Scope

Provide spot exhaust ventilation over the stove that exhausts steam, cooking pollutants, smoke, and odors to the outside of the home.

- Replace an existing recirculation kitchen fan with a kitchen exhaust fan that is ducted to the outside or

- Install a new kitchen exhaust fan that is ducted to the outside.

- Based on the kitchen’s current layout, determine the best location for the new ducted exhaust fan: a range hood fan, a fan integrated with an overhead microwave oven, a wall unit mounted directly above the stove, or an undercabinet range hood fan. For a cooktop located in an island, a ceiling-mounted exhaust fan is best but if a downdraft system is used, ducting will likely be located beneath the floor.

- Choose a kitchen exhaust fan that will achieve air flow, sound, and pollutant removal goals.

- Follow manufacturer’s installation instructions.

- Use a metal duct with a smooth interior, as required by code.

- Use the duct size recommended by the manufacturer to maximize air flow.

- Determine the shortest, most direct route in which you can install the duct to run from the unit to the exterior.

- Terminate the duct at the exterior wall or roof; install a hooded termination vent with a damper and screening to keep out pests. Flash and seal around the duct terminus.

- Seal all seams and joints in the duct and seal the duct-fan connection with mastic or UL-181 tape.

- Provide make-up air to the kitchen if the kitchen exhaust fan flow rate exceeds 400 cfm.

- Have the flow rate third-party tested and confirmed.

For more information see the Pre-Retrofit Assessment of Ventilation Systems.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Kitchen exhaust ventilation, properly ducted to the outside, is an essential component of good indoor air quality (Figure 1). Research has identified kitchens as the primary location where most harmful pollutants are generated in the home. During the cooking process, moisture and pollutants are released into the home, from the cooking fuel source and from the ingredients themselves. The health effects of cooking pollutants (such as particulate matter, formaldehyde, and NO2) are well established. A helpful summary of research on this issue is published by the California Air Resources Board. In addition to controlling pollutants, the control of odors and moisture from cooking is another important aspect of acceptable indoor air quality in homes. Compounding the issue of pollutants is the fact that kitchens are one of the most popular places to gather in the home, which increases occupants’ exposure to cooking pollutants and increases carbon dioxide levels in the kitchen.

Many kitchens do not have adequate ventilation systems installed. Common kitchen ventilation scenarios one is likely to encounter in existing homes include the following:

- Recirculating Mechanical Ventilation

- Many of the existing fans located in kitchen range hoods, downdraft systems, and integrated into over-the-range microwaves are recirculating fans, not exhaust fans that are ducted to the outside. Recirculating fans do not provide ventilation that is compliant with modern codes.

- Natural Ventilation

- Many older homes have no mechanical ventilation but instead rely on natural ventilation via an openable window.

- Fan on Ceiling or Wall

- A kitchen exhaust fan that is located in a general location such as on a wall or on the ceiling away from the stove will not capture and remove kitchen pollutants as effectively as a range hood fan located directly over the cooktop, even if that ceiling or wall exhaust fan is ducted to the outside.

- Fan Ducted to Attic or Crawlspace

- Ducted exhaust fans that terminate in an attic or crawl space are not compliant with code and can cause moisture problems and re-introduce pollutants into the living space.

When ducted to the exterior, mechanical kitchen ventilation systems can significantly reduce exposure to cooking pollutants, but while this is considered best practice, because codes do not require it, the practice is not commonly seen in older homes. A 2018 study was conducted of tightly constructed homes without range hoods (Militello et al. 2018). The homes in the study “relied on ventilator exhaust grilles [general ceiling or wall exhaust fans] in the kitchen area to remove the pollutants. This strategy, in general, did not prove to be effective. The particulate emissions from cooking overwhelmed any exhaust removal and spread to the rest of the house” (Militello et al. 2018). The combination of ducting and using a range hood rather than an area kitchen exhaust fan will reduce kitchen pollutants in any home.

