Scope

Install insulation without misalignments, compressions, gaps, or voids along the thermal envelope of the house.

All ceiling, wall, floor, and slab insulation should achieve Grade I level insulation installation criteria as defined by the Residential Energy Services Network (RESNET).

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Gaps, voids, and compressions that cause the insulation to lose contact with the surface it is intended to insulate can cause cold spots in walls, ceilings, and floors. These cold spots may encourage the formation of condensation in the wall cavity, floors, or ceilings.

The Residential Energy Services Network (RESNET) grades insulation installation quality in its Home Energy Rating System Standards, with Grade 1 being the best installation (RESNET 2013).

Grade 1 Installation requires that insulation material should uniformly fill wall cavities, filling each cavity from side to side and top to bottom, without substantial gaps or voids around obstructions. Batt insulation should be cut to fit around any wiring or piping installed in the wall cavities.

Blown insulation, such as loose fiberglass, cellulose, or mineral wool fibers, flows easily around obstructions, such as wiring and piping, to provide complete coverage in the cavities. To install blown insulation, the open cavities are first covered with a netting that is stapled to the stud faces. A slit is cut in the netting in each cavity and the insulation is installed with a hose inserted through the slit. The installer can easily see where the insulation is going to ensure that each cavity is completely filled without voids.

Spray foam is another option that readily fills areas around obstructions in wall cavities, and it has the advantage of providing both air sealing and insulation. The foam completely fills the open wall cavities and is trimmed flush with the stud faces before installing dry wall. Spray foam insulation is made of petroleum, soy, or castor oil-based polyurethane and is available in open-cell, low-density products or closed-cell, high-density products. Both insulate and air seal; high-density products can also provide a vapor barrier. Another option is sprayed-on cellulose or mineral wool that is mixed with adhesive and water then sprayed into the open cavities and allowed to dry before drywalling.

Additional information about insulation, including descriptions of the many types of insulation available, their R-values, applications and advantages and disadvantages of each kind, and installation guidance can be found in the Building America Best Practices Series Volume 17: Insulation, A Guide for Contractors to Share with Homeowners.

How to Install Insulation to RESNET-Defined Grade I

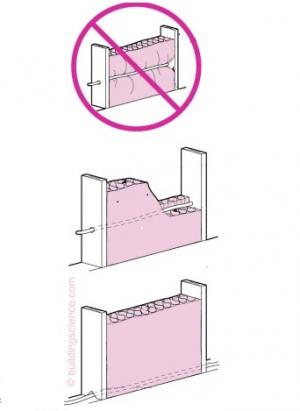

Install insulation without misalignments, compressions, gaps, or voids in all wall cavities along the thermal barrier of the house. Figure 1 shows proper installation of batt insulation without gaps or voids. Figure 2 shows incorrect installation; the insulation was not cut to fit around wiring so the insulation will not be in full contact with the drywall along the length of the wall cavities.

Figure 1. Unfaced fiberglass batt insulation is installed to completely fill the wall cavities and is sliced to fit around wiring, piping, and other obstructions in the wall cavities. (Source: PNNL and ORNL.) Figure 2. This faced fiberglass batt insulation was incorrectly installed; it should be cut to fit around wiring and obstructions so that it can completely fill the wall cavity without compressions and voids. (Source: PNNL and ORNL.) Install wall insulation so that it is enclosed on all six sides in each wall cavity. It should completely fill the wall cavities as shown with the blown fiberglass insulation in Figure 3, the blown cellulose in Figure 4, and the spray foam in Figure 5. It should be in substantial contact with the sheathing material on at least one side (interior or exterior) of the cavity.

Figure 3. Blown fiberglass insulation fills netted wall cavities and flows easily around wiring and other obstructions to provide a uniform insulating layer without gaps or voids. (Source: PNNL and ORNL.)

