Scope

In high wind zones, construct unvented insulated sloped roof assemblies to resist the wind pressures that can occur during high-wind events such as hurricanes and to minimize the entry of wind-borne rain, snow, or burning embers.

- Install structural roof deck sheathing using the fastener schedule recommended by IBHS Fortified Home.

- Seal the roof deck using one of the following methods:

- Apply self-adhering polymer modified bitumen membrane to the entire deck.

- Tape seams in sheathing with 4-in.-wide compliant flashing tape and cover with compliant underlayment.

- Seal the underside of the roof deck by applying closed-cell spray adhesive foam to all seams in sheathing and between sheathing and framing.

- Insulate above the roof deck, by installing one or more layers of rigid foam insulation with seams staggered and taped. Then install an exterior sheathing layer that is air-sealed by either covering the entire sheathing layer with a fully adhered membrane or sealing the seams with an approved flashing tape.

- Or, insulate below the roof deck with closed-cell spray foam or a combination of closed-cell spray foam and fibrous insulation.

- Install roof cladding rated for the climate zone.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

In high wind zones, roof assemblies need to be able to resist the wind pressures that can act on them during high wind events such as hurricanes. This guide provides guidance for the construction of unvented, sloped, insulated roof assemblies in high wind zone areas.

Sloped roof assemblies can be constructed with no venting and insulated at the roof line to form an unvented, insulated (conditioned) attic; the insulation can be installed either below or above the structural roof deck. Unvented attics provide several disaster-resistance benefits. They have no vents through which wind-borne rain, snow, or burning embers can enter the attic. They are also more resistant to wind pressure-caused failures due to soffit collapse in high wind events.

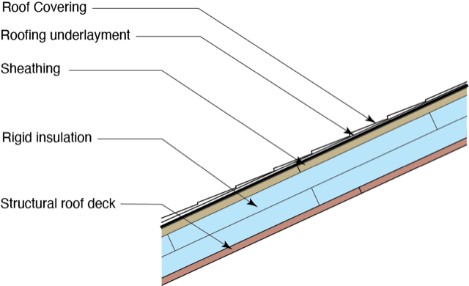

Even with unvented roof designs, in roof assemblies where the insulation is above the structural roof deck, air pressure differences during high wind events can lead to loss of roofing along with roof sheathing. This is more likely to happen if the seams in the lower decking and upper sheathing layers are not sealed (Figure 1) and air is allowed to enter the assembly creating positive pressure under the roofing which is simultaneously being pulled by negative exterior pressures on the leeward side of the building. These air pressure relationships are further explained below.

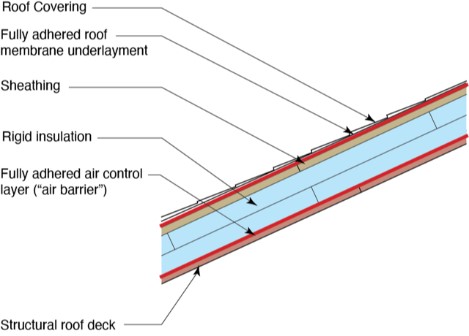

To keep air out of the assembly, a fully adhered roof membrane underlayment is recommended. A fully adhered air control layer should also be installed over the lower structural roof deck sheathing (Figure 2). Alternatively, flashing tape or membrane strips that are compatible with the plywood or OSB sheathing could be used in place of either fully adhered roof membrane underlayment. The seams in the rigid foam layers should also be sealed with acrylic tape. Tapes and membrane selection for sealing the upper roof deck sheathing and the lower structural roof deck sheathing joints should follow the recommendations of the IBHS in their guide Seal the Roof Deck: Choosing the Right Tape. This guide also provides recommendations for the acrylic-based tapes for sealing the rigid foam insulation.

For increased wind resistance, the lower structural roof deck sheathing should use sheathing, fasteners, and a fastener pattern recommended by the Insurance Institute for Business & Home Safety (IBHS) in their Standard Detail Set for Fortified Roof. For the upper deck sheathing, the fasteners should be epoxy-coated steel screws installed 6-inches on-center that penetrate through the lower deck sheathing. Rigid insulation should be limited to a maximum thickness of 10 inches and installed using multiple 2-inch-thick sheets with joints offset horizontally and vertically.

