Scope

Design a ventilation and exhaust system for multifamily dwelling units and common spaces that complies with all relevant codes and standards and provides adequate indoor air quality.

- Perform preliminary planning:

- Determine what code or program requirements must be met, including local or state code, programs such as ENERGY STAR or Indoor airPLUS, and ASHRAE 62.2.

- Determine appropriate ventilation rates based on local code or above-code programs.

- Determine appropriate local exhaust rates for kitchens, bathrooms, and other areas where exhaust is required.

- Assess heating and cooling systems, including duct work – especially if the ventilation system may be integrated with a central air handler or if indoor humidity control is needed.

- Select an appropriate ventilation system that complies with the applicable codes, programs, or standards.

- Design the system, taking into account ventilation supply needs, exhaust needs, and exhaust makeup needs.

- Install and commission the ventilation system.

See the Compliance tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

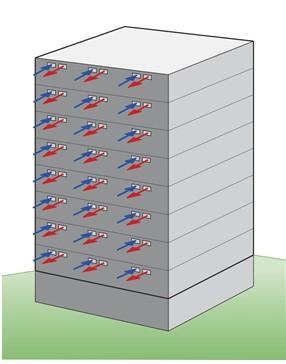

This guide provides ventilation and exhaust strategies for dwelling units and common spaces in multifamily buildings (Figure 1). For an overview of whole-building ventilation systems in new single-family homes, see the Building America Solution Center Guide Whole-House Ventilation Strategies for New Homes. For existing single family homes, see the guide Whole-House Ventilation Strategies for Existing Homes; also see the Pre-Retrofit Assessment of Ventilation Systems. The Solution Center also contains installation guides for a variety of ventilation and air handler components. For information on indoor air quality, a common reason that people install ventilation systems, see the ASHRAE Residential Indoor Air Quality Guide (Schoen et al. 2018).

Ventilation: Supply and Exhaust

There are two primary aspects to any ventilation system: supply of outside air, and exhaust of inside air. Air cannot enter a space without air also leaving the space, and air cannot leave a space without air entering to replace it. A designer should be intentional about how air enters and leaves a space. Ways that outside air can be provided to a space include supply fans, dedicated outdoor air systems (DOAS), energy recovery ventilators (ERVs), air handler intake vents, passive intake vents, or infiltration. Ways that air can be exhausted from a space include local exhaust fans, ERVs, air handler exhaust vents, passive vents, or exfiltration.

Ventilation systems can rely on supply fans only, exhaust fans only, or both supply and exhaust fans. When ventilation is provided by exhaust fans only, air is forced to enter the space by infiltration through cracks and gaps in the walls, windows, and other areas of the envelope. Similarly, when ventilation is provided by supply fans only, air is forced to exit the space by exfiltration through cracks and gaps in the envelope. When ventilation is provided by both supply and exhaust fans flowing at the same rate, infiltration and exfiltration are not induced. This is known as balanced ventilation, and may be required by some codes and programs.

An early step for a designer is to study the applicable codes, programs, and standards to learn the ventilation airflow requirements. Most state codes as well as programs such as ENERGY STAR reference the ASHRAE 62.1 and 62.2 standards for residential and commercial ventilation. These standards contain tables for ventilation requirements, such as Table 4.1A from ASHRAE 62.2-2010, which is referenced by ENERGY STAR Multifamily New Construction Versions 1/1.1/1.2.

Local Mechanical Exhaust

All occupied spaces require general ventilation, but only certain spaces require local exhaust for the targeted removal of contaminants and odors (e.g., bathrooms and kitchens). Local exhaust can be intermittent, where an exhaust fan is on only part of the time, or continuous, in which the fan runs all the time. Local exhaust must be considered as part of the overall ventilation strategy. Ventilation and local exhaust are interrelated, even though they may have separate flow requirements and may use separate equipment. Again, most codes and programs reference ASHRAE 62.1 and 62.2 standards for residential and commercial ventilation. These standards contain tables for local exhaust requirements for specific space types, such as Table 5.1 from ASHRAE 62.1 2010.

Compartmentalization

Compartmentalization is the term used to describe approaches to control air flow between units in multifamily buildings. The basic concept is to treat a multifamily building as a group of single-family units that are stacked on top of and next to one another (Figures 2 and 3). Compartmentalization prevents air from one unit from entering other units, reducing the transfer of odors, poor-quality air, smoke during a fire event, and contaminants. Compartmentalization is a necessary first step in any well-functioning multifamily ventilation strategy. See the guide Air-Sealing and Compartmentalization in Multifamily Buildings for information on how to achieve effective compartmentalization.

