Scope

Air-seal the floor above an unconditioned basement or crawlspace and make sure floor insulation is in full contact with this subfloor air barrier.

- Seal all seams, gaps, and holes in the subfloor air barrier with caulk or foam.

- Air-seal rim joists.

- Install insulation in floor joist bays without misalignments, compressions, gaps, or voids.

- Install supports to keep insulation in permanent contact with the air barrier above, for example, metal staves for batt insulation or netting for blown insulation.

- If spray foam insulation is used for the floor cavity insulation, the spray foam can serve as the air barrier if it is at least 5.5 inches thick if open-cell or at least 1.5 inches thick if closed-cell spray foam insulation.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Floors can account for one-fourth to one-third of the building enclosure’s surface area. When defects in the air barrier and insulation system exist, heat loss through floors over unconditioned basements or vented crawlspaces can cause uncomfortably cold floors and increases in space conditioning costs as well. Heat loss in floors can be caused by

- Conduction losses, also known as thermal bridging, when heat transfers through framing members dues to a lack of insulation

- Air leakage, due to the lack of an effective air barrier or unsealed holes in the air barrier

- Misalignment of the air barrier and thermal barrier, which allows gaps to exist, for example between batt insulation and the drywall, which allow air to flow in wall cavities due to convective currents or holes in the air barrier, which rob the insulation of its effectiveness (EPA 2011).

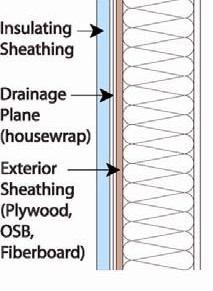

To prevent these heat losses, the insulation layer in the floor should be continuous and consistent and should be completely aligned with (in continual contact with) the air barrier separating the house from the unconditioned space below. When basements or crawlspaces are uninsulated the air barrier is typically the subfloor, which consists of plywood or OSB. Any holes around plumbing wiring, etc., in the subfloor must be sealed.

Note, best practice in all climates is to connect the crawlspace or basement to the house by air-sealing and insulating along the walls of the basement or crawlspace and providing air exchange between the house and the basement or crawlspace to condition that space. See the guide Air Sealed, Insulated Basements and the article Crawlspaces - Either In or Out by Joe Lstiburek (BSC 2020). This should especially be considered in homes located in hot humid climates and in cold climates where HVAC equipment and plumbing pipes will be located in the crawlspace (especially in cold climates) or if the basement may be used for living space, the crawlspace or basement should be insulated along the walls rather than in the ceiling to include these areas within the thermal envelope of the home. The thermal envelope consists of the continuous air barrier and thermal barrier/insulation which surround the home's walls, ceilings, and foundation. (See the guide Continuous Air Barrier in Exterior Walls for more information.) However, if HVAC equipment is not located in the basement and plumbing lines can be protected, it might be reasonable to establish the thermal and pressure boundary in the floor above the basement, rather than along the foundation walls.

How to Insulate and Air-Seal the Floor above an Unconditioned Basement or Crawlspace

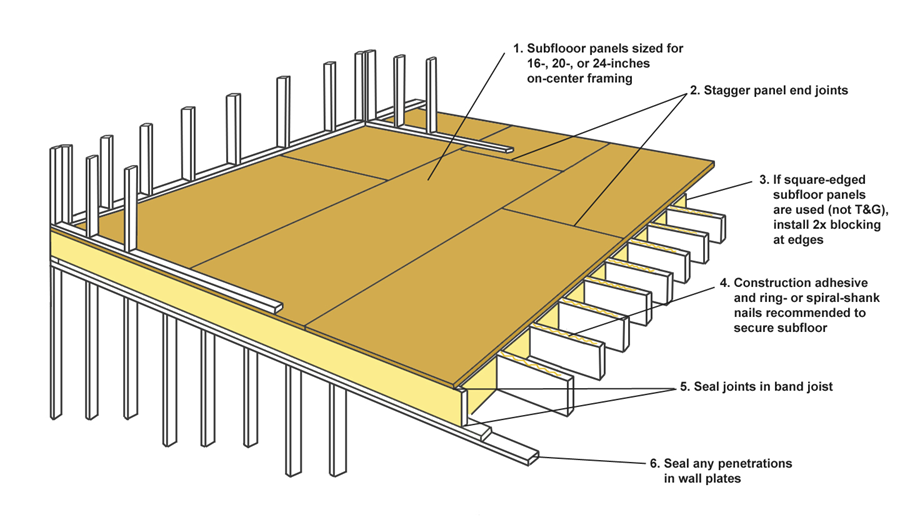

- Install a subfloor that can serve as a continuous air barrier between the crawlspace or basement and the house above. In most cases, this air barrier will be plywood or OSB floor sheathing. Install the subfloor sheathing panels as follows (APA 2011):

- Install subfloor in panel widths that align with the framing (typically 16-, 20-, or 24-inches on-center).

- Stagger subfloor panel end joints.

- Use tongue-and-groove subfloor panels or install blocking beneath panel joints.

Apply construction adhesive or caulk at panel seams and between subfloor panel and framing members.

Figure 1. Seams in the subfloor are sealed with construction adhesive so that the subfloor can serve as an air barrier separating the garage from the living space above.

