Scope

Construct framed walls using advanced framing details like using the minimum amount of wall studs permitted by code to reduce thermal bridging and allow more space for insulation.

- Specify 24-inch on-center for 2x6 wall framing rather than 16-inch on-center 2x4 wall framing.

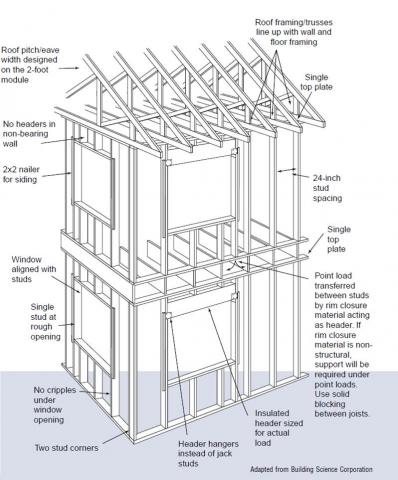

- Design for wall lengths and heights, window and door sizes, etc., on a 2-foot grid, wherever possible to reduce framing members in walls and to reduce lumber and materials waste.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

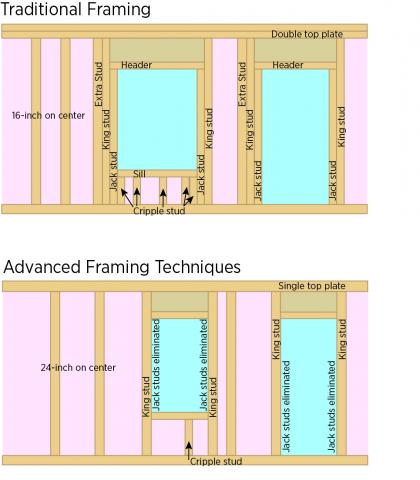

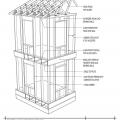

Adding more studs than necessary wastes lumber and reduces the wall’s thermal resistance because the lumber blocks cavity space that could be filled with insulation and because each stud represents a thermal bridge that can transfer heat between the interior and exterior of the building. Wood-framed houses have traditionally been built with 2x4 studs spaced 16-inches on-center. Research has shown exterior framed walls can be adequately supported by 2x6 studs spaced 24-inches on-center. This wider spacing reduces the number of studs in the wall, thus reducing thermal resistance and increase the amount of space available for insulation. Building walls of 2x6s 24-inch on-center has long been permitted in building codes in most jurisdictions, and is particularly appropriate for colder climates (IECC Climate Zones 5-8) where higher wall R-values are required (Baczek, Yost, and Finegan 2002; DOE 2002; Lstiburek 2010). In some jurisdictions, particularly in hurricane zones, 16-inch on-center is the maximum stud spacing allowed; check with local code officials.

This 2x6, 24-inch on-center stud spacing is one of many components of advanced wall framing that reduce costs and provide materials and energy savings. Techniques for installing 24-inch on-center exterior and interior wall framing and single top plates are described below. Other techniques are described in other resource guides: see Insulated Corners, which explains how to construct corners with 2 studs instead of 3 studs to permit more insulation, Insulated Headers for tips on how and when to build open and insulated headers over windows and doors, Minimal Framing at Doors/Windows for efficient framing around doors and windows, and Insulated Interior/Exterior Wall Intersections for ways to reduce framing and add insulation where interior walls intersect exterior walls.

In one study employing several advanced framing techniques, such as 2x6 24-inch on-center wall framing, 24-inch on-center floor joist and rafter spacing, 2x4 24-inch on-center interior framing, 2-stud corners, open and insulated headers, reduced studs around windows and doors, and single top plates, all of the measures combined contributed to energy savings of 13% over standard framing but this single measure alone - switching from 2x4 16-inch on-center to 2x6 24-inch on-center framing– accounted for energy savings of 11% (Lstiburek and Grin 2010). The energy savings is accounted for by two factors – the thicker wall enables wall insulation to be upgraded from R-13 to R-19 and less studs mean less thermal bridging.

Building scientists suggest that builders should consider the “whole-wall” R-value as opposed to the center-of-cavity or rated R-value of the insulation. In one study, a 2x4 16-inch on-center wall was insulated with batts labeled R-13, but researchers calculated the actual whole-wall insulation value of the wall at R-9.4 (or 72% of R-13) when the thermal conductivity of the framing, windows, and doors are taken into account. In the same simulation, researchers found that the calculated whole-wall R value of a 2x6 24-inch on-center wall insulated with R-19 batts, was R-15.2, or 80% of R-19 (Baczek, Yost, and Finegan 2002). While both walls had a lower whole-wall R-value than rated R-value, the 2x6, 24-inch on-center wall with R-19 performed closer to its rated R-value because the wall had less thermal bridging.

