Scope

Plan a successful Heat Pump Water Heater (HPWH) installation in a single-family home.

- Learn how HPWHs are different from traditional electric-resistance (ER) and fossil-fuel water heaters.

- Choose a HPWH model with the right capacity.

- Select an installation location that will ensure a smooth installation, efficient water heater operation, and occupant comfort. OR, if replacing an existing water heater, determine what modifications to the location, if any, are needed.

- Ensure an adequate supply of heat energy (a “thermal resource”) for the heat pump.

- Address condensate removal requirements.

See the Compliance tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Heat pump water heaters (HPWHs) are at least three times more energy efficient than the most efficient electric-resistance or combustion (natural gas, propane, or oil) water heaters. Compared to electric-resistance water heaters HPWHs have higher up-front costs but significantly lower operating costs. Electric utility programs and tax credits are often available to help offset the initial purchase cost. HPWHs are also part of a pathway to lowering carbon emissions, both in homes and for electrical generation.

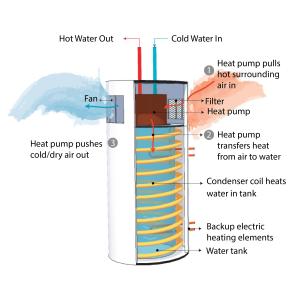

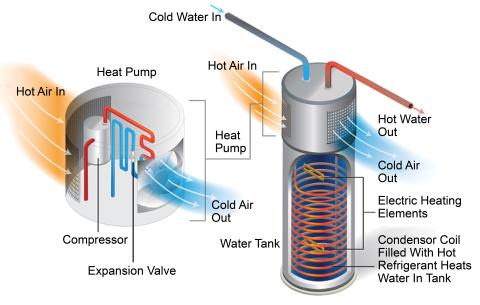

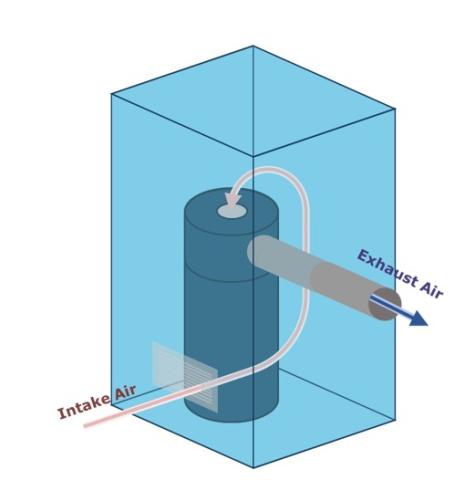

Fundamentally, an HPWH works by pulling heat from the surrounding air and moving it to the water stored in the tank to provide domestic hot water (DWH) (see Figure 1). Compared to traditional electric resistance or fossil-fuel heating technologies, HPWHs are much more energy efficient because they use heat found in the air instead of converting electricity or chemical energy into heat.

HPWHs come in a variety of configurations and sizes. This guide deals with the most common type: integrated, consumer HPWHs. Integrated HPWHs have their heat pump compressor and heat exchanger attached directly to the water heater’s storage tank.

“Consumer” refers to the fact that these units are sized for a single household. These are the HPWHs you are most likely to see at a home improvement store. Sometimes they are called “hybrid” water heaters because many models have electric resistance heating elements like traditional electric water heaters, and they can switch from heat pump mode to standard electric mode if needed.

There are other heat pump technologies that can provide both domestic hot water and space heating, including split-system air-to-water heat pumps and ground-source heat pumps (also known as geothermal heat pumps, described in the Solution Center guide Ground-Source Heat Pumps). These technologies may be suited for some applications but are not discussed in this guide.

Thermal Resource

The heat in the air around a HPWH provides the thermal resource, which is the heat energy the HPWH “pumps” into the stored water. All air holds heat, but the warmer the air, the easier it is for the heat pump to extract that heat. As the HPWH extracts heat from the air, the thermal resource is depleted, i.e., the air around it cools down. To keep the HPWH running efficiently, the thermal resource needs to be refilled. This can happen through air movement as warmer air from other parts of the house circulates into the space where the HPWH is located, or via conduction through the walls of the HPWH space from warmer parts of the house, or from heat given off by other appliances such as clothes dryers or freezers located in the same space as the HPWH.