Central Ventilation Systems vs Individual Unit Systems

Ventilation can be provided via central systems, where a single air-distribution system supplies and/or exhausts multiple dwelling units, or via individual unit systems where each dwelling unit has its own isolated system, similar to a single-family home.

Central systems can be more complex to design, maintain, service and operate. However, they also tend to be less expensive in initial construction cost than individual unit systems in multistory buildings where large numbers of units are involved.

Central systems can have difficulty providing individual unit ventilation based on individual unit needs. For example, central systems typically assume all units have tenants and as a result often over ventilate. This results in increased energy usage. Where central systems are used it may be desirable to decouple units from the central systems when the units have no tenants – when units are vacant. This can be accomplished with a damper that closes when the unit is vacant. However, this design approach introduces the possibility of neglecting to open the damper again when an apartment is reoccupied. Further, if the ventilation flow rates to each apartment building are hard-balanced rather than automatically balanced by constant airflow regulators, the system will not adjust properly to the closing and opening of individual unit dampers. Note that whatever approach is implemented the approach must meet applicable code requirements and program requirements.

Where central systems are used in multistory buildings it is necessary to thoroughly seal ductwork. Riser (supply and return) ductwork leakage is a significant energy penalty. In addition, it is necessary to air seal vertical service shafts at each floor level.

Many central systems rely on a DOAS, which must condition the outdoor air directly. If an ERV isn’t used, this approach lends itself to fossil fuel as the heating source because the extreme entering air temperatures can be a challenge for a heat pump. With individual systems, outdoor air is often mixed with air handler return air before being conditioned. This tempers the air and can allow in-unit heat pump systems to be used more readily.

Regular maintenance of individual unit systems can be more straightforward than central systems, but may be challenging simply due to the numbers of units needing to be maintained. For example, a 100-unit building may have 100 filters to change and 100 screened intakes that need to be kept clear. These systems may require entry into occupied apartments for filter changes. Maintaining screened intakes that are several stories off the ground adds an additional challenge, particularly if they can’t be accessed from a balcony.

In some cases, central systems may better dehumidify and precondition air prior to supplying individual units.

Individual unit systems require large numbers of penetrations in exterior facades (Figures 4 and 5). The 2021 IRC specifies requirements for locating ventilation air intakes and exhausts in Section M1504. The 2021 IBC defers to the 2021 IMC for similar requirements, which are found in sections 401.4 and 403. Check your local codes for requirements in your jurisdiction.

Venting Kitchen Exhaust to the Exterior

Recirculating kitchen range hood fans do not provide effective contaminant removal and odor control. Kitchen range hood fans should be exhausted to the exterior. However, where large kitchen range hood fans are installed, they can lead to excessive depressurization of individual units. Large kitchen range hood fans that exhaust to the outside in multifamily construction should be provided with interlocked make-up air ducts or passive air inlets. According to ASHRAE Standard 62.2 – 2022, the minimum recommended intermittent exhaust ventilation rate for a kitchen range hood fan is 100 cfm. Note that make-up air is not required by ENERGY STAR or most local building codes when lower cfm exhaust vented range hood fans are installed (less than 400 cfm).

Intermittent vs Continuous Ventilation

Continuous ventilation when units are occupied provides more effective contaminant control and odor control and allows for lower airflow rates than intermittent ventilation. A lower continuous airflow rate is more effective than a higher intermittent airflow rate.

Note that local intermittent kitchen exhaust is typically significantly higher than the required occupant ventilation rate; it should be considered separately from occupant intermittent vs continuous ventilation.

Exhaust vs Supply vs Balanced Ventilation

Exhaust-only ventilation without provision for make-up air at the ASHRAE Standard 62.2 – 2022 rates leads to significant depressurization in units that are constructed to meet the 2021 IRC or ASHRAE Standard 62.2 – 2022 air tightness requirements. This can pull air from corridors and adjacent dwelling units, especially if the exhaust-only systems are intermittent rather than continuous. If intermittent, one unit may be highly depressurized while adjacent units are not, based on whether or not each unit’s exhaust fans are running. This can lead to large pressure differences between units, driving the transfer of air. Exhaust-only ventilation in multifamily construction should be provided with make-up air. One approach is to provide passive air inlets (Figure 6).

Supply-only ventilation for multifamily construction at the ASHRAE Standard 62.2-2022 rates leads to significant pressurization of units. This has the unintended consequence of driving air into corridors and potentially neighboring units, resulting in potential odor and contaminant transfer. As with exhaust-only ventilation, intermittent ventilation is particularly problematic. One approach to address significant pressurization is to provide passive air outlets.

