Scope

Plan for the installation of a central heat pump water heating system for domestic hot water in a multifamily building project.

- Understand space considerations of central HPWHs and provide adequate space for both inside and outside components.

- Understand and plan for sound, comfort, and aesthetic considerations.

- Determine which market delivery type is most appropriate for the project: a fully-packaged skid system, fully-specified built-up system, or a custom-engineered system.

- Determine which HPWH type is most appropriate for the project: single pass HPWH, multi-pass HPWH, or integrated HPWH.

- Determine system configuration type.

- Properly size the HPWH system.

- Minimize hot water recirculation loops, properly manage condensate, and provide proper mounting for storage tanks.

- Install, startup, commission, and maintain the central HPWH system.

See the Compliance tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Central heat pump water heating (CHPWH) systems for domestic hot water production in multifamily buildings are an important technology in reducing building energy use and decarbonizing the building sector. Properly designed, installed, and functioning CHPWH systems can be three to four times as efficient as gas and electric resistance water heating systems. New programs, codes and policies supporting the use of CHPWH systems are being adopted, and this is encouraging more projects to deploy this technology (Figure 1).

There are significant differences in the approach to CHPWH design and installation compared to conventional gas and electric resistance water heating technologies. This document provides guidance to building owners, developers, and designers as they make the transition to CHPWH systems. These are only general recommendations; designers must apply their own best practices and work with equipment providers to be sure their design is appropriate for their specific application.

Central HPWHs versus Distributed HPWHs versus Gas-Fired Systems in Multifamily Buildings

An alternative to central HPWH systems is to install a single heat pump water heater (HPWH) for each dwelling unit or a single HPWH for a cluster of several dwelling units. For information on those approaches, refer to the guide Distributed Heat Pump Water Heaters for Multifamily Buildings. Smaller multifamily buildings have historically tended to have more in-unit (distributed) water heating systems while larger, especially taller, buildings have trended towards central installs. Central systems offer an advantage for maintenance in that all equipment is outside the dwelling units, making access straightforward. On the other hand, central systems require a hot water circulation (HWC) loop throughout the building to ensure that hot water can be provided to every unit within a reasonable amount of time. The circulation loop is an additional mechanical system whose components, configuration, controls, and maintenance must be carefully considered in the design of any central water heating system, whether heat pumps or more traditional fossil fuel systems.

Space Considerations

Central heat pump water heating can offer advantages over in-unit approaches by keeping all equipment out of the dwelling unit. The space occupied by the in-unit water heater can then be reclaimed for use within the dwelling. Clustered in-unit systems can offer space advantages similar to central systems but potentially without the need for a circulation loop. Compared to central gas-fired systems, CHPWHs take up more area due to the larger physical size of the heating equipment and the need for more hot water storage.

Sound, Comfort, and Aesthetic Considerations

Using a central system avoids some potential complications that can come with in-unit installations, such as in-dwelling HPWHs being too loud or producing too much cool air in a small space.

At the same time, the central heat pumps themselves are larger and louder than individual in-dwelling HPWHs or gas-fired central systems. If the heat pumps are placed outside or on the roof, considerations must be made to comply with local sound level requirements. Screens or similar features may also be desired, just like those used with any other large exterior mechanical equipment.

Loads Heated by CHPWH Systems

There are two distinct water heating loads in multifamily buildings with a central domestic hot water (DHW) plant:

- Primary DHW heating load: The primary heating load is caused by hot water usage. This load is the heat required to raise the entering city water temperature to delivery temperature.

- HWC temperature maintenance heating load: The temperature maintenance load is caused by heat loss from the piping in the hot water circulation loop (HWC). This load is the heat required to maintain the temperature of the HWC loop (typically maintained from 115-125°F).