Further, studies show that the majority of residents don’t operate their range hoods routinely, or as designed, to properly ventilate the space during the cooking process, often citing the operation of their kitchen exhaust system as too loud. A homeowner survey of kitchen exhaust use by Lawrence Berkeley National Lab found that noise was one of the most common reasons that residents did not use their kitchen exhaust system (20.7%) and many did not consider kitchen exhaust to be necessary (47.7%) (Mullet et al. 2013). Adding an outdoor duct as a retrofit application will not only improve indoor air quality by reducing exposure to cooking pollutants but may also come with additional benefits such as significantly reducing the operating noise, making occupants more likely to use the fan. Even with older fans with higher sone ratings, adding ducting to the outside can significantly lower noise levels.

Even though adding a kitchen exhaust duct can make such an impact on indoor air quality and noise, the conversion is rarely done in existing homes, except as part of a major kitchen renovation. When the retrofit is performed, ducting kitchen ventilation to the outside in an existing home is often done by an electrician, general contractor, or handyman. If part of a broader kitchen renovation, it may be done by a kitchen remodeler or an HVAC contractor. It is important to ensure that the scope of installing a kitchen exhaust duct is broadly considered. Missing important installation considerations and steps can result in a ventilation system with inadequate air flow or inadequate capture efficiency. Capture efficiency is measured as the percentage of emissions captured and vented to a control device. Until recently, this was a largely ignored area of performance in kitchen exhaust, but manufacturers are beginning to market their fans’ performance related to capture efficiency.

There are multiple important things to take into account when scoping out the project, including whether you are converting or replacing the existing system or installing a new system, and where and what type of fan system to install, as well as where and what type of duct to install. These will be described in the following sections.

Converting or Replacing Existing Recirculation System

If a recirculating system is installed, there are a few things to consider. In many cases these fans can be configured to operate as a recirculation fan or an exhaust fan. However, some can only be operated as recirculation fans. Check the fan’s ability to operate as an exhaust fan. Refer to manufacturer installation instructions if available or search online. If you intend to reconfigure a recirculating fan for use as an exhaust fan, check to see if it is capable of pulling the required amount of air. It may be necessary to have an energy audit or other assessment to determine this information unless the contractor installing the range hood can test the fan.

Even if the existing recirculating fan can be converted to a ducted exhaust fan, the homeowner may still wish to install a new exhaust fan to achieve better performance, including higher energy efficiency and quieter operation. Kitchen fans can become coated with grease and grime over time that decreases performance and is hard to clean off. When looking for a new fan, look for models that are ENERGY STAR rated.

Note: A common scenario for wall-mounted chimney range hoods is to look as though they are ducted when the flue is actually just for aesthetics and is not connected to any duct system (Figure 2). Check behind the chimney piece to see whether a duct is attached to the range hood.

Installing a New Kitchen Exhaust System

When installing a new ducted kitchen exhaust fan, the layout of the kitchen will determine the type of unit that can be installed. If there are cabinets above the range, an under-cabinet range hood is appropriate. For kitchens with open space above the range, a wall-mounted range hood is likely the best option. For ranges on an island, a ceiling-mounted hood would be ideal.

Follow the manufacturer’s installation instructions for range hood placement to maximize capture efficiency. The minimum acceptable flow is 100 cubic feet per minute (CFM) when operating intermittently, or 5 air changes per hour (ACH), based on kitchen volume, according to ASHRAE 62.2-2019. Code minimums are also established in the 2018 International Residential Code (IRC), Section 1505.4.4. The Home Ventilating Institute (HVI) provides a variety of fan size recommendations based on system location and configuration. Current ENERGY STAR criteria require that exhaust fans have a minimum efficiency of 2.8 CFM/Watt and a maximum sound rating of 2.0 Sones. Check to see if the system has been tested for capture efficiency.

