Scope

Insulate a vented attic in an existing home by installing blown insulation on the ceiling deck of the attic, as follows:

- Before any retrofit work is done, inspect the roof and attic; repair any leaks, remove active knob and tube wiring, and remediate any hazardous materials.

- If existing bath fans vent into the attic, they must be vented to the outside.

- Remove any existing insulation, debris and dust, and prepare the attic floor for air sealing and loose-fill fibrous insulation.

- Seal all attic floor penetrations with sealant, one-part spray foam, or rigid blocking material as needed.

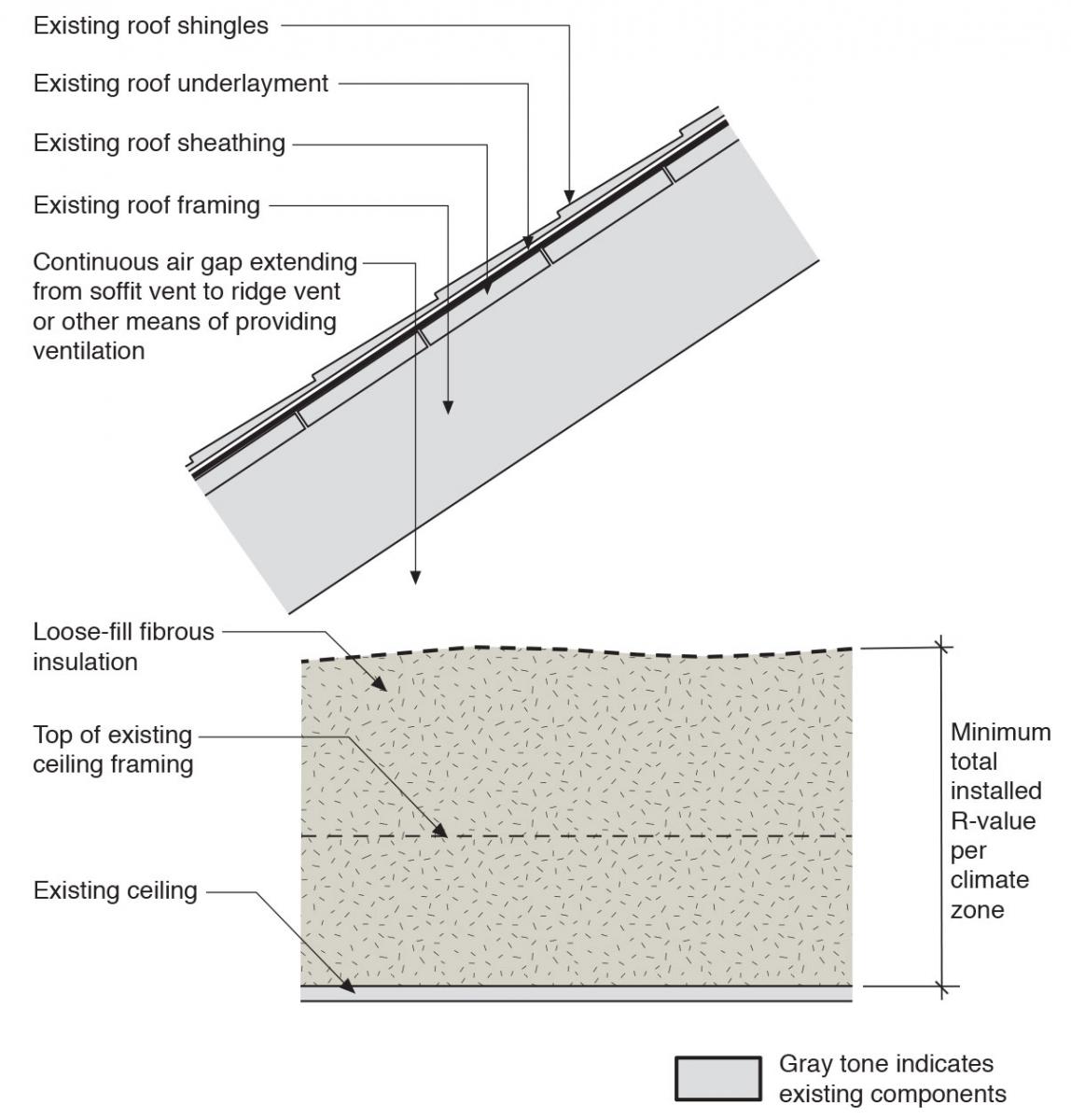

- Verify that proper ventilation of the attic is provided with soffit vents (preferred) or gable and ridge vents. Verify that there is a baffle at each soffit vent extending from the top plate to above the height of the insulation to provide a pathway for ventilation air while keeping insulation out of the soffit vents.