Hybrid Design

Most HPWHs on the market today are hybrid models, which supplement the heat pump with one or more electric resistance (ER) heating elements. ER is faster than heat pump heating and can operate in any room temperature but is far less efficient. Therefore, the ER backup is useful when hot water demand is unusually high or air temperatures are unusually low, but the less time the water heater needs to rely on ER use, the more energy efficient it will be.

Most hybrid HPWHs allow the user to select between operating modes, which changes how the unit uses the two different heating methods. Options, names, and control logic vary by manufacturer and model, but common control schemes include:

- Heat Pump Only: Water heater does not use ER, or only uses ER if the heat pump is temporarily disabled.

- Hybrid: Water heater switches between heat pump and ER to balance efficiency and capacity.

- Fast Heat: Water heater uses both heat pump and ER simultaneously.

- Electric Resistance: Water heater uses only ER heating.

Using a heat-pump-only operating mode yields the highest energy efficiency levels. Proper sizing of the HPWH is necessary to ensure user comfort and satisfaction while using this mode. To balance efficiency and performance, some home owners switch to Fast Heat mode when they host guests, but use Heat Pump Only mode most of the time.

Practical Differences between Heat Pump Water Heaters and Traditional Water Heaters

Because HPWHs work a little differently than traditional water heaters, there are a few things to keep in mind when planning to install a HPWH and to live with one in your home.

- HPWHs make cool, dry exhaust air.

- HPWHs make condensate (water) that must be drained away.

- HPWHs make more sound than other types of water heaters.

- HPWHs are larger than other types of water heaters (see Figure 2).

Efficiency and Capacity Ratings

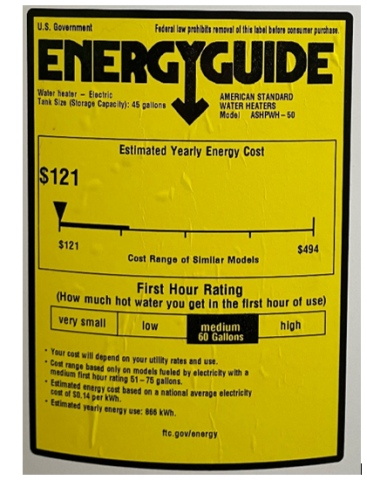

Federal standards rate tank water heaters with two important numbers: Uniform Energy Factor (UEF) and First Hour Rating (FHR). UEF is a measure of energy efficiency; FHR is a measure of how much hot water the water heater can supply. Both are meant to be useful for real-world use of water heaters across the United States. A number of things can change the efficiency and supply in a specific household, including how much hot water people use and when, the temperature of the water coming into the house, and the environment the HPWH runs in.

Uniform Energy Factor (UEF)

UEF reflects energy efficiency and higher is better. Basically, UEF is the amount of useful energy produced by a water heater divided by the amount of energy it uses. A UEF of 1.0 means that all of the energy used by a water heater is changed into heat and drawn out of the tank. ER-only water heaters have UEFs below 1.0 because some of the energy they use is lost when the heat inside the tank radiates into the air. HPWHs have UEFs above 1.0 (typically 3.5 – 4.0) because most of the heat they deliver comes from the surrounding air rather than the electrical supply.

First Hour Rating (FHR)

FHR reflects hot water delivery capacity. It measures the number of gallons of hot water the water heater can deliver in one hour, starting with a fully heated tank. It is a more useful measurement for choosing a water heater than the size of the tank, especially when comparing different heating technologies. Fossil-fuel water heaters usually have the highest FHR (and lowest UEF). Hybrid HPWHs often have slightly higher FHRs than ER-only water heaters because they can use both the heat pump and ER element at the same time. HPWHs without ER backup will have lower FHRs. The FHR needs to easily meet the highest demand period of the day (typically morning showers) to avoid running out of hot water. FHR is shown on a water heater’s Energy Guide label (see Figure 3).