Range Hood System Requirements

Exhaust hoods installed over domestic open-top broiler units should be made of metal and have a 1/4-inch clearance between the hood and the underside of combustible material or cabinets. The hood should extend the full width and depth of the cooktop, discharge to the outside, and have a backdraft damper (2018 IRC- Section M1505.2.1). Check the manufacturer-included damper to make sure that it is airtight. An additional or substitute damper may be necessary. A range hood, fan-integrated microwave, or downdraft system may be selected, but be careful to examine the performance features of these options, as not all options will provide equivalent removal of pollutants. If reconfiguring an existing unit, remove the existing unit from the wall and follow the manufacturer’s instructions for reconfiguring from a recirculation fan to an exhaust fan. Note that this may involve electrical work, depending on existing wiring. A qualified installer should perform any electrical alterations. When replacing an older recirculating fan with a new system, it is possible that wiring will need to be changed to accommodate modern controls. The older system may only have had an on/off switch while a newer system may be variable speed, requiring different wiring details. Find information on certified fan products at hvi.org.

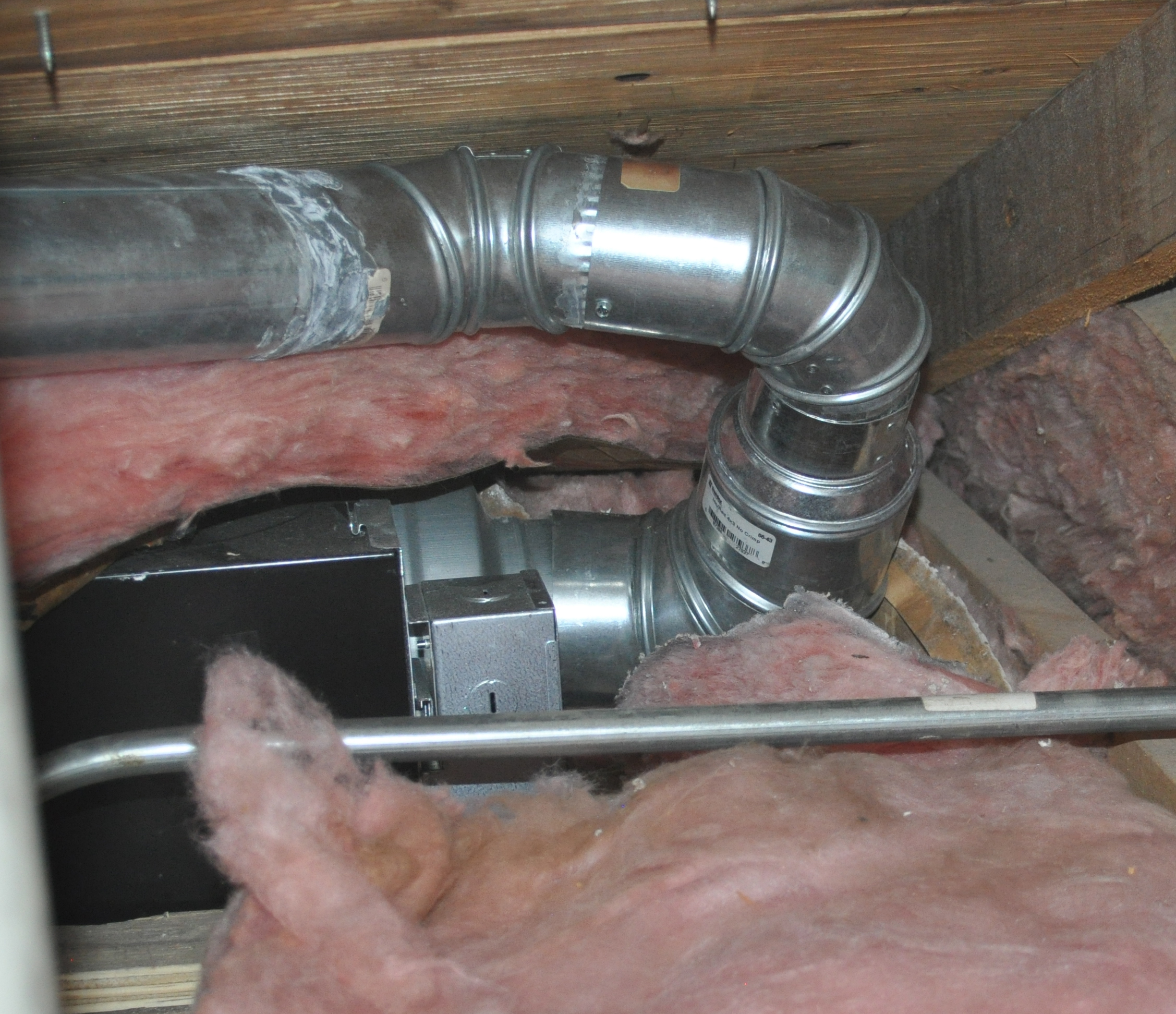

Duct Material

The duct serving the range hood should be made of rigid metal such as galvanized steel or stainless steel and should have a smooth interior surface. Metal or plastic flex ducts are prohibited. This is a common code violation related to kitchen exhaust systems. PVC ducts may be used for downdraft exhaust systems.

Duct Size

To ensure the duct is correctly sized, refer to the manufacturer’s installation instructions for duct size. The larger the duct, the less it will restrict air flow. Using a duct that is too small for the required air flow will significantly reduce the achieved flow rate. To achieve the rated air flow of the selected fan, the correct duct size is needed. The size recommended by the manufacturer will vary by model and sometimes by exit direction (horizontal or vertical duct). Depending on the exit option selected, an exhaust system may require a round or rectangular duct. For example, a range hood might use a 6-in. round duct or an equivalent 3.25 x 10-in. rectangular duct. Ducts can be transitioned from rectangular to round via connector pieces. Cut openings in the ceiling or wall for the exhaust duct no wider than needed to fit the duct and any needed insulation. An opening that is too small will not allow installation of the duct. An opening that is too large will complicate air sealing measures and may require additional supports.