The distinction between primary DHW heating and HWC temperature maintenance heating is important because these two loads have different impacts on CHPWH system efficiency and reliability. Primary DHW usage brings cold water into the CHPWH system, which heat pump water heaters (HPWH) can heat very efficiently. On the other hand, the HWC loop returns tepid water to the CHPWH system, which HPWHs often have difficulty heating efficiently. These differences often require special approaches to heating each load. This contrasts with traditional gas heating systems, which may use a single piece of equipment to cover both loads.

CHPWH System Component Overview

Components of the CHPWH system and their functions are listed below.

Primary heat pump water heater(s)

- Heats cold city water to DHW temperature to be used by the building or stored for future use.

Primary DHW storage tanks

- Store heated DHW to serve the building’s hot water needs.

- Provide buffer capacity to prevent HPWHs from turning on and off rapidly (short cycling).

- Provide hydraulic separation to prevent rapid DHW temperature and pressure fluctuations at the HPWH and mixing valve inlet.

- Facilitates grid-friendly operation: Storage capacity permits HPWH usage during off-peak hours, enhancing grid efficiency and reducing costs.

Temperature maintenance system (present in some piping configurations)

- Isolates the primary HPWH from the warm water returning from the HWC loop.

- Uses either a dedicated HPWH, electric resistance, or gas heater to maintain HWC loop temperature.

Back-up/supplemental heater(s)

- Provides primary DHW and/or temperature maintenance heating if the HPWH is unable to satisfy the load.

- The back-up heater could be gas, electric resistance, or HPWH. It can be integrated into the storage or temperature maintenance tank, or it can be a piece of stand-alone equipment.

Thermostatic mixing valve (TMV)

- Maintains safe DHW delivery temperature.

- Allows DHW to be stored at temperatures greater than DHW delivery temperature to combat bacterial growth and maximize stored energy.

Controls

- Turn on and off HPWHs, back-up/supplemental heaters, and temperature maintenance heaters based on primary storage and temperature maintenance tank temperatures.

- Raise alarms upon equipment failure or failure of DHW delivery.

- Enable communication with electric utility or time schedule to allow for load shifting of energy use away from utility peaks or higher priced electricity periods.

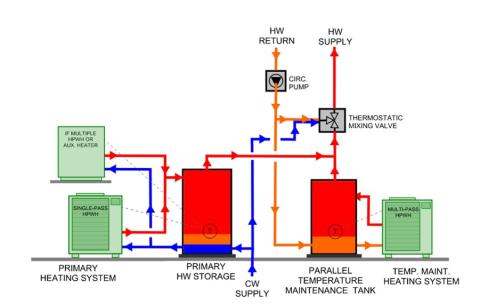

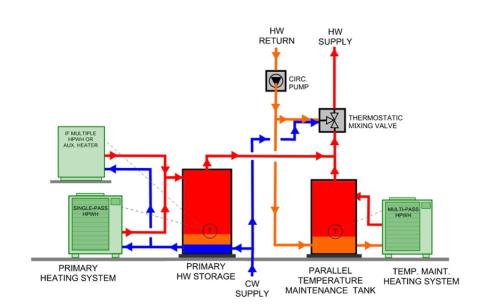

Figure 2 presents a schematic of major CHPWH components. The figure also introduces an important concept: multiple heat pumps may be operated in a bank to achieve the needed output capacity. Likewise, multiple storage tanks may also be used to achieve the total building storage needs. Not all components shown in Figure 2 are used in every system configuration.

Market Delivery

There are three main ways CHPWH systems are delivered to market: fully packaged systems, fully specified built-up systems, and custom engineered systems.

Fully Packaged / Skid System

A fully packaged or skid system provides all major CHPWH components pre-assembled and packaged. The CHPWH system manufacturer assembles and pipes all components of the CHPWH system at the factory and ships to the installer as a pre-assembled unit (Figures 3, 4, and 5). This could also contain several pre-manufactured assemblies to be piped with clear instructions on connecting the pieces together in the field to allow for ease of shipment and greater space flexibility. The CHPWH system manufacturer provides all necessary CHPWH system design info to the engineer of record for permit submittal and provides all necessary installation and operation instructions for the installer to pipe building connections (water/power/anchorage) to the system. This system is the least prone to design and installation error, but proper commissioning is still crucial to ensure equipment is functional.

