Scope

To minimize water waste at hot water faucets:

- Design a compact plumbing distribution system.

- Use a recirculation line (or hot water priming loop) and short “branches” to each hot water fixture.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

To reduce water use and energy losses associated with hot water, homes should be designed with plumbing layouts and hot water distribution systems that reduce the amount of time it takes for hot water to get from the water heater to each plumbing fixture. Traditional hot water distribution systems consist of a trunk and branch distribution with a relatively long and large diameter main line feeding smaller branches that flowed directly to plumbing fixtures or split to serve multiple fixtures. Even in relatively small homes of 1200 square feet, the volume to the furthest fixture can exceed 1.5 gallons and the time-to-tap can be more than 90 seconds.

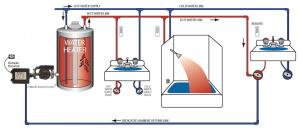

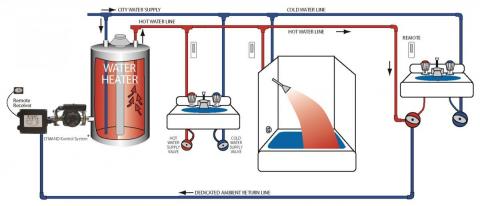

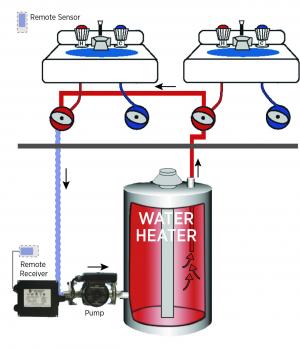

One water and time saving alternative is to install a circulation loop that brings the supply portion of the loop close to each plumbing fixture or appliance. The most energy efficient way to operate the pump is to use demand – initiated controls. As shown in Figure 1, a circulating pump draws hot water through the supply portion of the loop and returns to the water heater any ambient-temperature water residing within the loop. Ideally the circulation loop should be located where it can be kept as short as possible and within 10 feet of every fixture (Acker and Klein 2006).

Demand-initiated recirculation systems have been found to be more energy-efficient than other timer-or temperature-based recirculation systems, because hot water is only drawn into the recirculation loop when hot water is needed. When the user activates the pump by pushing a button or via a motion sensor located near the hot-water fixture, a sensor measures the starting (ambient) temperature of the water in the pipe. The controls allow the pump to operate until a small rise in temperature has been measured (typically 5F). The Zero Energy Ready Home (ZERH) specification also allows recirculation systems that operate based on “adaptive” scheduling, meaning that they “learn” the hot water demand profile in the home and adapt their operation to meet the occupant’s schedule.

Demand-initiated circulation systems offer builders more flexibility than other techniques for reducing hot water delays because they can be installed to accommodate the layouts in a wide variety of floor plans. Some floor plans may benefit from the installation of more than one circulation loop, each with its own pump and controls.

How to Design a Demand Plumbing Distribution System:

- Designate a proposed location for all hot water plumbing fixtures and appliances. Best practice design specifies that hot water fixtures be as close to the water heater as possible to minimize heat loss in pipes.

- Design plumbing trunks and branches to store as little water as possible by running the smallest diameter pipe allowed by code between the hot water source and each fixture.

- To achieve a higher level of efficiency, calculate the stored volume between each water source and water use point and ensure that not more than 0.5 gallons of water is stored between the water source and the use point. If the volume between each water source and water use point is more than 0.5 gallons, redesign the floor plan and plumbing layout until it is less than 0.5 gallons. See the Compliance tab for information regarding pipe volume per length for various pipe diameters.

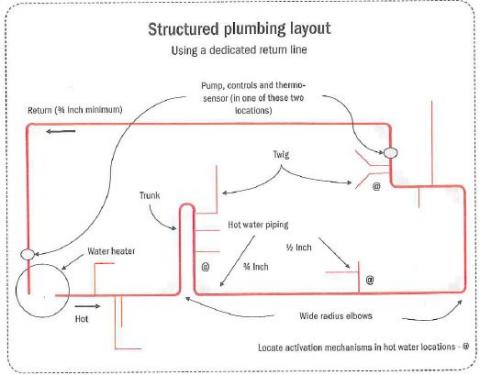

- Record all plumbing design features on plumbing diagram (Figure 2).

- Install the circulation loop and branches to according to the codes outlined in the Compliance tab (including correct pipe diameter and insulation). The minimum diameter on the supply and return portions of the loop shall not be less than ¾ inch nominal. For more information on pipe insulation, see the guide Pipes in Exterior Walls.

- Install all pumps, controls and sensors according to the plumbing diagram and manufacturers instructions. Controls should shut off the pump when the correct change in temperature is measured. Controls should also have a feature to prevent operation if the water is above 105°F.

- Commission the system. See Inspection and Verification Guidance for WaterSense Labeled New Homes for more information.

Another efficient plumbing layout method to consider is Core Plumbing.

Success

Ensure all hot water pipes are adequately insulated throughout the home. Insulation can help save energy on water heating costs, especially in households with multiple hot water draws in a row (example: many morning showers). The 2015 IECC states that all piping ¾ inch nominal and larger shall be insulated. In addition there are certain cases where insulation is also required on smaller diameter piping. For more information see the guide Pipes in Exterior Walls.

Wherever possible, locate both hot and cold water pipes on interior walls as an extra precaution against freezing conditions. When water pipes must be located on the exterior wall of the home, ensure they are located toward the inside of the wall, yet still surrounded by at least 1 inch of insulation. Be aware of interior freezing conditions during long vacation periods.

EPA WaterSense Inspection Protocol

For builders seeking certification through the U.S. Environmental Protection Agency's WaterSense program, a verifier will test all hot water delivery systems to ensure compliance with the HCO's WACM (WaterSense Approved Certification Method) requirements using the testing protocol described in the Compliance tab.

Climate

No climate-specific information applies.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Demand Pumping System =

Traditional hot water distribution systems consist of a trunk and branch layout. This consists of a relatively long, large-diameter main line that feeds smaller branches that flow to plumbing fixtures or split to serve multiple fixtures. Even in relatively small homes of 1,200 square feet, the volume to the furthest fixture can exceed 1.5 gallons and the time to the tap can be more than 90 seconds. An effective option for saving water in new homes is to lay out the plumbing in "series" to each fixture and appliance with a dedicated return to the water heater from the most remote location (This is called "structured plumbing"). An in-line pump is installed near the water heater to move the cold water sitting in the pipes back through the water heater before it comes out of the hot water tap, to reduce the amount of water wasted while waiting for hot water. A similar system can be set up for existing homes that locates the pump at the most remote fixture. To save energy, the pump can be set up as an "on-demand" system that is activated by a sensor or switch to avoid the needless calculation of hot water that occurs with inefficient, continuously recirculating pump systems. DOE’s Zero Energy Ready Home program requires that no more than 0.6 gallons of hot water be discharged from a hot water fixture before hot water delivery. Recirculation pump systems must be based on an occupant-controlled switch or an occupancy sensor.