Scope

Plan a successful installation of integrated consumer heat pump water heaters (HPWH) to supply domestic hot water in a multifamily residential building.

- Learn why multifamily buildings present additional challenges for HPWHs and how to overcome those challenges.

- Choose between a one-to-one or clustered approach.

- Size the HPWHs appropriately.

- Use installation locations that will ensure a smooth installation, efficient water heater operation, and occupant comfort.

See the Compliance tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

This guide provides strategies for successfully using integrated consumer heat pump water heaters (HPWH) in multifamily buildings. In this guide, the term “integrated consumer HPWHs” refers to the standard HPWHs found in home improvement stores that are typically used in single-family homes (Figure 1). In multifamily applications, these HPWHs are installed either individually in each dwelling unit (one-to-one) or using a clustered approach where each individual HPWH serves just a few dwelling units. This guide builds on information about consumer HPWHs presented in the guide Heat Pump Water Heaters for Single-Family Homes. That guide provides a valuable background for using this guide. For guidance on using centralized heat pump water heating systems for multifamily buildings, see the Central Heat Pump Water Heaters for Multifamily Buildings.

Heat pump water heaters work by pulling heat from the surrounding air and moving it to the water stored in the tank to provide domestic hot water (DHW). Integrated refers to the fact that the heat pump’s compressor and heat exchanger are integrated into one unit attached to the water storage tank. These models are often called “hybrid” water heaters because they combine heat pump technology with traditional electric resistance hot water technology. Consumer water heaters have storage volumes and heating capacities that are appropriate for a household. Throughout this guide, “HPWH” refers to integrated consumer HPWHs.

Compared to a centralized water heating system, using consumer water heaters in multifamily homes:

- Reduces the length of hot water runs.

- Can simplify utility billing.

- Allows the use of off-the-shelf equipment.

- Avoids complicated control systems.

- Allows water heating systems to be maintained and serviced by residential plumbers.

- Does not require a dedicated mechanical room for water heating.

Using consumer water heaters rather than centralized water heaters in multifamily buildings is an appealing approach for owners of smaller buildings and buildings that don’t have dedicated maintenance staff. It is most popular in small- to mid-size multifamily buildings, those with seven or fewer floors.

Deployment Options for Consumer Water Heaters in MUltifamily Buildings

Options for deployment of consumer water heaters in multifamily buildings include one-to-one and cluster deployments.

One-to-One Deployment

When using consumer water heaters in multifamily homes, a common approach is a one-to-one deployment, i.e., installing one HPWH for each dwelling unit. This is the simplest deployment from a billing standpoint, if tenants will be paying for their domestic hot water.

Cluster Deployment

Another approach is for each HPWH to serve “clusters” of two to four dwelling units. The clustered approach can minimize the amount of floorspace required for water heating and can reduce the cost of both initial HPWH purchase and operating costs.

The cluster approach can be a bit more difficult to plan for than a one-to-one approach. It also means that any problems with one HPWH will affect multiple units. The water heaters should be located as close as possible to the hot water uses in the dwellings. For a three-story building, this could mean placing the HPWH on the second floor to serve the dwellings adjacent, above, and below. The HPWH should be installed in a common area such as off a corridor or in a stairwell so its filter can be easily serviced by building maintenance personnel. Additionally, depending on jurisdiction, cluster deployments may require the metering of hot water use by dwelling. If required, approaches such as those traditionally found in central water heating systems, like sub-metering devices, can be used.

Issues with Heat Pump Water Heaters in Multifamily Homes

There are things building owners need to plan for when installing heat pump water heaters.

Space Limitations

Compared to single-family homes, floor area in multifamily dwelling units is typically much more limited. HPWH installation plans must be as compact as possible to remain practical.

Sound Irritation

HPWHs produce noise when running that some residents find irritating and it may be difficult to physically distance the water heater from residents within the sometimes smaller footprint of a multifamily dwelling. Therefore, sound control should be considered.

Air Cooling Effect

When running, HPWHs produce a cool, dry exhaust. As with sound, this creates a challenge for ensuring resident comfort in small dwellings.