Fully Specified Built-Up System

With a fully specified built-up system, a single CHPWH system provider specifies and delivers all CHPWH system components based on engineer-provided building characteristics (Figure 6). The CHPWH system provider provides all necessary CHPWH system design info to the engineer of record for permit submittal and provides all necessary installation and operation instructions for the installer to assemble and pipe the CHPWH system in the field. This method is more prone to design error than a fully packaged system but offers greater flexibility. Careful installation validation is key for this system’s success.

Custom Engineered System

A custom engineered system is designed independently of product manufacturers. The engineer of record individually specifies and sizes all CHPWH system components as part of their DHW plant design process and the plumbing installer sources each component from the distributor of their choice. This market delivery method is flexible and theoretically has the potential to be as efficient and reliable as the other two methods but carries the greatest risk of design and installation errors. Careful review and commissioning of the CHPWH system for design and installation verification are key for this system’s success.

Types of Heat Pump Water Heaters

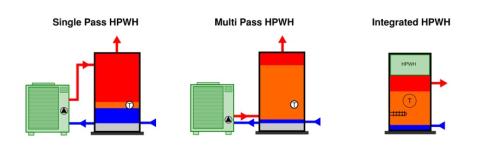

The three most common types of commercial HPWHs available in the US market are single-pass, multi-pass, and integrated (Figure 7). In single-pass and multi-pass HPWHs, the heat pump is separate from the storage tank. The single and multi-pass systems have the largest heating output capacities of the three types and are the most common in CHPWH applications.

Single Pass HPWH

The single-pass HPWH contains all heat pump components in a single package (compressor, heat exchangers, fan, expansion valve, HPWH controls) and is piped to one or more storage tanks. The heat pump adjusts the water flow rate through its heat exchanger to heat to a target water temperature in a single pass, regardless of inlet water temperature.

Advantages

- Single pass heating cycle maximizes heat pump energy efficiency.

Disadvantages

- Some single pass HPWHs require HWC temperature maintenance heating be provided by a separate heater (largely dependent on refrigerant type)

Ideal/Common Applications

- Medium/Large multifamily and commercial DHW systems with or without a HWC loop.

- HPWH installed outdoors or in commercial parking garage with other CHPWH system components installed in a nearby mechanical room.

Multi Pass HPWH

The multi pass HPWH has the same form factor as the single pass but does not adjust water flow rate through its heat exchanger. Instead, water is heated typically 5-10°F with each pass through the heat pump and sent to a mixed temperature storage tank, much like a gas water heater.

Advantages

- Capable of efficient HWC temperature maintenance heating without a dedicated temperature maintenance heater.

- Installation practice is similar to gas water heater installation.

Disadvantages

- Often lower efficiency than single pass

- Requires more storage and heat pump capacity than single pass systems due to mixed storage.

Ideal/Common Applications

- Medium/Large multifamily and commercial DHW systems with a HWC loop.

- HPWH installed outdoors or in commercial parking garage with other CHPWH system components installed in a nearby mechanical room.

Integrated (Unitary) HPWH

An integrated HPWH is a self-contained water heating system that includes the heat pump, primary storage tank, back-up supplemental heater, and controls in a single unit. The integrated HPWH is most common in single family residential applications but commercial grade units with larger storage and heating capacities are also available.

Advantages

- All CHPWH system components are contained in a single package.

- Simple and cost effective for small DHW loads.

Disadvantages

- Require indoor installation.

- Default to electric resistance heating below ~40°F ambient air temps.

- Hard to predict if a specific application will trigger excessive back-up electric resistance usage because of tank and control dynamics.

Ideal/Common Applications

- Adjacent clusters of multifamily apartments ( see the guide Distributed Heat Pump Water Heaters for Multifamily Buildings).

- Small commercial loads with consistent internal heat gains (e.g. commercial kitchens, office buildings).

