Showing results 2251 - 2500 of 4973

Right - A drywall gasket is installed along the top plate before installed drywall.

Right - A durable, vented cover is installed over this exhaust duct to prevent bird and pest entry

Right - A floor-to-floor hold down can be installed as a retrofit without removing the siding.

Right - A hand saw is used to remove wall material for a small through-the-wall HRV; 6 of 14.

Right - A heat recovery ventilator supplies all living spaces with fresh air while transferring heat for energy savings.

Right - A high-efficiency (95 AFUE) wall-hung gas-fired boiler heats water for the hydro-coil space heating system and also provides a back-up for the solar hot water system.

Right - A hole is drilled into the wall for installation small through-the-wall HRV; 5 of 14.

Right - A home-run (also called central manifold or parallel piping) system distributes hot water directly from a distribution manifold next to the water heater to each fixture using individual small-diameter PEX pipes.

Right - A lattice of 1X4 furring strips provides a ventilation gap between the decking and metal roofing for this shed roof.

Right - A moisture sensor is installed on the roof to control the sprinkler system.

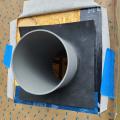

Right - A second layer of flashing tape is applied over the EPDM gasket and first layer of tape at sides and top around the duct; 14 of 14.

Right - A small through-the-wall HRV duct is installed in an exterior wall; 7 of 14.

Right - A smart vapor barrier wraps the walls and window frames of this home. Seams are taped to provide an air- and water-resistant barrier.

Right - A stand-alone dehumidifier is located in the return air closet of this multifamily dwelling located in a humid climate

Right - A technician applies a thin layer of closed-cell foam to air-seal an unvented attic assembly before filling the ceiling joists with batt or blown insulation.

Right - A technician wraps the foundation piers with a vapor retarder in preparation for laying vapor retarder over the floor of this crawlspace.

Right - A termite shield and a sill gasket are installed between the sill plate and the foundation on a raised slab foundation.

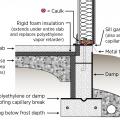

Right - Additional potential locations for slab-on-grade insulation include (a) under the slab and outside the perimeter with optional underground moisture block, (b) under the whole foundation, or (c) on top of the slab.

Right - After installing the EPDM gasket around the HRV duct, first the lower edge, then the sides of the gasket are taped; 11 of 14.

Right - After installing the EPDM gasket around the HRV duct, first the lower edge, then the sides, then the top of the gasket are taped; 12 of 14.

Right - After installing the EPDM gasket around the HRV duct, the lower edge of the gasket is taped first before taping the other edges of the gasket; 10 of 14.

Right - After wrapping the posts, a technician lays a vapor retarder over the floor of a crawlspace.

Right - Air barrier is present and installed between the floor system and unconditioned space.

Right - Air barrier is present between the dropped ceiling/soffit and the attic.

Right - Air barrier is present between the dropped ceiling/soffit and the attic.

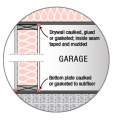

Right - Air-sealing the wall between the garage and the home is vital for occupant health and safety.

Right - All seams in the HVAC equipment and ductwork are sealed with mastic; because the HVAC equipment is in the garage, it is an air-sealed closet.

Right - Aluminum accordion coverings are permanently installed and can be deployed quickly but must be manually closed from the outside.

Right - Aluminum or polycarbonate panels attach to permanently mounted railings and require installation from the exterior.

Right - An energy recovery ventilation (ERV) brings fresh air into the home while exhausting stale air. Both ducts pass through a heat exchanger where heat from the warmer duct is transferred to the cooler duct.

Right - An EPDM gasket is installed around an HRV duct installed in an exterior wall; 9 of 14.

Right - An in-line air flow testing station is installed in a straight section of smooth metal duct (red outline) to determine the air flow rate of a fresh air intake for a whole house ventilation system.

Right - An installer uses canned spray foam to air seal joints in an existing subfloor.

Right - An ultra-efficient (COP 5.7) ground source heat pump provides hot water to an air coil in the central air handler which uses a variable-speed electrically commutated fan motor to distribute conditioned air to the home’s ducts.

Right - An unvented attic with no soffit vents, borate-treated fascia board, metal drip edge, and concrete block construction on this south Florida home help make it resistant to hurricanes, pests, and wind-born wildfire embers.