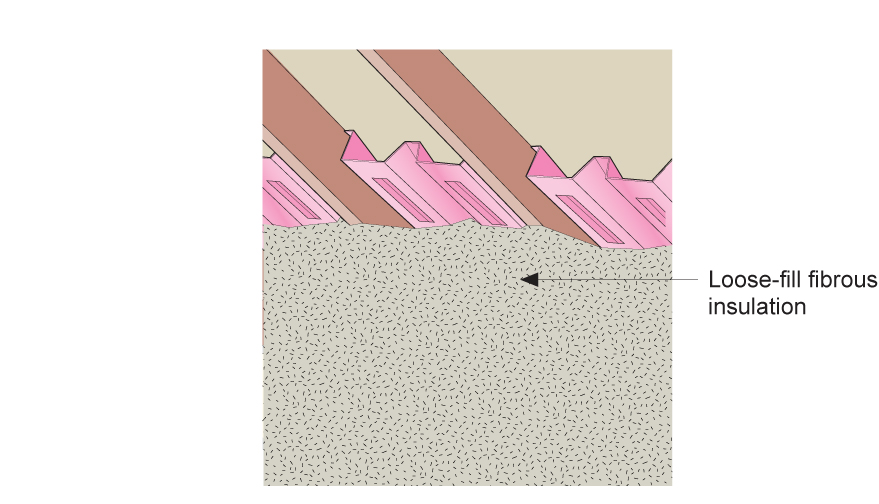

- Install blown loose-fill insulation over the attic floor to levels that meet or exceed the current adopted building and energy codes.

This approach is suitable for projects with a vented attic where the thermal boundary is established at the attic floor/ceiling plane. This approach requires that there be sufficient height between the underside of the roof deck and the top plate at the eave to install the full code-required amount of insulation while maintaining an air gap for ventilation above the insulation. Installing HVAC ducts and air handlers in vented attics is not recommended.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

Many older homes have little or no attic insulation. Loose-fill insulation such as blown cellulose or blown fiberglass can be installed at the ceiling plane/attic floor to improve thermal performance in a vented attic.

Care should be taken when installing blown insulation to ensure that it fills all ceiling joist bays with no gaps or voids around wiring or piping and that it covers the tops of the joists to stop thermal bridging. The depth of coverage should be even across the field of the attic. The blown insulation should be installed in accordance with RESNET Grade 1 installation criteria.

The ceiling plane or attic floor should be thoroughly air sealed prior to installing insulation. Robust and continuous air control is critical to a high-performance thermal enclosure. The existing insulation must be removed to provide access to the ceiling plane for air sealing. Debris and dust should also be removed so that sealants will have good adhesion. Seal all cracks, seams and holes using caulk or spray foam sealants. Use solid blocking for any larger holes or open soffits. Metal blocking and collars can be constructed around hot flues to keep insulation from touching them. Covers can be purchased or constructed to cover, air seal, and insulate recessed can lights that are not insulated ceiling airtight (ICAT) rated. See Attic Air Sealing Guide and Details.

If existing insulation was removed from the attic floor to perform air sealing, it may be reinstalled if it is in good condition. However, existing attic insulation is often contaminated with construction debris, plaster scraps, animal droppings, etc. Older loose-fill may be vermiculite insulation which can contain asbestos. The safest approach may be to dispose of the old insulation and install only new insulation.

The presence of flooring above the ceiling joists in an attic will make it difficult to air seal at the ceiling plane (attic floor). If the air control is to be established at the ceiling plane, then any attic flooring installed above that must be removed to provide full access to the ceiling surface. Alternately, it may be possible to transition the air barrier to the top of the existing attic floor. To successfully execute this option, sufficient insulation is required outboard (on top of) the floor to control condensation and a robust air control connection must be made from the top of the exterior walls to the perimeter of the attic flooring.

In climate zones 6 or higher, a Class I vapor barrier (e.g., polyethylene) or Class II vapor retarder should be installed above the ceiling drywall as required by code. Class I vapor barriers should be avoided in climate zones 5 and below, as condensation can occur on the attic side of the vapor barrier in summer months during air conditioning periods. (See BSD 102 Attic Ventilation.)

One benefit of a vented (rather than unvented) attic is that interior-sourced moisture will be vented out of the attic space before causing damage to the roof sheathing. Another advantage of vented attics in cold climates is that they help to reduce the chances of ice damming on the roof. Ice dams occur when heat leaks from the conditioned space (through holes in the ceiling plane, insufficient insulation, or heat loss from ductwork) and melts the snow on the roof. This melted snow travels down to the edges of the roof where it refreezes, creating icicles and ice dams. Attic ventilation helps to “flush away” this heat before it can melt the snow. See BSI-046: Dam Ice Dam, and BSD-135: Ice Dams.

