Scope

Upgrade a crawlspace floor in an existing home by adding insulation as follows:

- Determine if the crawlspace floor surface is suitable for walking and storage.

- Install either rigid foam insulation under a thin slab or or closed-cell spray foam insulation over the crawlspace floor. If the crawlspace will be accessed frequently for storage, choose rigid foam and a concrete slab.

- If there is a history of flooding or water leakage in the crawlspace, provide proper drainage.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Crawlspaces can be designed and constructed as mini-basements, part of the house and within the conditioned space. When crawlspaces are included within the thermal enclosure, they should be insulated and air sealed on their perimeters and should have a continuous sealed ground cover. In cold climates or in very low-energy-consuming buildings, installing insulation below on the floor of the crawlspace is also recommended. When a crawlspace floor is air sealed and insulated and the crawlspace walls are air sealed and insulated, the temperature and humidity conditions in the crawlspace become very stable and essentially identical to the interior of the building. See the guide Unvented Crawlspaces and Conditioned Basements for more information.

The building code does not specifically call for insulation at the crawlspace floor. Therefore, minimum thermal resistance (R-value) requirements for slabs should be followed. See the Climate tab for R-values.

If it is not possible to treat the crawlspace as a part of the house, such as in flood zones in coastal areas or in dry climates where it is not necessary, it is important to construct the house such that the crawlspace is isolated from the house, i.e., is outside of the home’s thermal boundary. Homes with uninsulated, unsealed crawlspaces should be treated like homes built on piers with thorough air sealing of the floor and floor joists and insulation installed on the underside of the floor in full contact with the floor.

Conditioned crawlspaces perform better than vented crawlspaces in terms of safety, health, comfort, durability, and energy consumption. These benefits are particularly evident when the crawlspace is used to locate HVAC equipment and ducting. Vented crawlspaces in humid climates have experienced serious moisture and mold problems, because rather than venting moisture out, the crawlspace have allowed hot, humid outside air into the crawlspace where it has caused condensation to form on the cooler floor joists, causing moisture issues that have cost builders and homeowners significant resources to repair. Despite the obvious problems with existing vented crawlspaces and the obvious benefits of conditioned crawlspaces, there is not a significant trend toward the construction of conditioned crawlspaces. One of the reasons typically cited by builders and designers is “the code does not allow me to build unvented crawlspaces.” This is both generally correct and misleading. The model codes do not allow the construction of “unvented” crawlspaces – except in very limited circumstances, but they do allow the construction of “conditioned” crawlspaces. The distinction is important and necessary. When the crawlspace is sealed, insulated, and provided with heated and cooled air, it is considered conditioned space. The space is part of the “interior” of the building and should be heated, cooled, and ventilated as part of the building’s heating, cooling, and ventilating strategy.

Whether or not the crawlspace is included within the conditioned space of the home, it must always have a ground cover that prevents evaporation of ground moisture into the crawlspace. There are many ways to provide a durable ground cover or liner. The option used depends on the resources available and the frequency of people entering the crawlspace to either store possessions or to maintain equipment. This ground cover must be continuous around piers and supports. (See the guides Capillary Break at Crawlspace Floor - Polyethylene Sheeting under Concrete Slab and Capillary Break at Crawlspace Floors - Polyethylene Lapped Up Walls and Piers or Secured in the Ground.)

If there are any moisture issues in the crawlspace or around the foundation, those must be taken care of before insulating the crawlspace floor. See the guide Water Management of Existing Crawlspace Floor for more information. If a sump pump is needed see the guide Drain or Sump Pump Installed in Basements or Crawlspaces.

Consider testing radon levels in the basement and home prior to the crawlspace insulating project. If a radon mitigation system is needed, install the radon vent pipe and stack before insulating the crawlspace floor.