Duct Exit Route, Layout, and Complications

Locate the shortest, most direct route to the exterior in which the appropriate duct size can fit, taking into account any obstacles and complying with termination location requirements. This varies depending on the location of the equipment and the floor plan of the home. Ducts should not be combined with other duct systems. Often complications arise that prevent a complete direct route. Choose a route that not only minimizes duct length, but also limits elbows in the duct run. Longer ducts and more elbows will reduce flow rate, sometimes to the point where a fan with a higher rated CFM must be considered. Elbows not only reduce flow but can allow the build up of grease over time. Many fan models have the ability to duct from the top or from the back of the unit to better accommodate duct runs that could go vertical or horizontal.

Longer duct runs will need to be supported according to code. Depending on the code adopted, the code may refer to the duct manufacturer’s instructions or to a maximum of 10-foot intervals. The fact that the ducts are metal will prevent sagging between supports but duct supports may be necessary if the run is longer than 10 feet (see 2018 IRC M1601.4.4).

Interior Wall Complications

If the equipment is located against an interior wall, the shortest route may be through the attic (typical in a one-story house). For two-story homes with the kitchen on the first floor on an interior wall, often this means running the duct up and through cabinets to the exterior. If a duct is passing through finished space to reach the exterior, it could run through an available floor cavity if joists are running parallel to the duct. If not, a soffit should be considered. Review the maximum length guidelines specified in the current local building code. The shortest run possible is ideal.

Kitchen Island Range Complications

A kitchen island range often encounters similar exit route complications to that of an interior wall. For ceiling-mounted island range hoods, the most direct route may be through the roof. For a downdraft system, the duct would need to run through the floor joists to the exterior or through a soffit in the story below.

Exterior Wall Complications

If the equipment is located on an exterior wall, ducting to the exterior can be simpler, but sometimes structural members are obstacles to direct routes to the exterior.