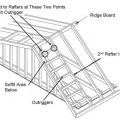

Right - Anchorage to increase the wind uplift resistance of outlookers forming the overhang at a gable end truss wall.

Right - Attach exterior insulation with insulation washers and tape the seams of the insulation is used as an air barrier.

Right - Automatic metal roller shutters are always in place and can be electronically or manually opened and closed.

Right - Baffles above the raised heel trusses and wind dams behind the trusses will keep wind from blowing the cellulose insulation away from the eaves.

Right - Baffles are installed in attic to keep blown insulation from blocking soffit vents and ventilation path

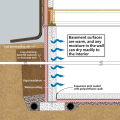

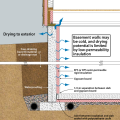

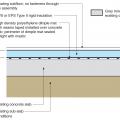

Right - Basement slab with a capillary break of either gravel or a drainage mat.

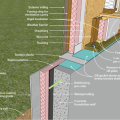

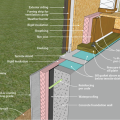

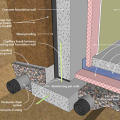

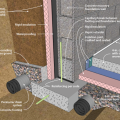

Right - Basement with exterior XPS or EPS insulation and insulation under the basement slab.

Right - Below-grade concrete has been properly sealed against moisture and is now having insulation installed.

Right - Blocking has been installed between the ceiling joists and air sealed in place with canned spray foam to stop air flow beneath the attic knee wall.

Right - Blown insulation in existing attic provides even coverage completely filling the attic space to a depth that covers the ceiling joists.

Right - Braced wall line spacing is correctly calculated for determining wall bracing in accordance with the IRC.

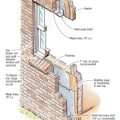

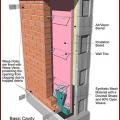

Right - Brick veneer is installed with a 1-inch air space behind the brick, metal flashing and weep holes above and below the windows and at the base of the wall to direct out water that gets behind the brick.

Right - Closed-cell spray foam covers the ceiling and joists to insulate and air-seal the ceiling deck.

Right - Closed-cell spray foam covers the interior of the foundation wall and wall framing is placed to the inside of the spray foam.

Right - Closed-cell spray foam insulation fills the wall cavities of the exterior walls in this home retrofit

Right - Closed-cell spray foam is installed as a skim coat to provide air tightness to an exterior wall cavity before installing batt or blown cavity insulation.

Right - Closed-cell spray foam is used to retrofit an existing rubble basement foundation wall.

Right - Closed-cell spray foam was applied to the interior of a foundation wall.

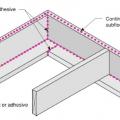

Right - Comprehensive air sealing of the walls includes caulking of the subfloor-sill plate seams and corner seams, taping of electrical boxes, and spray foaming around pipe penetrations.

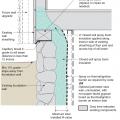

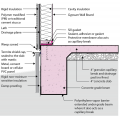

Right - Concrete masonry unit (CMU) basement wall showing exterior insulation and sill detail; above-grade wall has sheathing to the inside of the rigid foam.

Right - Continuous wall sheathing and blocking has been installed to brace the raised heel trusses.

Right - Corners of window are protected with draining house wrap that laps onto the sides of the window trim, paint-on flashing at window trim corners, and self-adhered flashing to reinforce corners.

Right - Correct angle for installing an engineered structural screw to secure a rafter to a wall for hurricane resistance.

Right - Corrugated house wrap is installed over the sheathing (in this case SIPs) and overlapped and taped at all seams.

Right - Counterflashing tops a layer of step flashing which comes down above the asphalt shingle and a layer of L-shaped base flashing which comes down and extends below the shingle; the base flashing is adhered to the roof underlayment with mastic, shown

Right - Dense vines growing on a covered trellis along the west side of this home provide effective shade for the wall and windows and create a shaded, protected walkway and outdoor seating area.

Right - Dovetail-shaped plastic mesh is installed to collect mortar droppings at the base of the wall to keep weep holes from being clogged.

Right - Drywall was installed before installing the duct chase to ensure the ducts will be separated from the attic.

Right - Ducts and heat pump cabinet are properly sealed with mastic, high MERV filter is installed, and duct and refrigerant lines are air sealed at ceiling.

Right - Each individual unit in this multifamily building has its own energy recovery ventilator (ERV) to provide balanced ventilation to the dwelling

Right - Electrical box in exterior wall is completely sealed with liquid flashing.