Other HPWH Equipment

Variable Refrigerant Flow (VRF) or Variable Refrigerant Volume (VRV)

In buildings served with VRF systems for space conditioning, hot water generation units can be used to provide DHW with refrigerant-to-water heat exchangers. While these systems are often more expensive than the CHPWH equipment discussed in this guide, they may be well suited to larger buildings and can provide enhanced heat recovery where cooling is needed for much of the year.

Water source/ground source HPWHs

Water source HPWH products may be a good option for applications with access to a body of water, a ground loop, or waste heat in the form of warm water.

Desuperheaters

In some large commercial applications with refrigeration or chiller equipment (such as grocery stores or buildings with large cooling loads) a desuperheater can be used to capture heat from refrigerant before it reaches the condenser. This may provide some or all water heating while making the cooling cycle more efficient.

CHPWH System Configurations

There is not always one “correct” CHPWH system configuration to use in a building. The specific system configuration depends on factors such as climate, building size, physical space within or around the building, equipment availability, and cost. All the example configurations in this guide can function efficiently and deliver hot water if designed, sized, and installed correctly. Alert the mechanical designer on the project early on to the desire to have a CHPWH so they can determine the most practical configuration. Similarly, inform the architect so they can coordinate the space needed for the system. Ultimately, the largest deciding factor for the system configuration may be the availability and price of specific heat pumps.

This section provides a general overview of the main CHPWH system configurations. For more detailed design guidance, see references listed on the More tab.

Dedicated HWC Temperature Maintenance Systems

In a dedicated HWC temperature maintenance configuration, the heating of the two loads, primary DHW and HWC temperature maintenance, is separated so equipment for each can be optimized. In dedicated systems, it is usually desirable to use a single-pass heat pump for the primary DHW. Then, there are two basic options for HWC temperature maintenance: parallel or series heating.

HWC Return to Parallel Temperature Maintenance Tank (Parallel Loop Tank)

Figure 8 shows a schematic of a system with parallel HWC temperature maintenance. In the parallel loop tank configuration, HWC return water is routed to a dedicated temperature maintenance tank that is heated using a dedicated multi-pass heat pump. The multi-pass heat pump can be tuned to efficiently provide the small temperature increase required for HWC temperature maintenance.

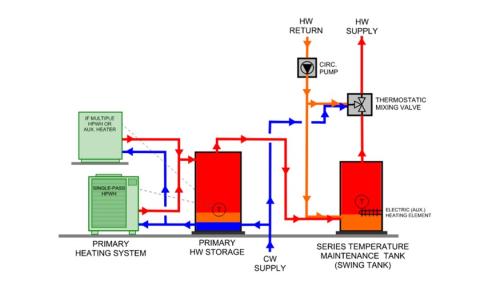

HWC Return to In-Series Temperature Maintenance Tank (Swing Tank)

Figure 9 shows a series HWC temperature maintenance configuration, also called a swing tank configuration. In this system type, HWC return water is routed to a dedicated temperature maintenance tank (called the “swing tank”) that is plumbed in series with the primary DHW storage tank(s). The swing tank is typically equipped with an electric resistance water heating element. The key to operation is a high primary DHW storage temperature (150°F or greater, well above the building delivery temperature). When DHW is used by the building, hot make-up water flows from the high temperature primary storage tank and through the swing tank on its way to the fixtures. The hot primary storage water mixes with, and heats, the water in the swing tank as it passes through. The passive heating of the swing tank – heat transferred from the primary storage into the swing tank – allows the highly efficient primary HPWH to provide a significant portion of the HWC temperature maintenance heating during times of high DHW usage. At times when the HWC temperature maintenance heating is not fully accomplished by this pass-through primary water, the electric resistance element makes up the difference.

