Scope

If fireplaces are installed, ensure that ventilation air is provided directly to the fireplace and conduct combustion safety testing to ensure the fireplace will not be backdrafted by other exhaust fans in the home.

- Meet applicable code requirements for the installed fireplace, woodstove, pellet stove, or masonry heater.

- For use of a fireplace as a backup heat source during power outages, ensure that

- Chimney or flue has been cleaned and inspected for cracks, damage, animal debris, and creosote buildup.

- Damper is open and there is a proper draft before starting a fire.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

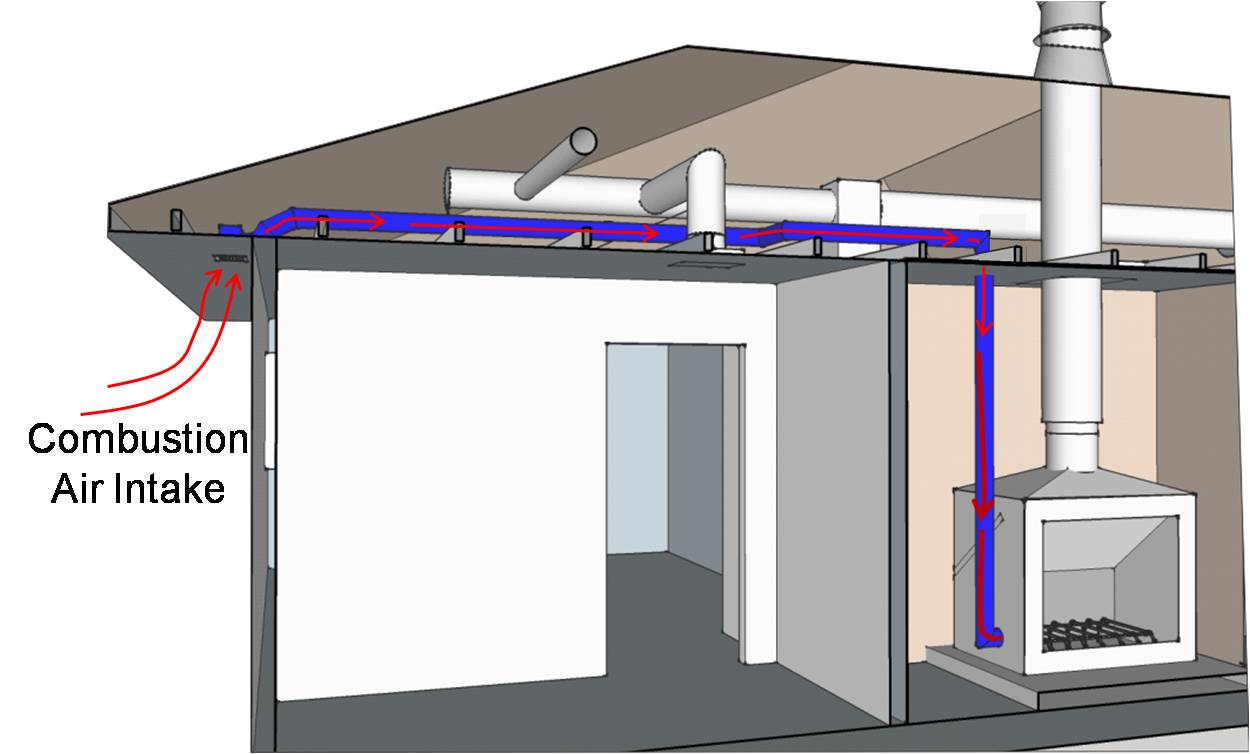

A fireplace needs adequate combustion air to function properly and safely. Combustion air can come from inside the home or from outdoors. Like other combustion appliances, fireplaces come in three types: natural-draft, mechanically drafted, and direct-vent sealed-combustion. The first two take all or some of their combustion air from the indoor space. The third, direct-vent sealed-combustion, takes 100% of its combustion air directly from outdoors.

A direct-vent fireplace has a dedicated combustion air inlet that ducts air from the outside directly to the fireplace box and tight-fitting glass doors across the face of the fireplace opening to prevent room air from being used as combustion air. Direct vent fireplaces are typically gas fueled. Because a direct-vent sealed-combustion fireplace draws its combustion air directly from outdoors, it is not affected by house air tightness or exhaust fan size.