The vented attic approach requires that there be sufficient height at the attic eaves for code-level required amounts of insulation. In mixed- and cold climates (zones 4 and above), inadequate insulation raises risks of wintertime condensation at the top plate due to cold surfaces. If the roof is too low at the eaves to install adequate amounts of blown insulation, then alternative solutions are to fill the space over the top plate to the baffle with closed-cell spray foam or to cover the top plate area with rigid foam board. (Spray foam and rigid foam have higher R-values per inch than blown insulation. Spray foam has the added advantage of air sealing the top plate-to-drywall seams and the baffle-to-top plate seam.) Another option is to convert the attic to a sealed, insulated space by sealing the soffit vents and insulating along the underside of the ceiling deck with closed-cell spray foam or above the roof deck with rigid foam. In new home construction, a common solution to increase the roof height for insulation above the top plate is to use raised heel trusses. Older existing roofs are unlikely to have raised heel trusses and raised heel trusses are not likely to be installed as a retrofit measure unless a complete reconstruction of the roof is required, for example if a second or third story is being added.

The vented attic approach requires that there be sufficient height at the attic eaves to maintain an air gap above the insulation for ventilation air traveling from the soffit vents to the ridge vents. The vent space should be at least 2 inches high and the width of the framing bay at each soffit vent (Lstiburek 2006). Baffles should be installed at each soffit vent to provide this pathway for ventilation air to move up past the insulation along the underside of the roof deck to ridge vents or mushroom cap vents located near the ridge. The lower edge of the baffle can be sealed to the attic floor at the outside edge of the top plate with spray foam, which also air seals the top plate-to-dry wall seams. The baffles also serve to prevent insulation from covering the soffit vents and they can prevent “wind washing,” i.e., when wind blows in the soffit vents and pushes the insulation back from the eaves.