Condensate Drain

Heat pump water heaters do need to be located where the condensate line can be safely drained, typically to a floor drain, utility sink, or clothes washer drain pipe. It is sometimes possible to drain condensate to the landscape rather than the plumbing system. The discharge location will need to be able to absorb or dissipate the condensate and heat tape may be necessary to prevent freezing and blocking of the drain line. Draining to the exterior is not an appropriate option if the drain lines will be at risk of freezing, if frozen condensate could create a slipping hazard (e.g., on a sidewalk), or if condensate water would be a nuisance in any other way (e.g., dripping on decks or outdoor equipment). Locating the HPWH in a room with a floor drain and water-resistant flooring is also a wise precautionary measure in the unlikely event of a water leak, a risk shared by all types of water heaters.

Sizing

Every HPWH has a First Hour Rating (FHR) which reflects its water delivery capacity. FHR is a measure of the number of gallons of hot water the water heater can deliver in one hour, starting with a fully heated tank. It is a more useful measurement for choosing a water heater than the size of the tank, especially when comparing different heating technologies. Refer to the guide Heat Pump Water Heaters for Single-Family Homes for more sizing information.

Sizing for One-to-One Deployments

Sizing a HPWH for one-to-one installations can be done simply by making an estimate of the minimum FHR needs of the dwelling unit and selecting a model that exceeds that minimum.

Sizing for Clustered Deployments

Sizing for a clustered approach uses the same principles but can be more complex. Changing the number and size of dwelling units in a cluster changes the combined FHR minimum that will need to be met by a single shared HPWH. The range in FHR ratings of HPWHs allows for different combined maximums. The layout of the building can also place limitations on which units can be clustered together.

Typically, 65- and 80-gallon HPWHs can serve two or three units. Additional guidance can be found in Table 7 of the American Society of Heating Refrigeration and Air Conditioning Engineers (ASHRAE) Handbook – HVAC Applications 2019, Chapter 51, Service Water Heating.

Cluster deployments typically involve longer average hot water runs than one-to-one designs. The plumbing design measures described in the guide Heat Pump Water Heaters for Single-Family Homes can be especially beneficial in these cases. Vertical-stack clusters can help minimize run lengths. To minimize hot water delivery time to units, it may be necessary to use a circulation loop and pump. To simplify the design, circulate the loop only to the entry point to the unit, not within the unit, and operate the loop pump with an occupant-activated button from within the unit, not continuously, on a timer or with an aquastat. Unnecessary circulation seriously degrades HPWH efficiency and can jeopardize hot water delivery, so attempts should be made to design the hot water piping layout to eliminate the need for recirculation systems. This might impact the size and shape of clusters, location and layout of bathrooms, pipe sizing, pipe layouts, etc.

Here is a recommended approach to sizing a HPWH for cluster deployment:

- Identify a range of specific HPWHs with different FHRs to consider for the project.

- Make an estimate of each dwelling unit’s minimum FHR requirement.

- Using floorplans, look for ways to cluster units that:

- Minimize the total number of HPWHs required while ensuring that each HPWH’s FHR is at least as great as the sum of the FHR requirements of the units it serves.

- Allow the placement of HPWHs where their sound and exhaust can be mitigated.

- Keep hot water lines short and minimize supply line volume so that circulation loops are not required.

Elevated Storage Set Point Temperatures

It is possible to increase hot water delivery capacity by increasing the storage setpoint temperature. This allows you to store more heat in the same amount of water. However, for the safety of users, a thermostatic mixing valve must be installed to add cold water to the water leaving the water heater so that the plumbing system delivers water at a safe temperature. Buying and installing these valves significantly increase costs and can increase the total amount of space required for installation. Further, using higher setpoint temperatures reduces efficiency and can accelerate aging of the tank. In most cases, it is preferable to choose a larger water heater than to use a higher setpoint.

Small-Space Installation Strategies

In rooms smaller than 450 ft3, (for example, 7ft x 8ft with an 8ft ceiling), a HPWH is likely to operate much less efficiently than in larger spaces. In multifamily buildings, HPWHs are often installed in smaller spaces and it is therefore commonly necessary to ventilate those spaces. The passive and active ventilation techniques described in the guide Heat Pump Water Heaters for Single-Family Homes are appropriate for multifamily.

