Scope

If multiple exhaust fans in the home share a common exhaust duct, back-draft dampers are installed for each fan.

- Inspect each fan to see if it has an integral back-draft damper.

- If no back-draft damper is included, install dampers immediately above each fan to ensure that each fan has its own damper.

- Remove packing tape from the back-draft dampers before installing.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

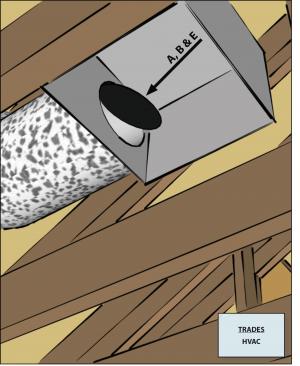

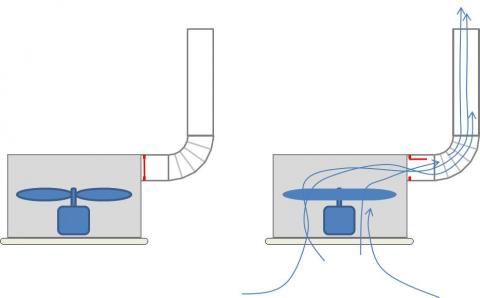

Exhaust fans should always be ducted to a location outside the home (see the guides Kitchen Exhaust and Bathroom Exhaust). Ideally, each exhaust fan should have its own individual duct to the outside. However, builders sometimes prefer to connect the exhaust fans to a common exhaust duct, for reasons of layout or a wish to minimize penetrations through the roof. A common exhaust duct can be used if each fan has a back-draft damper to prevent cross-contamination when the fan is not running. In very humid climates, HVAC installers will sometimes also install a motorized damper in the duct closer to the roof outlet to prevent moist air from drifting in when the fan is off and condensing on fan parts or entering the home. Some exhaust fan models come with an integral motorized damper to prevent airflow when the fan is not operating. Inspect the fans and add a damper if one is not already included with the fans.

How to Install Back-Draft Dampers in Exhaust Fans to Make a Shared Duct Possible

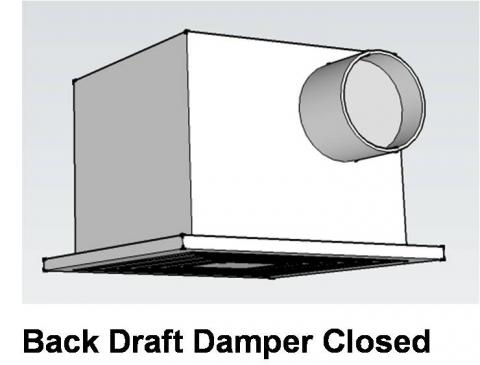

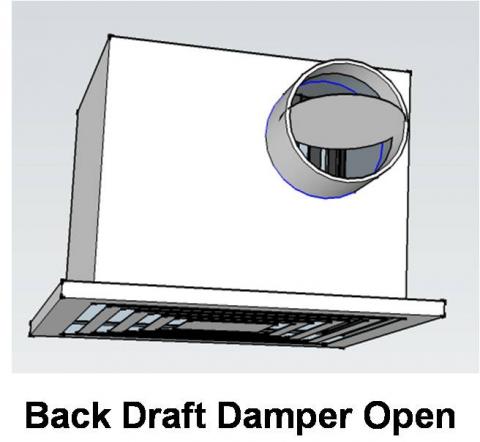

- Install back-draft dampers where the exhaust duct meets the exhaust fan in each fan unit. The dampers should open when the fan is actively exhausting and should shut when the fan is off (Figures 1 and 2). When the exhaust fan is operating, the back-draft damper is pushed open by airflow to allow air to exit through the exhaust duct (Figure 3).

2. Remember to remove any packing tape used to hold the dampers closed during shipping.

Success

In homes with multiple exhaust fans, the HERS rater will inspect the ventilation system exhaust ducts to ensure that one of the following is true: 1) each unit has its own exhaust duct that is individually ducted to the outside, or 2) if the units share a common exhaust duct, each fan has a back-draft damper to prevent cross-contamination when the fan is not running.

Climate

Mechanically controlled dampers limit ventilation to prevent over-ventilation in humid or extreme temperature conditions.

Training

Compliance

Retrofit

SCOPE

If exhaust fans share a common duct, verify that each fan has its own damper; install if missing.

See the Scope tab for additional job specifications.

If the project will involve working in the attic, see the assessment guide, Pre-Retrofit Assessment of Attics, Ceilings, and Roofs.

For more on supply ventilation, see the U.S. Department of Energy’s Standard Work Specifications on exhaust ventilation.

DESCRIPTION

If exhaust fans share a common duct, verify that each fan has its own damper; if dampers are missing or nonfunctioning, install new dampers, as described in the Description tab.

COMPLIANCE

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Quality Installed Exhaust Fans = Professionally Installed Exhaust Fans

Exhaust fans should be professionally installed for best performance, especially if the fans are used as part of the home’s indoor air quality ventilation system. A trained technician will ensure that the fan has an adequate flow rate for the application, the damper is functional, the exhaust vent is properly installed to vent to the outside, air sealing is done around the fan box and vent duct, noise levels meet sone requirements, and if timers are to be used, that they are properly installed and set.