Figure 4. Blown cellulose insulation completely fills the netted wall and ceiling cavities and flows easily around wiring and other obstructions to provide a uniform insulating layer without gaps or voids. (Source: PNNL and ORNL.) Figure 5. Spray foam insulation is installed in open wall cavities to air seal and insulate. (Source: PNNL and ORNL.) Faced batt insulation should be stapled to the surface of framing (Figure 6). Side-stapling is permitted, provided the tabs are stapled neatly (no buckling), the batt is only compressed at the edges of each cavity to the depth of the tab itself, and the batt meets the other requirements of Grade I.

Figure 6. Faced fiberglass batt insulation can be stapled to the stud faces or slightly inset, but avoid compressing the batts and slit the insulation to fit around wiring and other obstructions. (Source: PNNL and ORNL.) Install slab edge insulation for slab-on-grade floors if the floor surface is less than 12 inches below grade and if required by code in your climate zone. Slab insulation should extend to the top of the slab to provide a complete thermal break (Figure 7). If the insulation is installed between the exterior wall and the edge of the interior slab, the insulation may be cut at a 45-degree angle away from the exterior wall, allowing the poured slab concrete to cover and protect the top edge of the insulation.

Insulating the slab edge will keep the floor warmer and reduce the potential for condensation and elevated relative humidity by allowing the inside surface temperature of the slab perimeter to more closely track the home’s interior temperature. If the slab is monolithic with a grade beam (Figure 7), the insulation is installed on the exterior of the slab edge/grade beam and continues vertically to the bottom of the grade beam. Use insulation material that is appropriate for ground contact such as XPS, rigid fiberglass, or rigid rock wool and use insect controls appropriate for the region. The above-ground portion of the rigid foam should be protected from UV and impact damage with coated fiber cement board.

Figure 7. Rigid foam slab edge insulation is installed along the exterior edge of a monolithic slab foundation. (Source: PNNL and ORNL.)

When the slab is independent from the perimeter foundation wall, insulation may be installed either on the exterior of the foundation wall or between the foundation wall and the slab (Figure 8), which provides more protection for the insulation from the elements. When the insulation is between the foundation wall and the slab, it forms a bond break and it should also extend horizontally under the slab either at the perimeter or under the entire slab.

Figure 8. Rigid foam forms an insulating bond break between the foundation wall and the slab. (Source: PNNL and ORNL.) - Where an insulated wall separates a garage, patio, porch, or other unconditioned space from the conditioned space of the house, install slab insulation to provide a thermal break between the conditioned and unconditioned slab. Where specific details cannot meet this ENERGY STAR Ver. 3, Rev 11. requirement, provide the detail to EPA to request an exemption prior to the home’s qualification.

Success

Home energy raters are required to inspect and probe in, around, or through the insulation and/or vapor retarder in several places to see whether insulation is installed to RESNET Grade 1 standards. During inspection, insulation and vapor retarders may be cut or pulled away so raters can see installation details. The raters should replace or repair the vapor retarder and insulation as necessary. During inspection (typically before drywall is installed), if the exterior sheathing is visible from the building interior through gaps in the cavity insulation material, it is not considered a Grade I installation.

Typical R-values for common insulation materials are summarized in this table, which also identifies the vapor retarder classification for each insulation.

Climate

The amounts of insulation that must be installed in various building components are specified by code and vary by climate. The U.S. Department of Energy Building Energy Code Program identifies the building codes currently in force for each state.

For more information on the insulation levels required in the 2009 and 2012 International Energy Conservation Code (IECC), which are specified by climate zone, see the 2009 and 2012 IECC Code Level Insulation – ENERGY STAR Requirements and 2015 IECC Code Level Insulation – DOE Zero Energy Ready Home Requirements.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Insulation Quality Installation =

Poorly installed insulation can result in higher heating and cooling costs, comfort problems, mold and other moisture problems. Professionally-installed insulation meets industry best practices as specified for Grade 1 installation by the Residential Energy Services Network (RESNET). This includes no gaps, voids, compression, or misalignment with air barriers; complete air barriers; and minimal thermal bridging. This creates conditioned spaces that require very little heating and cooling, along with even comfort and quiet throughout the house.