Scope

Select and install a whole-house fan to reduce or eliminate air-conditioning.

- Assess the benefits and drawbacks of a whole-house fan based on local climate, air quality, occupant needs, and code requirements.

- Select which type of whole-house fan to install (traditional, insulated joist-mount fan, ducted, or roof mounted).

- Size the fan based on house size, climate, and cooling strategies.

- Ensure adequate venting is installed in the attic.

- Ensure adequate openable window area is installed in the house.

- Air-seal the ceiling below the attic.

- Air-seal all walls and floors separating the living space from the garage, crawlspace, or other unconditioned areas with potentially unhealthy air.

- Follow manufacturer’s instructions to install the whole-house fan, paying close attention to air sealing the ceiling penetration.

- If not included with the product, construct insulated covers or dampers for the fan and/or ceiling vent to reduce heat loss or gain when the fan is not in use.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

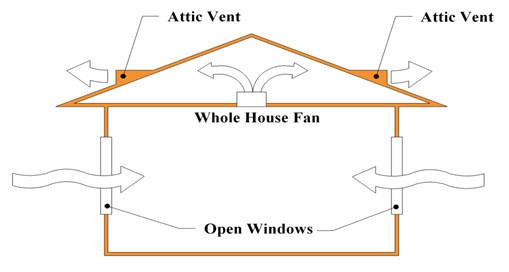

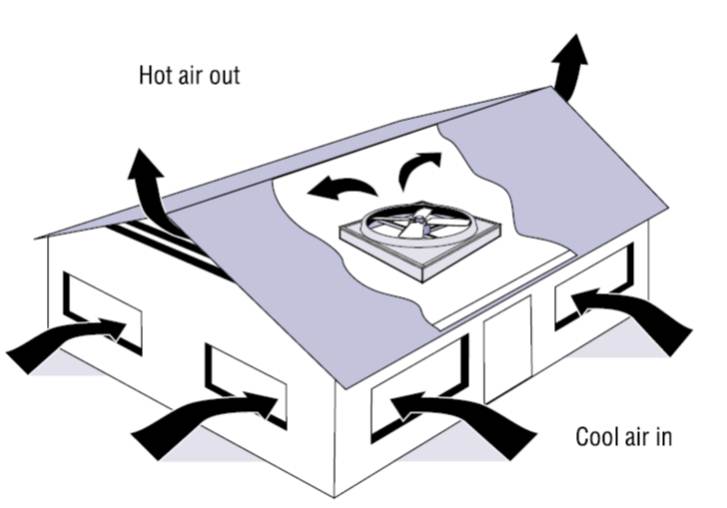

A whole-house fan is a fan installed in the ceiling (usually) to help cool the house by drawing air in through open windows at times when the outside air is cooler than the inside air. The fan pulls hot air out of the house and blows it into the vented attic (Figure 1), or the fan can be ducted to vent directly outdoors.

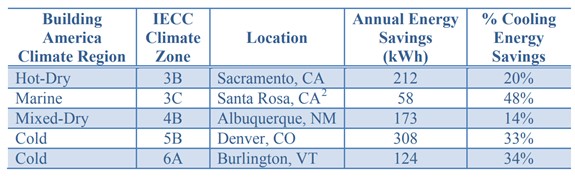

Whole-house fans can provide an economical alternative to air conditioning (see Table 1). They provide cooling by exhausting warm air from the house, pre-cooling the thermal mass of the house, and increasing airflow across the skin of occupants. See the Passive and Low-Energy Cooling guide for information on cooling strategies using whole-house fans. Whole-house fans should not be used at the same time as air conditioning. However, they can be used to reduce A/C usage at night or during the milder parts of the cooling season.

Whole-house fans are effective in all climates, but are best suited to climates where the nighttime temperatures during the cooling season are lower than about 67°F, and the temperature difference between the daytime high and the nighttime low is more than about 25°F (Givoni 1991). The fan or intake grille should be located on a horizontal ceiling at or near the center of the house, for example at the top of the stairs in a two-story house. When necessary, some fan models can be installed vertically in exterior walls or attic knee walls.