Another option for sealing and insulating the attic at the roofline is to install closed-cell spray polyurethane foam (SPF) adhesive on the underside of the lower structural roof deck sheathing to seal the joints in the assembly resulting in a continuous air control layer (“air barrier”) (Figure 3). Additional closed-cell spray foam or a combination of closed-cell spray foam and fibrous insulation can be installed along the underside of the roof line to the attic R-value desired or required by code. For more on these approaches, see the Building America Solution Center guides Application of Spray Foam Insulation Under Plywood and OSB Roof Sheathing and Below Deck Spray Foam Insulation for Existing Roofs.

For information on the selection and installation of roof coverings, see the guides Asphalt Shingle Roofs, Clay or Concrete Tile Roofs, or Metal Roofs.

Understanding High Wind Related Air Pressures and Roof Failures

Significant air pressure differences act across buildings due to the action of wind. In general, sloping roof assemblies experience positive wind pressures on the windward side and negative wind pressures on the leeward side of the building. In high wind events, if soffit assemblies collapse, excessive wind can enter the attic space on the windward side pressurizing the attic space. When this attic positive air pressure is coupled with the negative pressure on the exterior surfaces of the leeward side of the building, the air pressure difference across roof sheathing and roof cladding elements such as shingles, tiles, and metal roofing significantly increases. This significant air pressure increase can lead to the loss of parts or all of the roof assembly.

It is common in sloped roof assemblies that are insulated above the structural roof deck to utilize mechanically attached (rather than fully adhered) roof underlayment, upper deck sheathing, and multiple layers of rigid insulation. In residential construction, the upper deck sheathing and the structural roof deck are typically plywood or oriented strand board (OSB). In residential construction, the rigid insulation is most commonly isocyanurate or extruded polystyrene (XPS).

Under high wind events, the total wind pressure is resisted by all of the elements of the roof assembly. A series pressure relationship provides a reasonable approximation of what occurs.

P(t) = P(c) + P(u) + P(d) + P(i) + P(i) + P(sd)

Where P(t) = total wind pressure

P(c) = roof covering pressure

P(u) = underlayment pressure

P(d) = deck pressure

P (i) = insulation pressure

P(sd) = structural deck pressure

The most airtight (“tightest”) element experiences the greatest pressure. In most sloped roof assemblies, the tightest element is the roof covering itself – shingles and their underlayment, tiles and their underlayment, or metal roofing and its underlayment. Interior spaces can simultaneously experience high positive pressures, especially if a window or door is “blown in” or fails. This type of high positive interior pressure increases the risk of roof failure. In a multi-layer roof assembly where elements (or layers) are not sealed and a mechanically attached roof underlayment is used, the roof covering and the roof underlayment can fail.

In high wind zones, fully adhered roof membrane underlayments are recommended. Additionally, a fully adhered air control layer (“air barrier”) should be installed over the lower structural roof deck sheathing (Figure 2). This approach reduces the air pressure difference across the roof coverings and thereby reduces the risk of failure to “blow off”. Additionally, the fully adhered roof membrane underlayment provides a “second line of defense” should the roof coverings blow off. Finally, the lower fully adhered air control layer (“air barrier”) provides a “third line of defense” should the upper deck sheathing and the rigid insulation be lost. It is also recommended that the joints in the rigid insulation layers be taped or sealed.

Success

In high wind zones, fully adhered roof membrane underlayments are recommended.

Climate

This approach is climate independent – it works in all climates to reduce the risk of roof covering and roof underlayment “blow off.” In cold climates, this approach also addresses high interior moisture loads that can lead to condensation within the layers of the roof assembly.

See the Compliance tab for more information on the minimum levels of roof assembly insulation required for each climate zone.

Training

Compliance

Retrofit

For existing roofs where the roof covering will not be removed. IBHS Fortified Home permits the seams to be sealed on the underside of the roof deck using closed-cell spray adhesive foam applied to all seams in sheathing and between sheathing and framing.

For information on converting an existing vented attic to an unvented insulated and conditioned attic, see the Building America Solution Center guides Water Managed Roof – Re-roofing and Adding Insulation Over a Sloped Roof and Below Deck Spray Foam Insulation for Existing Roofs.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.