Scope

Protect entry doors and sliding glass doors against fire, wind pressures, windborne debris, and heat loss and gain during wildfires, hurricanes, severe storms, extreme heat, or extreme cold by installing insulated, impact-rated, and fire-rated doors or by installing impact-rated storm shutters or panels to protect the doors.

- Consider installing insulated and airtight doors in all climates.

- Determine if protection for entry doors and sliding glass doors is required.

- Determine the most suitable type of doors or protection products.

- Install products in accordance with the manufacturer’s instructions and applicable building codes including any local requirements for specific product approvals. Installing impact-rated doors or providing doors with a storm protection covering is a requirement of the Insurance Institute for Business and Home Safety® (IBHS) Fortified Home Hurricane Standard.

- Inspect exterior doors and hardware periodically to ensure good working order, preferably before hurricane or wildfire season.

- In wildfire-prone areas, use doors with a minimum 20-minute fire rating and for glass doors, use multi-layered tempered glass.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Insulated, air-sealed doors are an important component of an energy-efficient and durable home. They are also key to a home’s ability to weather extreme heat or extreme cold events. In areas prone to high winds or wildfires, however, doors require features beyond insulation and air-sealing to help keep a home safe.

Resistance to High Winds

Door assemblies must be strong enough to withstand wind pressures acting on them and be fastened securely enough to transfer those wind pressures to the adjacent wall. Pressure failures of doors can allow glazing to fracture or glazing frames or supports to fail. Anchorage failures can allow the entire door to be ripped from the wall, as shown in Figure 1. Either type of failure results in the failure of the building envelope and allows wind and water to enter the building.

Installing impact-rated doors or providing doors with a storm protection covering is a requirement of the Insurance Institute for Business and Home Safety® (IBHS) Fortified Home Hurricane Standard and IBHS Fortified Home High Wind Standard Silver designation. FEMA, as part of the Intermediate Mitigation Package, notes that all exterior entry doors should be protected from windborne debris and design wind pressure. At least one entry door should be operable from inside the living space if opening protection is in place. Entry doors should be protected by either protecting the existing door with an impact-resistant covering or providing an impact-resistant door (FEMA P-804, 2010, Wind Retrofit Guide for Residential Buildings).

Damage to glazing systems (windows) in doors can be prevented, or at least minimized, by using glazing or opening protection systems that have been designed to resist wind and windborne debris forces specified in the building code. See Figure 2. Impact-resistant (i.e., debris-resistant) systems provide protection using laminated glass or polycarbonate glazing systems. The use of physical opening protection systems such as storm shutters or panels, fabric screens, or structural wood panels is also a common means of achieving protection for glazing. Impact-resistant doors and storm shutters and panels must be third-party tested and rated. Note that storm shutters and panels are typically not rated to reduce wind pressures on the doors they protect, so doors must always be installed to withstand wind pressures. Impact-resistant doors commonly include reinforced frames, tighter weatherstripping, and energy-efficient glass.

A very effective solution for protecting the glazing is impact-resistant glazing systems. Impact-resistant windows provide in-situ protection and require no human action or involvement after installation; the protection system is always in place and does not need to be installed prior to storm events. Further, these systems do not need to be closed, lowered, or installed like storm panels or shutter systems.

Another option is storm shutters, also known as hurricane shutters, which are permanently installed so they are always in place and ready to be closed. The primary types of storm shutters for doors are rolldown, accordion, and colonial shutters.

A third option, storm panels, are temporary coverings that are installed when needed, then removed and stored, for example, in a garage or shed. Panel hardware must be corrosion resistant and permanently mounted on the house, using a combination of tracks, bolts, and wingnuts for quick installation. Storm panels are commonly constructed of corrugated steel, aluminum, or polycarbonate, or screens made of fabric.

Regardless of the type of protection chosen, proper installation of the door, weather stripping, and flashing are also critical to reduce water infiltration.

