Scope

All crawlspaces should have a ground covering of polyethylene sheeting that serves as a capillary break and vapor barrier to keep ground moisture and soil gases from entering the crawlspace where they can be pulled into the home through cracks in or around the subfloor.

- Use ≥ 6-mil polyethylene sheeting.

- Lap any seams in the sheeting by 6 to 12 inches and seal the seams with a continuous bead of acoustical sealant, butyl rubber, or butyl acrylic caulk, or with tape manufactured to seal or patch polyethylene.

- Seal the sheeting around any pipes coming up from the ground.

- Lap sheeting up walls and piers at least 6 inches and attach to the walls or piers with mechanical fasteners. Or, secure sheeting to the ground by staking at the perimeters of the crawlspace.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Moisture in crawlspaces can cause harm to the home by promoting mold and rot along floor joists and rim joists. Moisture can enter a crawlspace if it migrates into the soil beneath the crawlspace then enters the crawlspace as liquid water or water vapor from the soil, which can then condense on floor joists. To prevent water or water vapor from entering the crawlspace, the crawlspace floor should be covered with a heavy polyethylene plastic capillary break that is sealed to the walls and piers to provide a continuous vapor barrier. This plastic ground cover should be installed regardless of whether the crawlspace is vented or unvented. This plastic covering will also help keep soil gases from entering the home. This task should be included in the contract for the appropriate trade depending on the workflow at the specific job site.

Moisture can enter a crawlspace from sources other than vapor from the ground. In vented crawlspaces, the dominant source of crawlspace moisture is bulk water intrusion from improper grading of the site, lack of perimeter drainage, improper irrigation practices, etc. See these other Building America Solution Center guides for more information about good water management practices around the home site: Final Grade Slopes Away from Foundation, Patio Slabs, Porch Slabs, Walks, and Driveways Slope Away from House, Gutters and Downspouts, and Footing Drain Pipe.

In humid climates, water vapor in warm outdoor air can enter through crawlspace vents and condense on cooler framing. In humid climates, building scientists recommend building insulated, unvented crawlspaces (see Unvented, Insulated Crawlspaces).

Because radon accumulation in a home cannot be measured until after the home is built, as an added precaution, consider installing a passive radon venting system, which collects soil gasses under the plastic and vents them through the roof via a vent pipe (see Vertical Radon Ventilation Pipe).

How to Install a Polyethylene Ground Cover

- Spread a layer of 6-mil or thicker polyethylene across the entire ground surface. Edges should lap up side walls.

- Overlap all seams by 12 inches and tape them. Ensure that surfaces where tape will be applied are clean and dry.

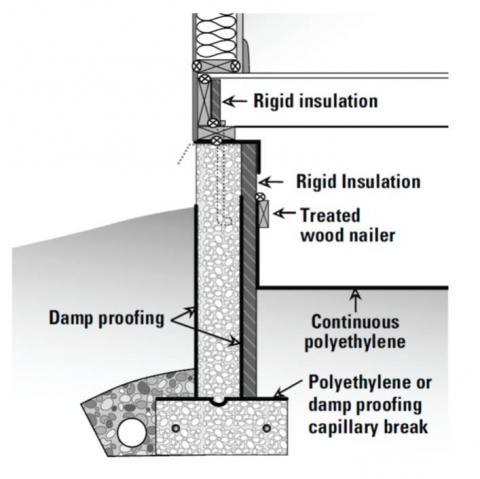

Attach the polyethylene to the walls at least 6 inches up the walls or to a height at least equal to the exterior ground level. Attach the polyethylene with pressure-treated wood furring strips or other mechanical fasteners. The edges can be sealed to the wall with fiberglass mesh tape and duct mastic. Or, secure the sheeting to the ground by staking at the perimeters of the crawlspace with landscape fabric stakes.

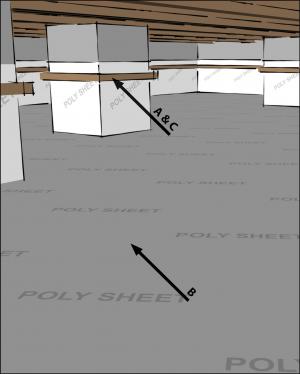

Figure 1. A continuous layer of polyethylene covers the crawlspace floor and is attached to the wall with wood nailing strips. - Lap the vapor retarder up the sides of any interior columns at least 4 inches above the crawl space floor; mechanically fasten the polyethylene to the pier and seal the edges.

- For added durability, consider one of the following:

- Lay one polyethylene groundcover at the beginning of construction. When construction is completed, install a second sheet over the first sheet to cover any rips in the first sheet (make sure the first sheet is dry and free of organic matter). Seal the top sheet to the walls.

- Lay a vinyl runner or extra plastic over any areas that will get traffic, such as a service path to the furnace.

- Cover the single sealed layer of polyethylene with a concrete slab 2 or more inches thick. (See the guide Capillary Break at Crawlspace Floor – Polyethylene Sheeting under Concrete Slab.)

Success

Visually inspect the crawlspace to ensure that the earthen floor is completely covered with a layer of polyethylene sheeting at least 6 millimeters thick, that the sheeting extends up the sides of each wall or pier and is mechanically fastened with wood furring strips or other fasteners, and that any seams in the plastic are overlapped 6 to 12 inches and taped or sealed.

Climate

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

Compliance

Retrofit

Investigate the crawlspace of an existing home to determine whether the home has a vapor barrier covering the crawlspace floor and what state it is in. If no vapor barrier is present, install one as outlined in the Description tab. If a 6-mil vapor barrier is present in the crawlspace but it is unsealed at the seams, or not attached to walls or piers, it may be possible to repair it by taping any tears, overlapping and taping any seams, and attaching pieces with house wrap tape or another compatible sealing tape to extend the vapor barrier up the walls. The barrier should be fastened to the walls and piers with furring strips or other mechanical fasteners as described in the Description tab. Another, more durable, option is to cover the existing vapor barrier with a new layer of ≥ 6-mil polyethylene then seal that layer at all seams and secure it to the walls and piers as described in the Description tab.

If any standing water, mold, rotten wood, or hazardous materials are present in the crawlspace, these conditions should be addressed before replacing the vapor barrier.

See the following Building America Solution Center guides for more information:

Radon guidance from EPA, HUD, NIH, OSHA, and FEMA can be found in Homeowner's and Renter's Guide to Reducing Radon After Disasters and Radon: Worker and Employer Guide to Hazards and Recommended Controls.

The U.S. Department of Energy’s Standard Work Specifications has additional information on moisture and vapor barriers in crawlspaces and worker safety in crawl spaces.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

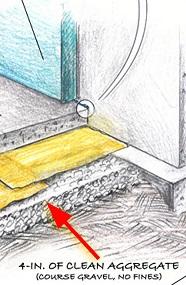

Foundation Capillary Break over Aggregate = Foundation Floor Water Barrier

Without an effective moisture barrier, water can penetrate the pores of a concrete foundation slab, which can potentially lead to moisture-related issues. To prevent moisture from wicking up into the concrete slab and foundation walls, a water-proof layer is installed under the concrete consisting of 6-mil plastic sheeting overlapped and taped at the seams or soil-contact-rated rigid foam taped at all seams. Under this barrier is a 4-inch layer of gravel to help moisture drain away. In crawlspaces, plastic sheeting should installed over the dirt floor.