Scope

When specifying and installing combustion heating equipment, choose the highest efficiency equipment the project will allow. Select models that are direct vented meaning they are equipped with a pipe to bring combustion air directly from outside to the combustion chamber and they have a second sealed vent pipe to carry exhaust gases directly to the outside from the appliance.

- All combustion space and water heaters should be direct vented or mechanically drafted. Do not install naturally drafted combustion appliances within the conditioned space of the home.

- Ensure that all fireplaces and wood stoves located in conditioned spaces are vented to the outdoors and supplied with adequate combustion and ventilation air according to the manufacturers’ installation instructions.

See the Compliance Tab for links to related codes and standards and voluntary federal energy-efficiency program requirements.

Description

When installing combustion furnaces, boilers, and water heaters inside the home’s pressure boundary (i.e., within the conditioned space of the home), the safest (and usually most energy efficient) type of equipment to install is a direct-vent, sealed-combustion appliance.

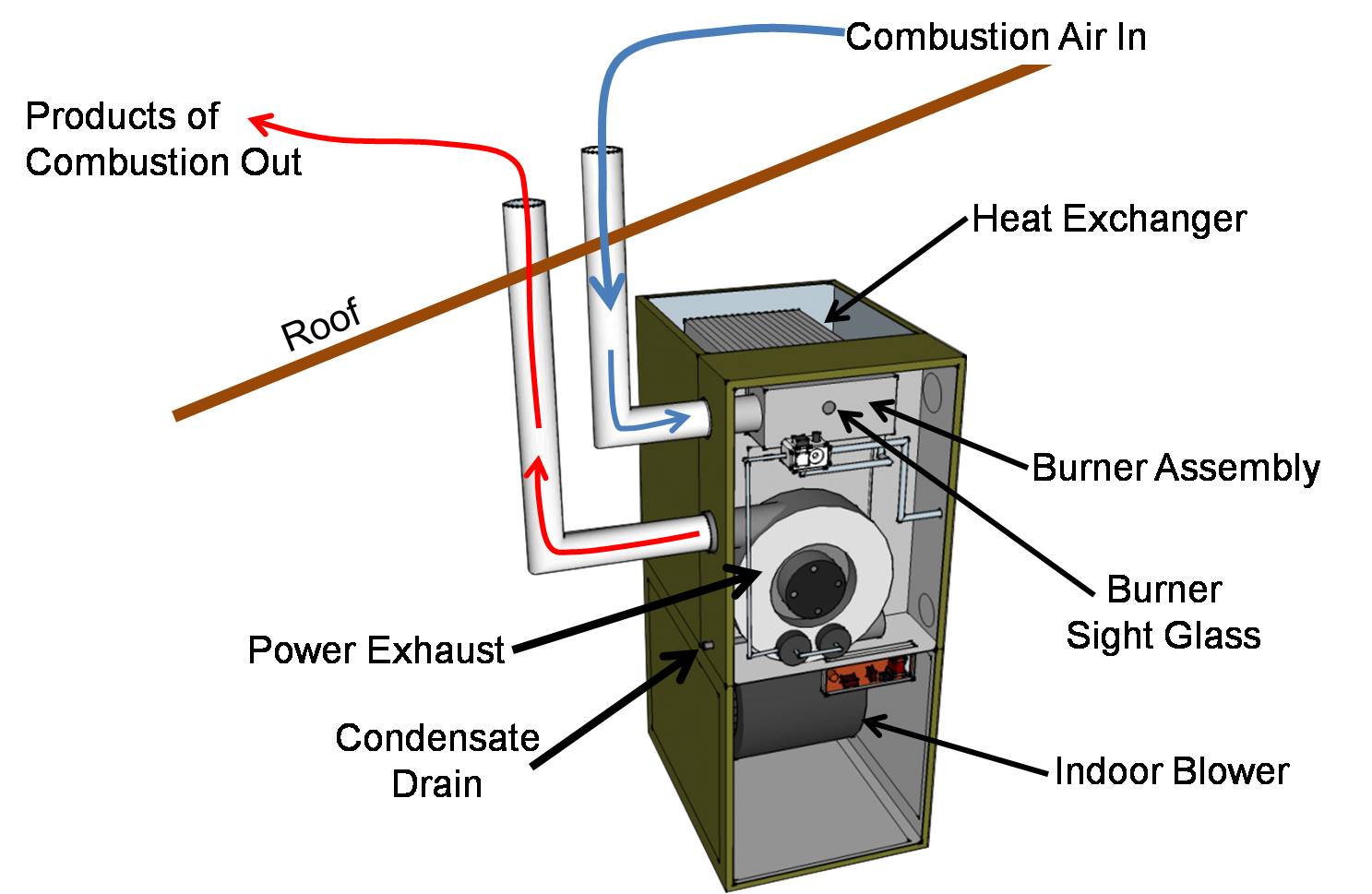

A direct-vent sealed-combustion furnace, boiler, or water heater brings combustion air directly from outdoors to the sealed combustion chamber through one sealed pipe and exhausts the byproducts of combustion (carbon dioxide and nitrogen) to the outdoors through a second sealed pipe (Figure 1). Because of this sealed combustion and sealed exhaust venting, the risk of backdrafting is eliminated. Combustion air (oxygen) enters the furnace through the sealed pipe and goes directly from the outdoors to the burner assembly. There it mixes with the fuel and is electronically ignited in the sealed combustion chamber. The heated air passes through a primary heat exchanger, which extracts most of the heat, and then through a secondary heat exchanger, where more heat is extracted, cooling the exhaust gases to the point that they condense. The condensed water and carbon dioxide exit through a condensate drain, while the remaining flue gases exit to the outside through the sealed exhaust pipe, which can be made of PVC because of the low temperature of the gases (Figure 2). Condensing furnaces have annual fuel utilization efficiencies (AFUE) of 90% to 98%.

