Scope

Insulate a foundation wall by adding spray foam insulation to the interior side as follows:

- Inspect the existing foundation wall for any deficiencies and make any necessary corrections including fixing any water intrusion or moisture issues in the basement, crawlspace or along the foundation wall, prior to commencing the retrofit work.

- Install closed-cell spray foam insulation along the inside of the foundation wall and sill beam to the minimum thermal levels specified in the current adopted building code.

- Apply thermal/ignition barrier as required by the current adopted building code.

For more on slab foundations, see the U.S. Department of Energy’s Standard Work Specifications.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

In most existing houses, the basement or crawlspace walls are uninsulated. One method for insulating the walls is to cover the interior surface with spray foam.

Most homes have foundation walls made of concrete (cast concrete or concrete block) or constructed of irregular discrete pieces, such as fieldstone, brick, or rubble. The primary distinctions between these foundation types is the character of the surface of the wall – either a flat surface or an irregular surface – and the water permeability of the wall, which is quite high for walls built of irregular discrete pieces. The use of spray foam interior insulation is appropriate for either type.

Measures should be taken to protect foundation walls from bulk water (even if they are not being insulated). If the grade around the perimeter does not slope away from the house, make grading adjustments so that it slopes away at 5% grade for at least the first 3 feet and if possible, 10 feet. If gutters are installed, the downspouts must direct water away from the perimeter of the house and the gutter system must be regularly maintained to prevent overflowing, leaks, or breaks in the system because these can concentrate water along the building foundation. Another protective measure is to provide a trench of gravel around the perimeter that extends out at least as far as the roof drip edge. This helps disperse bulk water that comes from the roof so that the top of the foundation wall is not continually splashed. It is especially important to keep bulk water away from the exposed part of stone or brick foundation walls to reduce the impacts of freeze-thaw cycles.

