Scope

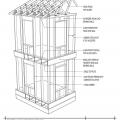

Construct framed walls using advanced framing details like minimal framing at windows and doors to reduce thermal bridging and allow more space for insulation.

- Limit framing to a maximum of one pair of king studs per window opening.

- Limit framing to a maximum of one pair of jack studs per window opening to support the header and window sill.

- Install additional jack studs only as needed for structural support and cripple studs only as needed to maintain on-center spacing of studs.

- Limit framing to necessary structural requirements for each door opening.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

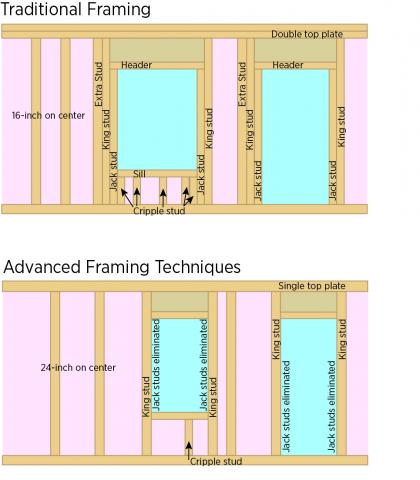

In stud-framed walls, extra studs are often installed around windows and doors, even when they are not needed to bear structural loads. Window and door openings should have no more than one pair of king studs, one pair of jack studs, and the minimum number of cripple studs needed to maintain on-center spacing of studs. Adding more studs than necessary wastes lumber and reduces the wall’s thermal resistance because the lumber blocks cavity space that could be filled with insulation and because each stud represents a thermal bridge that can transfer heat between the interior and exterior of the building.

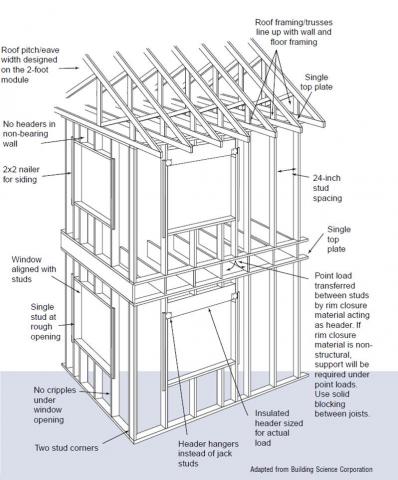

Building scientists estimate that standard stud construction may use 5% to 10% more board feet of lumber than necessary and add up to 30% more pieces of lumber than needed (Lstiburek 2010). By using advanced framing techniques, builders can reduce the amount of lumber used and save money as well. Building Science Corporation found savings of up to $1,000 per home in materials and labor were possible for production builders who used a combination of several advanced framing techniques (Lstiburek and Grin 2010). Advanced framing techniques should be specified in the framer’s contract. For more about advanced framing, see Minimum Wall Studs.

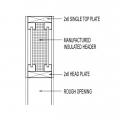

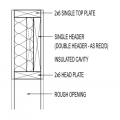

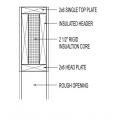

The framing pieces that surround windows and doors include king, jack, and cripple studs, headers, and sills. The full-length stud on each side of a door or window is called a king stud. A header is a piece of framing installed horizontally directly above the door or window opening and extending to the king stud on each side of the opening. The header rests on jack studs that are nailed in place next to the king stud on each side of the opening; jack studs extend to the bottom plate of the wall. A saddle or sill is another horizontal piece that goes under the window opening and is nailed to the inside of each jack stud. Because typical stud spacing is 16- or 24-inch on center and most windows and doors are wider than this, cripple studs are installed below window openings from the sill to the bottom plate in the location where a common stud would have been if the space had not been left open to accommodate the door or window. Depending on the header height, cripples are sometimes located above the window extending from the header to the top plate.

How to Install Minimal Framing at Doors and Windows

- Design homes on a two-foot grid with 2x6 studs spaced 24 inches on-center (See Minimum Wall Studs). Align windows and doors with this two-foot stud spacing to reduce the number of extra king studs needed.

2. Hang insulated headers with metal hangers instead of jack studs.

3. Attach 2x2s to the outside edge of the kings studs if nailers are needed to attach trim or siding, rather than using extra king studs, if “nailable” OSB sheathing is not installed.

Success

Advanced framing details should be specified in the construction plans (i.e., framing elevations should be provided) and these plans should be reviewed by the site supervisor and lead framer. The construction supervisor should ensure that framing crews are knowledgeable of or trained in advanced framing techniques. The framing should be visually inspected by the site supervisor before the drywall is installed.

Climate

No climate specific information applies.

Training

CAD

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Reduced Wall Framing = High-Efficiency Wall Framing

Traditional wall framing uses more lumber than is necessary and limits a builder’s ability to insulate walls. Wood and other framing materials are not good insulators. Heat can move through them from one side of the wall to the other. High-efficiency advanced framing uses techniques like thicker studs spaced further apart, two studs rather than three or more studs in corners, aligning windows and doors on a two-foot grid, and other steps to reduce the amount of lumber in the walls, while allowing more room for insulation.