shear walls and, in turn, the rest of the structure from laterally racking, displacing, or overturning during a high-wind or seismic event.

New construction and retrofit are opportunities to upgrade the exterior structural sheathing to meet standards and building codes and to decide if selecting an above-code strategy for an added level of protection is the right choice for the project.

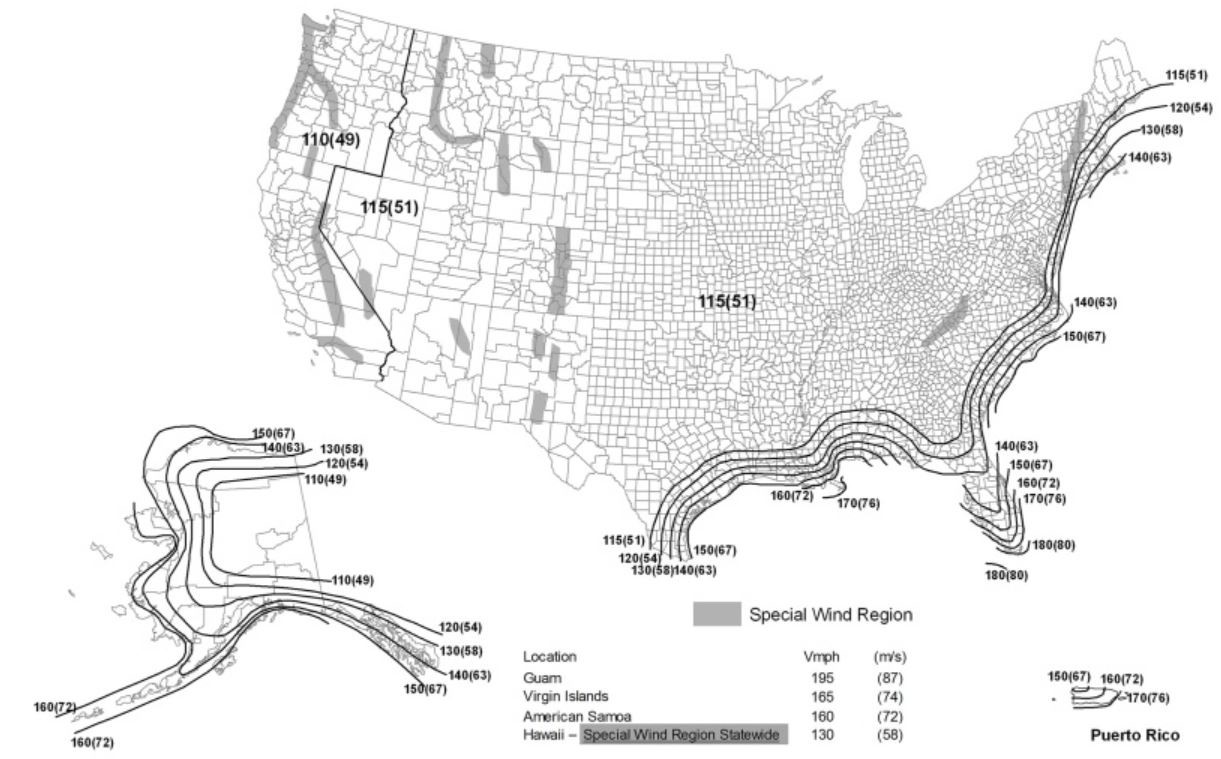

The International Residential Code (IRC) requires exterior building components and their attachments to be capable of resisting design wind-pressures. For some high-wind regions, the IRC requires wind design in accordance with other methods including the International Building Code (IBC) (2018 IRC R301.2.1.). Homes located in coastal high-wind areas including Hurricane-Prone Regions generally require enhanced attachment that can withstand greater wind speeds than the rest of the country. The IRC defines Hurricane-Prone Regions as areas along the Atlantic and Gulf Coasts where wind velocity is >115 mph, and Hawaii, Puerto Rico, Guam, the Virgin Islands, and American Samoa (see the IRC wind map in the Climate tab). Confirm with the local building department if the house is in a hurricane-prone region and if local requirements exceed those of the IRC.