Right - Engineered portal frames are used for wall bracing to resist wind and earthquake loads.

Right - Engineered structural screws are installed to secure a stud to a top and bottom plate for increased hurricane or seismic resistance.

Right - EPA WaterSense-rated low-flow plumbing fixtures are verified as using less water than typical plumbing fixtures.

Right - External outlet wall penetration is flashed with tape that is properly layered with house wrap.

Right - Fiberglass/mineral wool insulation thermally isolates the garage from the interior occupied space above.

Right - Flaps are cut into house wrap installed over an HRV duct then taped out of the way to install flashing; 8 of 14.

Right - Flex duct installed with adequate support and pulled taut to provide adequate air flow

Right - Flex duct installed with frequent supports, straight runs, and gradual turns to allow good air flow

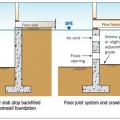

Right - Flood resistant slab and crawlspace foundations elevate the floor above the design flood elevation.

Right - Foil-faced polyisocyanurate insulating rigid foam sheathing is installed below the floor framing of this house built on piers; however, the seams should be sealed with metal taped and the plumbing elevated and protected.

Right - Foil-faced polyisocyanurate insulating rigid foam sheathing is installed rather than fibrous insulation below the floor framing of this house built on piers

Right - Foil-faced polyisocyanurate rigid foam board is tightly installed and sealed against a concrete foundation wall prior to installing fibrous blanket insulation.

Right - Foil-faced polyisocyanurate rigid foam is attached to the existing exterior wall with vertical wood furring strips

Right - Furring strips create an air gap to allow penetrating moisture to drain instead of wicking into walls; they also provide a nailing surface for siding.

Right - Furring strips were installed with blocking to allow adequate room for 4 inches of mineral wool.

RIght - Furring strips, house wrap, and siding are installed in the field after assembling panelized walls.

Right - Gasket installed at marriage wall connection prior to assembling modules

Right - Here, air control is established by taping the seams of the plywood panel sheathing. The roof sheathing is also trimmed flush with the wall sheathing to allow a simple and airtight connection between the roof and wall assemblies

Right - Hole drilled to verify sealant is present - Hole will be sealed after verification

Right - House wrap is carefully installed from the top of the roof line to the foundation; seams are overlapped and taped to provide a continuous air- and weather-resistant barrier

Right - House wrap is lapped back over first layer of flashing tape, then a second layer of flashing tape is applied to the sides around the duct; 13 of 14.

Right - House wrap is overlapped “shingle” style to direct moisture down and away from the house; seams will be taped so house wrap serves as both an air and weather barrier.

Right - HVAC ducts should be well-supported with minimal bends and pinching.

Right - Impact-resistant glass protects windows from wind-borne debris and is always in place, requiring no manual deployment during a storm.

Right - In areas prone to costal flooding, elevate the bottom floor well above the design flood elevation.

Right - In cooler climates, landscape shading should focus on the east- and west-facing walls, while leaving the south side of the house clear for solar access in winter (well-sized roof overhangs could provide summer shading for the south-facing windows)

Right - In hot climates, paint flat roofs light colors to reflect solar heat gain.

Right - Install backflow prevention devices on plumbing pipes to prevent wastewater from entering the home's plumbing system.

Right - Installation steps for the L-bent strap method of bracing a gable end wall

Right - Insulating sleeve for small through-the-wall HRV unit with sealing gasket; 3 of 14.

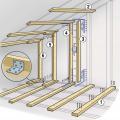

Right - Ladder blocking allows insulation to be installed in exterior walls at interior-exterior wall intersections.

Right - Lawn clippings were placed evenly to create a layer of mulch around the garden.

Right - Leaf guards allow rainwater into the gutter but keep combustible debris out, increasing the home's resistance to wildfires.

Right - Lookout or outrigger framing for a gable overhang provides two points at each outrigger to add metal connectors to strengthen the overhang against wind uplift.

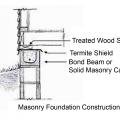

Right - Make concrete masonry unit foundations more termite resistant by using a solid masonry block or bond beam for the top course, installing a termite shield, and using a borate-treated sill plate.

Right - Manometers are placed away from the indoor side of the fan during blower door testing

Right - Mastic is being installed to air seal the wood-to-wood joints in this wall.

Right - Metal connectors provide uplift resistance at the rim joist between floors in new construction for a continuous load path.