Sizing

When determining which size HPWH is best for your home, start by considering FHR. There are several online tools that can help you determine the best HPWH size to maximize energy efficiency while providing adequate hot water for the family and home size. See the Heat Pump Water Heater Installation Tool in the Building America Solution Center. Other sizing guidance can be found in these sources:

- U.S. Department of Energy’s Energy Saver page on “Sizing a New Water Heater.”

- Hot Water Solutions Buyer's Guide.

- Uniform Plumbing Code.

Once you have determined your HPWH size, you can find products that meet the sizing requirement on the Northwest Energy Efficiency Alliance’s Advanced Water Heating Specification Qualified Products List.

When and Why to Upsize

Counterintuitively, increasing the tank size of a HPWH generally increases efficiency. As hot water demand approaches a HPWH’s output capacity, it will need to use more ER heating to meet the demand, thus lowering efficiency. Choosing a larger tank means that the HPWH can cover more hot water use with what’s already in the tank before turning on the ER. A good goal is to be able to meet the highest-demand period of a typical day without using ER.

You might also want to go up a size if your HPWH will have a more challenging situation than the national average. FHR values are based on tests performed in 67.5° F air and with 58° F supply water. Installing a HPWH in a space that regularly experiences cooler air temperatures or colder supply water will reduce its actual output capacity. Choosing a larger tank size can overcome that reduction.

The only real downside to upsizing is that larger models are more expensive. Upsizing might not be an option if you don’t have room for a larger tank.

Smart Plumbing Design

While not specific to HPWHs, there are best practices that can reduce hot water demand without reducing utility and satisfaction for occupants. Best practices include using insulation, reducing supply line volume, installing low-flow fixtures and water-efficient appliances, and avoiding the use of hot water recirculation loops when possible.

Insulation

Insulation can help retain heat:

- Apply continuous pipe insulation to all hot water lines: R-3 or better is recommended. See Figure 4.

- Insulate the cold water supply line within three feet of the HPWH.

- Install an R-10 insulating pad underneath the HPWH to reduce heat loss to the floor. 2-in.-thick squares of polystyrene foam are available from hardware stores for just this purpose. (They are required by code in some jurisdictions.) See Figure 5.

Reduce Supply Line Volume

Reducing the amount of water sitting between the HPWH and fixtures will reduce wait times for hot water and overall heat loss.

- Locate hot water uses (particularly bathrooms, but also kitchen and laundry) near each other and near the water heater.

- Use the smallest sufficient diameter of pipe.

Hot Water Circulation

Hot water circulation loops can usually be avoided in single-family construction when following the above advice. If circulation is needed, the loop should only run on demand, through the use of a user-activated switch. Continuous circulation seriously degrades HPWH efficiency.

Efficient Fixtures

Reduce overall hot water demand with:

- low-flow and/or EPA WaterSense-labeled showerheads and faucets

- cold-water, front-loading ENERGY STAR-certified clothes washers

- ENERGY STAR-certified dishwashers.

Elevated Storage Set Point Temperatures

It is possible to increase hot water delivery capacity by increasing the storage setpoint temperature. This allows you to store more heat in the same size tank. However, for the safety of users, a thermostatic mixing valve must be installed to add cold water to the water leaving the water heater so that the plumbing system delivers water at a safe temperature. Buying and installing these valves significantly increase costs and can increase the total amount of space required for installation. Further, using higher setpoint temperatures reduces efficiency and can accelerate aging of the tank. In most cases it is preferable to choose a larger water heater than to use a higher setpoint.

Installation Considerations

THERMAL RESOURCE

For spaces inside the structure’s thermal envelope (i.e., within the exterior insulated walls of the building), whether the space is actively conditioned or not, a room of 700 cubic feet or more (for example, an 8 x 12-ft room with an 8-ft ceiling) provides a sufficient thermal resource. Basements, mechanical rooms, and laundry rooms commonly meet these criteria.