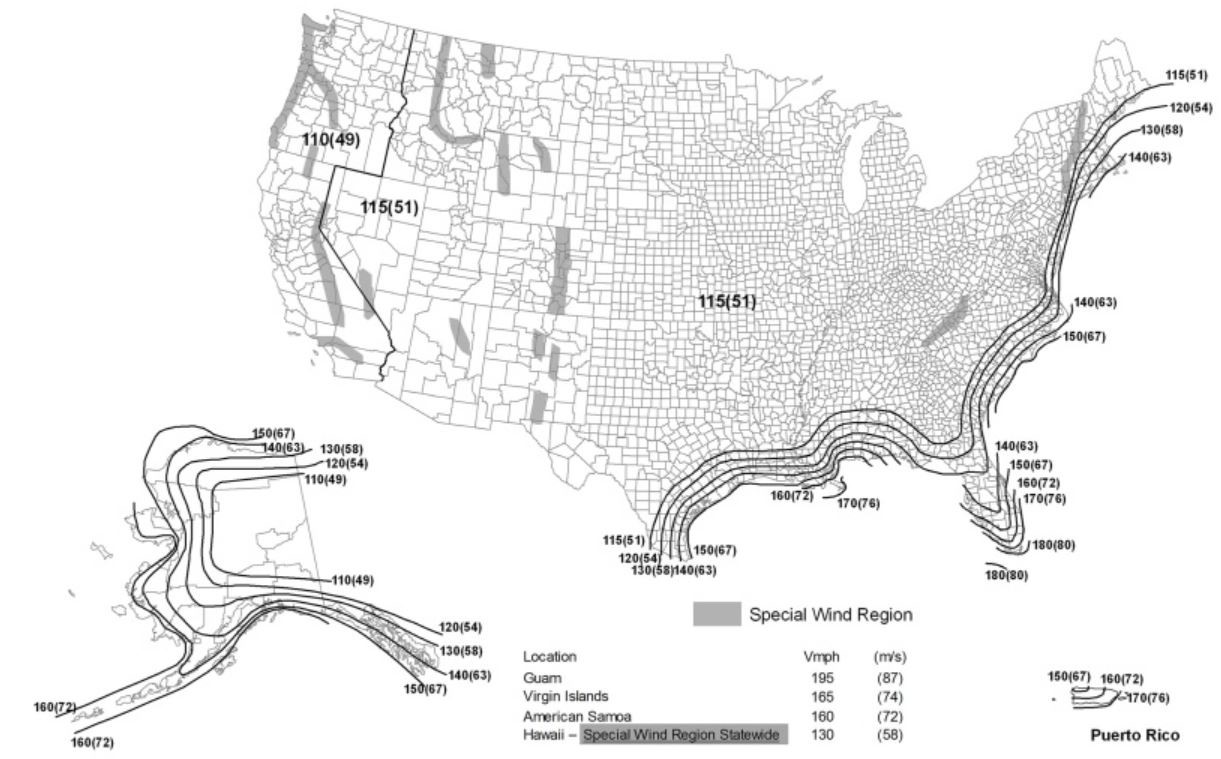

The International Residential Code (IRC) requires exterior building components and their attachments to be capable of resisting design wind-pressures. For some high-wind regions, the IRC requires wind design in accordance with other methods including the International Building Code (IBC) (2018 IRC R301.2.1). Homes located in coastal high-wind areas including Hurricane-Prone Regions, generally require enhanced attachments that can withstand even greater wind speeds. The IRC defines Hurricane-Prone Regions as areas along the Atlantic and Gulf Coasts where design wind velocity is greater than 115 mph, and Hawaii, Puerto Rico, Guam, the Virgin Islands, and American Samoa. The IRC further requires that exterior glazed openings are protected using impact-resistant glass, shutters, or panels for new homes located in windborne debris regions, defined as regions within hurricane-prone regions where the design wind velocity is equal to or greater than 140 mph or 130 mph within 1 mile of the coast. (See the IRC wind map in the Climate tab.) Confirm with the local building department if the house is in a hurricane-prone or windborne debris region and if local requirements exceed those of the IRC.