Designs that use exterior air as the thermal resource can be particularly useful for multifamily in the right climates. The HPWH can be installed in a closet-sized room that is part of the structure but outside its thermal envelope. For example, the closet could be located along an exterior wall or corner; the closet walls adjacent to the interior would need to be insulated. In hot and warm climates, a passive ventilation technique can be used to exchange air with the exterior. In moderate climates, active ventilation should be used. Alternatively, ducts attached to the HPWH’s intake and exhaust can be run to the exterior. (See the guide Heat Pump Water Heaters for Single-Family Homes.) Use appropriate terminations on the ducting to prevent the intrusion of water and pests. Ensure that the air is both drawn from and exhausted to the outside. If the air is taken from outside the thermal envelope and exhausted inside, or vice versa, it will create a pressure differential that will increase the building’s air leakage rate.

See the guide Heat Pump Water Heaters for Single-Family Homes for important details on equipment clearances that may affect the HPWH placement or the floorplan.

Locating a HPWH

The ideal location for a HPWH:

- Has ready access to a thermal resource.

- Is close to hot water uses.

- Can be acoustically isolated from bedrooms and living areas.

- Allows exhaust to be discharged where it is unlikely to cause discomfort.

- Is near a plumbing drain line to collect condensate.

Potential Locations

There are several potential locations for HPWHs in multifamily buildings: in closets within each dwelling unit; in closets on each dwelling unit's porch or balcony; in a corridor or breezeway closet outside the dwelling unit; in a building's utility room, mechanical room, or laundry room; or in unused space, for example in the stairwell. The first two options work for one-for-one deployments while the remaining location options can serve one-for-one or clustered deployments; another advantage of these "out-of-unit" locations is that they enable easy access to the HPWHs for servicing by maintenance staff. Considerations for these options are listed in Table 1. Potential floorplan options for multifamily installations of these out-of-unit locations are shown on the Training tab.

| Location | Considerations |

|---|---|

| Interior Corridor or Breezeway Closet | Ventilate (passive) to interior corridor or breezeway. Separate from dwellings with fire-rated walls. |

| Drain condensate to adjacent bath’s drain line. | |

| Consider additional soundproofing. | |

| Under-Stair Closet | Ventilate (passive) to interior corridor or breezeway. |

| Add plumbing drain or convey to existing bath drain stack. | |

| Not adjacent to any living space. | |

| Utility Room | If large room, no ventilation is needed. |

| If floor space is available, could install multiple HPWHs. | |

| Can drain condensate to existing stack for adjacent bath. | |

| May be able to use waste heat from other mechanicals in room. |

In-Unit Closet

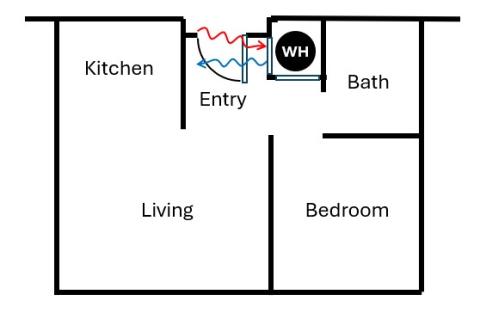

HPWHs can be installed inside dwelling units in small closets with passive ventilation to ensure sufficient air exchange. An example of this is given in Figure 2. This deployment option is appropriate for any climate.

- Carefully consider the location of the lower ventilation area, as it will become a source of cool, dry air when the HPWH is running. Entryways are often the best location for this discharge.

- Consider the noise reduction options described in the guide Heat Pump Water Heaters for Single-Family Homes.

- If the dwelling has an in-unit laundry, consider co-location; the HPWH can take advantage of waste heat from the dryer and the washer drain line can be used to handle the HPWH condensate.

- One downside to this approach is that maintenance staff will have to enter dwelling units to clean the filters.

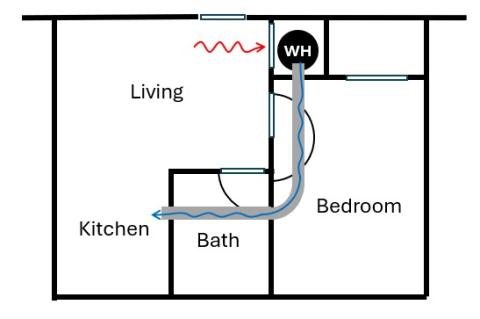

If the unit cannot be arranged to allow exhaust to discharge to an adjacent space without disturbing residents, exhaust can be ducted to a better location. When ducting the exhaust, be sure to use insulation to prevent condensation on the cool exterior surface of the duct. An example of this is given in Figure 3.