For spaces outside the structure’s thermal envelope, like unconditioned garages or crawlspaces, the same volume requirement (700 ft3) is sufficient, but air temperatures must also be considered. The plumbing must never be at risk of freezing, and it is best if air temperatures do not regularly fall below 50°F. Heat pump efficiency drops with ambient air temperature. See the Climate tab for more.

When it is not practical to provide a 700-ft3 space, strategies are available to improve the thermal resource. See the section on small space installation strategies below.

While HPWHs use heat from the air, they have a minimal effect on a house’s heating and cooling system when installed correctly. If installed in a space like a garage, unconditioned basement, or attic, they have no effect. If installed inside the thermal envelope, only part of the heat used by a HPWH will come from the heating system. The house thermostat will not “notice” all the heat used by the HPHW. Some of the heat comes from removing moisture from the air and this does not change the space temperature. Further, the cooling effect of the heat pump is generally limited to a small area, it has a limited effect on heating system runtime. That localized cooling effect sometimes even mitigates the need for increasing space heating energy by reducing heat losses if the HPWH is installed in a space on an exterior wall or in a basement. During cooling season, any effect the HPWH has on the cooling system is a benefit. In the “shoulder” seasons, when outdoor temperatures tend to go above the desired indoor temperature during the day and below it overnight, a HPWH can smooth out that daily cycle by using the excess heat available during the day. This can reduce the load on the heating and cooling system. In any case, switching to a HPWH will reduce your total household energy consumption and it doesn’t require increased space heating capacity.

For detailed information on interactions between HPWHs and space conditioning systems, see:

- Interaction between Heat Pump Water Heaters or Other Internal Point Source Loads and a Central Heating System

- Understanding HPWH Interaction with Space Conditioning Systems in the Field

- Heat Pump Water Heater Model Validation Study

- The HPWH Handbook: American Council for an Energy Efficient Economy 2018 Summer Study on Buildings

Clearances

Three feet by three feet of floor space and a ceiling of at least 7 ft is typically enough space for a HPWH. This allows for installation, operation, and maintenance. Additional room could be needed if local code requires the tank to be elevated off the floor or if ducting needs to be attached for active ventilation. (See the section below on Active Ventilation (forced air).) Tighter spaces may work so long as the following items are addressed.

Check the installation manual for clearance minimums for the unit you are installing. Minimum side clearances are typically 0 to 7 inches; top clearances are typically 9 to 16 inches.

HPWHs may have their hot and cold water connections on the side of the unit, and they are taller than other types of water heaters with the same storage capacity. Make sure you have room for all your connections – and sufficient working space.

Make sure that the positioning allows for easy access to inspect the water heater and controls, connect data ports, change the air filter, and drain the tank.

Ensure the intake and exhaust paths are sufficiently free and open. Remember the exhaust port will blow cool air when the water heater is running. Once you’ve taken care of the items above, consider if the exhaust is likely to be a nuisance and if there’s a better position. If the HPWH installation is part of a larger construction or remodel project, cover the intake and exhaust (with plastic or cardboard) between unpacking and startup. This will prevent debris from entering the heat pump compartment.

Condensate

HPWHs produce a neutral, non-toxic condensate that must be drained away. Unlike condensing gas water heaters, which produce acidic condensate as a combustion byproduct, there are no special piping or handling requirements for heat pump water heaters other than to convey the condensate to a drain.

Ensure the water heater is level so condensate properly collects into and drains from the condensate collection pan. Non-level installation can lead to uncontrolled condensate overflow. As always, follow product installation instructions and heed applicable code.

The condensate outlet is typically a few feet off the floor, making it easy to run to any nearby laundry sink or floor drain. With a P trap, the condensate can also be tee’d into any drain line. If none of these options are available, you can use a condensate pump of the kind commonly used with air conditioners to run the condensate line overhead to a drain. Heat pump water heaters and air conditioners can use the same condensate pump if the layout allows, as shown in Figure 6.

Depending on climate, layout, and local code, condensate can also be drained to the exterior landscape instead of the sewer. Draining to the exterior is not an appropriate option if the drain lines will be at risk of freezing, if frozen condensate could create a slipping hazard (e.g., on a sidewalk), or if condensate water would be a nuisance in any other way (e.g., dripping on decks or outdoor equipment).