Insulation and Thin Slab over Dirt/Gravel

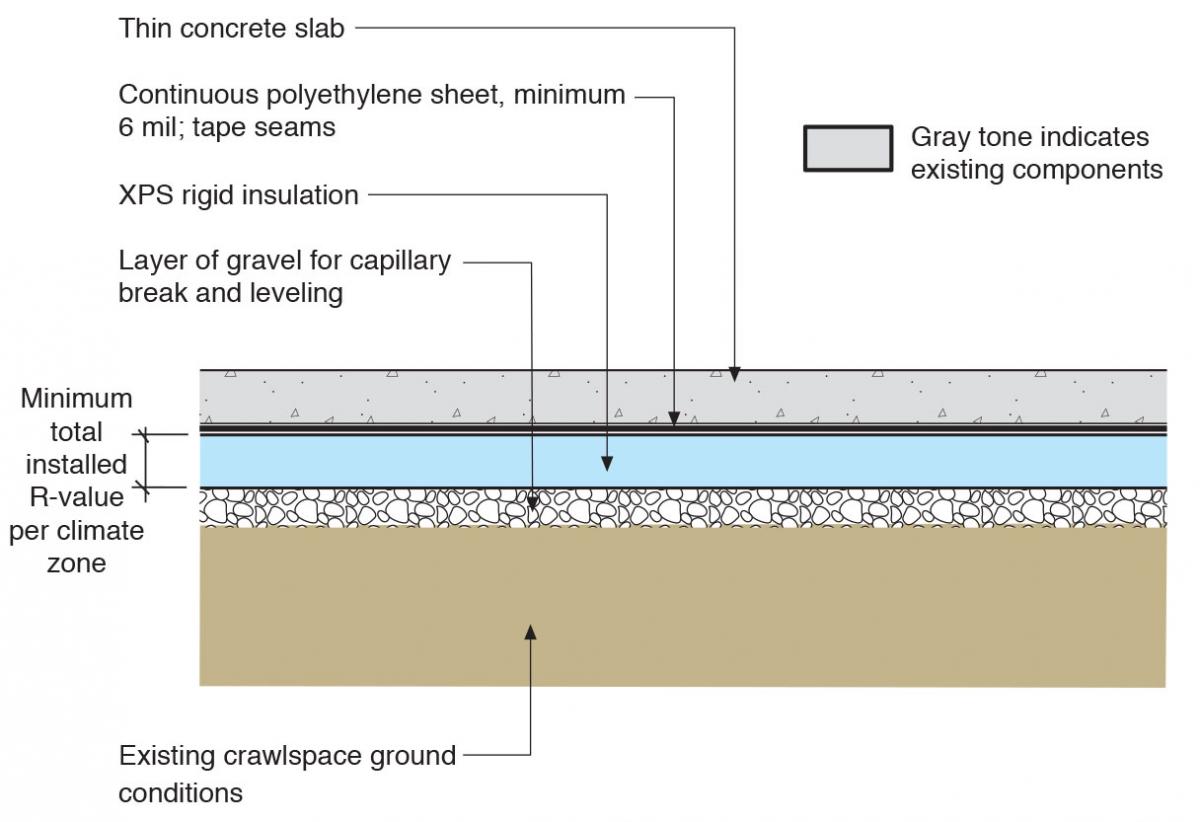

The crawlspace floor assembly shown in Figure 1 provides a surface suitable for light storage. (This floor design is also suitable for slab on grade construction.)

How to Install Insulation and Thin Slab Over Dirt/Gravel

- Install drainage pipe and a sump pump that pumps to daylight away from the house or to the sewer system if there is a history of flooding or pooling water in the crawlspace.

- Spread a layer of gravel for leveling. Slope to drain if a drainage system needs to be installed. See Figure 1.

- Install radon mitigation system if needed.

- Install XPS rigid foam insulation.

- Install a continuous 6-mil polyethylene sheet with seams taped. See the guide Capillary Break at Crawlspace Floor - Polyethylene Sheeting under Concrete Slab for more information.

- Install a thin layer of concrete as a finished surface.