Example Scenario: A kitchen range is located on an exterior wood-framed wall. This wall has a stud directly in the center of the range, blocking the shortest, straightest exhaust duct run. Duct elbows could be used to twist the duct around the stud to reach the exterior, resulting in a less-than-ideal duct installation with reduced air flow. Or, the contractor may be able to cut out a portion of the stud to allow the duct to pass through, then install framing pieces above and below to transfer the load to surrounding studs.

Duct Termination

Vent the kitchen fan exhaust to the outside, not into an attic, crawlspace, or space between floors. Terminating the duct within the home violates code and will introduce moisture and kitchen pollution into the indoor environment. The exhaust duct must vent outside and the terminal end of the duct must be a minimum of 10 feet away or 3 feet above any air inlet and at least 3 feet away from any operable window (see 2018 IRC, Section M1504.3). Additionally, the fan cannot exhaust air onto walkways, a common scenario for townhome communities (see 2018 IRC, Section R303.5.2).

Example Scenario: A kitchen on an exterior wall had a range installed immediately next to an operable window during a previous kitchen renovation. An exhaust duct installed above the range directly through the exterior wall will exhaust too close to the window, violating code and allowing odors and kitchen pollutants to re-enter the space when the window is open. A solution may be to route the duct vertically through the roof or at least high enough on the wall to terminate at least three feet from the window. Another solution might be to convert the window to a section of solid wall.

The penetration in the exterior building envelope must be flashed to prevent the intrusion of bulk moisture and must be sealed with caulk, foam, or a gasket to prevent air leakage through the building envelope. The duct termination must be covered with louvers, a screen, or a grille to protect the exhaust duct from weather and pests. The EPA Indoor airPLUS program requires a pest screen at exhaust terminations. Duct terminations should be integrated aesthetically with the exterior cladding. Installations of kitchen exhaust ducts often do not take into account how to integrate the duct termination with the exterior cladding, resulting in a termination grille that is simply screwed on top of the exterior siding. Planning the installation of cladding finishing pieces as part of the work will help avoid an eyesore at the end of the project.

Duct Sealing and Insulation

All duct joints and seams must be sealed with either mastic or UL 181 tape. Failure to seal the seams will result in duct leakage and reduced air flow. In some cases, duct leakage may also result in unwanted condensation in the home. Warm moist air from a kitchen exhaust system leaking into cold spaces will cause surface condensation. Careful sealing of all possible points of leakage will prevent major performance issues on the exhaust duct. Connect the exhaust duct to the fan box with mechanical fasteners and seal with mastic or UL 181 tape. Air seal any holes in the fan box with mastic or UL 181 tape.

Although duct insulation is not required for exhaust ducts, for ducts passing through unconditioned space in colder climates duct insulation is recommended to prevent condensation. All penetrations created for the duct should take into account the width of any planned insulation to avoid crushing or compressing the insulation.