Stud spacing can also affect cost savings. In one study of a 2,910-square foot home, switching from 2x4 16-inch on-center framing to 2x6 24-inch on-center framing reduced board feet of lumber by 1,634 feet and cut costs by $171. When other advanced framing measures were added, like switching to single top plates, 24-inch spacing of interior walls, and open headers, lumber costs were reduced $1,117 (Baczek, Yost, and Finegan 2002).

Framing on a two-foot also saves money by reducing material waste. Most sheet goods (plywood, OSB, foam insulation) come in 4x8-foot sheets. When the entire home is designed on a 2-foot grid from roof rafters to wall framing to floor joists, sheet good and lumber waste are greatly reduced. Reducing the number of studs in the walls by one-third also reduces labor costs in terms of the time it takes to handle, cut, install, drill through, and attach to studs. Based on numerous field experiments, Building Science Corporation estimates savings of up to $1,000 per home in materials and labor are possible for production builders who use a combination of advanced framing techniques (Lstiburek and Grin 2010).

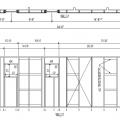

Advanced framing techniques should be specified in the framer’s contract. Detailed framing elevations should be prepared after confirming that these advanced framing techniques are permitted by code in the local jurisdiction. There is a cost associated with redrawing existing floor plans or providing framing details for new plans, but the cost per home is minimal if the plan will be used several times. Also, cost savings will be realized because the details will help gain building official approval, improve accuracy for materials purchasing, clarify instructions for the lead framer, assist in training subs, and greatly improve the chances that the specified measure will actually be implemented (Baczek, Yost, and Finegan 2002).

How to Construct Walls with Fewer Studs

- Design homes on a two-foot grid with 2x6 studs spaced 24-inches on-center. Align rafters, wall studs, and floor joists so that the load is transferred and adequately supported to allow installation of single top plates. Align windows and doors with this two-foot stud spacing to reduce the number of extra king studs needed. [See Minimal Framing at Doors/Windows.]

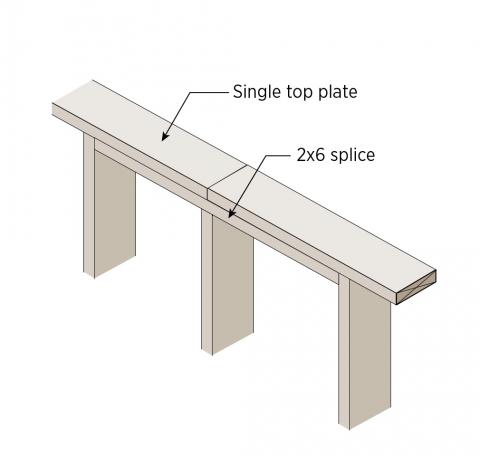

- Specify single top plates in framing elevations. For an 8-foot wall, don’t purchase standard precut 92.5-inch studs, purchase 8-foot (96-inch) studs and cut them to 94 inches (Lstiburek 2010).

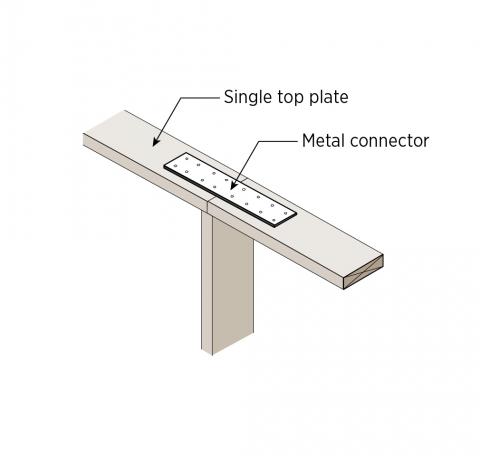

3. Connect top-plates using either a metal plate or a wood splice.

4. For interior walls, specify 2x4 studs placed 24-inch on-center with single headers. Non-structural connectors can be installed for non-load-bearing interior walls.

Success

Advanced framing details should be specified in the construction plans (i.e., framing elevations should be provided) and reviewed with framers. The construction supervisor should ensure that framing crews are knowledgeable of or trained in advanced framing techniques. The framing should be visually inspected by the site supervisor before electrical, plumbing, HVAC, and drywall are installed.

Climate

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

CAD

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Pacific Northwest National Laboratory

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

Reduced Wall Framing = High-Efficiency Wall Framing

Traditional wall framing uses more lumber than is necessary and limits a builder’s ability to insulate walls. Wood and other framing materials are not good insulators. Heat can move through them from one side of the wall to the other. High-efficiency advanced framing uses techniques like thicker studs spaced further apart, two studs rather than three or more studs in corners, aligning windows and doors on a two-foot grid, and other steps to reduce the amount of lumber in the walls, while allowing more room for insulation.