The mechanically drafted fireplace uses an exhaust fan attached to the top of the chimney. The exhaust fan pulls combustion gases up and out of the chimney while the fireplace is in use. Some, if not all, of the combustion air typically comes from the conditioned space. Mechanically drafted fireplaces are less affected by building air tightness or indoor exhaust fans but they do have the ability to backdraft other naturally drafted appliances.

Natural-draft fireplaces are the most affected by the combination of building air tightness and mechanical exhaust systems. When a natural-draft fireplace is in full operation or at maximum burn, the natural draft of the fireplace will be hard to overcome; it can move as much as 400 CFM of air up the chimney. Because of the density expansion factor (about 1.6), only about 250 CFM is actually being exhausted out of the building. Nevertheless, it is possible for a natural-draft fireplace, at full burn, to backdraft other natural-draft-vented combustion appliances in the home.

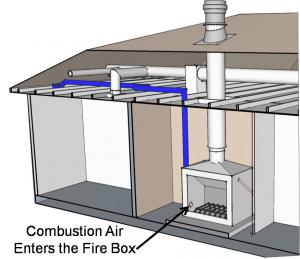

However, when the chimney is cooler, such as when a fire is just getting started in a cold fireplace or when a fire has burned down or is on a low flame, the natural-draft fireplace is more vulnerable to being backdrafted. During these conditions, a small kitchen or bath exhaust fan (50 CFM) could backdraft the combustion pollutants from the fireplace into the home. To avoid this, install a dedicated combustion air duct to bring outside air directly to the fireplace for combustion air and select a fireplace with tight-fitting glass doors.

For wood-burning stoves and other appliances EPA implemented the Residential Wood Heater New Source Performance Standard (NSPS) and two voluntary programs - the Fireplace Program and the Hydronic Heater Program to help improve wood-burning devices and substantially reduce pollutant emissions to the outdoor air while maintaining energy efficiency.

EPA-Certified wood stoves meet the requirements of the NSPS, which has governed the manufacture and sale of wood stoves and certain wood-burning fireplace inserts based on emissions testing since 1988. EPA-Qualified appliances, such as wood fireplaces and wood hydronic heaters, meet emission levels set by EPA’s Voluntary Fireplace and Hydronic Heater Programs. An EPA-certified appliance must adhere to regulatory emission requirements established by EPA, while appliances that meet the voluntary emission standards set by EPA are considered "EPA-qualified."

EPA-Certified wood stoves typically use up to one-third less firewood than older, less-efficient stoves. When wood is not completely burned, a complex mixture of gases and particles is created and emitted as wood smoke. In EPA-certified stoves, most of the wood is burned, resulting in more heat for the home from the same amount of wood. EPA-certified wood stoves are designed with better insulation and improved airflow, which promotes more efficient combustion. This overall improved combustion process reduces the risks of producing pollutants from incomplete combustion, which could leak from the appliance itself directly into the indoor environment. Additionally, as more gases and particles are burned inside the stove, less smoke and fewer chemical and particulate pollutants are emitted from the vent stack or chimney into the ambient outdoor atmosphere. This helps improve outdoor air quality and reduces the amount of pollutants that could be drawn back into the home (or neighboring homes) through imperfect air barriers or other openings in the building envelope.

EPA maintains and periodically revises the list of EPA-Certified and EPA-Qualified wood-burning appliances to help housing professionals and homeowners make better purchasing decisions. The listed models have been tested and shown to burn cleaner and more efficiently than other, similar models. Any wood stove or fireplace that meets the requirements of the EPA Certified or EPA Qualified designation are identified with metal tags. See the References/Additional Information section below for lists of EPA-certified wood stoves and EPA-qualified wood hydronic heaters and wood fireplaces.

The Washington State Department of Ecology publishes Wood Stoves, Fireplaces, Pellet Stoves, and Masonry Heaters along with a list of wood stoves compliant with Washington state standards.

How to Test for Proper Ventilation of Natural-Draft Fireplaces

- If installing a natural-draft fireplace, install a dedicated combustion air duct that brings outside air directly into the firebox. Install a fireplace that has tight-fitting glass doors across the face of the fireplace opening.

- The rater will verify that the total net rated exhaust flow of the two largest exhaust fans is ≤ 15 CFM per 100 ft2 of occupiable space.