Balanced ventilation strategies address depressurization and pressurization issues in multifamily construction without the need for passive air inlets or outlets. Balanced strategies also provide the option for energy recovery or heat recovery in high performance multifamily construction.

Part-Load Humidity Control

In mixed-humid climates and hot-humid climates (IECC Climate Zones 1A through 4A) supplemental dehumidification is necessary in units that are constructed to meet the 2021 IRC where the sensible cooling load has been dramatically reduced. Many air conditioning systems do not have sufficient dehumidification capability for multifamily units ventilated at ASHRAE Standard 62.2 – 2022 rates in mixed-humid climates and hot-humid climates. With the low cooling loads of well-sealed and insulated multifamily units, the air conditioning system may not run long enough to provide sufficient dehumidification. Separate systems may be required.

Energy Recovery Ventilation (ERV) vs Heat Recovery Ventilation (HRV)

A heat recovery ventilator (HRV) transfers heat between incoming and outgoing streams of air whereas an energy recovery ventilator (ERV) transfers both heat and moisture (Figure 7).

At the ventilation rates recommended for multifamily units by ASHRAE Standard 62.2 – 2022, excessive humidity may occur in mixed-humid and hot-humid climates thereby requiring supplemental dehumidification. In cold climates excessive dryness may occur when multifamily units are ventilated according to ASHRAE Standard 62.2 – 2022, thus requiring humidification. To reduce the need for dehumidification and humidification, energy recovery ventilators (ERV’s) should be considered.

Note that ERVs do not make a space drier or more humid than it already is. They simply help maintain the existing humidity level within the building enclosure. They prevent the excessive dryness or humidity that could be caused by the high ventilation rates necessary to control indoor contaminants.

During the summer in mixed-humid and hot-humid climates the indoor air in a dwelling is typically cooler and drier than the outdoor air due to the operation of the mechanical systems. When this conditioned indoor air is exhausted to the exterior through an energy recovery ventilator (ERV) its “coolness and dryness” are transferred to the incoming hot and humid air making the incoming hot and humid air cool and dry. This approach significantly reduces the energy consumption of the multifamily unit.

During the wintertime in cold climates, indoor air is typically warm and humid as compared to outdoor air due to the operation of the mechanical systems providing heating and the occupants providing humidification by breathing, cooking, and washing. When this conditioned indoor air is exhausted to the exterior through an energy recovery ventilator (ERV) its “warmness and humidness” are transferred to the incoming cold and dry air making the incoming cold and dry air warm and humid. This approach typically reduces or eliminates the need for humidifiers and reduces energy consumption. Note that humidifiers can be significant contaminant sources if distilled water is not used and if the humidifiers are not cleaned on a weekly basis.

Ventilation System Options

There are many possible configurations for providing ventilation to individual dwelling units within a multifamily building. Systems can be “local,” “whole-home,” or “central,” where one system serves multiple dwellings. Several options are shown in Figures 8 through 16. Note that some options may not be allowed by code in some jurisdictions. For all configurations, the 2021 IRC specifies requirements for locating ventilation air intakes and exhausts in Section M1504. The 2021 IBC defers to the 2021 IMC for similar requirements, which are found in sections 401.4 and 403. Check your local codes for requirements in your jurisdiction.

Individual Unit Systems

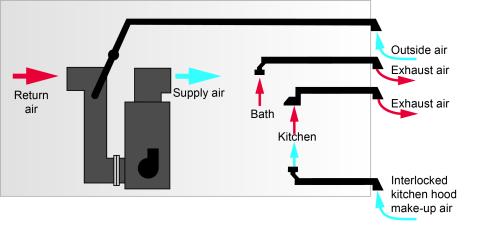

Forced Air – Outside Air to the Return Side of the Air Handler

See Figure 8. In this configuration, an outside air duct is connected to the return side of the air handler and the air handler operates continuously. The air handler is interlocked with a continuous bathroom exhaust fan. The air handler should have an ECM motor and variable speed fan. It typically does not need to always operate at full speed. The ventilation rate should be set by local code, the IRC, or by ASHRAE Standard 62.2. The rate at which outside air is brought in through the outside air duct is matched by the exhaust rate of the bathroom exhaust. This provides balanced ventilation and avoids significantly pressurizing or depressurizing the space.

For example, if 45 cfm is supplied via the outside air duct then the bathroom fan exhausts continuously at a rate of 45 cfm. If two bathrooms are in the unit then the exhaust rate is split between the two bathrooms. A single exhaust fan is used with an exhaust grille in each bathroom. Note that the IRC requires bathroom and toilet room mechanical exhaust capacity of at least 20 CFM when operated continuously. For intermittent operation the requirement is 50 CFM.