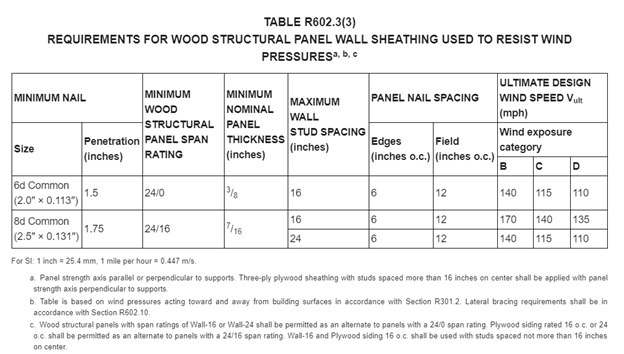

Section R602 of the 2018 IRC specifies minimum wall-sheathing thickness and fastening requirements for structural panels. See IRC Table R602.3(3) below for minimum wood structural panel span length, thickness, nail size, nail spacing, nail penetration, and stud spacing for the various wind exposure categories.

Section R602.10 of the IRC provides prescriptive construction details and requirements for braced wall lines and braced wall panels for buildings exposed to different wind speeds.

Gable end wall bracing is also a requirement for the silver designation in the Fortified Home program conducted by the Insurance Institute for Business and Home Safety® (IBHS) offers guidance, best practices, and voluntary construction standards and programs for building in disaster-prone areas including hurricane and high-wind zones. The IBHS Fortified Home™ standard is designed to make homes more resilient and durable; guidance is available for New Construction and Existing Homes in Hurricane zones and High-Wind zones. There are three levels of Fortified Home: Fortified Roof™ focuses on the roof; Fortified Silver focuses on roof overhangs, opening protection, gable ends, and attached structures; Fortified Gold focuses on tying all components of the structure together. The IBHS Fortified Home program includes the following additional above-code guidance and requirements for structural sheathing.

- Wall Impact Resistance - Ensure that all exterior walls are constructed using a wall system that provides, at a minimum, the resistance to wind pressures and debris impact provided by 7/16-in.-thick OSB wood structural panels attached to wood wall framing.

- For Gable End Wall Sheathing - Gable end walls must have structural wall sheathing (minimum of 3/8-in. plywood or OSB or equivalent).

- For Gable End Wall Bracing - Gable end walls need to be braced. See BASC Guide on Lateral Bracing Gable End Walls.

How to Install Exterior Structural Sheathing and Interior Shear Wall Construction

- Wood frame exterior walls must be fully sheathed, including areas above or below wall openings, with minimum 7/16-in. wood structural panels. Interior shear walls must be fully sheathed including areas above or below wall openings with minimum 7/16-in. wood structural panels on both wall faces.

- Walls continuously sheathed with structural sheathing (OSB or plywood).

- Minimum of 3/8-in. structural sheathing panels are required for gable end walls. Gable end walls must be tied to the structure. They may include steel connection plates or straps. Connections should be made at the top and bottom of the gable end wall.

- Hurricane clips or framing anchors are required on all rafter-to-wall connections.

- Upper- and lower-story wall sheathing must be nailed to the common rim board.

- No form of intermittent bracing (e.g., metal strapping) shall be allowed on an outer wall. Intermittent bracing may only be used for interior braced wall lines.

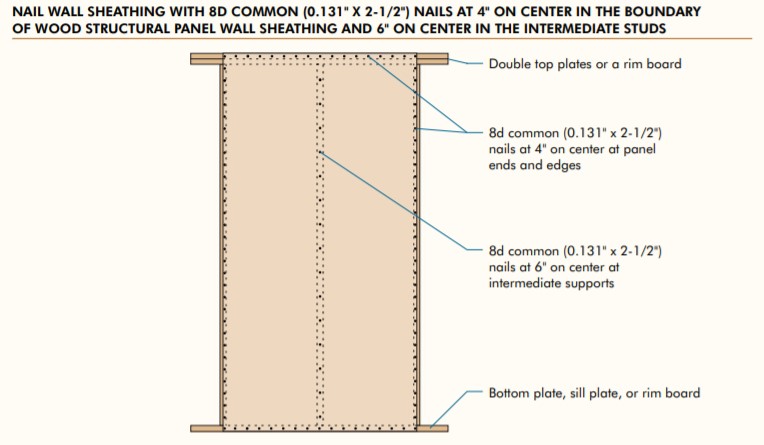

- Nailing of wall sheathing shall be increased to 8d ring shank or 10d nails on 4 inches on center along the edges and 6 inches on center in the field.