Controlling Whole-House Fans

Whole-house fans can be operated by an on/off switch, multi-speed control, and/or timer control. Controllers can be wall-mounted or remote. Regardless of control mechanism, the occupant must ensure windows are open before turning the fan on.

Automatic control of whole-house fans based on indoor and outdoor conditions is possible. This type of control would require sensors and a controller to automatically switch the fan on and off. Just as importantly, however, automatic control would require an automated way to let air in when the fan is turned on. This would mean automatically controlled windows or intake vents, or intake vents with gravity dampers. Such vents and dampers could result in year-round energy waste through leakage and conduction. Due to complexity, cost, and the potential for energy waste, automatic control of whole-house fans is generally not recommended. Off-the-shelf automatic control options that overcome these obstacles may become available in the future.

In all non-humid climates, the basic control strategy for a whole-house fan is to turn the fan on when the temperature outside is lower than the temperature inside, and to turn it off when the reverse is true.

If the home is located in a humid climate, the same strategy can usually be applied as long as air-conditioning is not present or not used. In these regions, there may be times when the high humidity of the outdoor air makes it uncomfortable or undesirable even when the outside temperature is lower than the inside temperature. In these situations, it is up to the occupants to decide whether they prefer the fan on or off. It is never recommended to operate a whole-house fan when the outside air temperature is higher than the inside air temperature, as this can cause moisture issues within the home.

It is not recommended to operate a whole-house fan in coordination with air-conditioning in a humid climate. Moving back and forth between A/C and whole-house fan operation will lead to situations where the whole-house fan can actually increase the load on the air-conditioning system due to the highly humid air it can introduce. This is because air-conditioning not only cools air but dries it out as well. This drying of the air takes a significant amount of energy. If very humid air is brought into the home, the next time the A/C comes on it will spend energy removing that humidity. In humid regions, the best approach is to keep the air-conditioning off and use the whole-house fan when the seasonal temperatures allow (generally spring and fall). Once the summer becomes hot enough to call for extended air-conditioning, the whole-house fan should be kept off until seasonal temperatures cool down again. During in-between periods when nights are cool but A/C is used during the day, a simple rule of thumb can help determine whether or not it will be beneficial to operate the whole-house fan at night in a humid climate. If the nighttime temperature will be at least 10°F cooler than the daytime inside air, then it will generally be fine to operate the whole-house fan during the night.

Types of Whole-House Fans

Traditional Whole-House Fans

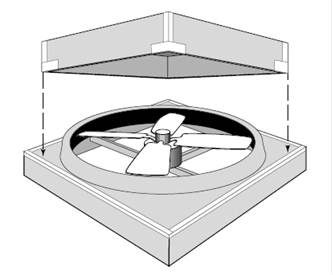

Traditional whole-house fans were mounted in the ceiling and pulled air directly upward from the living space into the attic. They often required a ceiling joist to be cut because they were too large to fit between joists. Uninsulated gravity dampers would open due to airflow when the unit turned on (Figure 2). These fans developed a reputation of being noisy and very leaky in the winter.

Insulated Joist-Mount Whole-House Fans

Ceiling-mounted whole house fans with insulated dampers were developed to fit between standard joists, making installation much easier than larger traditional models. These fans come with well-insulated dampers, greatly reducing heat loss as compared to traditional models (Figure 3). The dampers are motorized to open when the fan is in use and close when the fan is off. Airflows for these units are typically lower than the larger traditional whole-house fans or the newer ducted styles.

Ducted Whole-House Fans

Ducted whole-house fans are a newer design that uses a short, curved, acoustic duct to greatly reduce the transmission of noise to the living area (Figure 4). These units are typically hung from the roof framing to reduce vibration. The ceiling-mounted intake is designed to fit between joists. They come with insulated dampers and a high-efficiency motor. This design overcomes most of the issues consumers have had with traditional fan assemblies.

Roof-Mounted Whole-House Fans

Roof-mounted whole-house fans are a modification to the modern ducted designs. In this design, the fan is mounted to the roof, then ducted to the ceiling of the conditioned area (Figure 5). The curved acoustic duct greatly reduces the transmission of noise to the living area. These fans also have insulated dampers at the ceiling level and a high-efficiency motor for the fan.