A vented kitchen range hood is ducted separately to the exterior and is interlocked with a separate make-up air duct, fan, or passive air inlet to maintain relatively balanced ventilation.

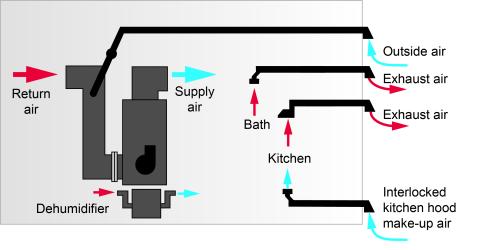

Forced Air – Outside Air to the Return Side of the Air Handler plus Supplemental Dehumidification

See Figure 9. This is the same system as shown above in Figure 8, but with supplemental dehumidification provided by a dehumidifier. The dehumidification can take many forms – from portable dehumidifiers hooked to a permanent drain to high-capacity whole-home systems that are central to the dwelling unit.

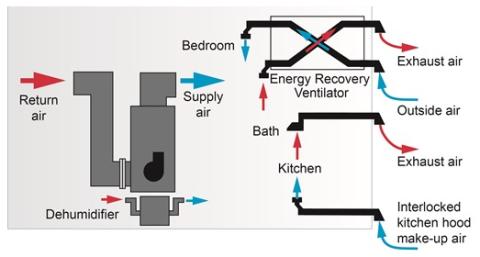

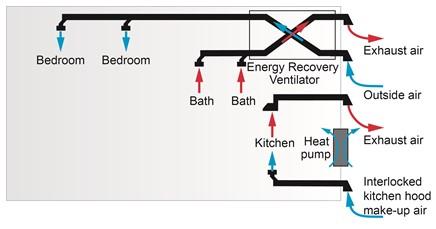

Forced Air – Energy Recovery Ventilator

See Figure 10. A fully ducted energy recovery ventilator (ERV) provides balanced ventilation independent of the forced air conditioning system. The ERV extracts air from the bathroom(s) and supplies air to the bedroom(s). The ventilation rate should be set by local code, the IRC, or by ASHRAE Standard 62.2.

A vented kitchen range hood is ducted separately to the exterior and is interlocked with a separate make-up air duct or fan or passive air inlet to maintain relatively balanced ventilation.

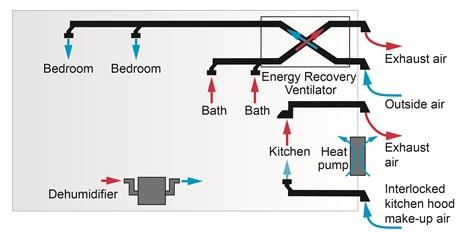

Forced Air – Energy Recovery Ventilator – Supplemental Dehumidification

See Figure 11. This is the same system as shown above in Figure 10, but with supplemental dehumidification provided by a dehumidifier. The dehumidification can take many forms – from portable dehumidifiers hooked to a permanent drain to high-capacity whole-home systems that are central to the dwelling unit.

Packaged Terminal Heat Pump – Energy Recovery Ventilator

See Figure 12. A fully ducted energy recovery ventilator (ERV) provides balanced ventilation independent of the packaged terminal heat pump (PTHP) conditioning system. The ERV extracts air from the bathroom(s) and supplies air to the bedroom(s). The ventilation rate should be set by local code, the IRC, or by ASHRAE Standard 62.2.

A vented kitchen range hood is ducted separately to the exterior and is interlocked with a separate make-up air duct or fan or passive air inlet to maintain relatively balanced ventilation.

Packaged Terminal Heat Pump – Energy Recovery Ventilator – Supplemental Dehumidification

See Figure 13. This is the same system as shown above in Figure 12, but with supplemental dehumidification provided by a dehumidifier. The dehumidification can take many forms – from portable dehumidifiers hooked to a permanent drain to high-capacity whole-home systems that are central to the dwelling unit.

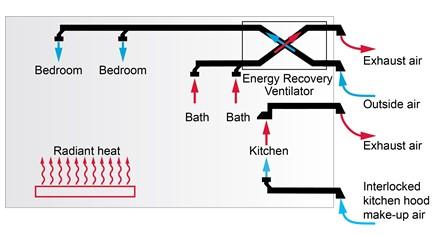

Radiant Heating – Energy Recovery Ventilator

See Figure 14. A fully ducted energy recovery ventilator (ERV) provides balanced ventilation. Heating is provided by a radiant heating system. The ERV extracts air from the bathroom(s) and supplies air to the bedroom(s). The ventilation rate should be set by local code, the IRC, or by ASHRAE Standard 62.2.