- Structural wood sheathing shall be extended to lap the sill plate and nailed to the sill plate using a 4-inch on-center nail pattern along the edges. Structural wood sheathing shall be nailed to the rim board if present with 8d ring shank or 10d nails at 4 inches on center along both the top and bottom edges of the rim board. See Figure 1.

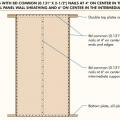

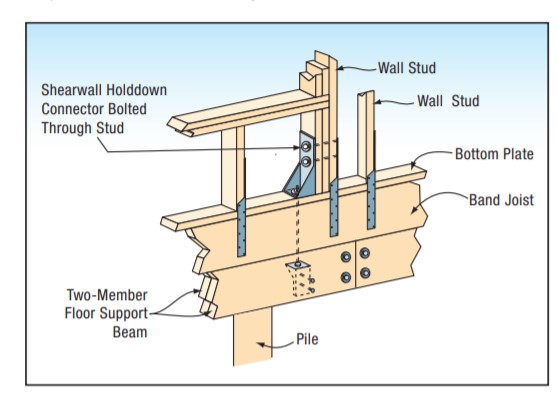

- Bolt the shear wall hold-down connector through the stud. See the anchor brackets and straps used as connectors in Figure 2.

- Install water resistive barrier (WRB) on the structural sheathing.

Success

To ensure success for the complete wall system (from cladding to dry wall), please view the Building American Solution Center Guides on the following topics:

- Advanced Framing: Insulated Corners

- Advanced Framing: Insulated Headers

- Advanced Framing: Insulated Interior/Exterior Wall Intersections

- Continuous Rigid Insulation Sheathing/Siding

- Drainage Plane Behind Exterior Wall Cladding.

Also see if local building codes have specific requirements or ask the local building department. For disaster resistance, comply with the requirements defined by Fortified Home (Fortified Technical Resources).

Climate

Exterior wall sheathing is more likely to be damaged or lost in hurricane-prone regions and other high-wind areas, leaving the house susceptible to wind and water intrusion. Proper installation is even more important in these areas to protect against storm damage.

Training

Compliance

Compliance

Retrofit

IBHS Requirement for Compliance for Existing Homes

Prescriptive methods for retrofitting gables 4 ft tall and taller are detailed in the gable end wall bracing retrofit section of the IBHS High Wind Standard and are consistent with methods included in an appendix to the International Existing Building Code (ICC 2018). These methods are intended for applications where the gable end wall framing is provided by a wood gable end truss or a conventionally framed rafter system. These prescriptive methods of retrofitting are intended to increase the resistance of existing gable end construction to out-of-plane wind loads.

Key recommendations (taken from the gable end wall bracing retrofit section of the IBHS High Wind Standard :

- Strengthen the vertical framing members of the gable end with the use of retrofit studs. See the discussion of gable end wall bracing in the Silver designation of the IBHS High Wind Standard.

- Brace the top and bottom of the gable end so the lateral loads are transmitted into the roof and ceiling diaphragms through horizontal braces. (See IBHS’s Gable End Wall Bracing Retrofit Section.)

- Make connections between horizontal braces and retrofit studs using metal straps and fasteners. (See IBHS’s Gable End Wall Bracing Retrofit Section.)

- Connect the bottom of the gable end to the wall below using metal bracket connectors. (See IBHS’s Gable End Wall Bracing Retrofit Section.)

- Make sure that the gable end wall sheathing is adequate (minimum requirement is for 3/8-in. OSB/plywood sheathing).

Minimum requirements for use of the prescriptive methods detailed in IBHS’s Gable End Wall Bracing Retrofit Section are as follows:

- The ceiling diaphragm must be a minimum of 1/2-in. drywall, 3/8-in.-thick plywood, or plaster installed over wood lath.

- The roof sheathing must be at least 3/8-in. plywood or OSB or 3/4-in. boards.

- Gable ends must have structural wall sheathing (minimum of 3/8-in. plywood or OSB or equivalent). If not, sheathing must be added that meets these minimum requirements as part of the retrofit.

Cases that are not covered in this retrofit guidance require that a licensed professional engineer design a gable end bracing system that will meet wind forces appropriate for the location. Note: Gable ends that are not covered in this retrofit guidance include:

- Gable end walls on rooms with vaulted or cathedral ceilings.

- Gable ends that are taller than 16 ft and/or have irregular shape.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.