Combined Primary Water and HWC Temperature Maintenance Systems

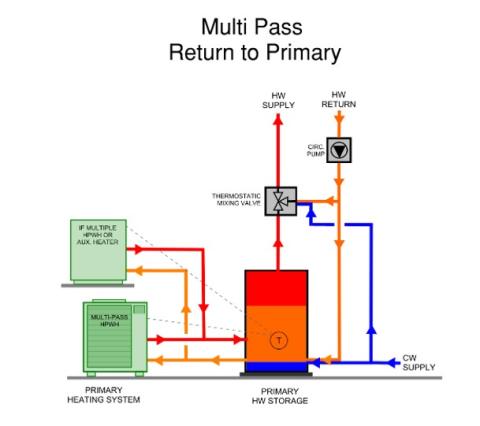

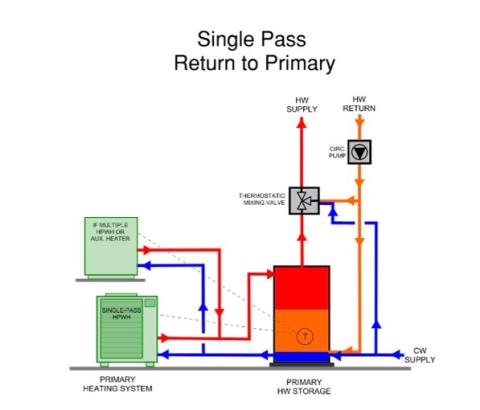

HWC Return to Primary

Figures 10 and 11 show HWC return to primary configurations. The defining characteristic of the return to primary configuration is that both loads, the domestic hot water usage and HWC loop heat loss, are satisfied by the same heat pump and storage tank. In the configuration, HWC return water is routed to the bottom of the primary DHW storage tank. The configuration is conducive for use with multi-pass HPWHs and most closely resembles typical gas-fired boiler systems. The configuration can also be used with single pass HPWHs that can handle sustained high inlet water temperatures.

Back-up/supplemental heating

Regardless of system configuration, back-up, or supplemental heating, should be considered. This additional equipment can serve the following functions:

- Provide full redundancy if HPWHs break down.

- Provide supplemental heating if HPWHs are sized to only provide partial heating in cold temperatures.

- Provide full heating if ambient temperatures drop below the operating range of the HPWHs.

Depending on configuration, the back-up heating may be in parallel or in series with the tanks or heating components. The important concept when implementing back-up heating is to set the controls so that it only runs when the heat pumps are not meeting the load.

Controls

Controls are an essential part of CHPWH system operation. Most fundamentally, they determine when to turn on and off the heat pumps. This is typically done by temperature sensors placed in thermowells at different heights in the storage tank and by temperature sensors in the return and supply water piping to/from the heat pump. Controls can be specific to a particular product. The need for temperature measurement at different tank heights often requires custom specification for such features when ordering storage tanks.

External reporting and alarms

External reporting is useful to ensure the CHPWH system is operating effectively. Many CHPWH systems have relied primarily on electric resistance back-up without building owners noticing because simple installation or equipment errors were present but there was no system put in place to notify the owner of system malfunction. This results in unnecessarily high electric utility bills and a failure to meet energy efficiency targets. The CHPWH system should have the capability to detect heat pump malfunctions and report those to a responsible party. Note, these are only useful if there is a party designated to receive and address them.

HPWH System Sizing Principles

Heat pump output capacity can be expensive while hot water storage is relatively inexpensive. Therefore, optimally sized CHPWH systems rely on large DHW storage tanks to satisfy peak DHW loads, with HPWHs running up to 16-20 hours per day to recharge the large storage tanks. Properly sized HPWH systems have much lower recovery and higher storage capacity than equivalent gas water heating systems. CHPWH systems must be sized differently from gas boilers. Overestimating the size of heat pump needed can unnecessarily increase the project cost.

Free, open-source CHPWH system sizing tools have been developed to simplify the complicated nature of sizing calculations. See the More tab for links. Several HPWH manufacturers have also created sizing tools with similar logic. The tools produce outputs useable by the designer to select primary HPWH output capacity, storage volume, and similar values for temperature maintenance systems.