A vented kitchen range hood is ducted separately to the exterior and is interlocked with a separate make-up air duct or fan or passive air inlet to maintain relatively balanced ventilation.

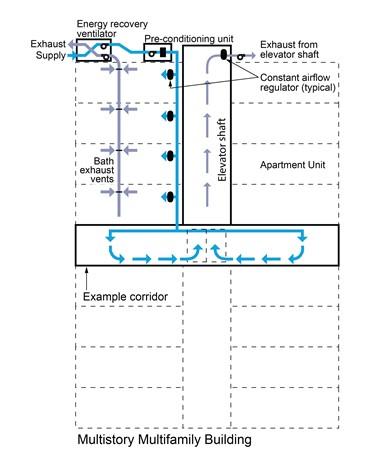

Central Ventilation Systems

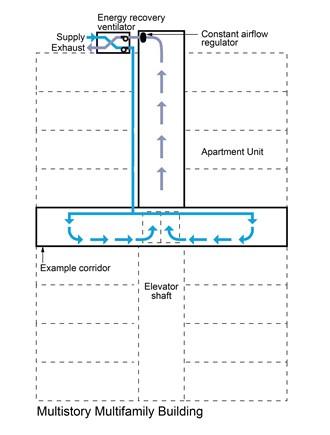

Central ventilation systems can serve both common spaces and individual dwelling units. Central system ductwork should be sealed to prevent duct leakage and floor-by-floor volume dampers should be provided coupled with constant airflow regulators (CAR) for each dwelling unit. CARs maintain a constant airflow rate across variable air pressure differences. Additionally, energy recovery is recommended through an ERV.

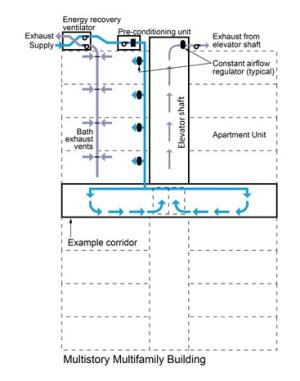

Figure 15 shows a central ventilation system providing ventilation to individual units as well as corridors. The individual units are exhausted via a central exhaust duct system connected to an energy recovery and pre-conditioning unit located on the roof. These ERV and pre-conditioning unit may be combined as a single unit or may be separate. This system supplies each dwelling unit with outside air such that each dwelling unit has balanced supply and exhaust flows. The ventilation system also supplies the corridors, which are then exhausted through the elevator shaft.

Common Area Ventilation

Common areas within multi-family buildings are typically corridors and separate meeting spaces or community rooms. Corridor ventilation is addressed in the guide Airflow Control in Elevator Shafts, Corridors, Stairwells, and Trash Chutes in Multifamily Buildings. Community rooms should have separate, balanced, ERV systems.

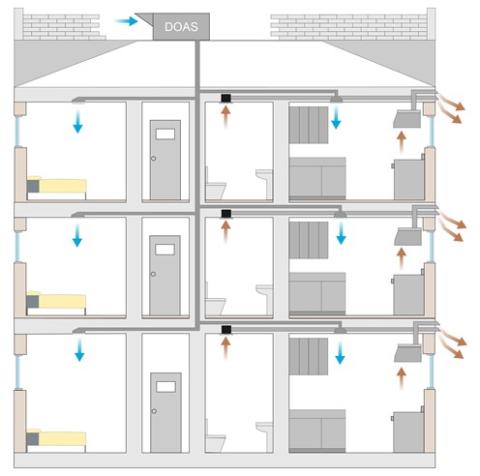

Figure 16 shows a central system that ventilates corridors and exhausts the elevator shaft using a central energy recovery ventilator. This configuration does not provide supply air to or exhaust air from individual dwelling units.

Success

All exhaust and supply systems should be commissioned. Airflow exhaust and supply rates should be verified by testing. Control and adjustment of flow rates should be provided by utilizing balancing dampers, controlled and actuated dampers, or constant-airflow dampers.

Climate

In mixed-humid climates and hot-humid climates (IECC Climate Zones 1A through 4A) supplemental dehumidification is necessary in units that are constructed to meet the 2021 IRC where the sensible cooling load has been dramatically reduced. Many air conditioning systems do not have sufficient dehumidification capability for multifamily units ventilated at ASHRAE Standard 62.2 – 2022 rates in mixed-humid climates and hot-humid climates, so separate dehumidification systems are needed.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

The following authors and organizations contributed to the content in this Guide:

Building Science Corporation

Pacific Northwest National Laboratory