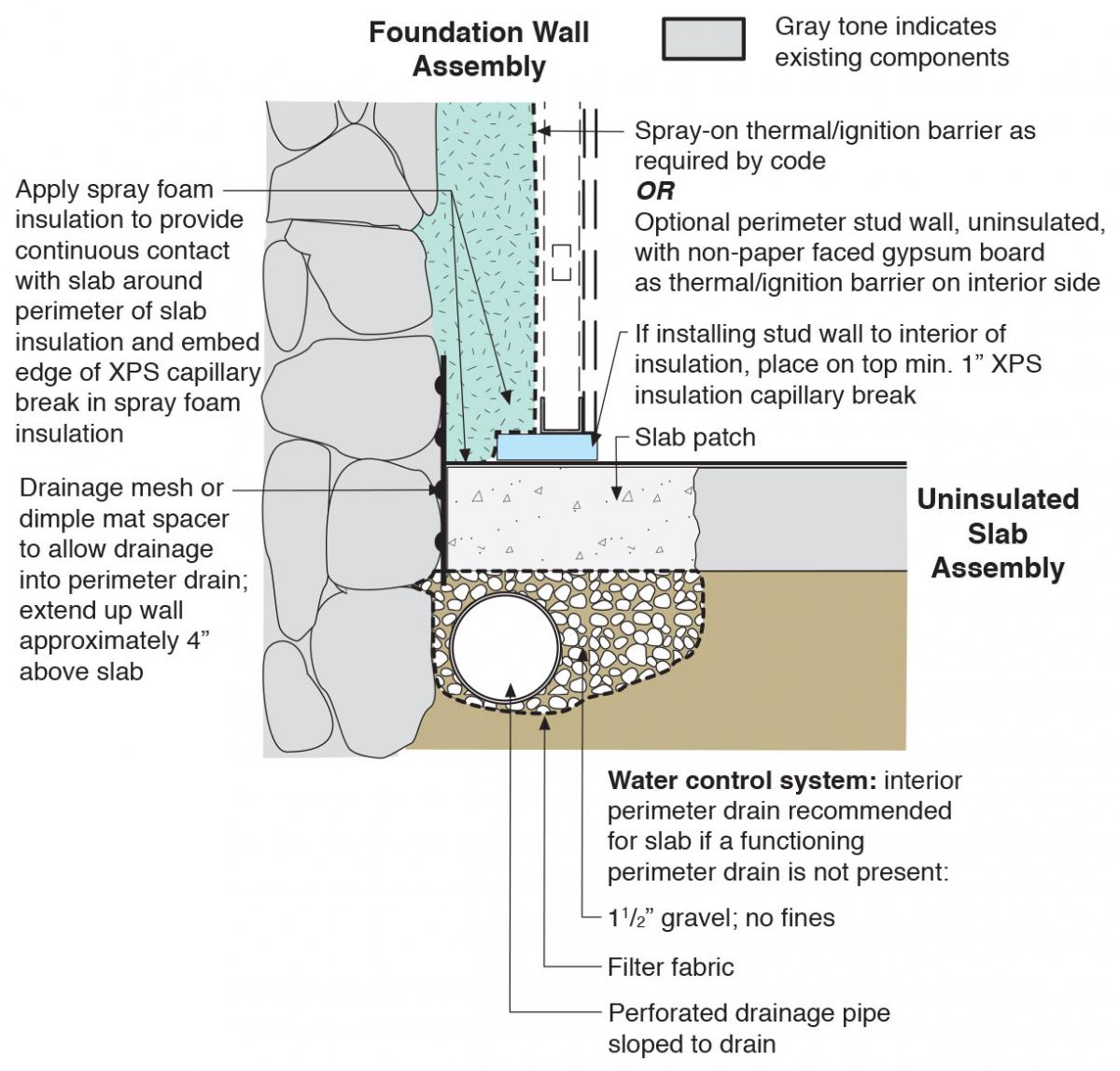

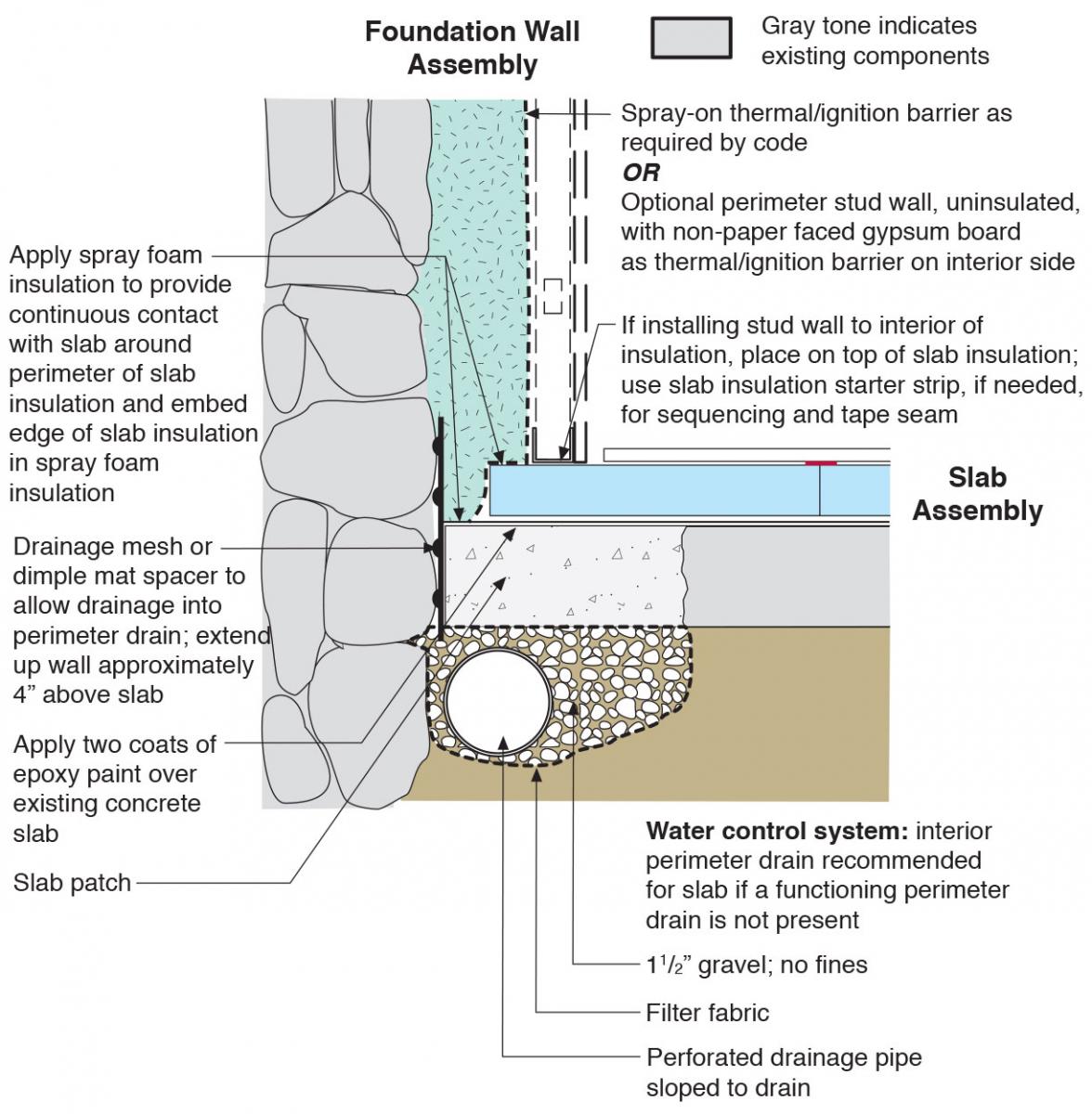

If necessary, a perimeter drainage system can be installed around the building’s exterior or interior (see Figure 2). For additional guidance on foundation drainage and moisture management see the guides “Drain or Sump Pump Installed in Basements or Crawlspaces”, “Damp-Proof Exterior Surface of Below-Grade Walls”, “Final Grade Slopes Away from Walls”, “Water Management of Existing Crawlspace Floor”