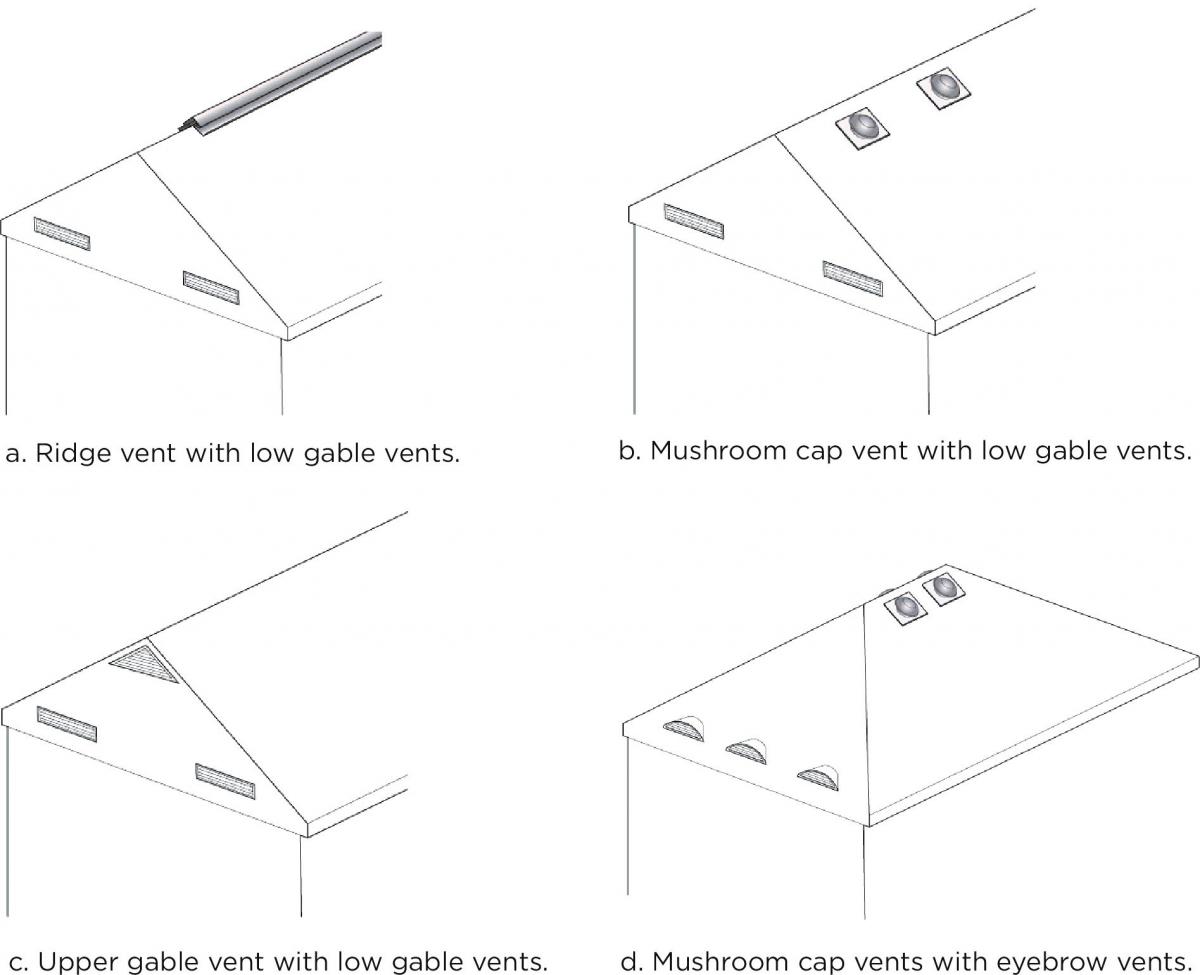

If the attic does not have soffit vents, attic ventilation can be provided by installing other types of vents such as gable or eyebrow vents down low near the attic floor, along with ridge vents or mushroom cap vents located up near the roof ridge.

Powered attic ventilators (thermostatically controlled fans that exhaust attic air during hot weather) can result in increased infiltration (and associated higher cooling loads). Studies have shown that powered ventilators have higher electricity consumption than their associated air conditioner savings (FSEC 2005/ Literature Review of the Impact and Need for Attic Ventilation in Florida Homes).

Installing HVAC ducts and air handlers in vented attics is not recommended. Locating ductwork and/or air handling equipment in a vented attic can contribute to energy losses, performance issues, and ice dam formation in snowy climates, especially if the ducts and air handlers are leaky or poorly insulated. One exception is if the ductwork can be encapsulated in spray foam and buried beneath the attic floor blown insulation. The ducts must be tightly air sealed and covered with a sufficient amount of spray foam insulation to minimize the risk of condensation forming on the outside of the ducts. See Ducts Buried in Attic Insulation. However, because mechanical equipment such as air handlers cannot be adequately air sealed, locating them in a vented attic is not recommended. If the air handler must be located in the attic then consider converting the attic to a sealed, insulated space.

How to Insulate Attic Floor with Blown Insulation

- Before any retrofit work is done, inspect the work area for active knob and tube wiring, bathroom fans venting into attics, roof leaks, and other hazardous conditions. Repair these conditions prior to adding insulation. Inspect for and remove or remediate hazardous materials like asbestos-containing vermiculite insulation.

- Remove any existing insulation, debris and dust, and clean the work area to allow for an adequate adhesion of sealant.

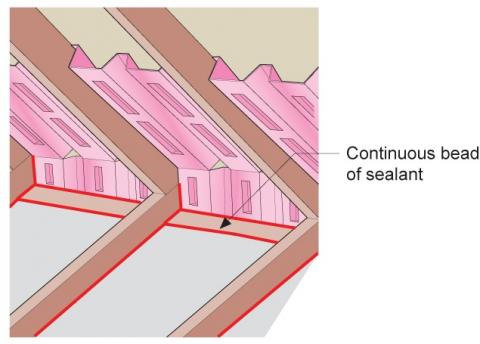

3. Seal all ceiling joints and penetrations with sealant. Seal top plate-to-drywall seams and top plate-to-baffle seams. Provide additional solid blocking for large holes and open soffits, install metal

blocking and collars around hot flues, and install covers over non-ICAT-rated recessed can lights. See GM-1001: Attic Air Sealing Guide and Details. Don’t block intentional openings such as combustion

air ducts and soffit, ridge, and gable vents.

4. Verify that proper ventilation of the attic is provided with soffit and ridge vents or eyebrow, gable end, mushroom cap, and/or other vents. (See Figure 5.) If soffit vents exist, inspect existing baffles and

install new baffles if needed (see Figure 3).

Figure 5. Four attic venting approaches for vented attics that don’t have soffit vents - vents are installed low for incoming air and high for outgoing air (Source: Courtesy of Building Science Corporation). 5. Install loose-fill fibrous insulation over the attic floor to levels that meet or exceed the current adopted building and energy codes for thermal performance. Cover the entire ceiling all the way to the top plate to provide adequate thermal resistance. The depth of the fibrous insulation should be as even as possible.