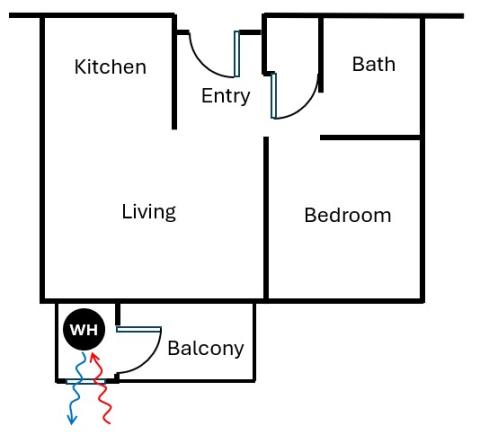

Exterior Closet

If dwelling units in warm climates have closets outside of the structure’s thermal envelope (such as a patio or balcony storage or mechanical closet), the HPWHs can be installed there. An example of this is given in Figure 4, where a vent is installed in the exterior closet wall.

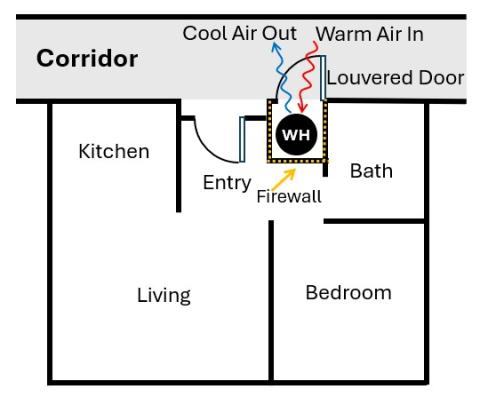

Internal Corridor Closet

If dwelling units are accessed via an internal corridor, HPWHs can be placed in closets accessible from the corridor. An example of this is given in Figure 5. This deployment option is appropriate for any climate.

- Ventilation will be required in order to exchange air with the corridor. Passive ventilation is recommended using a louvered door.

- Because louvered doors cannot meet the fire ratings typically required by code for dwelling unit perimeters, the walls between the HPWH closet and the interior of the unit will need to be built to the appropriate firewall rating.

- This firewall can also provide sound proofing between the dwelling unit and the HPWH.

- As corridors are only briefly occupied, the cool exhaust from the HPWH is unlikely to be a nuisance.

- The corridor access door allows maintenance of the HPWH without entering the dwelling.

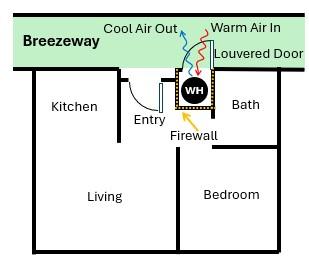

Breezeway Closet

Figure 6 shows a floorplan similar to the corridor closet deployment option shown in Figure 5 above; however, in this case, the closet door opens to an outside breezeway rather than an interior corridor. The thermal envelope of the structure should exclude the closet, i.e., the wall separating the closet from the dwelling unit should be insulated and air sealed.

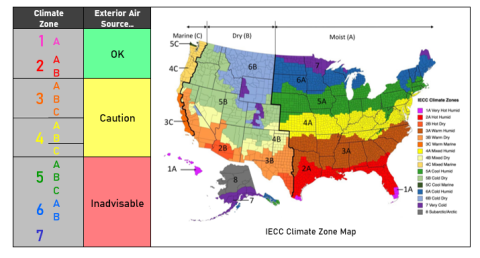

When installing a HPWH in an exterior closet or a breezeway closet, specifics of the deployment will depend on climate:

- IECC climate zones 1 and 2: Either passive or active ventilation of the closet will be effective.

- IECC climate zones 3 and 4C: Use active ventilation to help maintain enough heat flow across the evaporator. In the coldest months, HPWH efficiency is likely to be reduced.

- All other climate zones: Installation in an exterior closet is not recommended. (Instead, consider one of the approaches that doesn’t use outdoor air.)

With these deployments, it is sometimes possible to drain condensate to the landscape rather than the plumbing system. The discharge location will need to be able to absorb or dissipate the condensate and heat tape may be necessary to prevent freezing and blocking of the drain line.

