Scope

Select heat pump water heaters as an energy-efficient and lower-emissions alternative to electric-resistance or gas water heaters.

See the Compliance Tab for related codes and standards requirements, and criteria to meet national programs such as DOE’s Zero Energy Ready Home program, ENERGY STAR Certified Homes, and Indoor airPLUS.

Description

A “heat pump” is a device that moves heat from one place to another. A heat pump water heater (HPWH) moves heat from the surrounding space into the hot water tank. Most HPWHs are self-contained units just like standard water heaters. They are built like standard electric resistance water heaters with the added feature of a small heat pump unit attached to the top of the tank (Figure 1). Some heat pump water heaters, however, are configured as “split systems”, meaning the heat pump is installed separately from the storage tank. The tank and the heat pump are then connected by water piping. These split systems offer more flexibility in where the equipment can be located.

Heat pump water heaters operate as “hybrid” devices – i.e. they use the heat pump whenever possible, but built-in controls switch to conventional resistance heating when there are large hot water needs. HPWHs are far more efficient and have lower greenhouse gas emissions than standard electric units or gas-fired units. They are a viable alternative to tank-type water heaters or to instantaneous (tankless) water heaters. They can be used in place of electric resistance, natural gas, oil, or propane-fired water heaters.

From an energy cost standpoint, HPWHs can be expected to show savings when replacing a standard electric water heater. They can also be expected to show savings when replacing a gas or oil-fired water heater if the comparative cost of electricity is favorable compared to gas or oil. However, the upfront cost of heat pump water heaters tends to be higher than other types of tank water heaters.

HPWHs have additional design considerations compared to traditional storage water heaters. Like standard electric water heaters, most models require 240V electricity. If this is not possible in the home or location, new plug-in HPWHs can use standard 120V outlets. Because they remove heat from ambient air surrounding the water heater, they have a cooling effect on the space where they are located. This can impact the heating and cooling loads for the home, and/or cause localized discomfort. Ducting kits provided by the manufacturer can be used to route the cool exhaust air to another space if preferred. The year-round cooling effect is relatively small overall, but should be considered before installing a HPWH in cool or cold climates. Heat pump water heaters also generate more noise than other water heaters, and require drainage for condensate. For these reasons, HPWHs have special space and clearance requirements beyond those needed for other types of water heaters.

The HPWH products currently available in the market range in tank volume (gal), first-hour capacity ratings (gal), efficiency (UEF), as well as physical size and weight. Each of these should be considered when selecting a unit. Larger tank volume can result in higher efficiency operation because the unit will be drained of hot water less frequently. This results in less frequent use of the inefficient electric resistance elements and more use of the efficient heat pump. Larger tank volume can also increase a unit’s ability to meet greater hot water demands. However, a larger tank will also require more space and will generally increase first cost.

Water heater efficiency is rated by UEF, which stands for Uniform Efficiency Factor. UEF is used for gas water heaters as well as standard electric water heaters and heat pump water heaters. Higher UEF values indicate better efficiency. For reference, a typical UEF for a standard electric water heater would be around 0.9. An ENERGY STAR gas-fired tank-type water heater has a UEF of at least 0.81 or 0.86 (depending on size and usage pattern), and an ENERGY STAR instantaneous gas-fired water heater must have a UEF of at least 0.95 (these gas-fired ENERGY STAR requirements are as of 4/18/2023). Heat pump water heaters have much higher UEF values: an ENERGY STAR 240V integrated HPWH (not split system) must have a UEF of at least 3.30.

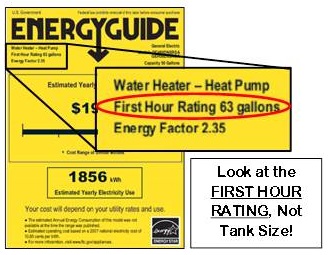

When selecting a water heater size, the first hour rating (FHR, listed in gallons) is probably the most important factor to consider (Figure 2). The FHR is the amount of hot water that a water heater can deliver in a single hour (when starting with a full tank of hot water). The FHR should be equal to (or greater than) the highest volume of water typically used during any hour of normal operation in the home. The U.S. Department of Energy's "Sizing a New Water Heater" site provides a worksheet to estimate target FHRs.

As seen when comparing UEF values, heat pump water heaters can easily be 2 to 4 times more efficient than standard units. However, the efficiency of HPWHs is profoundly affected by the way hot water is used. When large quantities of hot water are used in clusters, HPWHs will revert to electric resistance mode, reducing the efficiency of the unit. A homeowner can limit this effect by purchasing a larger HPWH, increasing the set point temperature, or changing behavior. By increasing the size and temperature of a HPWH, more hot water can be delivered at a given time before the resistance elements are needed. Spreading the water load over a longer period of time may also provide similar benefits (for example, if different occupants take showers at different times of day rather than one right after the other).