Sizing and Venting Recommendations

Whole-house fans are sized in terms of the amount of airflow they provide. This is measured in cubic feet per minute (CFM). The Home Ventilating Institute has a standard rating test for determining the CFM output of whole-house fans. This test is known as HVI-916. When assessing any fan, it is important to use the CFM rating as determined by HVI-916, not necessarily the CFM value advertised by the manufacturer. The California Energy Commission maintains the Modernized Appliance Efficiency Database System, which includes a product list of fans which have been rated based on HVI-916. Fans and their official ratings can be found by searching this list.

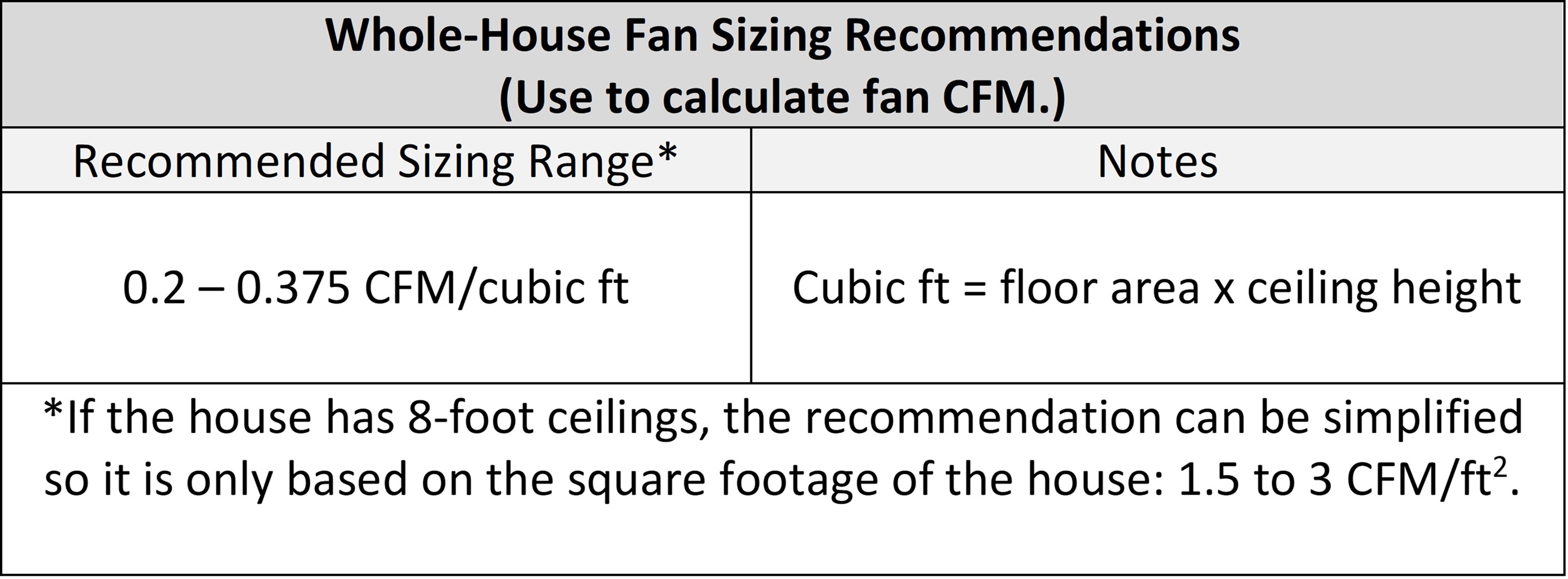

Sizing recommendations for whole-house fans can vary widely. The size of a fan should depend on climate, house size, the cooling strategy, and other factors. Code requirements, manufacturer recommendations, and field studies have indicated that 12 – 23 air changes per hour (ACH) can be effective (DOE 2012, CEC Title 24 2019 , FBC 2020, PG&E 2004 , FSEC 1986, FSEC 1992). This equates to about 0.2 to 0.375 CFM per cubic foot of conditioned area (floor area times ceiling height). For a house with 8-ft ceilings, this equals about 1.5 to 3 CFM/ft2 of floor area. Most recommendations are on the higher end of these ranges. Table 2 summarizes the recommended sizing range.

Sizing approaches for whole-house fans vary widely, but the range shown in Table 2 can narrow the field of options.