Comfort Factors

Exhaust

When the heat pump is running, the HPWH will exhaust air that is cooler (by 15° F or more, depending on conditions) and dryer.

Consider the impact of the HPWH’s cool exhaust on comfort. Occupants are likely to be less sensitive to it in spaces where strict temperature regulation is not expected (garages, utility rooms, unfinished basements) or spaces that are rarely occupied for long periods (laundry rooms, storage spaces). Avoid expelling exhaust into areas where air temperature is more important for comfort (living areas, bedrooms, dining rooms).

In some cases, the exhaust can be a benefit. In warm and hot climates, a cool draft at the entryway may be welcome. Locating the HPWH near equipment that produces waste heat (furnaces, refrigerators, clothes dryers) can both ameliorate comfort issues and provide additional heat for the heat pump.

Sound

HPWHs are not silent. The moving parts – the compressor and fan – will produce sound when running. Sound levels vary by make and model but are typically somewhere between a refrigerator and a clothes dryer.

When possible, choose an installation location away from living areas to reduce the likelihood of irritation from sound. Additional measures can further reduce the chance of irritation:

- Select a quieter heat pump water heater model.

- Insulate the walls of the room containing the heat pump water heater.

- If installing seismic strapping, use vibration isolating standoffs to attach the straps.

- Specify a model that allows residents to schedule water heater operations for times when the sound is less likely to irritate. Many manufacturers have models that can be controlled with an app for mobile devices.

Evaluate sound rating claims carefully. Different testing methods can produce significantly different results and might not be reflective of a specific installation environment. The Northwest Energy Efficiency Alliance’s Advanced Water Heating Specification specifies sound levels with a uniform procedure. Products in the Qualified Products List with a tier rating of 4 or 5 meet their strictest sound level requirements.

Small Space Installation Strategies

A room of 700 ft3 will provide a sufficient thermal resource for a HPWH. When retrofitting, it may not be practical to provide this amount of space. In rooms between 450 and 700 ft3 that are within the thermal envelope, the heat pump will likely operate at high efficiency most of the time. The small reduction in efficiency in this size range is likely to be preferable to altering the space. It will still significantly outperform other heating technologies. Below 450 ft3, the installation room should be ventilated to ensure high-efficiency operation. The following strategies have been tested and proven to be effective in even closet-sized spaces. Also see the manufacturer’s recommendations for venting options for small-space installations.

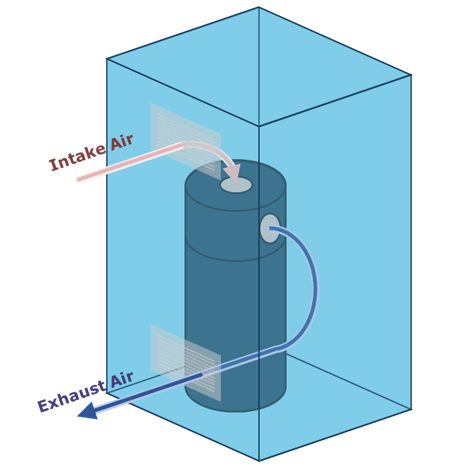

Passive Ventilation (Free Convection)

Successful passive ventilation depends on having sufficient open area both high and low in the installation room. The cool exhaust from the HPWH will settle downward and exit from the lower part of the room. This will draw in warmer air through the top from which the HPWH can extract heat (see Figure 7).

The passive ventilation option is appropriate for small interior rooms (closets, small laundry rooms).

Recommended passive methods include the following:

- Install a fully louvered door with a minimum net free area of 300 in2.

- Use fixed flat-slat louver panels or transfer grilles to create openings both high (within a foot of the ceiling) and low (within a foot of the floor). The high and low openings together should total at least 192 in2 (a pair of 14 x 14 in. grilles or two pairs of 12 x 8 in. grilles, for example).