Choosing a Location for a Heat Pump Water Heater

For retrofits/replacements, the HPWH will likely be installed in the location of the previous water heater, though some additional work may be required. Ensure that the following checklist can be met for the water heater location.

- Access to 240V electricity

- Condensate drain nearby

- Sufficient air volume (700 cubic feet)

- Sufficient height/space to meet clearance requirements

- Noise is not a problem

If any of the above conditions cannot be met, consider another location in the home or consider the alternative approaches described below.

If there is not access to 240V electricity, which may be the case if a gas water heater is being replaced, there are several options. First, determine if the electrical panel has any unused 30-amp circuits that could be wired to the location. If not, determine if a 30-amp circuit could be added to the panel. To do this, there needs to be physical space on the panel, as well as capacity in the panel to meet the load. If neither of these options is available, new 120V “plug-in” HPWH models may be a fit for this situation.

If there is not a condensate drain nearby, which may be the case if a traditional electric water heater is being replaced, there are options available. The condensate can be drained or pumped to a number of locations that might be nearby. The condensate is benign and does not require any special treatment or piping. A nearby furnace or air conditioner might have a condensate drain that can be utilized. The condensate can also be routed to a washing machine drain, or a utility sink.

If there is not sufficient air volume (700 cubic feet), which might be the case if the water heater is located in a closet, there are changes that can be made to ensure proper airflow. A fully louvered door can be installed to the space, allowing air from the adjacent room to flow to the HPWH. Grills can be installed in the existing door; they should be placed high and low on the door for proper circulation. A large air gap at the bottom of the door (undercut) may be used in place of the lower grill. Ducts can also be installed on the inlet and/or outlet of the water heater and routed to a larger space. Ducting kits are available from most manufacturers. If either inlet or outlet ducting is installed, a vent, louver, or an air gap at the bottom of the door or should still be present. If both inlet and outlet ducting is installed, no other venting is required.

If there is not sufficient height/space to meet clearance requirements, there are some alternatives to consider. New models are being released with “zero clearance” on three sides of the HPWH, meaning the tank can be installed in tighter spaces. HPWHs are often tall and require roughly 6” of clearance on the top to allow for filter changes. If the required height is not available, first ensure that potential obstructions are removed. Blocks or pedestals are not required for HPWHs. Split system HPWHs can also be considered when space is constrained.

If noise is a problem in this location, vibration isolation kits are available. Placing the HPWH on an insulating pad will also reduce noise. HPWHs continue to get quieter as technology progresses. New models are roughly as loud as a new dishwasher.

Finally, climate should influence where the HPWH is to be located. A heat pump water heater will cool the area around it. In hot climates, this will save energy and may not present much of a comfort issue in winter. In this case, it may be beneficial to locate the HPWH within the conditioned space or in an attached garage. In cool climates, semi-conditioned space may be preferred, as long as the ambient temperature in the space remains above the requirements of the heat pump model selected (typically about 40°F). Basements can work well, as can an attached garage.

Uses for Split System HPWHs

A split system HPWH may be used in cases where a unitary integrated HPWH might not work. Examples include locations with a space constraint, such as a very short location. There may also be insufficient airflow with no ability to fix the problem, or a complicated condensate drainage situation. A split system HPWH is able to work in these cases by separating the water storage from the heat pump. This results in a much shorter tank. Some split system units can be combined with existing water heaters. Some split systems require the heat pump to be located within a semi-conditioned space, while some can be placed outside like HVAC units. Most split systems use 120V electricity at the heat pump, allowing for more possible installation locations. This configuration of HPWH makes installing a HPWH possible in many homes that cannot accommodate an integrated HPWH.

How to Install Heat Pump Water Heaters

- Choose a location. Use the guidance in the "Choosing a Location for a Heat Pump Water Heater" section above to determine the best location for the new water heater.

- Assess the floor structure. If the floor is not designed to support the weight of the water heater, reinforce as necessary. A full 50 gallon water heater can weigh around 600 lbs, and an 80 gallon water heater will weigh around 950 lbs. Check the specifications of the specific model to be installed.

- Remove existing equipment (if applicable). In the case of existing home retrofits, follow accepted industry procedures and practices as listed in the Standard Work Specification (SWS):

- Remove old water heater and associated components.

- Seal any unused chimney openings.

- Remove unused oil tank, lines, and associated equipment.

- Install new HPWH. Follow the guidelines for installation as listed in the Standard Work Specification (SWS) . These requirements are as follows:

- Repair any existing water leaks before installation.

- Install an emergency drain pan. Connect a ¾” drain line or larger to tapping on pan and run to drain or pump to daylight.

- Install temperature and pressure relief valve according to manufacturer specifications. Temperature and pressure relief valve discharge tube will terminate within 6” of the floor, or as prescribed by local code.