The IRC contains specific requirements for the wind resistance of doors. Section R609.2 of the IRC requires that exterior doors be designed to resist the wind pressures specified in IRC Table R301.2(2). Table R301.2(2) lists positive and negative wind pressures for components and cladding for various locations within the building. Areas near roof and wall edges and areas near corners, where turbulence creates localized high wind pressures, must be designed for higher loads. IRC Table R301.2(2) is based on Exposure B conditions for buildings with a mean roof height of 30 feet or less. Table R301.2(2) pressures must be multiplied by factors listed in IRC Table R301.2(3) for different mean roof heights and exposures.

AAMA/WMDA/CSA 101/I.S.2/A440 (North American Fenestration Standard (NAFS)/Specification for windows, doors, and skylight) lists design test pressures of 15, 25, 30, and 40 psf. Doors used in areas where wind pressures are greater than 40 psf need to be tested per ASTM E330 (Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference). For residential construction, local officials must ensure that products proposed are adequate to resist the component and cladding loads of Table R301.2(2). For engineered construction, the designer should specify wind pressures required for doors and should base them on component and cladding loads from either Chapter 6 of ASCE 7-05 or Chapter 16 of the IBC.

Substitute anchorage systems are allowed if they provide equal or greater anchoring performance as demonstrated by accepted engineering practice. IRC Figures R609.7.2(1) through R609.7.2(8) provide minimum anchorage details to anchor window and glass door assemblies to the main force-resisting system. The details require doors to be anchored in a fashion that adequately transfers loads from the doors to the adjacent walls.

Resistance to Wildfires

In wildfire-prone areas, install fire-rated exterior doors or doors of non-combustible construction. Fire-rated doors are typically made of solid-core wood or metal. The International Wildland-Urban Interface Code (IWUIC) requires Class 1 and Class 2 ignition-resistant doors to be installed. The National Fire Protection Association (NFPA) 1144, "Standard for Reducing Structure Ignition Hazards from Wildland Fire," Section 5.7, states that exterior doors shall be solid-core wood no less than 1-3/4 inches (45 mm) thick, be constructed with non-combustible materials, or have a fire protection rating of no less than 20 minutes. The IWUIC requires windows within doors and glazed doors to be multilayered glazed panels made of tempered glass. Building codes already require tempered glass to be used in glass patio doors or other areas that are susceptible to human impact. Section 5.7 also states that windows within exterior doors shall be tempered glass, multilayered glazed panels, glass block, or have a fire-resistance rating of no less than 20 minutes. Window screens should be installed and constructed using non-combustible mesh to minimize the entry of embers through open windows.

Install approved fire-rated doors between an attached garage and a home’s living space. The 2021 International Residential Code requires openings between the garage and residence to be equipped with solid wood doors no less than 1-3/8 inches (35 mm) thick, solid or honeycomb-steel doors no less than 1-3/8 inches (35 mm) thick, or 20-minute fire-rated doors. These doors must be equipped with a self-closing or automatic closing device and be self-latching.

For exterior trim that covers the opening between the door frame and the exterior wall, install non-combustible or fire-resistant material such as fire-retardant-treated wood or fiber cement board.

How to Select and Install Exterior Doors

- Select outward-swinging doors to prevent strong winds from blowing the door open, because the door stop on the inside of the jamb provides more resistance strength than the latch mechanism alone.