Active Ventilation (forced air or ducted)

When passive ventilation is insufficient or an appropriate exchange air space is not adjacent to the installation room, the HPWH’s evaporator fan can be used to force air exchange with ducting:

- The exhaust (and/or intake) port of the HPWH is attached to 8-inch ducting. (See Figure 9.) Some models require a manufacturer-supplied adaptor. If ducting the exhaust, insulate the ducting to prevent condensation.

- The duct is run to another space to discharge (or collect) air. Shorter, straighter duct runs made with rigid ducting will increase the effectiveness of this approach.

- An opening is made in the closet to allow makeup air to enter (or exhaust to exit). That opening can be as small as 18 in2 and can be accomplished with an undercut at the base of the door. A small transfer grille is also effective.

It is also possible to duct both the intake and exhaust to a secondary space – another room within the structure or to the outdoors. In some climates it is appropriate – or even advantageous – for a HPWH to use outdoor air as its thermal resource. The warmer the makeup air, the more efficiently the HPWH will operate. However, if outside temperatures are regularly below 50°F, it’s best to use an indoor air source.

It is important that the intake and exhaust are both on the same side of the thermal envelope. If only the exhaust crosses the envelope, the HPWH will depressurize the structure, increasing the rate at which air leaks into the house. This increases the load on the air heating and cooling system and could cause air quality issues in the home depending on where the infiltration comes from.

If only the intake crosses the envelope, it will create positive pressure inside and force more of the already-conditioned air out through leaks.

Some ducting cautions (ENERGY STAR 2024):

- Do not duct only the HPWH intake air or exhaust air to the outside. Doing so will create a pressure imbalance that will lead to air infiltration or exfiltration, increasing the load on the space heating and cooling systems.

- Do not run any ducts between the garage and the HPWH. This may bring exhaust fumes or other contaminants into the living space.

- Do not duct both the HPWH intake and exhaust air to the outside in cold-climate regions or locate the HPWH outside in cold-climate regions. Intake air temperatures below approximately 40°F will trigger electric resistance elements and significantly reduce HPWH efficiency.

- Do not vent the HPWH exhaust air near a thermostat. The cooler exhaust air will provide a false reading to heating and cooling systems.

- Do not vent the HPWH exhaust air where the cool exhaust air will blow directly onto home occupants, to minimize comfort complaints.

Location Checklist

The ideal location for a HPWH will have:

- good thermal resource

- room to install and maintain the HPWH

- condensate drainage

- a 240 Volt, 30 Amp dedicated power supply

- separation from living areas to reduce discomfort from exhaust and sound

- short plumbing runs to hot water uses.

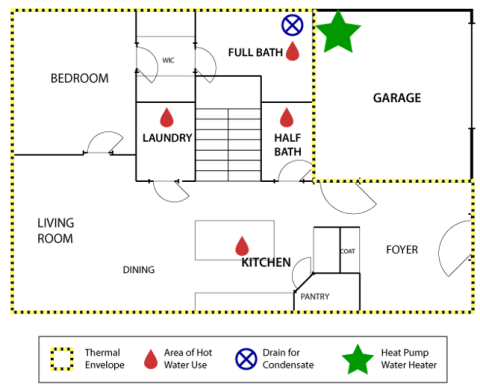

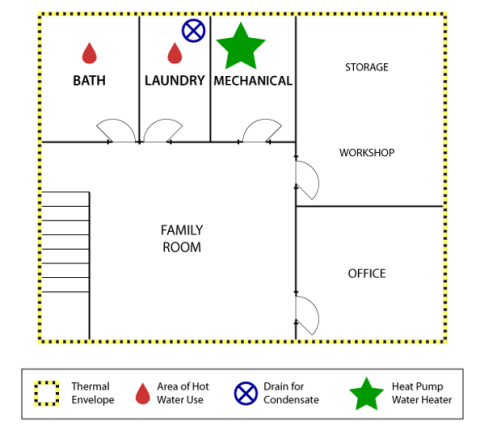

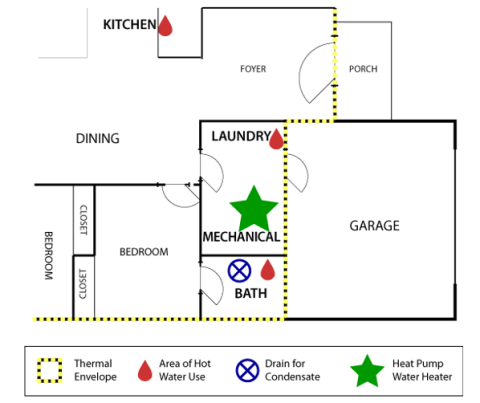

Figures 10, 11, and 12 show sample floorplans for heat pump water heater locations in a garage, basement, or laundry room.