- Install di-electric unions according to manufacturer specifications.

- Discharge temperature will be set to not exceed 120°F or as prescribed by local code.

- Commissioning will be in compliance with manufacturer specifications and relevant industry standards. The following will be checked once the system has been filled and purged:

- Safety controls

- Combustion safety and efficiency

- Operational controls

- Water leaks

- Local code requirements

- Occupants will be educated on the safe and efficient operation and maintenance of the system, including:

- Adjustment of water temperature and target temperature per local code

- Periodic drain and flush

- Install tempering Valve(s). Tempering valves, or thermostatic mixing valves, are a safety feature installed on hot water systems to reduce risk of scald.

- Insulate hot water lines.

Climate

A HPWH cools the air around it, so it will have an impact on the space conditioning loads of the building in which it is located. When a HPWH is located in conditioned space, there is a direct effect on space conditioning loads and possibly on comfort. In the summer, the HPWH will reduce the cooling load of the building; conversely, the heating load will be increased in the winter. A HPWH’s energy consumption and its impact on the space conditioning depend heavily on climate, home configuration, HPWH location, and the space conditioning systems used. Overall, however, HPWHs can be expected save energy even in heating dominated climates. In any case, the cooled air from the HPWH must be managed to ensure that there are no comfort issues for the occupants.

For HPWHs installed in unconditioned or “semi-conditioned” spaces such as basements, the space conditioning impacts are harder to determine. These spaces act as buffer spaces, so the impact of a HPWH on comfort and HVAC energy consumption is usually less. Research is ongoing to better quantify the space conditioning impacts of HPWHs when located in semi-conditioned spaces.

Research has determined that the cooling/dehumidification benefits and higher COPs of HPWHs are most advantageous in hot, humid climates. However, the energy needed to heat water in these regions is generally lower than for colder regions. If a home’s water heating cost is already low, there is less potential for savings from switching to a HPWH.

Training

Compliance

Compliance

The Compliance tab contains both program and code information. Code language is excerpted and summarized below. For exact code language, refer to the applicable code, which may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

ENERGY STAR Water Heater Key Product Criteria

To be ENERGY STAR labeled, electric water heaters must have a Uniform Energy Factor (UEF) ≥ 3.3 and a First-Hour Rating ≥ 45 gallons per hour. 120V and split system HPWHs must have a UEF ≥ 2.2. Based on the available electric water heating products in the market today, this can only be achieved by HPWHs. In addition, the electric water heaters must have a warranty ≥ 6 years on sealed system and comply with UL 174 and UL 1995 safety requirements, or UL 60335-2-40.

DOE Zero Energy Ready Home (Version 1)

Exhibit 1 Mandatory Requirements.

Exhibit 1, Item 1) Certified under the ENERGY STAR Qualified Homes Program or the ENERGY STAR Multifamily New Construction Program.

Exhibit 1, Item 4) Hot water delivery systems (distributed and central) shall meet efficient design requirements or water heaters and fixtures shall meet efficiency criteria.

Exhibit 2 DOE Zero Energy Ready Home Target Home.

The U.S. Department of Energy’s Zero Energy Ready Home program allows builders to choose a prescriptive or performance path. The DOE Zero Energy Ready Home prescriptive path requires builders to meet or exceed the minimum HVAC efficiencies listed in Exhibit 2 of the National Program Requirements (Rev 07 and 08), as shown below. The DOE Zero Energy Ready Home performance path allows builders to select a custom combination of measures for each home that is equivalent in performance to the minimum HERS index of a modeled target home that meets the requirements of Exhibit 2 as well as the mandatory requirements of Zero Energy Ready Home Exhibit 1.

Exhibit 2, Water Heater) ENERGY STAR levels for the system Energy Factor, are as follows:

- Gas/propane systems of ≤ 55 gallons, EF = 0.67

- Gas/propane systems of > 55 gallons, EF = 0.77

- Electric systems in detached dwellings, EF = 2.0

- Electric systems in attached dwellings, EF = 1.5

- For heating oil water heaters use EF = 0.60

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Home Innovations Research Labs, lead for the Partnership for Home Innovation (PHI), a DOE Building America Research Team

Pacific Northwest National Laboratory

Sales

Heat Pump Water Heater = High-Efficiency Heat Pump Water Heater

According to the Energy Information Administration, water heaters can account for 19% to 32% of a homeowner's utility bill. One option to reduce the amount of energy needed for water heating is to install a heat pump water heater. Although they use electricity, they can be two to three times more energy efficient than conventional electric-resistance water heaters. Heat pump water heaters operate on the same principle as the whole-house air source heat pumps, which move heat with electric compressors and pumps. However, instead of heating and cooling homes, they move heat from the surrounding space into the water tank.