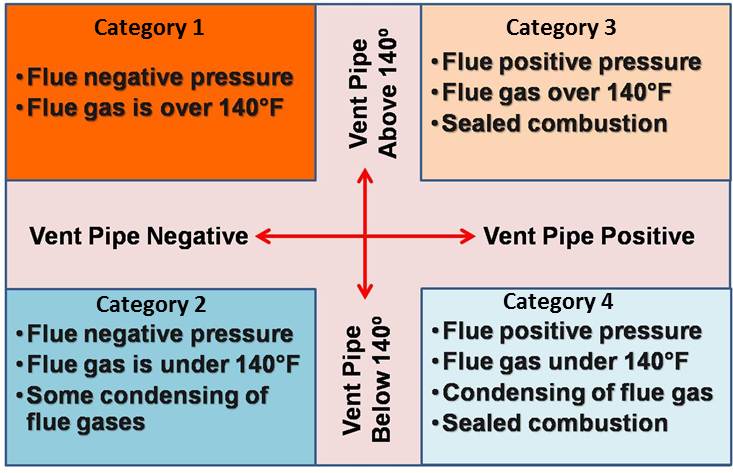

The National Fuel Gas Code identifies four categories for combustion furnaces and water heaters (see Figure 3). The categories are based on combustion type (sealed or unsealed) and vent pipe temperature. Direct-vent sealed-combustion furnaces are Category 4 appliances. The flue and vent pipe are under a positive pressure, flue gases are under 140°F, and water vapor (a byproduct of combustion) is condensed into water liquid and drained to the outside through a condensate drain. Combustion air is piped directly to the burner, which is sealed off from the CAZ (sealed combustion) and the byproducts of combustion (carbon dioxide and nitrogen) are power exhausted to outdoors.

A Category 2 appliance is a naturally aspirating furnace with a vent temperature below 140°F that does some condensing of the flue gases and has negative pressure in the vent. Nearly all Category 2 appliances are huge commercial furnaces. A Category 3 appliance is a furnace with a vent temperature above 140°F (high enough to avoid condensation in the vent) and the vent has a positive static pressure.

Category 1 combustion appliances are the oldest, least efficient type of combustion appliances. They have a flue gas temperature over 140°F and the flue pipe pressure is negative with respect to the space in which the appliance is located (referred to as the combustion appliance zone or CAZ). Category 1 appliances are either atmospheric or mechanically drafted. Atmospheric drafted (also called naturally drafted) furnaces use the heat in the flue to draw combustion air through the furnace and to lift combustion exhaust up and out of the chimney. Mechanically drafted category furnaces and water heaters use a small induced draft fan to pull air through the combustion chamber; however, the furnace still relies on flue temperatures to lift the combustion gases up the flue stack. Category 1 appliances are not direct vented (also known as sealed combustion); they are considered nondirect vented because there is no barrier between the burner and the CAZ. A Category 1 furnace or water heater draws its combustion and dilution air from the CAZ and the byproducts of combustion (carbon dioxide, nitrogen, and water vapor) are transported outside through the flue. Because Category 1 appliances draw their combustion air from the CAZ, they are susceptible to backdrafting.