Right - Metal connectors provide uplift resistance at the stud-to-bottom plate connection in new construction for a continuous load path.

Right - Metal drip edge flashing is installed above hose bib and top of metal flashing is taped to wall.

Right - Metal drip edge on this south Florida CMU home protects the top of the fascia and edge of the roof deck from water, wind-blown rain and embers, and insects.

Right - Mineral Wool insulation is installed on the exterior of wall with furring strips.

Right - Mold- and water-resistant fiber glass insulating sheathing is installed after panelized walls are assembled on site.

Right - Mulch covers the empty spaces in this garden, retaining moisture, moderating temperatures, and providing nutrients as it decomposes.

Right - New flashing has been installed to complete the air and water control layers at the window openings of this wall retrofit that includes insulating the wall cavities with spray foam

Right - Open-cell polyurethane spray foam to R-28 on underside of roof turns new attic into conditioned space for HVAC.

Right - Open-web floor and ceiling trusses provide space for ducts in conditioned space.

Right - Painter's tape is used to hold back house wrap while flashing layers are completed around the electric outlet.

Right - Panelized walls came to site with house wrap and furring strips pre-installed; seams will be overlapped and taped on site.

Right - Panelized walls came to site with house wrap pre-installed and ready to unfurl to cover foundation-to-sheathing seam.

Right - Panels of 7/16-inch treated plywood are inexpensive but take time to install and are difficult to install on higher windows.

Right - Peel and stick flashing and flashing tape seal a plumbing pipe that penetrates an exterior wall.

Right - Permeable rigid mineral wool insulation and appropriate water-management flashing details are integrated with new rigid foam siding to keep water away from the sill beam above the foundation wall

Right - Pieces of metal flashing are installed under each tile course along the valley centerline to prevent debris accumulation between and below concrete roof tiles.

Right - Plywood storm protection covering for windows is installed with removable threaded-rod fittings.

Right - Plywoood sheathing is taped at the seams to create a continuous air barrier that prevents air infiltration through critical junctures in the wall, such as at corners and between floors.

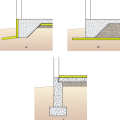

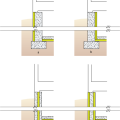

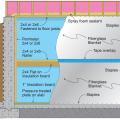

Right - Potential locations for basement insulation in new construction, slab insulation should always be underneath, with walls insulated (a) inside, (b) outside, (c) sandwiched inside, or (d) inside and outside of walls.

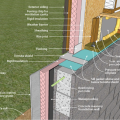

Right - Potential locations for crawlspace insulation: vapor sheeting should always cover the floor with insulation (a) outside walls, (b) inside walls, (c) both sides of walls, (d) sandwiched inside walls, or (e) under the first floor.

Right - Potential locations for slab-on-grade stem insulation in new construction: slab insulation should always be underneath, with stem walls insulated (a) inside, (b) outside, (c) not at all, or (d) outside with underground extension to repel moisture.

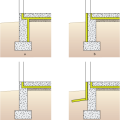

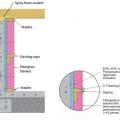

Right - Poured concrete basement wall showing exterior insulation and sill detail; above-grade wall has sheathing to the inside of the rigid foam.

Right - Poured concrete basement wall showing exterior insulation and sill detail; above-grade wall has sheathing to the outside of the rigid foam.

Right - Precast concrete basement walls come to the site with integrated rigid foam insulation and steel-faced concrete studs.

Right - Pressure reducing valves installed outside the home reduce water pressure before water is distributed to fixtures.

Right - Prevent condensation in fibrous insulation-filled basement wall cavities by installing rigid or spray foam between the frame wall and the concrete foundation wall and by not installing a Class I vapor retarder over the framed wall.

Right - Provide passive ventilation in hot climates by installing wind chases and vents.

Right - Raised-heel roof trusses allow more room at the eaves for attic insulation.

Right - Raised-heel trusses increase the roof height above the eaves allowing more space for insulation above exterior wall top plates; exterior wall sheathing extends up to keep wind from soffit vents from disrupting insulation.

Right - Reduce condensation risks to blanket insulation by installing perforated vapor retarder covered fiberglass blankets over rigid foam that is air-sealed at all edges; staple the blanket to nailers and top/bottom plates and tape over the seams.

Right - Retrofit of an existing basement slab by adding dimple plastic mat, rigid foam insulation, and a floating subfloor.

