Scope

Design a compact plumbing distribution system.

- Use a core (compact) plumbing strategy with all hot water fixtures positioned near and directly piped to a centrally located water heater to shorten plumbing runs and minimize water use in the home.

- Or, use a central manifold plumbing design with PEX piping runs going from a manifold near a centrally located water heater directly to each hot water use.

- Core and central manifold plumbing strategies must be considered early in the design process for the home.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

To reduce water use and energy losses associated with hot water, homes should be designed with plumbing layouts and hot water distribution systems that reduce the amount of time it takes for hot water to get from the water heater to each plumbing fixture. Traditional hot water distribution systems consist of a trunk and branch distribution with a relatively long and large diameter main line feeding smaller branches that flowed directly to plumbing fixtures or split to serve multiple fixtures. Even in relatively small homes of 1,200 square feet, the volume to the furthest fixture can exceed 1.5 gallons and the time-to-tap can be more than 90 seconds.

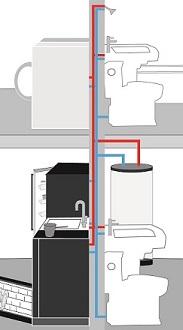

One efficient alternative is a “core” plumbing layout. Core systems utilize a compact central plumbing core, where plumbing areas (i.e., kitchens, bathrooms, laundry rooms) are placed in close proximity to the water heater. Hot water is piped to each plumbing fixture and appliance in as direct a path as possible. The key to central core designs is to determine the maximum allowable water that can run down the drain before hot water arrives and then work backwards to layout the floor plan and route the piping to achieve this goal. There may be more than one plumbing core, each with its own water heater serving nearby plumbing fixtures and appliances.

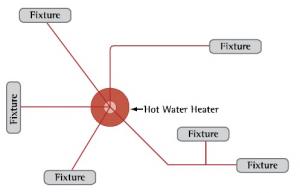

There are two basic configurations used to pipe a central core hot water distribution system: Long Trunk-Short Twigs (Figure 1) or Short Trunk-Long Twigs (Figure 2).

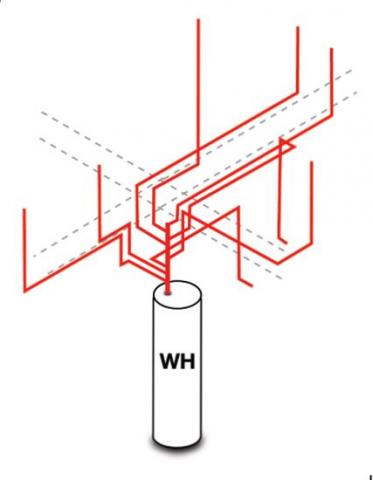

In both of these configurations the piping “radiates” out from the water heater and both configurations are found in traditional hot water distribution systems. However, in recent years Short Trunk-Long Twigs has come to be referred to as “homerun manifold” or “parallel piping,” terms that have been popularized by the manufacturers of valved manifolds. A homerun manifold is typically set up with individual lines of cross-linked polyethylene (PEX) piping running from the manifold directly to each fixture without branching off. One benefit of this system is that you can shut off each side of each fixture individually without impacting any other fixture. However, it does require a lot of piping. Some installers install submanifolds for each bathroom and for the fixture, reducing the amount of piping to each room.

As an alternative to valved manifolds, a non-valved tee could be thought of as a one-port manifold. Using a non-valved manifold with several tees also works well. The manifold may be constructed of either plastic or metal. The key for either configuration is to limit the volume between the water heater and the hot water outlets.

While any piping material can be used for central core systems, the use of flexible PEX allows the piping to be installed more quickly than rigid, non-flexible piping because fewer fittings are necessary during installation. Because the flexible piping is supplied as spools of continuous piping, plumbers can lay out relatively long piping runs without needing to install coupling fittings at regular intervals. Furthermore, by virtue of the piping’s flexibility, it can make changes in direction using continuous sweeping turns, eliminating the need for elbow fittings, which are time-consuming to install and contribute to the loss of pressure and heat as water moves through the system.

Efficient hot water distributions systems are no longer a mandatory requirement. However, because of the efficiency and savings offered by these types of systems, installing them can help a home get closer to achieving the 30% savings required to achieve certification. For instance, designing the system so that there are no more than 0.5 gallons of water left in any one path from the water heater to a plumbing fixture or appliance. This means that the sum of the volume in the trunk, branches and twigs, plus all of the fittings and the fixture supply pipes under sinks, the riser from the shower valve to the showerhead and the volume in the faucets and shower heads cannot exceed this amount. Table 1 in the Compliance section provides information that can be used to calculate the volume in the piping, including the fittings, from the water heater to the angle stop or valve serving the fixture or appliance. The article titled Part 3: Meeting the One-Cup Challenge, as found on the Alliance for Water Efficiency website, provides more details on this method.

How to Design a Core Plumbing Distribution System:

- Designate a proposed location for all hot water plumbing fixtures and appliances. Best practice design specifies that hot water fixtures be as close to the water heater as possible to minimize heat loss in pipes.

- Design plumbing trunks and branches to store as little water as possible by running the smallest diameter pipe allowed by code between the hot water source and each fixture.

- To maximize water savings, calculate the stored volume between each water source and water use point and ensure that not more than 0.5 gallons of water is stored between the water source and the use point. If the volume between each water source and water use point is more than 0.5 gallons, redesign the floor plan and plumbing layout until it is less than 0.5 gallons. See the Compliance tab for information regarding pipe volume per length for various pipe diameters.

- Record all plumbing design features on a plumbing diagram. Install the plumbing according to the codes outlined in the Compliance tab (including correct pipe diameter and insulation). For more information on pipe insulation, see the guide Pipes in Exterior Walls.

Another efficient plumbing layout method is Demand Plumbing.

Success

Ensure all hot water pipes are adequately insulated throughout the home. Insulation can help save energy on water heating costs, especially in households with multiple hot water draws in a row (example: many morning showers). The 2015 IECC states that all piping ¾ inch nominal and larger shall be insulated. In addition there are certain cases where insulation is also required on smaller diameter piping. For more information see the guide Pipes in Exterior Walls.

Wherever possible, locate both hot and cold water pipes on interior walls as an extra precaution against freezing conditions. When water pipes must be located on the exterior wall of the home, ensure they are located toward the inside of the wall, yet still surrounded by at least 1 inch of insulation. Be aware of interior freezing conditions during long vacation periods.

EPA WaterSense Inspection Protocol

For builders seeking certification through the U.S. Environmental Protection Agency's WaterSense program, a verifier will test all hot water delivery systems to ensure compliance with the HCO's WACM (WaterSense Approved Certification Method) requirements using the testing protocol described in the Compliance tab.

Climate

No climate-specific information applies.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Core Plumbing =

Traditional hot water distribution systems consist of a trunk and branch layout. This entails a relatively long, large-diameter main line feeding smaller branches that flow to plumbing fixtures or split to serve multiple fixtures. Even in relatively small homes of 1,200 square feet, the volume to the furthest fixture can exceed 1.5 gallons and the time to the tap can be more than 90 seconds. One efficient alternative is a compact hot water plumbing layout where the home is designed so that all rooms using water (e.g., kitchen, bathrooms, and laundry room) are placed in close proximity to the water heater. This results in hot water piping to each plumbing fixture and appliance in as direct a path as possible.