Scope

Air-seal and insulate double-walls that are half-height or full-height walls used as architectural features in homes.

- Install a continuous air barrier on the exterior of the interior wall.

- Seal all seams, gaps, and holes of the air barrier with caulk or foam.

- Install insulation in the interior wall cavity equal in R-value to other exterior wall cavity in the home, without misalignments, compressions, gaps, or voids.

OR

- Dense-pack the entire cavity of the double wall assembly with blown insulation, ensuring the insulation is in contact with the insulation to the top of the wall cavity with no misalignments, compressions, gaps, or voids in the insulation.

- Use spray foam insulation for the wall cavity. The spray foam can serve as the air barrier if it is at least 5.5 inches thick if open-cell or at least 1.5 inches thick if closed-cell spray foam insulation.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

The double walls described here are half or full walls included in a home design as an architectural feature that provides a more dimensional appearance. This is not the same as the double-wall construction technique used to provide deeper wall cavities for more insulation on all of the exterior walls of a home. That technique is described in Double-Stud Wall Framing.

The important thing to keep in mind about a double wall used as an architectural feature is that if it is located on the exterior wall of a home, it is part of the home’s thermal envelope. So, the wall must be insulated to at least the level of the home’s other exterior walls, and the insulation in the wall must be aligned with and enclosed by air barriers on all six sides.

There are three ways to insulate a double wall and achieve a fully aligned air barrier:

- Fill the entire cavity with blown insulation.

- Separate the interior cavity from the exterior cavity and fill the interior cavity.

- Insulate the exterior cavity with spray foam.

These three ways are described in the steps below. The insulation and fully aligned air barrier for an accent double wall may be installed by insulators, framers, or drywallers. This task should be included in the contract for the appropriate trade, depending on the workflow at the specific job site.

How to Air Seal and Insulate a Double Wall Using Blown-In Insulation

- Frame the exterior wall using the same stud framing as the rest of the exterior wall, preferably 2x6, 24-inch on-center. See Minimum Wall Studs. Sheathe with the same exterior sheathing as is used on the rest of the exterior walls.

- Install a second section of framing to the inside of the exterior wall framing, where the thicker wall is desired, using 2x4 or 2x6, 24-inch on-center framing. (See Figure 1.)

- Tack netting to the interior face of the interior wall studs and blow in loose fiberglass or cellulose insulation when the rest of the walls are insulated. Ensure that the wall is completely filled to the proper density to minimize settling.

- Drywall when the rest of the walls are drywalled. Caulk the drywall to the framing at the top plate, bottom plate, and studs. Mud and tape seams and corners. The interior drywall and exterior sheathing serve as the interior and exterior air barriers.