When determining whether to select at the higher or lower end of the recommended range, consider factors like local nighttime temperatures, the house’s solar and internal gains, and what cooling strategies are planned. See the Passive and Low-Energy Cooling guide for descriptions of ventilation cooling strategies. Flows on the higher end of the range may be needed for areas where night temperatures are warmer or for houses with high solar or internal gains. On the other hand, selections on the lower end of the ranges may be appropriate where night temperatures are lower, where a house is well-shaded, and/or where the homeowner wants to minimize noticeable airflow.

As an example, consider a 1,500 ft2 home with 9-ft ceilings. The volume of conditioned space is equal to the floor area times the ceiling height, or 13,500 cubic ft. Using the recommended range from Table 2, the owner should select a fan with a capacity higher than 2,700 CFM (13,500 cubic ft x 0.2) but lower than 5,060 CFM (13,500 cubic ft x 0.375). The house has large, poorly shaded west-facing windows, and local nighttime temperatures do not dip much lower than the mid-60s in the summer, so the owner chooses a fan closer to the upper end of the range, perhaps 4,500 CFM (HVI-916). Using a variable or multi-speed fan allows more flexibility when choosing and operating a whole-house fan.

Most whole-house fans blow air from the house into the attic. To be certain the attic can properly vent this air to the outside, it is recommended to have at least 1 ft2 of net-free vent area per 750 CFM of airflow (DOE 1999). Insect screens and louvers will reduce the net-free area of a vent by about 50%. If your attic vents have screens, the rule of thumb would simply be to double the calculation above, making it 2 ft2 of total vent area per 750 CFM of airflow. Extra vent area is fine, but too little vent area will reduce overall airflow and potentially push hot attic air back down into the house. See the following guides for more information on attic venting: Calculating Attic Passive Ventilation; Vented vs Unvented Attic; Attic Air Sealing, Insulating, and Ventilating for Ice Dam Prevention; Construct Roofs and Attics for Ice Dam Prevention; Condensation Control in Attics and Roofs in Cold Weather; Disaster-Resistant Roof Venting.

Enough open window area must also be provided to ensure proper operation (Figure 6). It is recommended to open at least 4 ft2 of screened window area per 1,000 CFM of airflow (DOE 2012). Only the open area of the window should count when doing this calculation. The open area of sliding windows, for instance, will typically be only 1/3 to 1/2 of the total area of the window. Other nighttime cooling equipment is available that uses electronic controls and a dampered outside air intake ducted to the home’s central air handler to draw in, filter, and automatically circulate cool nighttime air without opening windows.

Potential Issues

Because whole-house fans can draw large amounts of air out of the home (rated airflows from 1,000 to 10,000 CFM are typical), the whole-house fan can quickly depressurize the house if there are not enough windows open. It can also pull in unhealthy air from the garage or crawlspace. It is therefore important to ensure that all potential air leaks between the home and the garage, crawlspace, or other source of unwanted air are properly air sealed to prevent drawing air in from those locations.

Depressurization by whole-house fans can cause issues with gas- or propane-fired equipment. Combustion appliances that draw room air for combustion or have a standing pilot light are not recommended inside homes where a whole house fan will be operating. Combustion appliances should be sealed combustion with their combustion air coming from outside. Furnaces without a standing pilot light are acceptable if a switch is installed to prevent the whole-house fan from operating simultaneously with the furnace (DOE 2012). It is important that windows are open and fireplace doors and dampers are closed before turning on the fan.

If whole-house fans are operated during times when it is warmer outside than inside, humidity issues can arise inside wall, roof, and floor assemblies or in the living space itself. This is particularly the case in the more humid regions of the country. Warm, humid air pulled in from the outside by a whole-house fan can condense on the cool surfaces of a structure if it has been cooled by air-conditioning. This can allow mold to grow. Only operate a whole-house fan when the temperature outside is cooler than the temperature inside and when the air-conditioning is turned off. In humid climates, do not operate the A/C for at least several hours before or after the whole-house fan is turned on.