Closed-Cell Spray Foam over Dirt/Gravel

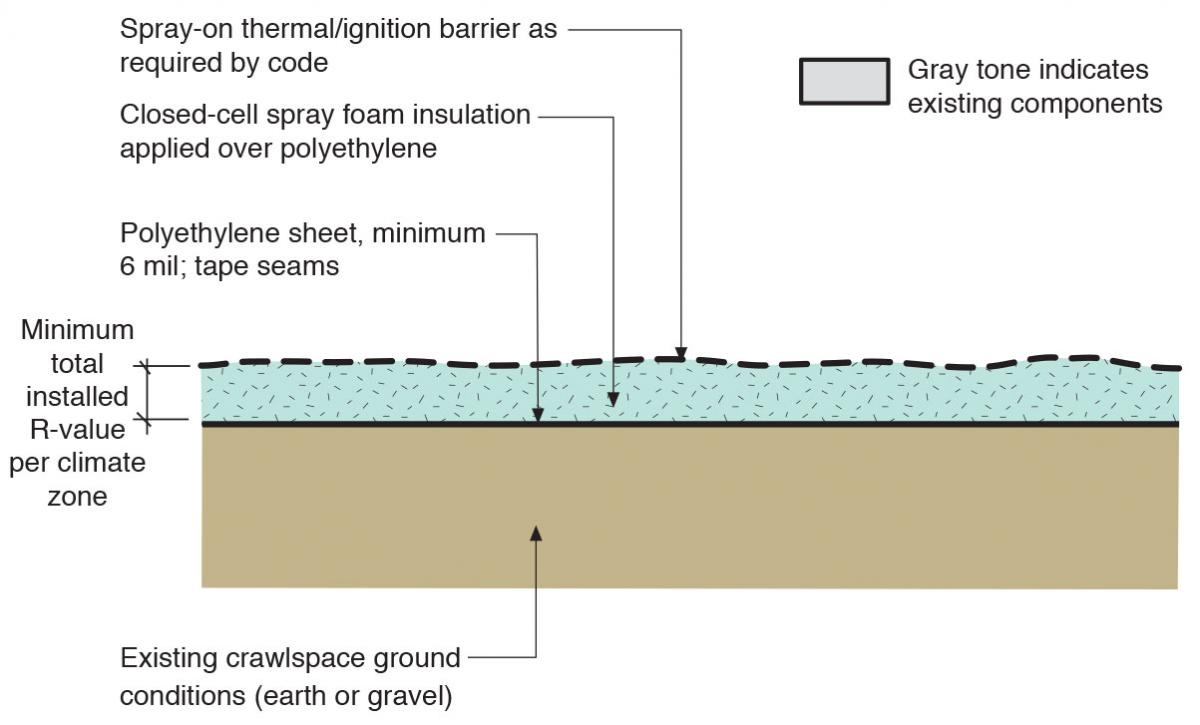

Closed-cell spray foam can be installed over a polyethylene vapor barrier directly onto the crawlspace floor as shown in Figure 2. This crawlspace floor assembly should not be used under a (future) concrete slab. This assembly is not appropriate in a crawlspace that needs to be accessed frequently.

How to Install Closed-Cell Spray Foam over Dirt/Gravel

- Install drainage pipe and a sump pump that pumps to daylight away from the house or to the sewer system if there is history of flooding or pooling water in the crawlspace.

- Level the existing ground cover (earth or gravel). Slope to drain if a drainage system needs to be installed.

- Install radon mitigation system if needed.

- Install a continuous 6-mil polyethylene sheet with seams taped.

- Install closed-cell spray foam over polyethylene. See Figure 2.

- Apply spray-on thermal/ignition barrier as required by code.

Groundwater Control for Crawlspaces

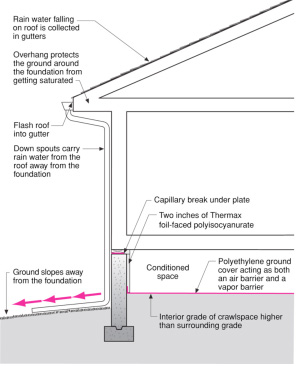

Keep rain water away from the foundation perimeter (See Figure 3).