Right - Rigid foam board is attached to the interior surface of the basement walls.

Right - Rigid foam insulation is installed along the exterior edge of an existing foundation slab.

Right - Rigid foam insulation is taped at seams and installed over a drainage pad of aggregate to serve as a capillary break under the basement slab.

Right - Rigid foam is installed over a waterproofing membrane that has been applied to the basement foundation walls.

Right - Rigid foam slab edge insulation is installed along the exterior edge of a monolithic slab foundation.

Right - Roofs with simple geometries are less susceptible to ignition from wind-borne embers getting lodged on the roof in a wildfire.

Right - Sealant is installed at the top and bottom plates of a gypsum covered wall separating a garage from the conditioned space of the home.

Right - Seam-sealing flashing tape is installed with roller to fully adhere to the OSB.

Right - Seams in coated sheathing and joints around window are properly sealed and flashed with tape and all nail holes are covered with paint-on sealant.

Right - Section view showing how to air-seal and insulate a basement wall with perforated blanket insulation by installing it over air-sealed rigid insulation board to reduce condensation risk in the fiberglass blanket.

Right - Skylights can add natural light in rooms with limited wall space and if openable can provide desirable ventilation, especially when located at the top of stair wells.

Right - Skylights provide natural light while maintaining privacy in a narrow second-story bedroom.

Right - Solar photovoltaic panels are installed on the highest parts of the roof to avoid being shaded by other parts of the house.

Right - Spray foam covers the walls and a sealed vapor retarder lines the floor of this unvented crawl space.

Right - Spray foam fills the walls and rim joists to air seal and insulate while caulk seals the framing joints.

Right - Spray foam insulates and air-seals the stone walls of this unvented crawlspace.

Right - Spray foam insulates the attic eave between the attic floor and the SIP roof panel.

Right - Spray foam insulation air-seals the ceiling-to-drywall seams at the wall top plate.

Right - Spray foam insulation has been sprayed onto the underside of the sloped roof and the gable end wall to provide a sealed, insulated attic for housing the HVAC ducts

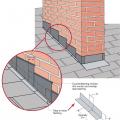

Right - Step flashing along a chimney is integrated in a layered manner with asphalt shingle roofing and topped with counterflashing that is embedded into brick mortar joint above

Right - Straps are spaced close enough together to provide adequate support of the flex duct

Right - Tape flashing keeps moisture out around and below the window; extra tape reinforces the corners to prevent tearing of the house wrap and to keep water out of this critical juncture.

Right - Technicians use adhesive when installing the vapor barrier along the walls of this crawlspace.

Right - The advanced controls in a programmable thermostat can be used to improve the efficiency of the home’s HVAC system.

Right - The air control membrane installed over the roof sheathing is continuous. It connects to the air control of the wall around the entire perimeter without interruption. The roof overhangs have been cut off to make this connection continuous

Right - The air handler for this geothermal heat pump is located in conditioned space.

Right - The attic access panel is insulated and weather stripped and a dam is built to hold back the blown attic floor insulation

Right - The automated ventilation system has a sensor built in switch that can detect indoor air pollution; if it senses a rise in humidity, VOCs, smoke, carbon dioxide, or small particulates, the system will turn on the nearest fan to eliminate pollution

Right - The basement foundation is insulated on the exterior and termite shield extends out past the top of the insulation.

Right - The basement walls are wrapped with 3 inches of XPS rigid foam that will be taped at the seams then covered with a dimpled plastic water barrier.

Right - The blanket fiberglass insulation is installed over a continuous layer of rigid foam insulation; the fiberglass is covered with a vapor retarder that is tape sealed at the seams.

Right - The butterfly damper of this crawlspace supply register opens when the HVAC fan is running; the damper duct is sealed with mastic and supported by strapping.

Right - The ceiling above the garage is air-sealed and insulated with spray foam.

Right - The ceiling above the garage is insulated and air-sealed with open-cell spray foam to keep garage fumes out of the living space above.

Right - The concrete basement wall is insulated on the interior with rigid foam; the footing detail is shown.

Right - The concrete masonry unit (CMU) basement wall has exterior insulation; the footing details include interior and exterior footing drain pipe.

Right - The conditioned basement is insulated on the interior with 1 inch of polyiso R-6.3 rigid insulation.

Right - The corrosion-resistant metal siding on this tiny house is fire resistant.