Make-Up Air

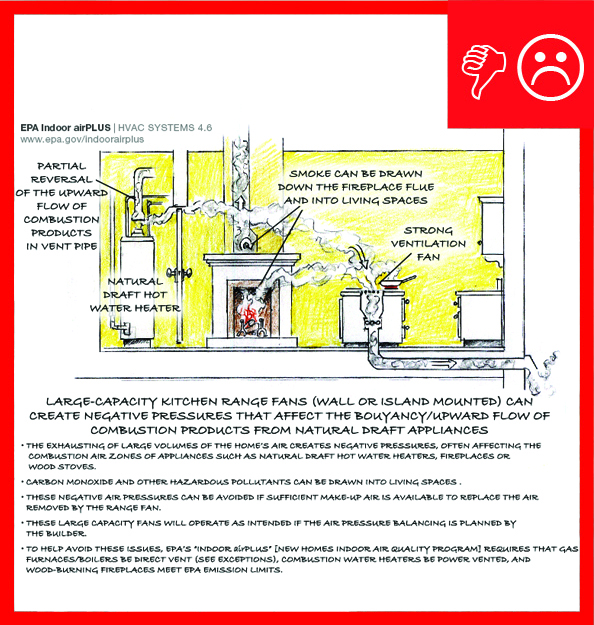

For homes with combustion appliances, it is important to provide make-up air to prevent hazardous conditions in which the range hood exhaust fan causes the combustion appliance to backdraft. The 2018 IRC, Section M1503.6, requires that if the range hood is capable of exhausting more than 400 CFM of air, make-up air must be provided. This only applies in homes with gas appliances that are atmospherically vented. This is a combustion safety issue. For homes adding a kitchen exhaust fan for the first time, if a ≥400 CFM exhaust system is installed, this requirement will apply, if there are any atmospherically vented combustion appliances in the home. Note that in earlier versions of the IRC, this requirement applies to all homes with ≥400 CFM kitchen exhaust systems, regardless of whether there are combustion appliances in the home.

Although 400 CFM is the code trigger for make-up air requirements, make-up air should be considered even for kitchen exhaust fans with lower CFM ratings. In a home with atmospherically vented combustion appliances, it is possible for a range hood to cause back-drafting even when pulling less than 400 CFM of air flow (see Figure 4). If the home has combustion appliances, consider adding make-up air regardless of the range hood’s rated CFM.

The IRC allows multiple options for providing make-up air. The makeup air can be provided mechanically or naturally directly to the kitchen, to a room that communicates with the kitchen, or to a duct system that communicates with the kitchen. This last option is the most common because it allows the introduction of make-up air into the home’s HVAC duct system, which prevents unconditioned outdoor air from being directly introduced into the space.

A damper is required for the make-up air inlet. Although the code allows this to be a gravity damper, a mechanical damper is preferred. Gravity dampers are not tested to any standard and are often field fabricated. It is conceivable that backdrafting could occur at pressures low enough that a gravity damper would not be forced open by the exhaust system.

Verification

The exhaust fan flow rate should be tested by a certified energy rater using test procedures listed in ANSI/RESNET/ICC 380-2016.

Success

- Each home will bring its own set of variables. Be prepared to adapt to site conditions and obstacles. Before beginning all work, map out multiple possible paths to the outdoors, paying close attention to structural barriers and allowable termination points. Consider that scope may be significantly broader than installing duct for a new home or complete kitchen renovation.

- Follow the manufacturer’s instructions for duct sizing and connecting the duct to the exhaust fan. In order for the fan to perform as expected, the correct sized duct and connection must be installed. A different sized duct will adjust the performance of the kitchen ventilation system.

- Follow the manufacturer’s instructions regarding the location to install the kitchen ventilation system. Center the unit over the range. Hoods should extend the whole width of the range top. Pay close attention to the recommended height the ventilation unit should be above the range top. The location of the system in relation to the range top plays a critical role in maximizing capture efficiency (the percentage of emissions captured and vented to a control device).

- See the Compliance Tab for requirements for Above Code Programs (ENERGY STAR Single-Family New Homes and DOE Zero Energy Ready Home), ASHRAE 62.2- 2019 Standards, and Building Code requirements (IRC and IECC). Be sure to check your local code for any additional requirements.

- Air seal all ducts and confirm the exhaust duct is sealed to the fan box with both mechanical fasteners and mastic and/or metal tape. Seal all penetrations to the exterior with caulk or spray foam.

- Ensure the duct is properly sealed using UL 181 tape or mastic to seal all joints and seams. Mastic is preferable.

- After installation, have a certified rater or energy auditor verify performance by conducting a flow hood test using ANSI/RESNET/ICC 380-2019.

- See the Success Tab in the Solution Center guide Kitchen Exhaust Fans for new homes for further guidance and more considerations to ensure a successful installation.

Climate

Consider insulating the exhaust duct in cold climates to avoid condensation on the duct.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.