When the fan is off during the winter months (and in summer when air conditioning is used), a whole-house fan represents a potential energy loss due to leakage and thermal losses through the dampers. Units must be carefully installed such that the ceiling remains well-sealed and insulated when they are not in use. These details are less challenging for newer designs (Figure 7) but are a particular issue for traditional whole-house fan designs. If the fan does not come with a well-insulated damper or cover, an insulated cover should be purchased or constructed for it. The cover will have to be removed by the owner during seasons when the fan is in use, so the design should be constructed so that it can be opened and closed from inside the house without accessing the attic. Alternatively, if attic access is not an issue, an insulated cover can be constructed that installs on the attic side of the fan.

Since whole-house fans exhaust air into the attic (pressurizing the attic) it is also important to air seal between the house and the attic to prevent attic air from leaking back into the house (DOE 2012).

Noise can also be a concern. Choosing a ducted fan with a curved or coiled flexible duct section between the fan and the occupied space can significantly reduce noise. A fan with multiple or variable operating speeds allows noise control as well as airflow control. Finally, whole-house fans can bring in pollen, dust, humid air, smoke, or pollution, and can be a security concern due to open windows.

HOW TO INSTALL AND AIR SEAL A WHOLE-HOUSE FAN

- Verify adequate ventilation in the attic, thorough air sealing of the home’s building envelope (particularly between the living area and the attic, crawlspace, and garage), that no combustion appliances are located in the attic, and that no atmospheric-vented combustion appliances are located in the home (DOE 2012).

- Determine a location for the fan on a horizontal ceiling at or near the center of the house, for example at the top of the stairs in a two-story house.