Utility Rooms and Dead Space

If the building has spare space in mechanical rooms, laundry facilities, or another similar space, these make great locations for a HPWH. Other mechanical systems often create waste heat that a HPWH can collect and use. The HPWH’s exhaust, in turn, can make the space more comfortable and even improve the efficiency of refrigeration systems.

Spaces under the lowest flight of stairs or above the highest are often large enough to be turned into a water heater closet, using passive ventilation like the corridor closet option described above.

Example Case

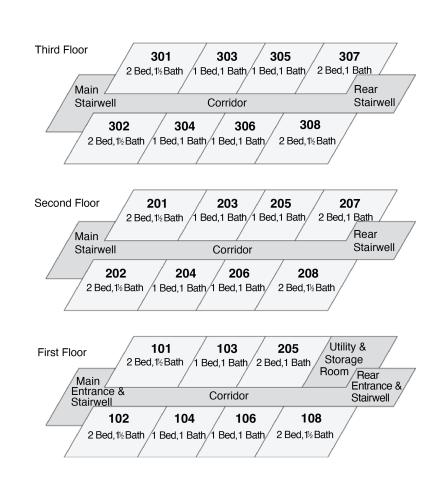

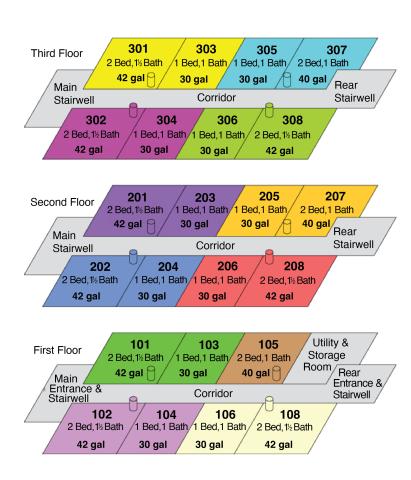

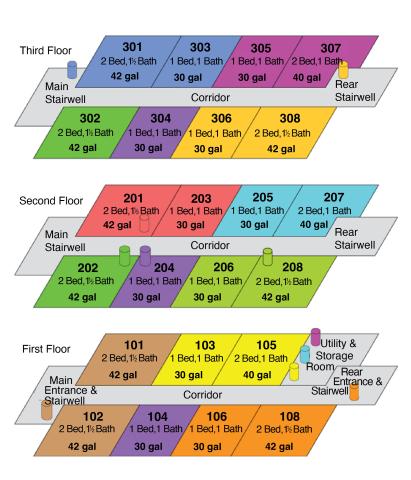

To illustrate the process, imagine a three-story building with a variety of unit sizes, laid out as shown in Figure 7.

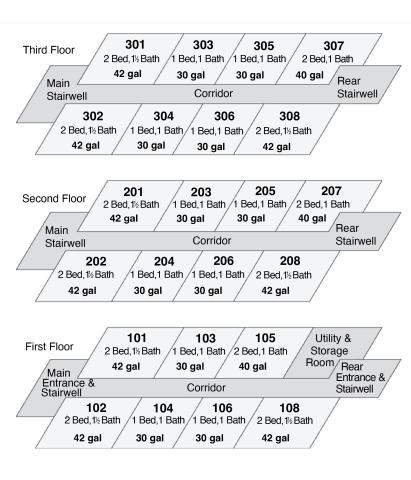

To begin, make an estimate of the FHR requirement of each unit or unit size. In the example building, there are 1-bed/1-bath, 2-bed/1-bath, and 2-bed/1½-bath units. FHR requirements of such units could be 30, 40, and 42 gallons. Those FHR requirements are added to the floorplan in Figure 8.

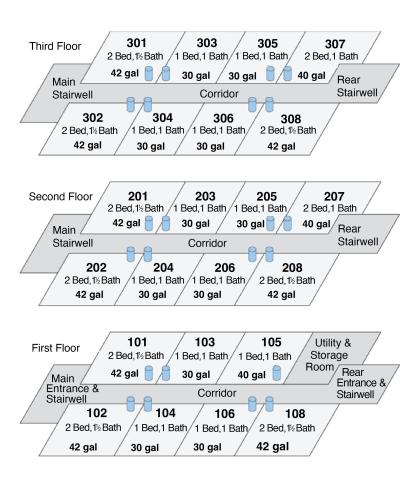

For a one-to-one deployment, each unit will need a HPWH with an FHR of at least the unit’s FHR requirement. The smallest standard HPWHs (with 40 to 50-gallon tanks) will be sufficient for even the largest of these dwellings. The 23-unit project could be completed with 23 small HPWHs, as shown in Figure 9.