General Installation Considerations

The following considerations apply specifically to the use of HPWHs in central water heating applications.

Hot Water Circulation Loop

Since HWC loop heat loss has a large, negative impact on system efficiency, steps should be taken to minimize it:

Provide high-quality, continuous insulation with insulated pipe hangers on distribution pipes. Refer to the Insulating Plumbing Pipes guide for more information.

- Use thermostatic balancing valves and variable speed pumping to reduce HWC flow when possible, which lowers HWC return temperature.

- Right-size distribution pipes using Uniform Plumbing Code Appendix M instead of Appendix A where jurisdictions allow. Smaller pipes mean lower surface area and less heat loss.

Condensate Management

During normal operation, HPWHs condense water vapor from the air onto their evaporator coils. This condensation collects in the HPWH drain pan and must be drained away. The condensate is neutral and non-toxic so no special material handling is needed. The following tips should be considered for condensate management:

- If the HPWH is located indoors, route condensate with an air gap to a nearby floor sink or equivalent drain with a P-trap. HPWH condensate can be treated the same as gray water.

- If the HPWH is located outdoors, ensure condensate doesn’t pool on walkable surfaces. It can drain in a garden bed, dry well, roof drain, or an equivalent drain that can handle gray water. If exposed to freezing temperatures, confirm the HPWH drain pan is heated and provide heat trace tape on the condensate drainpipe.

Heat Pump Mounting

Be sure to follow manufacturer guidance when locating and mounting heat pumps, and consider sound levels, expected snow accumulation line, maintenance clearance, and vibration isolation.

Tank Concerns

- Mounting: Full storage tanks are extremely heavy. Tank locations should be coordinated with a structural engineer early in the project. Structural plans often require seismic calculations for tank bracing. Access for tank installation and maintenance should be planned early with the general contractor. Large tanks may not fit through finished doors.

- Vertical vs Horizontal Storage: Vertical and Horizontal DHW storage tanks are both readily available to installers. Vertical storage tanks are recommended in single pass CWHPH systems to maximize stratification, while horizontal tanks can be used with multi-pass HPWHs since they do not rely as much on tank stratification.

Success

Installation, Start-up, Commissioning, and Maintenance

Installation, startup, commissioning, and maintenance are just as essential for success as proper CHPWH system design. High-level tips are noted below:

Installation:

- CHPWH system installation scope overlaps between mechanical, plumbing, electrical, and controls trades. Have all trades, designer, and manufacturer’s reps meet prior to installation to coordinate work.

- Equipment and tanks are large: coordinate lead times and schedule so there is a clear plan to get the equipment to the location and mounted.

Start-up:

- Engage manufacturer’s rep before start-up is required.

- Request a pre-startup checklist from component manufacturers and be sure the installer follows and submits the checklist before technicians attempt to start up the equipment.

- Send the sequence of operation for review before equipment start-up so anticipated adjustments can be discussed ahead of time.

Commissioning:

- Perform functional testing:

- Review sequence of operation.

- Turn on fixtures to draw tanks down and make sure HPWHs turn on as expected.

- Make sure HPWHs shut off when tanks are charged.

- Work with manufacturer to access alarm logs and other important diagnostic information.

Maintenance:

- Be sure a maintenance plan and schedule are provided by the manufacturer of system components (preferably both electronic and in the mechanical room in print).

- Have the HPWH technician educate the building maintenance staff on alarms and high-level diagnostics.

- Post a phone number for the HPWH technician on or near the HPWH to discuss any issues.

Climate

Central heat pump water heating is appropriate for all climate zones in the U.S. if the correct equipment is used. For example, CO2 refrigerant-based heat pumps can operate far below 0 °F.