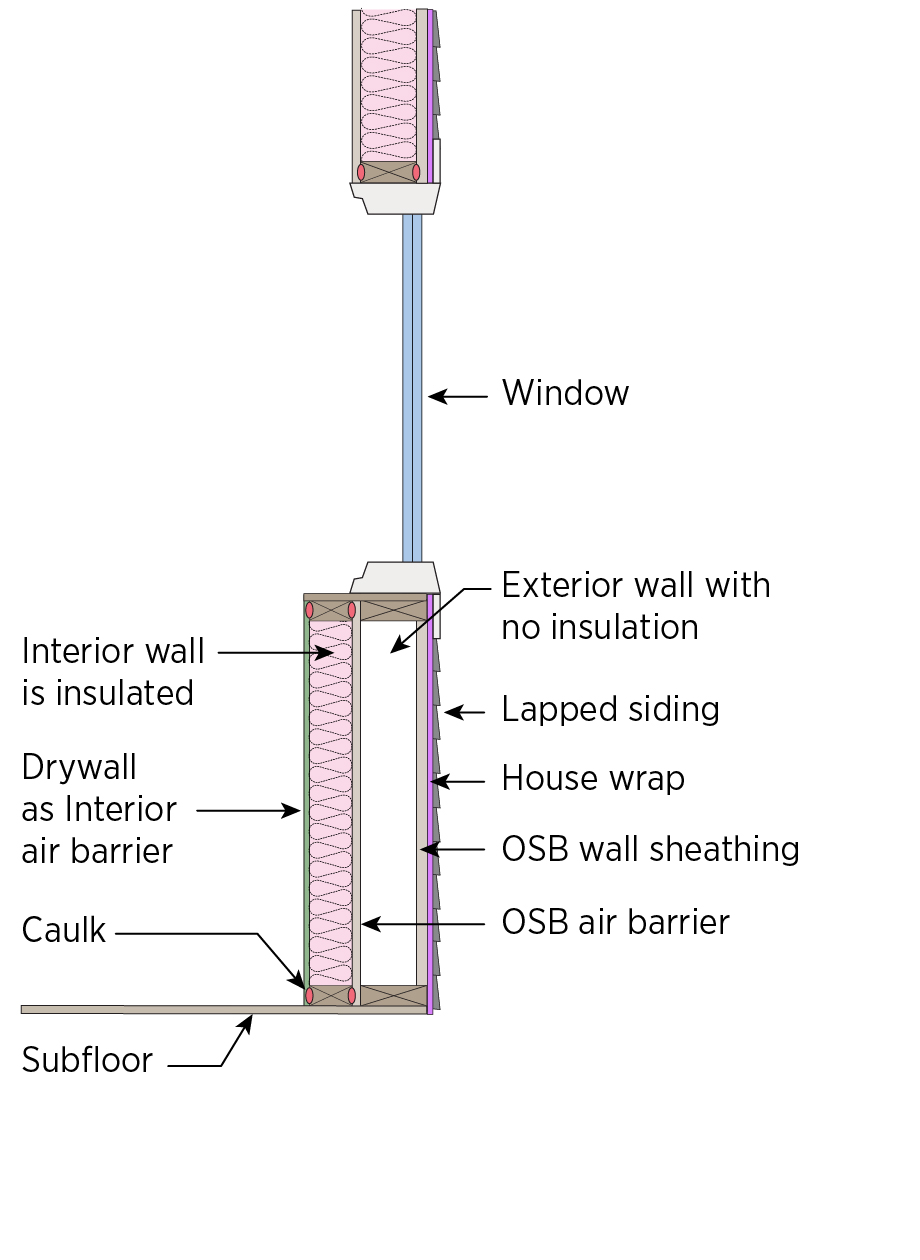

How to Air Seal and Insulate a Double Wall Using Batt Insulation

- Frame the exterior wall using the same stud framing as the rest of the exterior wall, preferably 2x6, 24-inch on-center. See Minimum Wall Studs. Sheathe with the same sheathing as is used on the rest of the exterior walls.

- Install an air barrier over the studs on the section of wall that will be double framed. (See Figure 2.) This air barrier can consist of drywall, OSB, plywood, or rigid foam. The use of polyethylene or any other material that is a Class 1 vapor barrier is not recommended.

- Caulk along the interior facing side of the air barrier at all four edges.

- Install the second wall framing using 2x4 or 2x6, 24-inch on-center framing. Push the second framing members against the caulk to seal the framing to the air barrier along all four sides.

- Fill the interior wall cavity with batt insulation to the R-value required for exterior walls in your climate zone.

- Drywall when the rest of the walls are drywalled. Caulk the drywall to the framing at the top plate, bottom plate, and studs. Mud and tape seams and corners. The interior drywall and exterior sheathing serve as the interior and exterior air barriers.