Garage Location for a Heat Pump Water Heater

Locating the HPWH outside the thermal envelope may not be appropriate in cold climates; see the Climate tab for further information.

Basement Location for a Heat Pump Water Heater

Laundry Room Location for a Heat Pump Water Heater

Service and Maintenance

Unlike other water heaters, HPWHs require maintenance of an air filter to ensure high efficiency. These are most often permanent, washable filters. Most models actively monitor operating conditions and will alert users when washing or replacement of the filter is needed. The frequency will depend on air quality. As with other tank water heaters, anode rods should be replaced when consumed and the tank should be periodically drained to remove sediment.

Safety

Scald Risk

As with other water heaters, HPWHs carry a scald risk. Refer to manufacturer documentation on appropriate temperature settings and use of mixing valves. HPWHs typically have digital setpoint controls, making it easier to control the specific temperature of delivered water.

Legionella

For those concerned about legionella and legionella control, refer to ASHRAE Standard 188-2018 and ASHRAE Guideline 12-2000.

TEMPERATURE AND PRESSURE RELIEF

As with other tank water heaters, HPWHs have temperature and pressure (T&P) relief valves to release water from the tank if the pressure becomes dangerously high. Ensure the T&P valve is properly installed and follow all manufacturer instructions and applicable codes.

Installation Checklist

When installing a HPWH, follow all manufacturer instructions and applicable codes. Use this checklist and refer back to the appropriate sections of this guide to ensure your installation plan will enable optimal performance:

- Verify adequate thermal resource (Thermal Resource).

- Address comfort issues like sound and exhaust (Comfort Factors).

- Provide sufficient clearances for fittings, airflow, access to controls, and maintenance (Clearances).

- Account for condensate drainage (Condensate).

- Provide correct electrical supply (grounded, correct conductor gauge and type, proper breaker size and type).

- Insulate pipes (Insulation).

Success

Integrated Design

An appropriate installation location is critical to realizing a HPWH’s energy savings potential, to avoid headaches during installation, and to ensure the comfort of the occupants. In new construction, it is important to consider installation factors early in the design process. For retrofits, it is important to consider what alterations may be needed.

Occupant Comfort Considerations

Consider the effect the HPWH’s sound and exhaust will have on occupants’ comfort. Locate away from sensitive areas or mitigate their effect.

HPWH Performance

Selecting a HPWH with a high UEF is important for achieving the highest energy efficiency levels, but the operating environment can have as much impact as the product’s design. The single most important factor that architects, mechanical designers, and installers can control is making sure the heat pump has access to heat.

Energy-Efficient Plumbing Design

Reduce water heating load by using insulation, reducing supply line volume, and installing efficient fixtures.

Climate

Appropriate Installation Locations

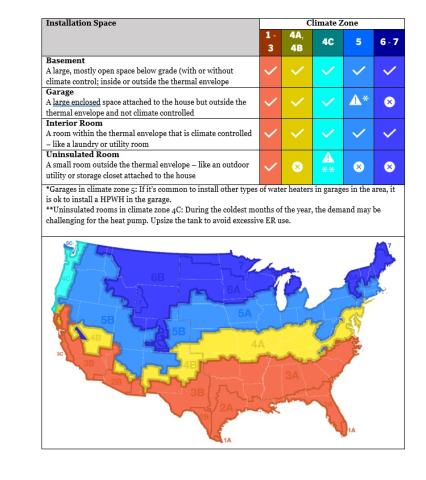

Climate determines where in the house it is appropriate to install a HPWH, as shown in Figure 1.