For a cluster deployment, it is useful to gather a list of HPWH models with different FHRs to consider for the project. For each size HPWH, note what combinations of dwelling sizes it could serve. The result would be a table like the example shown in Table 2.

| HPWH Size | First Hour Rating | Suitable Clusters |

|---|---|---|

Extra Small 40-gallon tank | 58 gallons | - Any one unit |

Small 50-gallon tank | 66 gallons | - Two 1/1 units |

| Medium 64-gallon tank | 78 gallons | - One 1/1 unit + one 2/1 unit - One 1/1 unit + one 2/1½ unit |

| Large 80-gallon tank | 92 gallons | - Three 1/1 units - One 2/1 unit + One 2/1½ unit - Two 2/1½ unit |

With the table in hand, look at the floorplan and make clusters out of the dwelling units. A simple plan would be to make pairs of adjacent units. Figure 10 illustrates a simple plan consisting of 11 pairs of dwelling units (the matching-colored units) clustered with medium-sized HPWHs and one individual unit (the brown unit) with a small HPWH.

Making use of the building’s specific layout and looking for less obvious cluster arrangements can sometimes reduce the number of HPWHs needed and the amount of space required within units. Figure 11 and Table 3 show another option for the same building that uses 11 HPWHs, with only four of them located inside dwellings.

| Cluster | Units | FHR Requirement | HPWH Size | HPWH Location |

|---|---|---|---|---|

| A | 101 + 102 | 84 gallon (42 + 42) | Large FHR: 92 gallons | Under main stairs |

| B | 103 + 105 | 70 gallons (30 + 40) | Medium FHR: 78 gallons | Utility room |

| C | 104 + 204 + 304 | 90 gallons (30 + 30 + 30) | Large FHR: 92 gallons | Unit 204 |

| D | 106 + 108 | 72 gallons (30 + 42) | Medium FHR: 78 gallons | Under rear stairs |

| E | 201 + 203 | 72 gallons (40 + 32) | Medium FHR: 78 gallons | Unit 201 |

| F | 202 + 302 | 84 gallons (42 + 42) | Large FHR: 92 gallons | Unit 202 |

| G | 205 + 207 | 70 gallons (30 + 40) | Medium FHR: 78 gallons | Utility room |

| H | 206 + 208 | 72 gallons (30 + 42) | Medium FHR: 78 gallons | Unit 208 |

| I | 301 + 303 | 72 gallons (42 + 30) | Medium FHR: 78 gallons | Above main stairs |

| J | 305 + 307 | 70 gallons (30 + 40) | Medium FHR: 78 gallons | Utility room |

| K | 306 + 308 | 72 gallons (30 + 42) | Medium FHR: 78 gallons | Above rear stairs |

Safety

Follow all manufacturer guidance and applicable codes. See the guide Heat Pump Water Heaters for Single-Family Homes.

Success

Integrated Design

Appropriate planning is critical to realizing a HPWH’s energy savings potential, to avoid headaches during installation, and to ensure the comfort of the occupants. In new construction, it is important to consider installation factors early in the design process. Design engineers will need to be actively involved early on, so that the space requirements for HPWH tanks can be coordinated with the architect before floor plans (and interior wall locations) are finalized. For retrofits, it is important to consider what alterations may be appropriate.

Occupant Comfort Considerations

Consider the effect the HPWH’s sound and exhaust will have on occupants’ comfort. Locate the HPWH away from rooms where the noise is more likely to be bothersome, such as bedrooms and living rooms, or mitigate its effect with insulation in the walls. See Heat Pump Water Heaters for Single-Family Homes: Comfort Factors for strategies.

HPWH Performance

Selecting a model with a high Uniform Energy Factor (UEF) is important for achieving the highest energy efficiency levels, but the operating environment can have as much impact as the product’s design. The single most important factor that architects and mechanical designers can control is the availability of heat energy.

Smart Plumbing Design

Reduce water heating load by using insulation, reducing supply line volume, and installing efficient fixtures in the kitchen, shower, and lavatories.