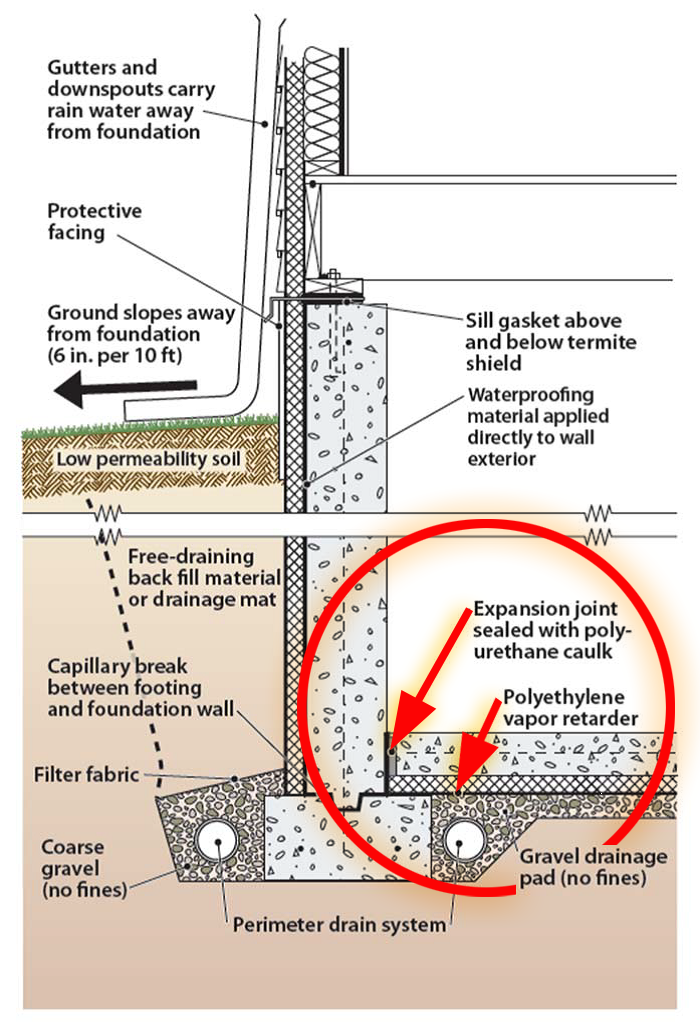

Crawlspaces should have perimeter drainage just like a basement when the crawlspace ground level is below the ground level of the surrounding grade. If there is a history of flooding or water leakage in the crawlspace and there is no functioning perimeter drainage system, a drainage system (e.g., an interior drain or gravel layer connected to an interior sump pit) must be installed under this assembly. See Figure 4. Also see the guide Drain or Sump Pump Installed in Basements and Crawlspaces.) An interior sump pit must have an airtight and gasketed cover. (See the guide Gasketed/Sealed Sump Pump Covers.)

Success

Level out the gravel/earth surface in the crawlspace for installation.

Install radon-mitigation pipe venting system if needed.

Perform any water needed water control measures before installing floor covering.

Overlap the seams of the polyethylene by at least 6 inches and secure with tape.

Install various assembly layers in a continuous manner around all penetrations such as piers and supports. Also lap up walls and around piers and secure with furring strips and fasteners, tape, or mastic.

Climate

The crawlspace floor assembly should be designed for a specific hygrothermal region, rain exposure zone, and interior climate.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Figure 2. Climate Zone Map from IECC 2021. (Source: 2021 IECC)

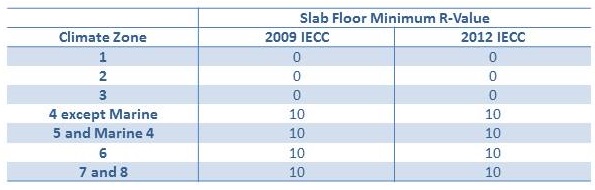

The insulation levels should be based on the minimum requirements for vapor control in the current adopted building code and the minimum requirements for thermal control in the current energy code. Additional insulation can be added above these minimums to create high R-Value floor assemblies. The table below provides the minimum thermal resistance (R-value) requirements for slab floors specified in the 2009 IECC (ICC 2009b) and the 2012 IECC (ICC 2012b), based on climate zone.

Table 1. Minimum R-Value Requirements for Slab Insulation. (Source: 2009 IECC and 2012 IECC)

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

High-R Foundation Insulation = High-Efficiency or Ultra-Efficient Foundation Insulation

There are two levels of foundation insulation: high-efficiency insulation, which meets the 2015 International Energy Conservation Code, and ultra-efficient insulation, which is 25% more efficient than this national code. Using high-efficiency and ultra-efficient insulation, along with professional installation (e.g., no gaps, voids, compression, or misalignment with air barriers; complete air barriers; and minimal thermal bridging) creates conditioned spaces that require very little heating and cooling, along with, even comfort and quiet throughout the house.