Scope

Upgrade existing exterior walls that are uninsulated or poorly insulated by adding blown-in insulation in the wall cavities.

- Determine if the insulation is to be installed from inside or outside the home.

- Access the existing walls to determine the location of existing framing and blocking.

- Drill or cut holes for insulation installation.

- Completely fill wall cavities with blown insulation to the manufacturer’s recommended density for “dense” installation.

- Verify that all of the wall cavities are filled.

- Patch walls. If installation was done from the exterior, repair or install a proper drainage plane and air barrier.

For more information on conditions that may be encountered when working with walls in existing homes, see the Pre-Retrofit Assessment of Walls, Windows, and Doors.

The U.S. Department of Energy’s Standard Work Specifications has additional information on dense packing blown insulation.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

When considering methods for insulating exterior walls in an existing home, one common and somewhat uninvasive method is known as drill and fill. In this method, small holes are made in the interior or exterior wall near the top of the wall at each wall cavity, then the wall cavities are filled with blown-in insulation. See Figure 1 and 2.) An ideal time to do an exterior installation is when a house is being re-sided. Re-siding offers the opportunity to check and install or re-install a drainage plane like house wrap if necessary. Re-siding also offers the opportunity to install exterior rigid foam insulation, in addition to or instead of cavity insulation. (See Rigid Foam Insulation for Existing Exterior Walls).

If the blown-in insulation is to be installed from the exterior as part of a siding replacement, an ideal opportunity is presented to improve the airtightness of the wall assembly with minimal effort. Exposed structural panels (plywood or OSB) can be effectively air sealed with fluid-applied air barriers, low-expansion foam, caulk, or quality tapes. Board sheathing should be covered by a house wrap, with all laps sealed with appropriate tape. Continuous rigid foam sheathing can be applied over existing sheathing to provide additional R-value, air sealing, and a continuous drainage plane.

It is critical for water management and durability that the wall assembly’s drainage plane be maintained. When blown-in insulation is added from the exterior, the drainage plane (if existing) will be breeched and it must be made whole by appropriate patching or full replacement. The chosen method will depend on the amount of access and the state of the existing drainage plane material. If the insulation is to be installed from the interior, the drainage plane will not be affected.

Depending on the level of disturbance to existing exterior walls (interior and exterior sides), be aware of lead safety rules for homes built prior to 1980. In addition, if a home has knob and tub wiring, the National Electrical Code (NEC) Article 394.1 scope does not allow insulation to be applied to or surround the wiring.

This guide primarily focuses on wood framing construction with exterior wood sheathing and interior gypsum wall board. For more information on drill and fill installation in wood-framed walls as well as in other exterior wall materials, see the Drill & Fill Installation Guide.

For other approaches to insulating exterior walls in existing homes, see the guides Spray Foam Insulation for Cavities of Existing Exterior Walls and Rigid Foam Insulation for Existing Exterior Walls.

How to Blow In Insulation into Existing Exterior Walls

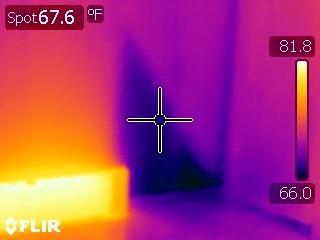

- Determine if the existing exterior wall cavities are insulated. Options for assessing insulation levels include making a small cut-out in the interior gypsum wall board, viewing cavity insulation from the side of an electrical junction box cutout (shut off power to electrical outlets to avoid potential safety hazards), or using an infrared thermal imaging camera to qualitatively assess insulation levels.

- If the wall cavities are empty proceed to step 2.

- If the wall cavities have some existing insulation:

- Existing blown insulation that has deteriorated can remain (or be vacuumed out) and additional blown insulation can be installed in the wall cavity to the desired fill and density.

- Existing batt insulation that has deteriorated can block blown insulation, preventing it from completely filling the cavity. Cut out a 1-foot strip along the wall near the floor on either the interior or exterior side of the wall, then pull out the old batt insulation to allow proper installation of the blown insulation into the wall cavities. Alternatively, use an infrared camera to verify that the blown insulation has adequately filled the wall cavities around the existing batt insulation.

- Decide if insulation is to be blown from the interior or from the exterior.

