Scope

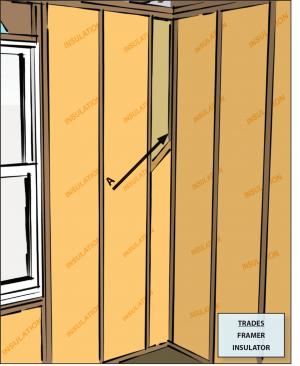

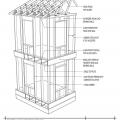

Construct framed walls using advanced framing details like insulated corners that reduce framing and thermal bridging and allow more space for insulation.

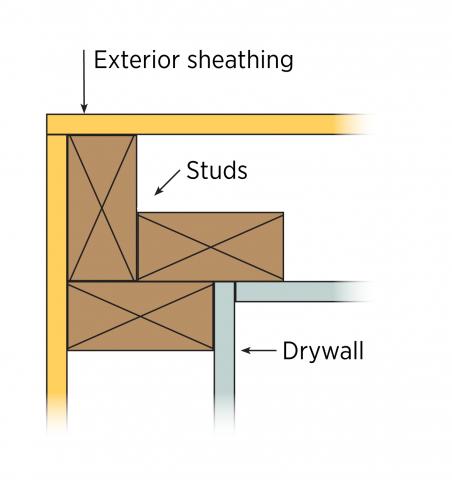

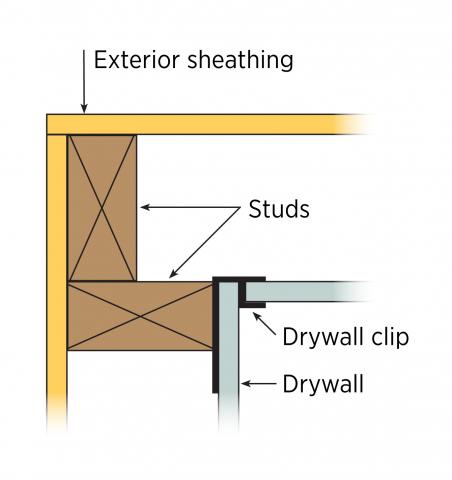

- Construct corners with two studs or three studs aligned to allow more room for insulation along the exterior wall.

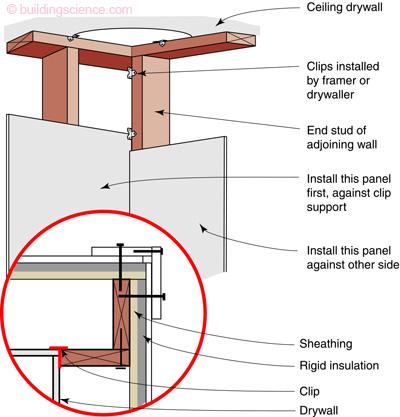

- Use drywall clips as needed to hold drywall in place.

- ENERGY STAR requires that the space provided at the corner allow for at least R-6 of insulation (ENERGY STAR).

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

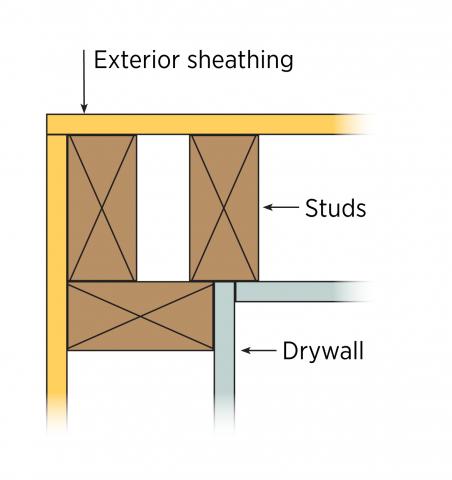

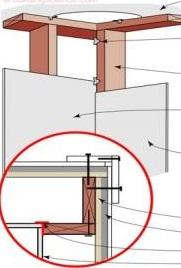

Exterior wall corners are typically framed with three studs. The third stud generally only provides a nailing edge for interior gypsum board and its typical placement blocks off the wall cavity, preventing insulation from being installed. If the third stud can be eliminated, there is more room inside the wall for insulation. Drywall clips, a 1x nailing strip, or a recycled plastic nailing strip can be used to create a two-stud corner that still provides a surface on which to hang the drywall. Using drywall clips also reduces opportunities for drywall cracking and nail popping, frequent causes of builder callbacks.

The designer should include the corner detail on building plans. It should be installed by the framer. If two-stud corners are used, they can be insulated by the insulation contractor. This task should be included in the contract for the appropriate trade, depending on the workflow at a specific job site. ENERGY STAR Version 3.0 requires that all exterior corners shall be constructed to allow access for the installation of ≥ R-6 insulation that extends to the exterior wall sheathing. See the Compliance tab for 2009 IECC-specified wall insulation levels.

How to Insulate Corners

Construct exterior corners to allow access for the installation of > R-6 insulation that extends to the exterior wall sheathing in one of the following ways:

- Construct a two-stud corner using a nailing strip or drywall clips, which allows the wall cavity at the corner to be insulated in sequence with the rest of the installation at full wall thickness.

- When drywall clips are used, they should be installed above the level of the interior trim so trim nails will not interfere.

- If installing trim, the noncoped trim piece should be installed first, against the drywall that bears on the clip, so that the coped trim piece can be nailed to the stud.

- If rigid foam is used as the sheathing instead of OSB or another solid nailable sheathing, install a wood nailer strip behind the sheathing if necessary for attaching exterior trim or siding at the corner on the side that does not have a stud.

Success

The quality of the insulation installation should be visually inspected by the site supervisor before the drywall is installed. It may be possible to detect heat loss at the corners of exterior walls with an infrared camera, if a sufficient temperature difference exists between the outside and the conditioned space of the house.

Climate

No climate specific information applies.

Training

CAD

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Pacific Northwest National Laboratory

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

2-Stud Corner w/Drywall Clips = High-Efficiency Corner Framing

Traditionally built homes use three or more studs in exterior wall corners leaving minimal space for insulation, resulting in thermal losses. By only using two studs and a clip to help hold the drywall, high-efficiency corner framing allows for insulation in the corners of a home and reduces heat loss. This in turn minimizes cold spots at corners while saving both energy and cost. It also helps minimize corner cracking because the two sheets of drywall that meet at the corner are effectively attached to the same stud, eliminating differential movement.