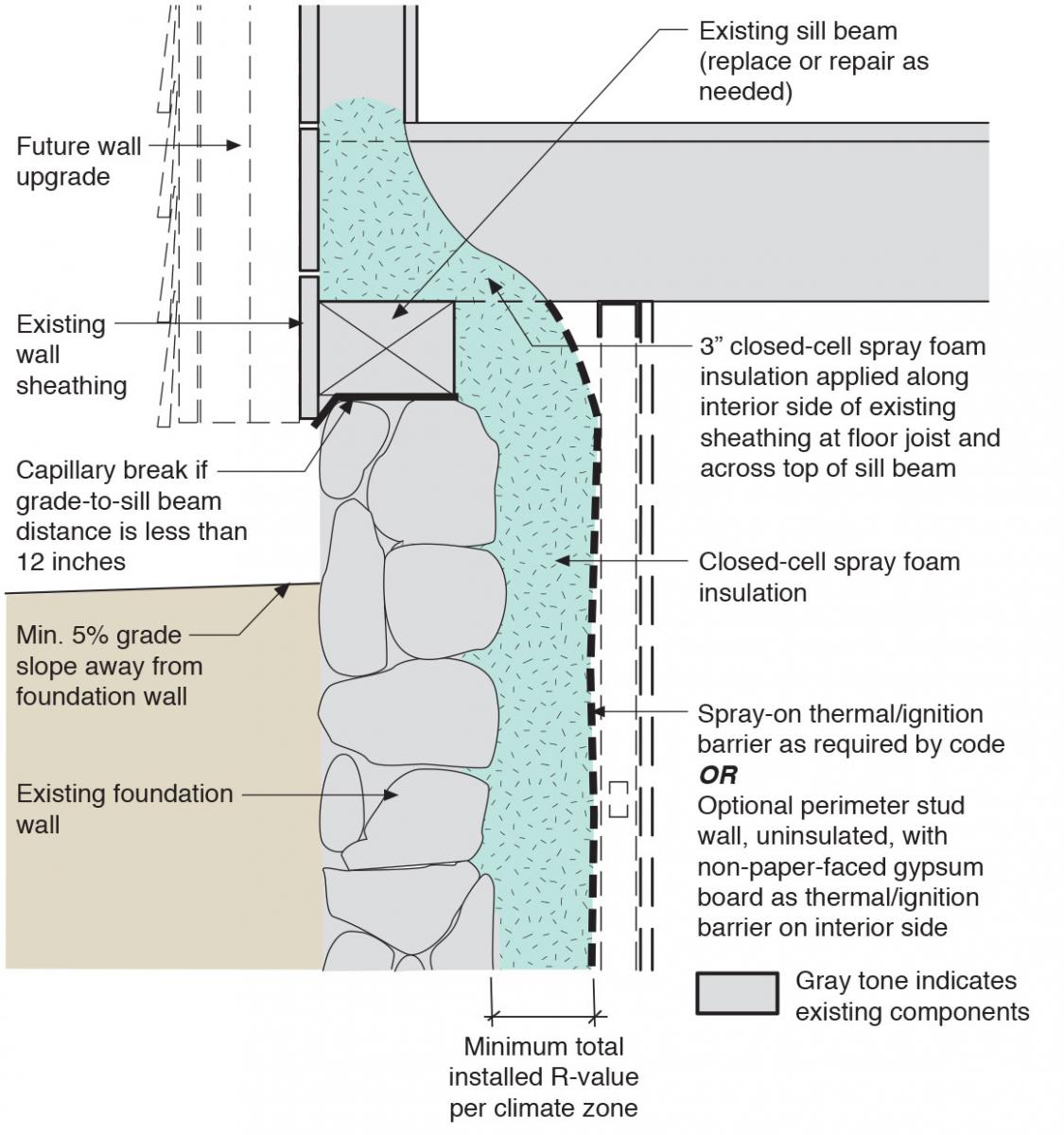

Before proceeding with the foundation wall retrofit, an assessment should be made of the condition of the sill plate or sill beam, which sits on top of the foundation wall. If there is no capillary break under the sill and/or if the sill is within 12 inches of the ground, it is possible that it has suffered water damage. If so, the damaged pieces should be replaced and at the same time, a capillary break should be installed under the new pieces. If there is no capillary break under the sill and/or the sill is within 12 inches of the ground, but there is no indication of damage, then it is likely that the sill has been able to dry. However, covering the sill, rim joist, and wall with spray foam will limit the ability of the sill to dry to the interior, so special treatment may be required at the base of the exterior wall. (See the guide “Flashing at Bottom of Exterior Walls” for additional information.)

It is recommended that the seams in the sill plate framing be caulked prior to insulating. For more guidance, see Air Sealing Sill Plates.

How to Install Spray Foam Insulation at Foundation Wall

- Inspect the existing foundation wall for any deficiencies. Make any necessary repairs prior to beginning the retrofit work. For stone or brick walls, take measures to protect the exposed part of the foundation wall from bulk water if necessary, such as grading the soil surface away from the structure, installing gutters and downspouts, and installing a footing drain.