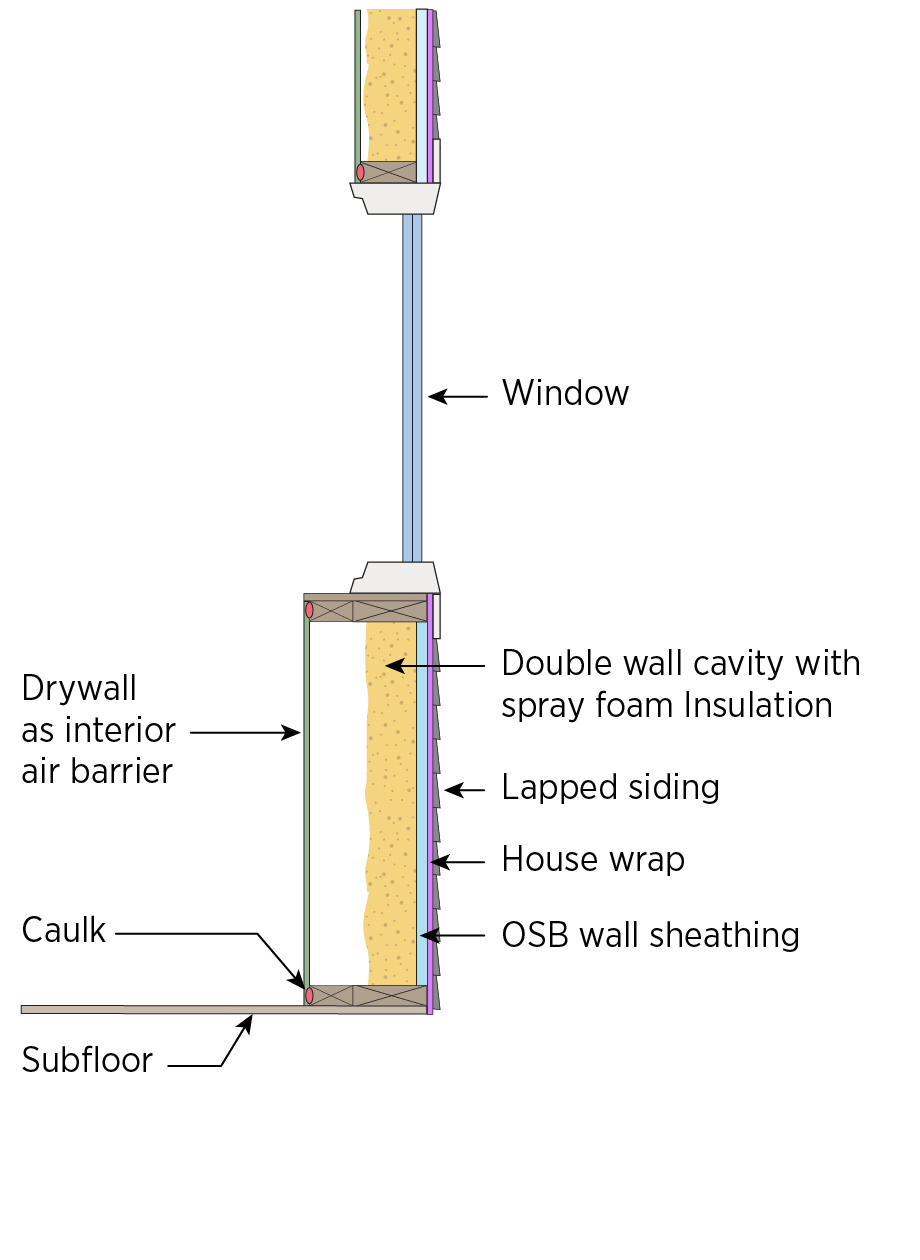

How to Air Seal and Insulate a Double Wall Using Spray Foam Insulation

- Frame the exterior wall using the same stud framing as the rest of the exterior wall, preferably 2x6, 24-inch on-center (see Minimum Wall Studs). Sheathe with the same sheathing as is used on the rest of the exterior walls.

- Install the second wall framing using 2x4 or 2x6, 24-inch on-center framing. (See Figure 3.)

- Fill the double-stud wall cavity with the desired depth of spray foam along the inside surface of the exterior sheathing.

- Drywall when the rest of the walls are drywalled. The foam does not need to touch the interior drywall, because the foam serves as its own air barrier. The exterior sheathing serves as the exterior air barrier.

Success

The site supervisor should visually inspect the exterior wall prior to installation of the drywall or a center air barrier to confirm that insulation has been fully aligned with the air barrier. Blower door testing used in conjunction with an infrared camera may help indicate areas of thermal bypass or lack of alignment between insulation and air barrier layers in walls after drywall is installed.

Typical R-values for common insulation materials are summarized in this table, which also identifies the vapor retarder classification for each insulation.

Climate

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Training

CAD

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Double-Wall Framing = Double-Wall Thermal Blanket

One way to achieve very high levels of insulation in walls is to build two stud walls separated by an air space. The inner wall provides framing for attaching gypsum board; the outer wall does the same for sheathing, a weather barrier, and siding. Two 2x4 framed walls spaced three inches apart will provide a wall cavity about 10 inches deep. This spacing eliminates thermal bridging. When fully insulated, this double-wall thermal blanket creates a quiet, efficient, and comfortable home.