Scope

If installing batts in the walls of an existing home, meet RESNET Grade 1 quality installation standards and meet or exceed code for the insulation level R-value requirement.

Unfaced fiberglass batt insulation is properly installed to completely fill the wall cavities and is sliced to fit around wiring, piping and other obstructions.

See the U.S. Department of Energy Standard Work Specifications for additional guidance on installing batt insulation in walls.

For guidance on working in walls, see the Pre-Retrofit Assessment of Walls, Windows, and Doors.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

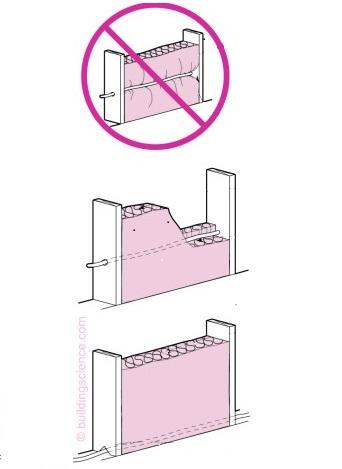

Fiberglass or mineral wool batt insulation is not likely to be installed as an upgrade to an existing home, unless an addition is being added or perhaps in the case of a gut rehab where drywall is removed and replaced. If batt insulation will be installed, install the insulation in a manner that meets the Grade 1 standards of the Residential Energy Services Network (RESNET) in its Home Energy Rating System Standards (RESNET 2013). Grade 1 Installation requires that insulation material should uniformly fill wall cavities, filling each cavity from side to side and top to bottom, without substantial gaps or voids (Figure 1). The batt insulation should be cut to fit around any wiring or piping installed in the wall cavities (Figure 2). For more information, see the Building America Solution Center guide, Insulation Installation Achieves RESNET Grade 1.

There are many factors to consider when installing batt insulation from either the interior or exterior. Understanding Vapor Barriers is a good primer on what needs to be considered regarding vapor retarders.

There are other insulation materials that might be considered for retrofit applications where the drywall will not be removed. These could include blown fiberglass or cellulose that is installed from the exterior of the wall using the “drill and fill” method as described in the guide Blown Insulation for Cavities of Existing Exterior Walls, or rigid foam, also typically installed on the exterior, which might be chosen as part of a home re-siding project as described in the guide Rigid Foam Insulation for Existing Exterior Walls. Spray foam might be considered for existing walls where either drywall or exterior cladding and sheathing will be removed. Each of these methods has its own advantages and disadvantages; see the referenced guides for more information when selecting a retrofit approach.

How to Install Batt Insulation in Walls in Existing Homes

- Consider the scope and goals of the project to determine the best insulation product for the job.

- If using batt insulation, select the appropriate size for your wall cavities and the right R-value for your project.

- Remove drywall and any old insulation from wall cavities.

- Air seal any gaps around penetrations and any seams in sheathing.

- Install batts in accordance with the RESNET Grade 1 standard: the batt insulation should uniformly fill the wall cavities, filling each cavity from side to side and top to bottom, without substantial gaps or voids (Figure 1).

- Cut or slice batt insulation to fit around any wiring or piping installed in the wall cavities (Figure 2).

- Install, mud, and tape new drywall.

Success

Visually inspect the batt installation to verify that the installation meets RESNET Grade 1 quality standards.

Typical R-values for common insulation materials are summarized in this table, which also identifies the vapor retarder classification for each insulation.

Climate

The exterior wall assembly should be designed for a specific hygrothermal region, rain exposure zone, and interior climate. The climate zones are shown on the map below, which is taken from Figure C301.1 of the 2012 IECC.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

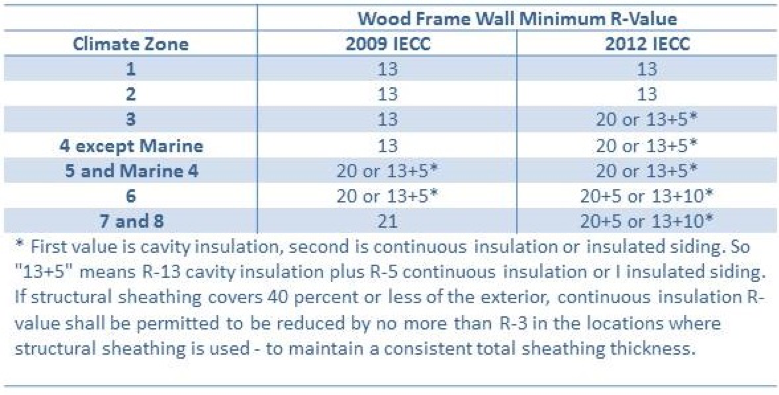

The insulation levels should be based on the minimum requirements for vapor control in the current adopted building code and the minimum requirements for thermal control in the current energy code. Additional insulation can be added above these minimums to create high R-Value exterior wall assemblies. The table below provides the minimum thermal resistance (R-value) requirements for exterior walls specified in the 2009 IECC (ICC 2009b) and the 2012 IECC (ICC 2012b), based on climate zone.

Table 1. Wall Insulation Requirements per the 2009 and 2012 IECC (same for 2015 and 2018 IECC).

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Pacific Northwest National Laboratory

Sales

High-R Wall Insulation = High-Efficiency or Ultra-Efficient Wall Insulation

There are two levels of wall insulation: high-efficiency insulation, which meets the 2015 International Energy Conservation Code, and ultra-efficient insulation, which is 25% more efficient than this national code. Using high-efficiency and ultra-efficient insulation along with professional installation (e.g., no gaps, voids, compression, or misalignment with air barriers, complete air barriers, and minimal thermal bridging) creates conditioned spaces that require very little heating and cooling, along with even comfort and quiet throughout the house.