- Where impact protection is required, select impact-resistant doors, panels, or shutters. Impact-resistant doors, panels, and shutters are rated and labeled in accordance with the following:

- ASTM E1996 (Standard Specification for Performance of Exterior Windows, Curtain Walls, Doors, and Impact Protective Systems Impacted by Windborne Debris in Hurricanes)

- ASTM E1886 (Standard Test Method for Performance of Exterior Windows, Curtain Walls, Doors, and Impact Protective Systems Impacted by Missile(s) and Exposed to Cyclic Pressure Differentials)

- AAMA 506 (Voluntary Specifications for Impact and Cycle Testing of Fenestration Products).

- In Florida’s High Velocity Hurricane Zone, doors, panels, and shutters must be tested and labeled in accordance with Testing Application Standard (TAS) 201 (Impact Test Procedures), TAS 202 (Criteria for Testing Impact and Non-Impact Resistant Building Envelop Components using Static Air Pressure), and TAS 203 (Criteria for Testing Products Subjected to Cyclic Pressure Loading) per the Florida Building Code.

- Use the manufacturer-recommended anchorage system or a substitute anchorage system that provides equal or greater anchoring performance as demonstrated by accepted engineering practice.

- When the space between the door frame and the wall’s rough opening is 1.5 inches or less, shims or bucks can be installed, and fasteners can extend from the door frame to the wall.

- When the space is greater than 1.5 inches, the bucks need to be securely fastened to the wall and the door. This requirement limits the sheer length of fasteners to 1.5 inches and reduces the potential for bending failures in the fasteners.

- Install proper flashing around the door as specified by manufacturer instructions. Protect flashing with overlapping house wrap or building paper. Use pan flashing to prevent damage to the subfloor.

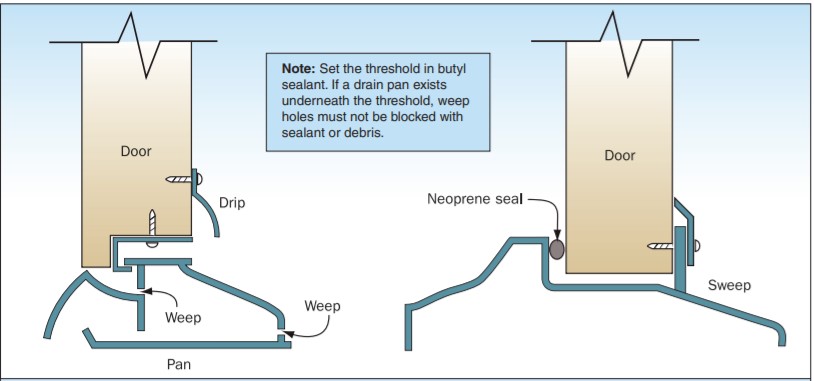

- Install drip flashing above the door to help keep rainwater from entering along the top of the door. A drip flashing design with an overlapping hook, as shown in Figure 3 can help keep out wind-driven rain. Install sweep flashing at the base of the door to keep out drafts and wind-blown rain, as shown in Figure 4. Weather stripping can be installed around the exterior door to help keep out wind-blown rain. In wildfire-prone areas, weather stripping can also help keep out embers and hot gasses.

- In wildfire-prone areas install fire-rated exterior doors made of solid-core wood or metal.

- Install approved fire-rated exterior doors between the home's living space and an attached garage. These doors must be equipped with a self-closing device and must be self-latching.

- For exterior trim that covers the opening between the door frame and exterior wall, install non-combustible or fire-resistant material such as fire-retardant-treated wood or fiber cement board.

For additional information, see the Building America Solution Center guides on the following topics:

- BASC Guide on Garage Doors are Pressure Rated

- BASC Guide on Windows have Impact Rated Glass or Protective Coverings

- BASC Guide on Structural Sheathing (plywood/OSB) in Exterior Walls

Success

Check local building codes or ask the local building department to understand specific requirements. Also see the Compliance tab for code information.