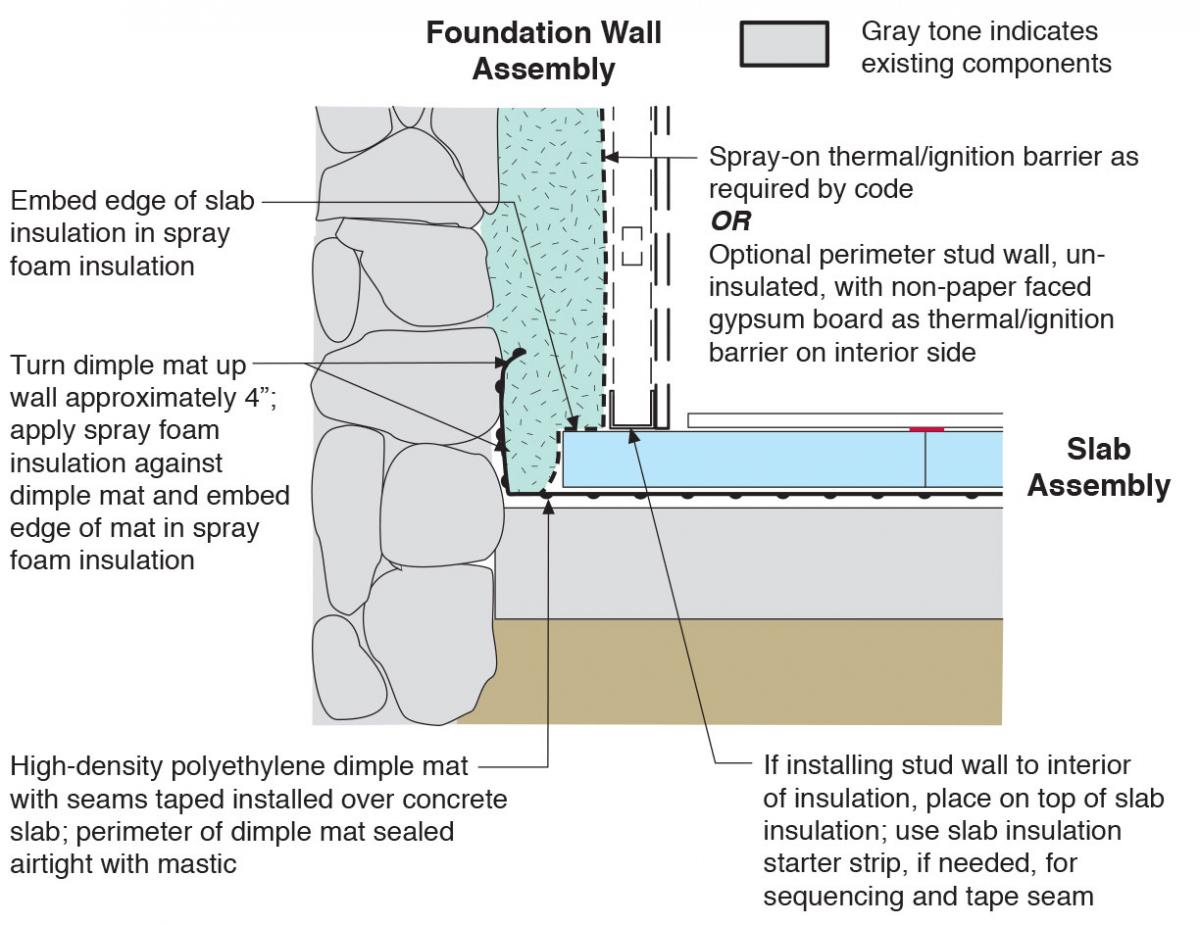

- Install closed-cell spray foam insulation at the foundation wall to at least the minimum levels specified in the local building code. Extend the spray foam over the sill beam. If the house has balloon framing, use spray foam insulation to fill the base of the wall cavity above the top of the foundation to air seal it to the back side of the existing wall sheathing, as shown in Figure 1.

- Apply a spray-on thermal/ignition barrier as required by the local code.

ALTERNATELY, build a perimeter stud wall on the interior side of the spray foam. Don’t insulate the stud wall. Cover it with non-paper-faced gypsum board as the thermal/ignition barrier on the interior side. If metal studs are used for the interior wall, do not insulate it unless the metal studs are placed at least 1 inch to the interior side of the foundation wall insulation.

Success

Provide a continuous layer of spray foam insulation extending from the base of the wall cavity above down to the basement slab.

Manage bulk and capillary water prior to the insulation/air seal retrofit.

Provide a thermal/ignition barrier as required by the current adopted building code.

Climate

The basement wall assembly should be designed for a specific hygrothermal region, rain exposure zone, and interior climate.