Climate

Air Temperature

When a HPWH is installed inside and draws air from within the structure’s thermal envelope, no considerations for climate are needed. HPWHs should never be installed in a location at risk of freezing, such as an uninsulated garage in a cold climate.

In some climates, it is appropriate – or even advantageous – for a HPWH to use outdoor air as its thermal resource. The warmer the makeup air, the more efficiently the HPWH will operate. If outside temperatures are regularly below 50°F, it’s best to install the HPWH indoors. Refer to manufacturer specifications and consider the specific site’s climate. The recommendations listed below and in Figure 1 are based on the U.S. climate zones specified by International Energy Conservation Code where lower numbers are warmer climates and higher numbers are colder climates:

- IECC Climate Zones 1 and 2: Exterior air source is ok.

- IECC Climate Zone 3 and 4: Interior air source is likely to produce better performance.

- All other climate zones: Interior air sources only.

Relative Efficiency

Regardless of climate, a HPWH will provide significant energy savings year-round, compared to other heating technologies.

While HPWHs use heat from the air, they have a minimal effect on a dwelling’s heating and cooling system when installed correctly. If installed in a room with limited air exchange with the rest of the structure, they have no effect. If installed inside the thermal envelope, HPWHs are a benefit to HVAC systems in the summer and have a negligible impact in the spring and fall shoulder seasons. In the winter, only part of the heat used by a HPWH will come from the heating system. Thermostats will not “sense” all the energy used by the HPHW. Some of the heat comes from removing moisture from the air and this does not change the space temperature. Further, the cooling effect of the HPWH is generally limited to a small area. Again, this localized cooling effect is not completely sensed by thermostats located in another area. In any case, research shows switching to a HPWH will reduce total energy consumption and it doesn’t require increased heating equipment capacity.

For detailed information on interactions between HPWHs and space conditioning systems, see:

- Interaction between Heat Pump Water Heaters or Other Internal Point Source Loads and a Central Heating System

- Understanding HPWH Interaction with Space Conditioning Systems in the Field

- Heat Pump Water Heater Model Validation Study

- The HPWH Handbook: Optimum Installation Practices and Answers to Lingering Research Questions

Training

Compliance

Compliance

Retrofit

Site Visit

Perform a site visit when planning a HPWH conversion.

Evaluate locations of existing water heaters to determine if they are suitable for a HPWH. If the current location is inadequate for a HPWH, look for other potential locations. Consider the following:

- Physical clearances: Is the location large enough for a HPWH? (See the Heat Pump Water Heaters for Single-Family Homes.) Is there a clear path to allow transportation of the HPWH to the location?

- Is the space at least 450 ft3, and if not, what options for ventilation are feasible?

- Would sound or exhaust be likely to cause discomfort and if so, what options are there for mitigation if needed?

- Where can the plumbing drain line for condensate discharge be located?

- Is there a power supply at the desired location and what is the voltage and amperage of the circuit?

- Is there an existing recirculation pump and are existing hot water distribution pipes insulated? Recirculation systems and uninsulated pipes can degrade the performance of HPWHs.

Solutions

While usually not recommended for new construction, consider these alternatives if necessary for a successful retrofit project:

Lower Power HPWH

If dedicated 240-Volt, 30-Amp circuits are not available where needed, there are HPWH models that can run on a 240-Volt, 15-Amp supply, or on a 120-Volt, 15-Amp supply. See the guide “Heat Pump Water Heaters for Single-Family Homes,” in the section “Existing Electrical Capacity.”

Remote Locations

When there isn’t space in or adjacent to a dwelling for a HPWH, it can be installed in a more remote location, such as a rooftop, basement, or parking structure. However, the length of hot water runs and exposure to exterior air in these types of installations can create their own challenges.

Split Systems

A split-system HPWH separates the heat pump component from the hot water tank. This separation may allow more design flexibility for the space constraints typical of multifamily buildings. For example, the heat pump unit can be installed on the building exterior. The products currently available have a higher cost than integrated models of comparable performance, but the market is evolving rapidly with new split-system HPWH models emerging every year.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

Laboratory Testing of Heat Pump Water Heater Performance: Impact of Airflow and Space Configurations

The following authors and organizations contributed to the content in this Guide.

Ben Larson and Sam Larson. Larson Energy Research.