Right - The duct shows redundant sealing including the caulk, tape, and flashing

Right - The electronics for this home’s smart home system, including a Wi-Fi router, and controls for lighting, HVAC, security, energy production and tracking are housed together with the electrical panel and HVAC equipment in the home’s utility room.

Right - The energy recovery ventilator ducts supply filtered outside air to multiple locations in the home and continuously exhaust stale air to provide clean, balanced ventilation.

Right - The exhaust duct has been mechanically fastened and sealed with mastic.

Right - The exhaust vent duct terminates to the outdoors with a vent cover that has been properly caulked and covered with a metal pest screen.

Right - The existing basement slab is retrofitted by installing a dimple plastic drainage mat, rigid foam insulation, and a floating subfloor.

Right - The garage roof is correctly oriented for the home’s solar shingle system.

Right - The geothermal heat pump provides hot water for radiant floor heating, domestic hot water, and the air handler for space conditioning upstairs.

Right - The high-efficiency wood stove is located on an interior wall in this home to provide a secondary heating source in cold climates.

Right - The home’s ground source heat pump preheats water for the air source heat pump water heater.

Right - The home’s high-efficiency gas boiler provides domestic hot water as well as in-floor radiant heat, while a high-efficiency heat pump provides cooling and a secondary source of heating.

Right - The house wrap is properly flashed and taped, and all penetrations are properly flashed.

Right - The HVAC ducts are located in conditioned space in a dropped hallway ceiling with very short duct runs for more efficient delivery.

Right - The kitchen exhaust duct termination is integrated aesthetically and functionally with the exterior cladding; however, the opening should be screened to keep out pests.

Right - The pipe penetration is properly flashed and furring strips are installed on each side in preparation for installing cladding

Right - The posts and floor of this crawlspace are covered with a heavy sheet of vapor retarder that is sealed to the post, the walls, and at all seams.

Right - The poured concrete basement walls are insulated along the inside with 2.5 inches of extruded polystyrene insulation.

Right - The precast insulated concrete walls of the basement provide a conditioned space for the high-efficiency (18 SEER, 9.5 HSPF) air-source heat pump, with its variable-speed fan, five-stage compressor, and MERV 11 filter.

Right - The rigid metal HVAC ducting is installed between the floor joists rather than in an unconditioned attic or crawl space to minimize heat loss.

Right - The sealed conditioned crawlspace provides a clean, dry, and temperate environment for the home’s supplemental dehumidifier.

Right - The seams in the OSB sheathing are sealed with a sprayer-applied sealant.

Right - The service penetration in the waterproofing membrane is well-sealed, and there is a drainage mat acting as a protective layer on the interior of the soldier piles and wood lagging.

Right - The service penetrations through the structural slab in this garage plenum are air sealed.

Right - The simple rectangular design of this home provides a large expanse of roof for solar panels.

Right - The slab-on-grade foundation is insulated with two layers (R-20) of XPS foam under the-slab and R-10 on the exterior of the stem walls.

Right - The underside of the attic roof deck is insulated with open-cell spray foam to provide an insulated space for HVAC equipment.

Right - the vapor barrier is extended up the sides of the piers in this crawlspace, which is sealed and insulated to house the HVAC ducts.

Right - The wall framing is connected to roof framing with metal ties for hurricane-resistant construction.

Right - The wall top plates are sealed with foam before installing insulation on the ceiling deck.

Right - The water and air control layers are properly integrated around the hose bib

Right - These attic knee walls are insulated with rigid foam and sealed with spray foam to form a continuous air barrier at the gable end of this cathedral ceiling.

Right - These homes have hurricane shutters to protect against high winds and to provide solar control.

Right - These interior solar screens help control glare and solar heat gain while maintaining view to the outside.

Right - These inverters convert the power from the home’s 6.8-kW of photovoltaic panels from DC to AC for connection to the grid; the inverters can also be connected to batteries for backup power storage.

Right - These raised heel roof trusses provide 16 inches of space over the outer walls for full insulation coverage at the attic perimeter.

Right - These removeable awnings provide ample shade to windows and patio space, reducing heat gain to the home.

Right - These retractable awnings provide shade to this outdoor living space and reduce heat gain and glare within the home.

Right - These roof insulation panels are installed in multiple layers with joints offset both vertically and horizontally. The plywood nail base fastened to the roof framing holds the insulation layers together snuggly thus minimizing gaps