For disaster resistance, comply with the requirements defined by the IBHS Fortified Home Program. The Insurance Institute for Business and Home Safety® (IBHS) offers guidance, best practices, and voluntary construction standards and programs for building in disaster-prone areas including hurricane and high-wind zones. The IBHS FORTIFIED Home™ standard is designed to make homes more resilient and durable; guidance is available for New Construction and Existing Homes in Hurricane zones and High-Wind zones. There are three levels of FORTIFIED Home: FORTIFIED Roof™ focuses on the roof; FORTIFIED Silver focuses on roof overhangs, opening protection, gable ends, and attached structures; FORTIFIED Gold focuses on tying all components of the structure together. The IBHS FORTIFIED HOME program includes the following guidance and requirements for exterior doors:

- All entry doors must be pressure and impact rated or protected by a system that is pressure and impact rated. At least one exterior entry door must be operable from inside the living space when opening protection is in place. The level of debris impact protection required for areas where the ASCE 7-05 design wind speed (Vasd) is greater than or equal to 110 mph and the ASCE 7-10 and ASCE 7-16 (Vult) design wind speed is greater than or equal to 130 mph is the large missile G test (9-lb 2x4 impacting end on at 50 ft/sec) as defined in ASTM E1996 and ASTM E1886 and AAMA 506.

- All entry doors and entry door protection systems must be rated for the design pressures appropriate for the exposure category, design wind speed, door size, and door location on the building. Products must be tested, at a minimum, in accordance with International Residential Code (IRC) accepted standards (or with locally adopted standards, if they are more restrictive) and installed in accordance with the manufacturer’s instructions.

Climate

Hurricane and High Wind Zones

Figure 1 indicates wind regions in the United States. Exterior doors are more likely to be damaged or lost in hurricane-prone regions and other high-wind areas, leaving the house susceptible to wind and water intrusion. Proper installation is even more important in these locations to protect against storm damage.

Wind Region Terminology

Hurricane-Prone Regions: areas along the Atlantic and Gulf coasts where V > 115mph, and Hawaii, Puerto Rico, Guam, Virgin Islands, and American Samoa.

Windborne Debris Regions: areas within hurricane prone regions where the design wind velocity equals or exceeds 140 mph or 130 mph within 1 mile of the coast.

High-Wind Areas (not code defined): generally where V > 115 mph including portions of Alaska.

Below is a summary of steps that can be taken to improve the storm resistance of exterior doors and doorways based on information from FEMA (FEMA P-762, 2009) and others.

- All exterior doors on homes in hurricane areas should be pressure and impact rated or protected by a system that is pressure and impact rated, according to IBHS (2019).

- Doors, door framing, and door hardware should be made of water-resistant, corrosion-resistant materials.

- Exterior doors should meet U-factor requirements for the home's climate zone, as required by local building codes.

- For increased disaster resistance in coastal and high wind areas, install exterior doors to swing outward rather than inward. Weather stripping should be installed on the interior side of the door to minimize decay.

- Doors should be properly flashed, weather stripped, air sealed, and set in pan flashings designed to resist the entry of wind and wind-driven rain.

- Consider designing the home’s entry with a vestibule or double-doored entry. Construct the entry with durable water-resistant flooring.

- Install water-resistant flooring at all entryways.

- FEMA’s “Technical Fact Sheet No. 6.1: Window and Door Installation,” (FEMA P-499 2010) provides some best-practice approaches that can be taken to reduce water infiltration. Pan flashing, weather stripping, and threshold seals are discussed. The Building America Solution Center guide Fully Flashed Window and Door Openings and the “Tech Note: Window and Door Flashing: Code Requirements and Best Practices” by Home Innovation Research Labs provide additional detailed instructions for installing window and door flashing.

Window and Door Assembly Capacities - Window and door assemblies must be strong enough to withstand wind pressures acting on them and be fastened securely enough to transfer those wind pressures to the adjacent wall. Pressure failures of doors or windows can allow glazing to fracture or glazing frames or supports to fail. Anchorage failures can allow entire door or window units to be ripped from their walls. Either type of failure results in the failure of the building envelope and allows wind and water into the building.