Impact of Ambient Air Conditions on HPWH Performance

HPWH capacity and efficiency vary with ambient air temperature because HPWHs harvest heat from the ambient air. It is more difficult for HPWHs to extract heat from cooler air. Furthermore, moisture in the air freezes on the HPWH evaporator when ambient temperatures are around 20-45°F, requiring a defrost cycle that further reduces heating capacity and efficiency. All equipment selections should be made with these factors in mind. Designers should request heating capacity (including defrost de-rate) and efficiency (COP) at the following air temperatures:

- Record low air temperature: confirm whether the HPWH will run in record low temperatures, even if capacity does not fully satisfy the peak design DHW load. If a HPWH will not reliably run below a region’s record low temperature, electric resistance back-up should be considered.

- Design cold air temperature: this will help designers determine how many HPWHs are needed to satisfy the load on a design cold day.

- Design hot air temperature: this will help designers determine whether the HPWH will run at the design hot temperature and if storage cycling volume is sufficient when HPWH capacity is at its peak.

Heat Pump Location

Since a clear design constraint is the ambient air temperature, there are benefits to locating the heat pump in areas that are protected from temperature extremes. For example, placing the heat pumps in a mechanical room in a below-grade parking garage allows the heat pump to draw air through the parking garage, tempering it from the cold winter extremes. Such a system could then exhaust its cold discharge air to the outside. Such an approach will raise operating efficiency in the winter and may allow certain equipment to be used in colder climates where they may otherwise not function in extreme outdoor cold. The effects of this type of installation on a garage’s exhaust, heating, or other mechanical systems would have to be considered.

Training

Compliance

Compliance

International Energy Conservation Code (IECC)

Washington State Energy Code (WSEC)

California Energy Code (Title 24, Part 6)

NEEA Advanced Water Heating Specification (AWHS) and Qualified Products List (QPL)

NEEA Commercial Heat Pump Water Heaters Qualified Products List (QPL)

Retrofit

When retrofitting existing buildings with HPWHs, consider the following in addition to typical CHPWH design decisions:

- Hot water circulation loop losses: In existing buildings, the losses can be measured with a flow meter and temperature sensors to definitively quantify the load. Doing so can aid in system design.

- Site visits: both the contractor and engineer of record should visit the proposed site to plan and discuss site-specific installation considerations.

- Space and thermal resource for HPWH: Confirm there is sufficient space for the HPWH with manufacturer-recommended maintenance clearances and that the designated space has access to enough thermal resource. If the HPWH is placed in a closed space, it will over-cool the space.

- Electrical capacity: Check that the electrical panel has sufficient capacity to serve the HPWH and any auxiliary equipment like circulation pumps, swing tank heater, or back-up water heater.

- Sound: HPWHs have varying sound levels. Be sure the HPWH is located far enough from a property line and occupied spaces to prevent noise issues.

- Condensate: Confirm there is a floor sink, roof drain, or garden bed that is sufficient to catch HPWH condensate.

- Repurposing existing equipment: Check if existing storage tanks can be re-purposed but confirm they have required connections and thermowells. Existing water heaters can be re-purposed to serve as a swing tank but should be inspected to be sure they are in working order.

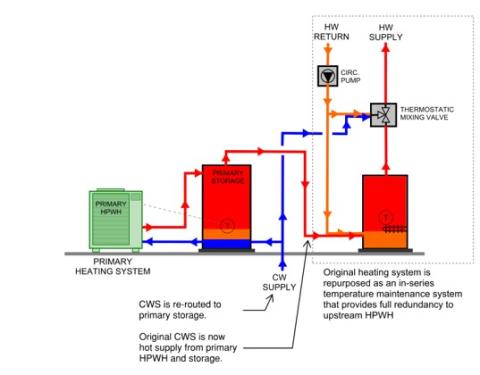

A building retrofit will likely require a custom engineering solution. One possible option is to install a primary HPWH as a pre-heater to the system and then convert the existing DHW plant to an in-series temperature maintenance system. The existing DHW plant would then serve as a temperature maintenance heater and be available for redundant/supplemental heating if the building can’t accommodate full HPWH capacity. Figure 1 illustrates this strategy.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.