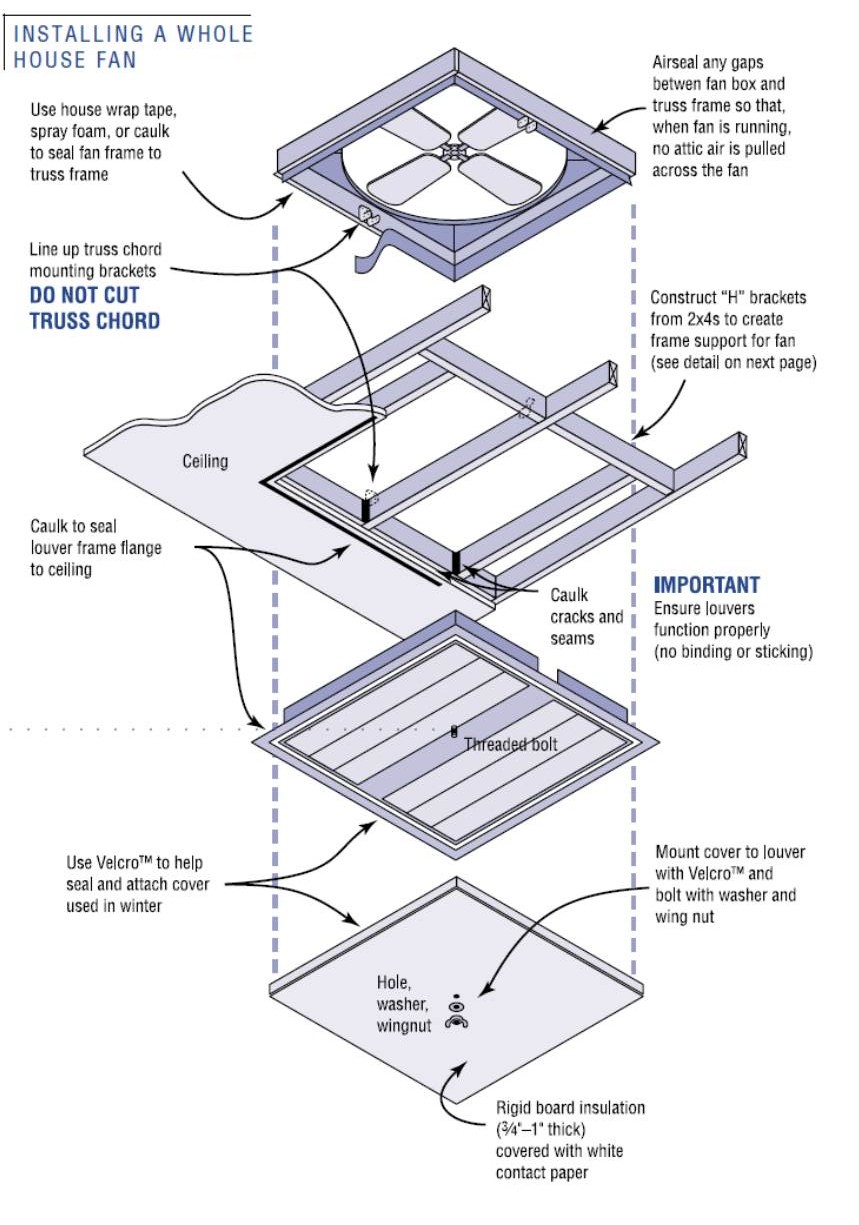

- Select a fan that will fit the ceiling joist spacing, i.e., one that is either 16 inches or 24 inches wide. For ducted fans, only the damper box must fit between joists. Do not cut ceiling joists to install the fan. Verify that there is a circuit available for connecting power to the fan. If the fan has an insulated cover that opens into the attic, verify that the cover will have room to open. Install the fan prior to blowing attic insulation.

- Frame out the ceiling joists (or lower truss members) to the size required by the fan manufacturer. Use framing lumber that matches the depth of the ceiling joists.

- Cut the drywall opening no larger than required for the fan, as the louver frame or grill will not cover the cut-out edges. Some manufacturers provide templates for this purpose.

- Seal the joints between the frame-out and the ceiling drywall with spray foam or caulk. Inspect the fan or damper box itself and seal any noticeable gaps. Use foam weather stripping or spray foam to create a seal between the fan or damper box and the frame-out and drywall.

- Position the fan or damper box on or in the frame-out as required and secure it in accordance with the manufacturer’s instructions.

- If using a ducted unit, the fan should be suspended from the roof framing such that it is above the insulation level and the duct will be curved (Figure 8)

- Wire the whole-house fan and controls according to the manufacturer’s instructions.

- At the ceiling below the fan, install the louver frame or grille.

- If using a traditional style fan, install plywood or manufacturer-supplied material around the fan box to prevent loose fill insulation from falling into the fan (DOE 2012).

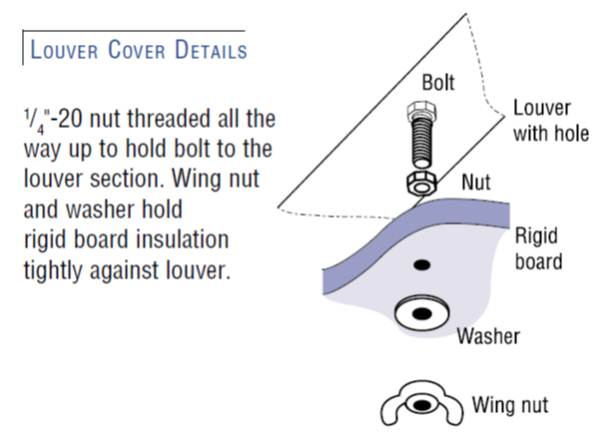

- If the whole-house fan does not have a built-in insulated damper/cover, construct a cover that attaches to the ceiling side of the fan. Use rigid foam, Velcro, or a threaded bolt and wingnut (Figures 9 and 10).

- If using a traditional style fan, purchase or construct a fan cover for the attic side of the fan. Make a box-shaped cover from rigid foam insulation and foil tape. Weather strip the bottom edge. Attach a tag to the underside of the fan reminding the homeowner that the attic-side cover is in place and must be removed during operation. (Figure 11).

Success

Inspect the whole-house fan to ensure that it is equipped with an insulated and gasketed cover on the house side or an insulated cover on the attic side that can be mechanically opened and closed from the house side. Some localities will not permit a whole house fan to be installed if a furnace is located in the attic or if there is a combustion appliance in the home that derives its combustion air from either the attic or the inside of the home unless the homeowner:

- encloses the combustion appliance so that it obtains combustion air from outside the home;

- ducts the whole house fan directly to the exterior; or

- provides a switching device that allows only one of the appliances (fan or furnace) to be on at a time (Davis 2001).