Both the International Residential Code (IRC) and the International Building Code (IBC) contain specific requirements for the wind resistance of windows and doors. Section R609.2 of the 2021 IRC requires that exterior windows and doors be designed to resist the wind pressures specified in Table R301.2.1(1) adjusted as in Table R301.2.1(2) or determined in accordance with ASCE 7. The 2021 IBC requirements are similar but are less presecriptive and more performance based. While the IRC has tabulated wind pressures, Chapter 16 of the 2021 IBC specifies acceptable methods of calculating wind loads and (in Section 1603.4) requires that construction documents list wind pressures for components and cladding.

IBC Section 1405.12, Exterior Windows and Doors, requires windows and doors to be tested in accordance with IBC Section 1714.5, which lists two methods of establishing wind resistance. Section 1714.5.1 allows doors and windows to be labeled per AAMA/WMDA/CSA 101/I.S.2/A440, and Section 1714.5.2 allows doors and windows to be tested per ASTM E330. The latter option has additional requirements regarding glass supports and framing that are outlined in Section 2403, and pressure ratings that are outlined in Chapter 16, the structural design chapter of the IBC.

AAMA/WMDA/CSA 101/I.S.2/A440 lists design test pressures of 15, 25, 30, and 40 pounds per square foot (psf). Windows and doors used in areas where wind pressures are greater than 40 psf need to be tested per ASTM E330. For residential construction, local officials must ensure that products proposed are adequate to resist the component and cladding loads of IRC 2021 Table R301.2.1(1). For engineered construction, the designer should specify wind pressures required for windows and doors and should base them on component and cladding loads from either Chapter 6 of ASCE 7-05 or Chapter 16 of the IBC.

Section R609.7.1 of the IRC requires that windows and glass doors be anchored in accordance with published manufacturer’s recommendations. The manufacturer’s installation instructions should match those used when the units were tested and certified. Substitute anchorage systems are allowed if they provide equal or greater anchoring performance as demonstrated by accepted engineering practice.

The IRC contains Figures R609.7.2(1) through R609.7.2(8) that provide minimum anchorage details. The details require windows and doors to be anchored in a fashion that adequately transfers loads from the windows and doors to the adjacent walls (the walls are called substrates in that code). When the space between the window or door frame and the wall’s rough opening is 1.5 inches or less, shims or bucks can be installed and fasteners can extend from the door or window frame to the wall. When the space is greater than 1.5 inches, the bucks need to be securely fastened to the wall and the door, or window frames need to be securely fastened to the bucks. This requirement limits the sheer length of fasteners to 1.5 inches and reduces the potential for bending failures in the fasteners. The IBC requirements are similar but do not provide the prescriptive details contained in the IRC. IBC Section 1705.1.1 requires windows and doors to be installed in accordance with approved manufacturer’s instructions.

To minimize issues related to corrosion, the use of fiberglass or vinyl frames are recommended for buildings located within 3,000 feet of an ocean shoreline. The use of stainless steel frame anchors, fasteners, and hardware is also recommended within these areas.

Wildfire Zones

In wildfire-prone areas, exterior doors should be fire rated.

Cold Climates

Colder climates will increase the potential for heat loss and air leakage, and the impacts of that heat loss, if exterior doors are not properly insulated and air sealed. If the door has windows, use high-performance glazing to reduce heat loss and minimize condensation potential in cold weather.

Extreme Heat

Ensuring doors are insulated and well air-sealed will help protect occupants during an extreme heat event. Additional measures to mitigate heat entry through the door include shading the door using a covered entryway or vegetation, avoiding or minimizing glass in the door assembly, and using a white or light color as the finish on the exterior side of the door.

Training

Compliance

Retrofit

The information provided for doors installed in new homes also applies to retrofitting of doors installed in existing homes.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.