- Verify that the exterior wall framing is not balloon framing. If the walls are balloon framed, blocking will need to be installed at the top and bottom of the walls to provide a barrier between the wall cavities and the basement below and attic above to allow for dense packing of the cavities.

- Identify the wall studs and use painter’s masking tape to mark them.

- Using a hole saw, drill 1-inch or 2-inch holes (depending on the size of the blower nozzle) in the center of each stud cavity, roughly 6 inches below the ceiling (see Figure 3). It may be necessary to also drill a lower hole to ensure the full cavity is packed with insulation. If there is blocking or other obstacles in the wall cavity (identified using infrared camera), make an additional hole below the blocking (see Figures 4 and 5). Remember to drill in to any cavities above door headers and above and below windows, as well as wall cavities behind cabinets on exterior walls. Also if a bathroom is on an exterior wall, bathroom tiles may need to be “popped” off prior to drilling a hole through the wall board.

- Blow in new insulation to the desired density. Confirm manufacturer’s lbs/ft3 recommendations to achieve “dense” packing. The common insulation type is a dense-packed blown cellulose or fiberglass insulation. For information on blowing machines and nozzles, see the Drill & Fill Installation Guide.

- Fill all exterior wall cavities then re-verify with an infrared camera to ensure that all cavities are completely filled before patching.

- Once verified, patch the holes. For interior penetrations, patch the holes with gypsum board or rigid foam plugs and joint compound. When dry, sand smooth then paint. For exterior penetrations, patch requirements will differ depending on whether siding was removed or remained in place. Repair the drainage plane and air barrier as needed before installing siding.

Success

Infrared imaging is a recommended tool to help identify framing and blocking in existing walls and to determine the thoroughness of insulation coverage. Voids will be most visible when there is a significant temperature difference between the outside and the conditioned space of the house.

Climate

The exterior wall assembly should be designed for a specific hygrothermal region, rain exposure zone, and interior climate. The climate zones are shown on the map below, which is taken from Figure C301.1 of the 2012 IECC.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

The appropriate vapor permeance and location of vapor control is dependent on the climate zone and the overall configuration of the insulated wall assembly. There are many factors to consider when installing blown-in insulation from either the interior or exterior. Understanding Vapor Barriers is a good primer on what needs to be considered regarding vapor retarders.

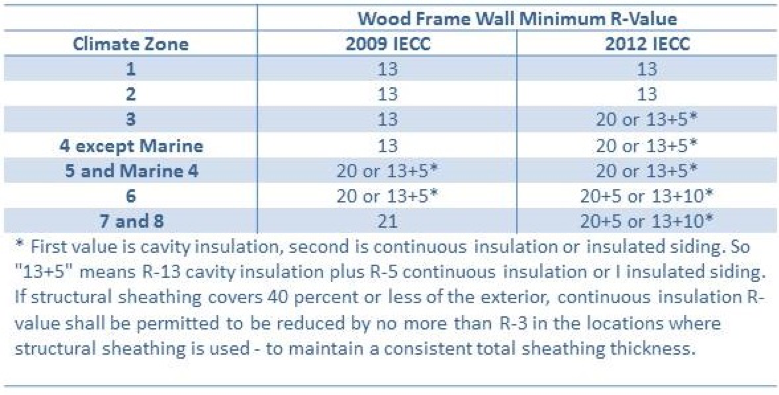

The insulation levels should be based on the minimum requirements for vapor control in the current adopted building code and the minimum requirements for thermal control in the current energy code. Additional insulation can be added above these minimums to create high R-Value exterior wall assemblies. The table below provides the minimum thermal resistance (R-value) requirements for exterior walls specified in the 2009 IECC (ICC 2009b) and the 2012 IECC (ICC 2012b), based on climate zone.

Table 1. Wall Insulation Requirements per the 2009 and 2012 IECC.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Steven Winter Associates, lead for the Consortium for Advanced Residential Buildings (CARB), a DOE Building America Research Team

Sales

Deep Energy Retrofit = Ultra-Efficient Deep Energy Retrofit

An ultra-efficient retrofit is a home renovation or upgrade that results in an energy-efficiency level at least 50% better than the home's, or similar home’s, historic energy consumption.