The home’s building envelope must be thoroughly air sealed to prevent outside air, especially from the garage, crawlspace, or attic, from being drawn into the house during fan operation. The attic must have adequate venting.

Climate

Whole-House fans can be effective in any climate, but they are more appropriate for dry climates than humid ones. As a general rule, climates that have nighttime lows below about 67°F during the cooling season (or shoulder seasons, if operated only then) and day-to-night temperature swings of about 25°F or greater are ideal for whole-house fans (Givoni 1991).

IECC climate zones 3B, 4B, and 5B are very well-suited to the use of whole-house fans. Zones 2B, 3C, 4C, and 6B are good candidates as well. Zones 4A through 6A and up to 8 can also make effective use of whole-house fan strategies, but humidity can be a concern. Historically, the southeastern regions made extensive use of whole-house fans for cooling before air-conditioning was in common use; however, Zones 1A through 3A would likely gain less benefit from whole-house fans due to higher humidity and higher nighttime temperatures.

In all humid regions, there may be times when the high humidity of the outdoor air makes it uncomfortable or undesirable to operate a whole-house fan even when the outside temperature is lower than the inside temperature. In these situations, it is up to the occupants to decide whether they prefer the fan on or off.

It is not recommended to operate a whole-house fan in coordination with air-conditioning in a humid climate. Moving quickly back and forth between A/C and whole-house fan operation will lead to situations where the whole-house fan can actually increase the load on the air-conditioning system due to the high-humidity air it can introduce. This type of back-and-forth operation with A/C also invites moisture-related issues such as mold and rot.

During periods when nights are cool but A/C is used during the day, a simple rule of thumb can help determine whether or not to operate the whole-house fan at night in a humid climate. If the nighttime temperature will be at least 10°F cooler than the daytime inside air, then it will generally be fine to operate the whole-house fan during the night and allow the A/C to come on during the day when needed.

Overall, humidity issues can be largely avoided by only operating the whole-house fan when it is warmer inside the house than outside, and when the A/C will not be on for at least several hours before or after the whole-house fan is operated.

Training

Compliance

Retrofit

SCOPE

In existing homes, air seal a whole-house fan to minimize air leakage to and from unconditioned attic spaces.

- If adding a new whole-house fan, see the Description tab.

- If air-sealing an existing fan, inspect and repair or replace any existing cover or air sealing for the whole-house fan, as needed. Then follow the guidance on the Scope and Description tabs.

For more information on conditions that may be encountered when working in existing attics, see the Pre-Retrofit Assessment of Attics, Ceilings, and Roofs. Also see the U.S. Department of Energy’s Standard Work Specifications (SWS) guidance on air sealing whole-house fans.

COMPLIANCE

Alterations

2009 IECC and 2009 IRC, 2012 IECC and 2012 IRC

2012 IECC, Section R101.4.3 / 2012 IRC N1101.3 and 2009 IECC 101.4.3 / 2009 IRC N1101.4.3 Alterations – General. Alterations to an existing building or portion of a building should comply with the provisions of the code as they relate to new construction without requiring unaltered portion(s) of the existing building to comply with this code.

2015 IECC and 2015 IRC, 2018 IECC and 2018 IRC

2015 IECC/2015 IRC, Section R501.1.1/N1107.1.1 Existing Buildings – General. Alterations to an existing building or portion of a building should comply with Sections R502/N1108, R503/N1109, or R504/N1110. Unaltered portions of the existing building are not required to comply.

R503.1/N1109.1 Alterations. General. Alterations to any building or structure should comply with the requirements of the code for new construction. Alterations should not negatively impact conformance of a building or structure to the provisions of this code; that is, code conformance should be the same as existed for the building or structure prior to the alteration. Alterations should not create an unsafe or hazardous condition or overload existing building systems. Alterations should be such that the altered building or structure uses no more energy than the existing building or structure prior to the alteration.

N1110.1 (R502.1) General. Alterations to any building or structure should comply with the requirements of the code for new construction. Alterations should not negatively impact conformance of a building or structure to the provisions of this code; that is, code conformance should be the same as existed for the building or structure prior to the alteration. Alterations should not create an unsafe or hazardous condition or overload existing building systems. Alterations should be such that the altered building or structure uses no more energy than the existing building or structure prior to the alteration.

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.