Figure 6. Loose-fill fibrous insulation is installed against the baffle to full code-required insulation height (Source: Courtesy of Building Science Corporation).

Success

Remediate or remove all hazardous conditions and materials prior to beginning any retrofit work. Examples of hazardous materials that may be found in attic/roof assemblies of existing structures include (but are not limited to) lead, asbestos, mold, animal dropping/remains, etc. Follow applicable laws and industry procedures for mitigation of hazardous materials. Engage the services of a qualified professional when needed.

For more information on vermiculite, see the EPA guide: Protect Your Family from Asbestos – Contaminated Vermiculite Insulation.

Guidance for mitigating asbestos-related issues from HUD, EPA, NIH, OSHA and FEMA is available in Homeowner's and Renter's Guide to Asbestos Cleanup After Disasters and Asbestos: Worker and Employer Guide to Hazards and Recommended Controls.

For guidance on handling knob and tube wiring, see Weatherization Assistance Program guide: Retrofitting Knob and Tube Wiring An Investigation into Codes, Assessment, Wiring Practices and Cost.

Seal all penetrations to provide a continuous air control layer at the attic floor. Visual inspection, infrared thermography, and blower door testing are all tools that can be used to verify air barrier continuity.

Install loose-fill fibrous insulation to provide adequate thermal resistance and to the levels specified in the current adopted building and energy codes.

Electrical junction boxes accessible from the attic will be buried during this insulation retrofit. The NEC (Article 314.29, 2005 NEC) requires junction boxes to be accessible "without removing any part of the building." This clause could be interpreted as including or excluding attic insulation. The ideal approach would elevate the junction box above the insulation level; alternately, a flag marker could be placed to indicate junction box location. A local code official could provide further guidance.

All roofs must be vented according to the applicable current adopted building code. If the roof is not vented according to the applicable building code then a qualified contractor in the state should be engaged to install the necessary venting.

Climate

The ceiling/attic floor assembly should be designed for a specific hygrothermal region, rain exposure zone and interior climate. The climate zones are shown on the map below, which is taken from Figure C301.1 of the 2012 IECC.

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

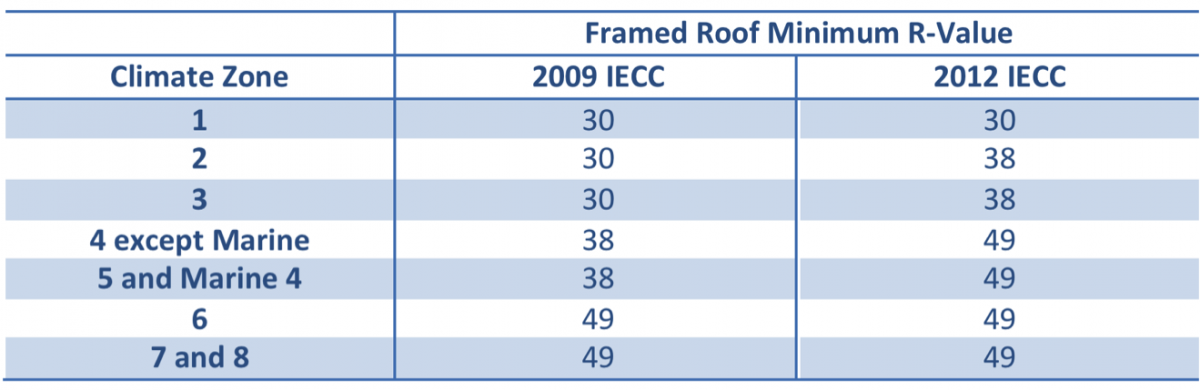

The insulation levels should be based on the minimum requirements for vapor control in the current adopted building code and the minimum requirements for thermal control in the current energy code. The table below provides the minimum thermal resistance (R-value) requirements specified in the 2009 IECC (ICC 2009b) and the 2012 IECC (ICC 2012b) based on climate zone for ceiling/attic floor assemblies.

Table 1. Attic Insulation Requirements per the 2009 and 2012 IECC.

Training

Compliance

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Building Science Corporation, lead for the Building Science Consortium (BSC), a DOE Building America Research Team

Sales

High-R Attic Insulation = High-Efficiency or Ultra-Efficient Attic Insulation

There are two levels of attic insulation: high-efficiency insulation, which meets the 2015 International Energy Conservation Code, and ultra-efficient insulation, which is 25% more efficient than this national code. Using high-efficiency and ultra-efficient insulation along with professional installation (e.g., no gaps, voids, compression, or misalignment with air barriers; complete air barriers; and minimal thermal bridging) creates conditioned spaces that require very little heating and cooling, along with even comfort and quiet throughout the house.