- Calculate the total occupiable space of the house. Per ASHRAE 62.2-2010, occupiable space is any enclosed space inside the pressure boundary and intended for human activities, including, but not limited to, all habitable spaces, toilets, closets, halls, storage and utility areas, and laundry areas.

- Calculate the net rated exhaust flow of the two largest exhaust fans. Per ASHRAE 62.2-2010 and published addenda, the term “net-exhaust flow” is defined as flow through an exhaust system minus the compensating outdoor air flow through any supply system that is interlocked to the exhaust system. Add together the rated exhaust flow of the two largest exhaust fans in the home. Subtract the air flow of any dedicated supply ventilation.

- Verify the total net rated exhaust flow is less than or equal to 15 CFM per 100 ft2 of occupiable space:

15 CFM per 100 ft2 ≥ (Largest Fan Rated Flow) CFM + (Second Largest Fan Rated Flow) CFM - (Supply Outdoor Air Intake) CFM ) / (Occupiable Space) ft.2

Success

If a fireplace is installed, make sure it has adequate ventilation. If the fireplace is naturally drafted, the rater must verify that the total net rated exhaust flow of the two largest exhaust fans is <= 15 CFM per 100 ft2 of occupiable space.

Climate

Winter Weather/Power Outage

For use of a fireplace as a backup heat source during power outages, ensure that

- Chimney or flue has been cleaned and inspected for cracks, damage, animal debris, and creosote buildup.

- Damper is open and there is a proper draft before starting a fire.

Depending on the climate zone of the building, a secondary heat source is perhaps the easiest way to increase resiliency during a severe winter weather event. In climate zones 4 and 5, a secondary heat source would only be used in an emergency but may still be worth the investment. In climate zones 6 through 8, a secondary heat source will be useful not only in emergencies, but in normal winter operations during extended periods of cold. In climate zones 7 through 9, where winter temperatures can become quite dangerous, it is an unnecessary risk for a home to depend on only one heat source. The secondary heat source for the building should not require the same fuel type as the primary heat source. In rural areas, a sealed wood-burning appliance can provide heat during severe winter weather events without the need for electricity. Several models of wood stoves and masonry heaters are ENERGY STAR labeled. Modern wood-burning stoves should be directly vented. Older style open-hearth fireplaces are not as effective nor as safe. Other options for secondary heat sources are non-electric pellet stoves and direct-vent non-electric gas heaters. Many pellet stoves, gas stoves, and gas fireplaces use electricity for starting or for blowers. Ensure that your appliance can be started and operated without electricity. Note that some gas stoves for cooking also require an electric starter; look for models that can be started manually.

In existing homes, older open-hearth fireplaces should be inspected to ensure they have not been blocked by prior owners and that the chimney flues are operational. Chimneys should be cleaned to remove debris and creosote that may have accumulated over time and that can lead to chimney fires. Older fireplaces can be fitted with efficient sealed combustion inserts that will improve safety and performance.

Training

Compliance

Retrofit

When conducting renovation work in older homes, identify any fireplaces or wood stoves located in the home and determine whether they are natural draft, mechanically drafted (with an exhaust fan at the top of the chimney), or direct vent (having an outside air source that brings outside air directly to the firebox). If the home has natural draft fireplaces and other renovation work will be done in the home that includes air sealing and insulating, a home energy rater should test the fireplaces after the renovation work is completed (as described in the Description tab) to verify that the fireplace’s ability to exhaust will not be overcome by other depressurization forces in the home. Consider upgrades to the fireplace such as installing an outside air vent and tight-fitting doors or a sealed combustion fireplace insert. These changes would improve the safety and efficiency of the fireplace.

For more information on combustion appliances, please see the assessment guide, Pre-Retrofit Assessment of Combustion Appliances.

The U.S. Department of Energy’s Standard Work Specifications has additional information on combustion appliances.

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.

Sales

Proper Ventilated Fireplaces = Ventilated Fireplace

Ventilated fireplaces typically burn natural gas or propane and use a vent to bring outside combustion air directly into the firebox. These fireplaces have tight-fitting glass doors across their face to prevent conditioned room air from being used as combustion air and then expelled through the flue. Consuming room air for combustion may deplete oxygen levels in the home and pull conditioned air out of the home. Exhaust gases are vented up a chimney or out a side wall. These closed-combustion systems are much less likely to experience spillage of combustion gases into the home. This improves both health and comfort while eliminating odors.