Atmospheric draft furnaces have efficiencies of 60% to 78%. These appliances are no longer sold in the United States but are still found operating in existing homes. Induced draft fan-equipped Category 1 furnaces have AFUEs of 78% to 83% and there are still models available on the market, although direct-vent furnaces are much higher efficiency and safer to operate. Natural draft water heaters are still sold, although safer and more efficient water heaters are available, such as power-vented models, which use a fan to push combustion gases out the flue, and direct-vent models, which use a sealed intake for combustion air and a sealed flue for exhaust gases.

Naturally drafted appliances are not recommended inside the home, especially in air-tight, high-efficiency homes, where exhaust fans or other combustion appliances such as fireplaces could depressurize the home and overcome the natural draft of an atmospherically vented appliance, thus backdrafting the appliance and pulling combustion gases into the living space.

Although most building scientists would not recommend them, naturally drafted furnaces, boilers, and water heaters are permitted by ENERGY STAR Version 3.0 in Climate Zones 1 through 3 if the Rater has followed Section 805 of RESNET’s Standards, encompassing ANSI/ACCA 12 QH-2014, Appendix A, Sections A3 (Carbon Monoxide Test) and A4 (Depressurization Test for the Combustion Appliance Zone), and verified that the equipment meets the limits defined within.

For additional guidance on how to conduct combustion safety testing, see the guide Combustion Appliance Zone (CAZ) Testing.

Success

When furnaces, boilers, and water heaters are installed within the home’s pressure boundary (i.e., within the thermal envelope), this equipment should be direct-vent/sealed-combustion equipment. ENERGY STAR permits non-direct-vented combustion appliances in Climate Zones 1, 2, and 3 if the Rater has followed Section 805 of RESNET’s Standards, encompassing ANSI/ACCA 12 QH-2014, Appendix A, Sections A3 (Carbon Monoxide Test) and A4 (Depressurization Test for the Combustion Appliance Zone), and verified that the equipment meets the limits defined within.

Climate

The map in Figure 1 shows the climate zones for states that have adopted energy codes equivalent to the International Energy Conservation Code (IECC) 2009, 12, 15, and 18. The map in Figure 2 shows the climate zones for states that have adopted energy codes equivalent to the IECC 2021. Climate zone-specific requirements specified in the IECC are shown in the Compliance Tab of this guide.

Cold Climates

In cold climates, in addition to proper sizing, it is critical to make sure that the air intake and exhaust discharge vents are located sufficiently above anticipated snow line. The intake should be sufficiently separated from the exhaust vent to prevent frost buildup on the cold air intake pipe. The exhaust discharge must be sufficiently high so that frozen condensation that may accumulate on the ground will not block the exhaust pipe. Condensate lines should be directed to an indoor drain.

Training

Compliance

Retrofit

When conducting renovation work in older homes, identify any combustion appliances located in the home (e.g., gas or oil-fired water heater, boiler, or furnace) and determine whether they are sealed combustion/direct vent appliances or older-model atmospheric-draft or induced-draft combustion appliances (also known as Category 1 appliances based on their designation in the National Fuel Gas Code; see the Description tab for an explanation of these categories). Any renovation work that will involve air sealing and insulating rooms, attics, basements, or crawlspaces that may contain category 1 appliances will impact how much air is available to the appliance for combustion. Combustion safety testing must be done before and after renovation work, as described in the Description tab. If the home currently has atmospheric-draft or induced-draft combustion appliances, the best course of action is to replace them with more efficient and safer-direct vent combustion appliances or other non-combustion equipment.

For more information on combustion appliances, please see the assessment guide, Pre-Retrofit Assessment of Combustion Appliances.

The U.S. Department of Energy’s Standard Work Specifications has additional information on combustion appliances.

See Compliance tab.

More

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The following authors and organizations contributed to the content in this Guide.