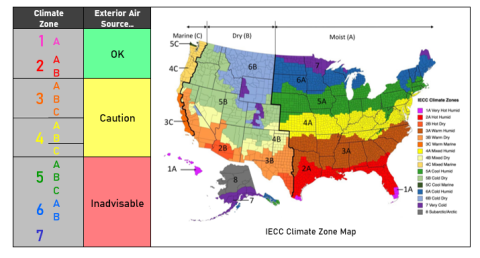

Outdoor Air Sources

In some climates, it is appropriate – or even advantageous – for a HPWH to use outdoor air as its thermal resource. The warmer the makeup air, the more efficiently the HPWH will operate. If outside temperatures are regularly below 50° F, it’s best to install the HPWH indoors and use indoor air as the heat source. Refer to manufacturer specifications and consider the specific site’s climate, but the following are provided as a general guideline (see also Figure 2):

- IECC Climate Zones 1 and 2: Exterior air source is ok.

- IECC Climate Zone 3 and 4: Interior and buffer space air source is likely to produce better performance.

- All other climate zones: Use interior air sources only.

Source Water Temperature

The incoming cold water temperature to the house varies by climate and season. The colder the source water temperature is, the more hot water must be mixed with it to achieve the desired temperature at the fixture. Therefore, hot water use typically increases in the winter. Further, water heaters recover more slowly in winter because more heat is required to bring colder water to the setpoint temperature. In colder climates, such as IECC Zone 5 and higher, consider upsizing the tank to avoid excessive ER use.

Relative Efficiency

Regardless of climate, a HPWH will provide significant energy savings year- round, compared to other heating technologies.

Training

Compliance

Retrofit

Sizing

When selecting a replacement water heater, it is best not to assume that the currently installed model is correctly sized. Use the Building America Solution Center Heat Pump Water Heater Installation Tool to estimate the minimum required First Hour Rating (FHR). If available, ask occupants about their experience with the old water heater. If they experienced runouts, ensure that the new HPWH has a higher FHR. It is common to size a water heater based on a dwelling’s maximum occupancy, but it can also be approached from the perspective of meeting the needs of current occupants.

Existing Electrical Capacity

When replacing an ER-only water heater, it is likely that the existing water heater is served by a 240-Volt, 25-/30-Amp circuit. If this is the case, a 240-Volt, 25-/30-Amp HPWH would be best. To avoid upgrading the electrical service when the house does not have sufficient available amperage, consider a 240-Volt HPWH with lower current requirements. Both 25- and 15-Amp HPWH models are available. Compared to their 30-Amp counterparts, these models will have equal heat pump performance; only the ER heating capacity is reduced.

To avoid installing a new circuit, consider a 120-Volt HPWH. These plug-in HPWHs typically have the same, or higher, capacity heat pumps compared to standard models. They have significantly lower ER heating output, or none at all. In these cases, ensuring a sufficient thermal resource is important not just for efficiency, but also to meet hot water demand. They are appropriate when the installation space will always be at least moderately warm, or for low-occupancy dwellings.

Thermal resource

A space of 700 ft3 or more is recommended for all HPWHs, but replacing and relocating a water heater installed in a smaller space is rarely practical. Spaces down to 450ft3 may still provide enough thermal resource to achieve strong energy efficiency. Below 450 ft3, ventilation should be increased. See “Small Space Installation Strategies.”

Condensate

Make a plan for how to drain condensate. See “Condensate.”

Split-System HPWHS

For particularly challenging retrofit installations, a split-system HPWH might open up other possibilities. These products divide the heat pump and the hot water storage tank into two separate pieces of equipment, usually with the heat pump designed to go outside. This can eliminate challenges with tight installation spaces and with thermal resource availability. However, installation cost and complexity as well as equipment prices can limit the practicality of this approach.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

Laboratory Testing of Heat Pump Water Heater Performance: Impact of Airflow and Space Configurations

The following authors and organizations contributed to the content in this Guide.

Ben Larson and Sam Larson. Larson Energy Research.