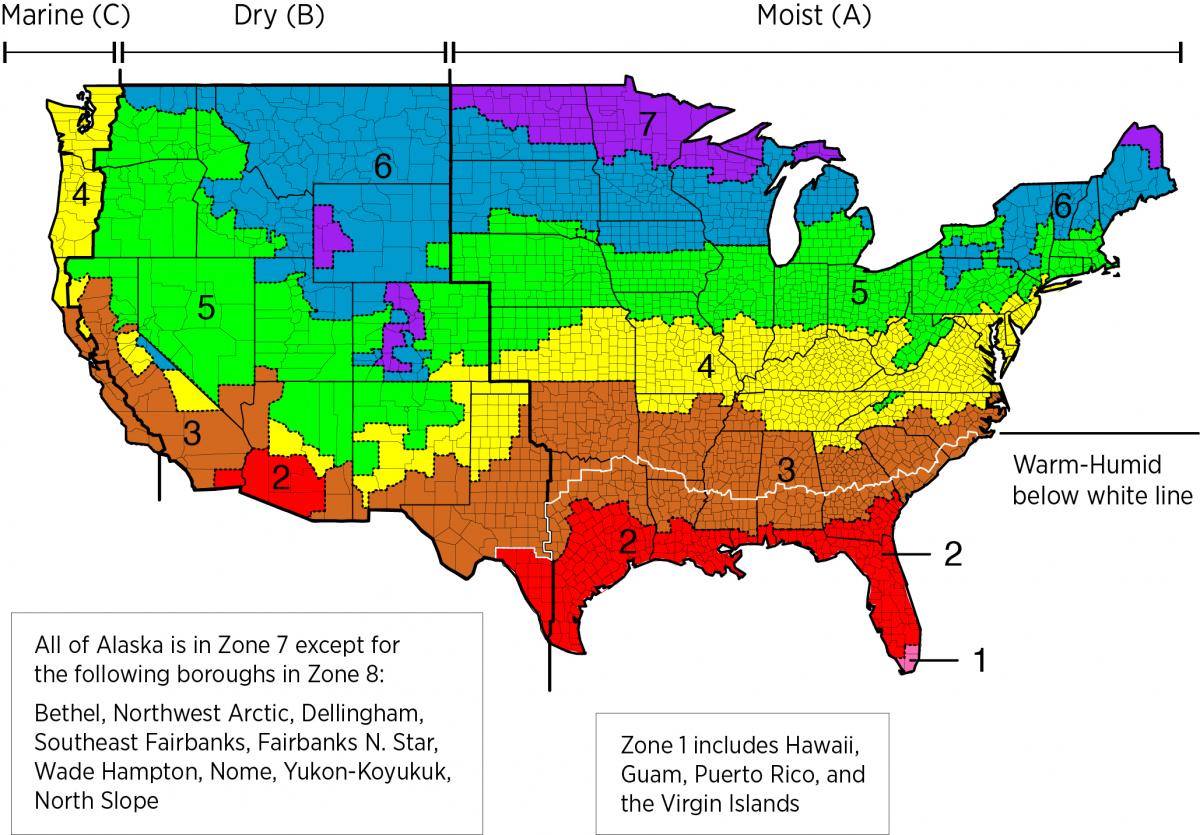

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Figure 1. Climate Zone Map from IECC 2009, 12, 15, and 18. (Source: 2012 IECC)

Figure 2. Climate Zone Map from IECC 2021. (Source: 2021 IECC)

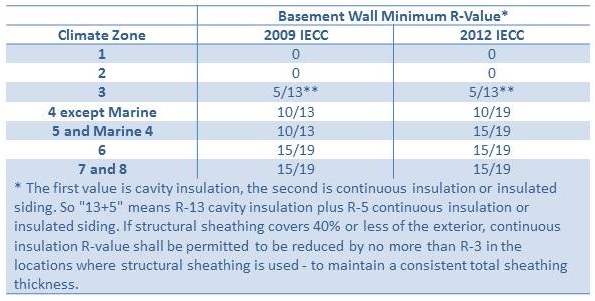

The insulation levels should be based on the minimum requirements for vapor control in the current adopted building code and the minimum requirements for thermal control in the current energy code. Additional insulation can be added above these minimums to create high R-value basement wall assemblies. The table below provides the minimum thermal resistance (R-value) requirements for basement walls specified in the 2009 IECC (ICC 2009b) and the 2012 IECC (ICC 2012b), based on climate zone.

Table 1. Minimum R-Value Requirements for Slab Insulation in the 2009 and 2012 IECC.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

High-R Foundation Insulation = High-Efficiency or Ultra-Efficient Foundation Insulation

There are two levels of foundation insulation: high-efficiency insulation, which meets the 2015 International Energy Conservation Code, and ultra-efficient insulation, which is 25% more efficient than this national code. Using high-efficiency and ultra-efficient insulation, along with professional installation (e.g., no gaps, voids, compression, or misalignment with air barriers; complete air barriers; and minimal thermal bridging) creates conditioned spaces that require very little heating and cooling, along with, even comfort and quiet throughout the house.