- Air-seal the band and rim joists and any penetrations.

- Block off any open floor joists running from the crawlspace to under other conditioned parts of the home. Use a rigid air barrier material and seal the edges with spray foam. Batt insulation is not a good air barrier. See the guide Garage Rim/Band Joist Adjoining Conditioned Space for more information.

- Seal around any mechanical penetrations such as piping, wiring, or ducts. Use rigid foam or plywood plus spray foam for large holes, as shown in Figure 2 (EPA 2011).

Seal the rim joists with rigid foam cut to fit and caulked or spray foamed at edges to seal in place (Figure 3). Rim joists can also be air-sealed and insulated in one step using spray foam insulation. To qualify as an air barrier, open-cell or closed-cell foam must have a finished thickness greater than or equal to 5.5 inches or 1.5 inches, respectively (EPA 2011). Batt insulation can be added over spray foam or rigid foam but should not be installed alone as it is not an air barrier (Figure 4).

Figure 2. All mechanical and plumbing penetrations through the subfloor need to be air-sealed.

Figure 3. Seal and insulate rim joists with rigid foam board cut to fit and sealed with foam or caulk.

Figure 4. Batt insulation is not an effective air barrier.

- Install insulation in the floor joists.

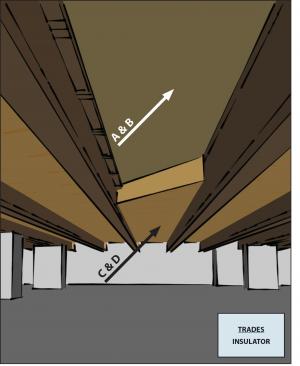

- Insulation should be fully "aligned" with the air barrier, i.e., in full contact with the subfloor above. There should be no gaps between the insulation and the sheathing above it like those seen in Figure 5.(EPA 2011).

- Batt insulation should fit tightly between the floor joists but avoid gaps, compressions, or voids. Batts should be fully lofted (not crammed or compressed into the space). Batts should be cut lengthwise to fit narrow joist bays, and split to fit neatly around electrical wiring running across joist bays. See the guide Insulation Installation Achieves RESNET Grade 1 for more on quality installation.

Spray foam insulation can be used to insulate the floor above a crawlspace or basement as well as the band joist. Spray foam provides high R-value and a continuous air barrier in one labor-saving application. To qualify as an air barrier, open-cell spray foam must have a finished thickness ≥ 5.5 inches and closed-cell spray foam must have a finished thickness ≥ 1.5 inches (EPA 2011).

Figure 5. Without wire stays or metal support rods, this batt insulation will not stay fully aligned with the subfloor air barrier.

- Support the insulation. Install metal staves or mechanically fastened wire to keep batts in continuous contact with the subfloor above.

Success

Blower door testing, conducted as part of whole-house energy performance testing, may help indicate whether air leakage at through the floor has been successfully sealed.

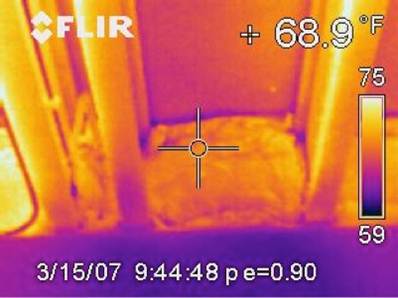

Infrared imaging. An infrared camera may also be used to determine air leakage through the floor over a garage if a sufficient temperature difference exists between the outdoors and the conditioned space above the garage. For best results, scan twice – first under static conditions before blower door testing has been conducted. This will allow the technician to evaluate the integrity of insulation behind the drywall, if the garage ceiling has been finished. Conduct a second scan with the blower door running in depressurization mode and the door between the house and the garage open. This will demonstrate the integrity of the air barrier, showing where air leakage has infiltrated the framing and seeped through insulation.

The infrared image below shows the rim joist area. Typically the darker areas indicate the areas that are the coldest, and represent the greatest amount of heat loss. Here, where the insulation meets the subfloor and the I-joists, you can see dark purple spots. These spots indicate heat loss or air leakage. These areas are where you want to be sure you air-seal before you insulate.

Diagnostic smoke. With the blower door pressurizing, the garage door closed, and the door to the house open, check for air leaks in the floor and near the rim joist with a smoke pencil. A smoke trail moving away from the smoke pencil indicates a leak to the outdoors that should be sealed.

Climate

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

CAD

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Fully Aligned Air Barriers = Whole-House Draft Barrier

A whole-house draft barrier is a continuous layer of air-tight materials that block air leaks. This barrier can be integrated with other materials to also function as a water barrier, thermal barrier, and vapor barrier. For example, rigid foam insulation can be used to block thermal flow as well as air flow when seams are sealed with tape, caulk, adhesives, or liquid-applied sealants. Some rigid foams have an integrated water control layer as well. Additionally, drywall can serve as an interior air barrier when the seams are taped and spackled, and caulk, spray foam, or gaskets are used to seal around wiring, plumbing, and other penetrations. It also serves as the vapor barrier when finished with paint. Insulation should be in full contact with the air barrier layer.